Marlin: Bltouch gets triggered but z Motor doesnt stop

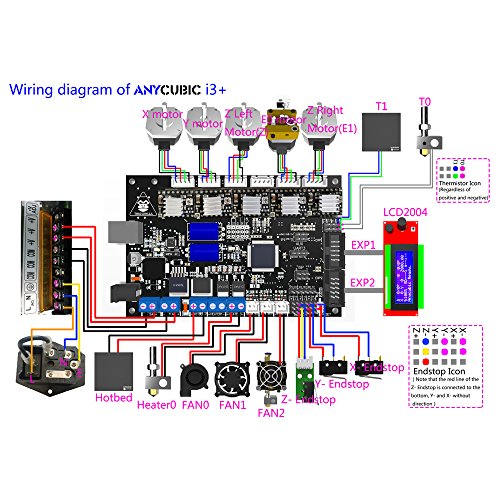

Hello Guys, i am Using marlin 1.1.8. BL Touch lights up red when triggered but z Motor doesnt stop when homing. All other endstops are working. Printer: anycubic prusa i3. Trigorilla Board arduino 2560 ramps.

EDIT: Fixed polarity for z endstop on bltouch was wrong

All 729 comments

Has it ever worked before on your printer or is this the initial situation?

Consider reading through the neighboring issue, it contains some tips that might help #12947

well guys I fixed it kinda. The Problem was the polarity of the sensor wires was reversed. Next Problem is when I start the print it starts somewhere on the left side of the bed not in the middle. Auto bed leveling and homing works. When I start pronterface and press the red x y Center button it runs into the x and y endstop. Here is my config

conf.zip

Here is my start gcode maybe it is important

gcodestart.zip

you are missing this define

//#define BED_CENTER_AT_0_0

remove //

what version of marlin?

Marlin 1.1.8 . First post is already shortened :D

done

I did defined it, but I am getting an error in Arduino ide "static assertion failed: RIGHT_PROBE_BED_POSITION can't be reached by the Z probe."

try #define RIGHT_PROBE_BED_POSITION 110 or a little less

I used 100 now I get

static assertion failed: BACK_PROBE_BED_POSITION can't be reached by the Z probe.

ohhh... now i remember things :-D

with #define BED_CENTER_AT_0_0

the center is 0 and one direction is positive number and other direction is negative

so you will most likely also have to adjust these

// The size of the print bed

define X_BED_SIZE 200

define Y_BED_SIZE 200

// Travel limits (mm) after homing, corresponding to endstop positions.

define X_MIN_POS 0

define Y_MIN_POS 0

define Z_MIN_POS 0

define X_MAX_POS X_BED_SIZE

define Y_MAX_POS Y_BED_SIZE

define Z_MAX_POS 160

if X and Y ednstop is precise at edge of bed i would use:

define X_MIN_POS -100

define Y_MIN_POS -100

define X_MAX_POS 100

define Y_MAX_POS 100

So should I comment the bed centre 0 0 out again?

nope, that one stays as is

i use 0,0 down in the lower left corner and its a long time since i have had a setup with 0,0 in center

and i'm 40 year old so not that fast at remember things

Configuration.zip

I did what you said and still gettin error: static assertion failed: RIGHT_PROBE_BED_POSITION can't be reached by the Z probe.

just me old

define RIGHT_PROBE_BED_POSITION 110

needs to be less than 100, but i cant remember how much lees

define BACK_PROBE_BED_POSITION 190

also needs to be less than 100

define FRONT_PROBE_BED_POSITION 20

can be closer to 100

remember than some of the 100's need to be negative 100

but when you home the printer now it will be very clear which of the 100's that need to be negative

When I home the Printer it goes to x 25 y 93 z 16.7

the reason i dont know which of the 100's that need to be negative is that i dont know if right side is the side it homes to

and if front or back is where Y homes

x 25 y 93 z 16.7

that makes sense

define X_PROBE_OFFSET_FROM_EXTRUDER 75 // X offset: -left +right [of the nozzle]

define Y_PROBE_OFFSET_FROM_EXTRUDER 7 // Y offset: -front +behind [the nozzle]

define Z_PROBE_OFFSET_FROM_EXTRUDER -1.7 // Z offset: -below +above [the nozzle]

25+75 = 100

93 + 7 = 100

i cant remember the logic on Z

how do you home?

G29?

with the screen. prepare -- > autohome

its like it homes the probe

try send G28 and see if that makes any difference

no difference with G28

and after G28

try send G0 X0 Y0

what we want to figure out is where printer thinks it is so we can change config and get it to be where we want it

how close to center was it after G28? and did it go to endstop first

so with g28 it homes somewher on the left side. If I send G0 X0 Y0 it runs into the Y endstop.

with G28 it should touch the endstops

do it touch the endstops?

G28 X if you only want to try and home X

Yes with g28

oki.... and it stays at the endstop after G28 ?

and after home how far is the nozzle from the bed edge?

is this your printer? http://www.anycubic3d.com/products/show/1048.html

It stays at the x and y endstop but it moves up in z . After Home the nozzle is a few mm away

oki, at least we are close to something that might work

is your printer the Mega on the link above?

what is strange is that with G28 it should home and be at -100 for X and Y

Try send G28 and then M114 and tell me what comes on serial

i'm looking at your latest config to see if we made a mistake

Its this one http://m.anycubic3d.com/support/show/594036.html

Its the prusa i3 Kit with Ultrabase.

The config ist from Here. https://www.thingiverse.com/groups/anycubic-prusa-i3/forums/general/topic:26690

config looks ok

Try send G28 and then M114 and tell me what comes on serial

so now i am back. I did g28 and M114. this is the Output X:25.00 Y:93.00 Z:16.70 E:0.00 Count X:2000 Y:7440 Z:6680

that is strange... can you attach configuration.h again as zip

and make sure its not an old copy :-D i have made that mistake many times

I just reflashed this:

Configurationf.zip

this is still the Output of M114

X:25.00 Y:93.00 Z:16.70 E:0.00 Count X:2000 Y:7440 Z:6680

you did not change these:

// Travel limits (mm) after homing, corresponding to endstop positions.

define X_MIN_POS 0

define Y_MIN_POS 0

define Z_MIN_POS 0

define X_MAX_POS X_BED_SIZE

define Y_MAX_POS Y_BED_SIZE

define Z_MAX_POS 160

you did not change this one either

//#define BED_CENTER_AT_0_0

but that still does not explain why X is at 25 after home

@thinkyhead can just shine the light of god wisdom on this one?

I uncommented and changed x_min_pos to -100 y min -100 x max 100 y max 100 but I get the error:

static assertion failed: RIGHT_PROBE_BED_POSITION can't be reached by the Z probe.

it's hard to help if you make changes back without telling, so make it look like this

define X_MIN_POS -100

define Y_MIN_POS -100

define Z_MIN_POS 0

define X_MAX_POS 100

define Y_MAX_POS 100

define Z_MAX_POS 160

define LEFT_PROBE_BED_POSITION 100

define RIGHT_PROBE_BED_POSITION -100

define FRONT_PROBE_BED_POSITION 100

define BACK_PROBE_BED_POSITION -100

define BED_CENTER_AT_0_0

but one Q, when you home does x move to left or right?

I changed it to your values but I cant upload it because I get the error

static assertion failed: LEFT_PROBE_BED_POSITION must be less than RIGHT_PROBE_BED_POSITION.

change the numbers arround

define LEFT_PROBE_BED_POSITION -100

define RIGHT_PROBE_BED_POSITION 100

i did not know what direction it moves when homing so i had a 50% chance of guessing right

now: static assertion failed: FRONT_PROBE_BED_POSITION must be less than BACK_PROBE_BED_POSITION.

I Change back and front aswell?

Would a Video of homing help?

yep.... since i guess what direction it moves at homing i only have 50% chance of correct guess

nope, video is not needed, maybe later if we get in big problems we cant find out

Well i switched front and back now i get static assertion failed: LEFT_PROBE_BED_POSITION can't be reached by the Z probe.

dont change it back... need to think

what side of nozzle is probe? right side?

and 75 mm from nozzle right?

ok I got it like this at the Moment:

define LEFT_PROBE_BED_POSITION -100

define RIGHT_PROBE_BED_POSITION 100

define FRONT_PROBE_BED_POSITION -100

define BACK_PROBE_BED_POSITION 100

define X_MIN_POS -100

define Y_MIN_POS -100

define Z_MIN_POS 0

define X_MAX_POS 100

define Y_MAX_POS 100

define Z_MAX_POS 160

define BED_CENTER_AT_0_0

see me 2 comments above yours :-D

so like this? :D

define FRONT_PROBE_BED_POSITION 100

define BACK_PROBE_BED_POSITION -100

what side of nozzle is probe? right side?

and 75 mm from nozzle right?

and no dont change anything

my bltouch is around 7cm on the Right side from the nozzle

like in this Picture here https://www.thingiverse.com/thing:2887389

oki... try:

define LEFT_PROBE_BED_POSITION -25

explanation: since probe is 75mm on right side of nozzle it can never get to -100, the best it can is -25

and maybe we will have to correct the others too

do you get an error for #define FRONT_PROBE_BED_POSITION ??

I get a lot of Errors in Arduino IDE with this values:

define LEFT_PROBE_BED_POSITION -25

define RIGHT_PROBE_BED_POSITION 100

define FRONT_PROBE_BED_POSITION -100

define BACK_PROBE_BED_POSITION 100

define X_MIN_POS -100

define Y_MIN_POS -100

define Z_MIN_POS 0

define X_MAX_POS 100

define Y_MAX_POS 100

define Z_MAX_POS 160

what errors?

These

error.zip

oh wait is this only one error?

dont change anything... these look easy to fix

will read them all

immer mit die ruhe :-D

try #define FRONT_PROBE_BED_POSITION -93

by the way, i think you are from germany, if there is something you cant explain in english i do understand german, but my spoken and written german is not always correct

Ok :D

With Front Probe -93 it compiles fine

What next?

upload to printer

then we need to check if where the printer think it is also is correct

so after connect to printer send G28

then M114

remember not g28 :-D

first one homes the printer

M114 tell where printer think it is

and sorry if i'm slow, but doing some light house cleaning :-/

Output: X:25.00 Y:93.00 Z:16.70 E:0.00 Count X:2000 Y:7440 Z:6680

but now the nozzle is at the back side of the bed

no Problem I have to do some cleaning as well :D

so its close to the back left corner?

as long nozzle is where it says it is we are good

close to the back Right Corner

of course, + is right and - is left

so at least it is at the place where it says it is

ok what next :D

Try and send G0 X0 Y0

it should go near the center now, unless the old man in Denmark got things wrong

but we have a better config now than before

it really goes near the Center in x and y :O

now.... to get it precise you will need to fine tune these 2 numbers

define X_MIN_POS -100

define Y_MIN_POS -100

they where just Theory number

ok how do I get them precise? :D

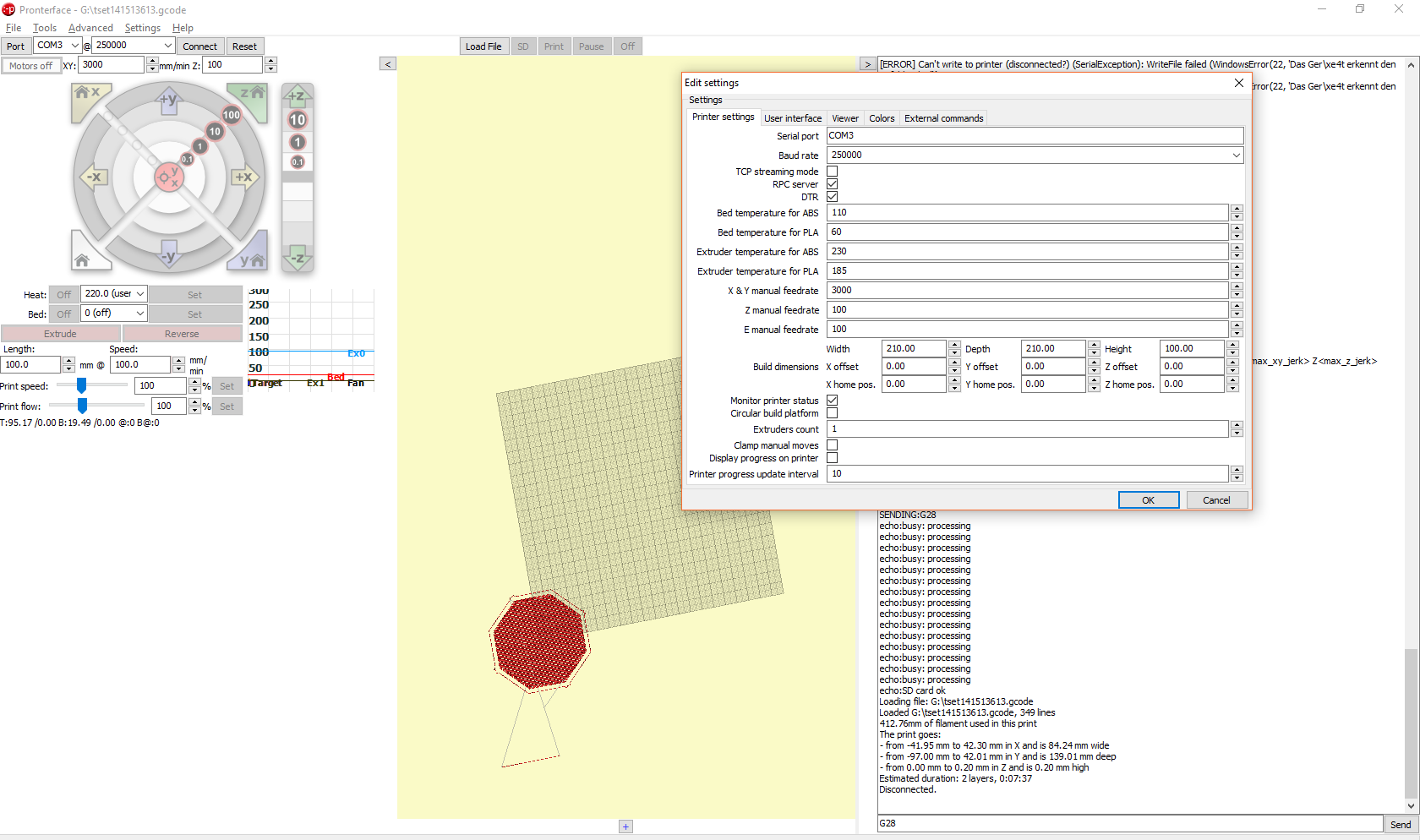

do you use pronterface to connect?

yes

do you have a picture of the bed?

will need to think how we get precise numbers so i dont confuse you

will be hard since there are no lines on the bed

can you draw a cross (X) on it so you know where precise is center is?

Maybe you can somehow extract the numbers out of their config : https://www.thingiverse.com/groups/anycubic-prusa-i3/forums/general/topic:26690

because it should fit for the same Printer

yes wait a sec

but the idea is to home it, then send G0 X0 Y0

then move it in pronter face until nozzle is in cross middle

and then use M114 to see where it is

then you know the difference

let me look at the link

so from here right: https://github.com/duisenberg/AnyCubic-I3/tree/master/Firmware/Marlin_1.1.5

any suggestions with what I should draw on the bed?

draw a cross..... big X

then you know where center is

with what? a pen?

yep, something you can remove with alcohol and something that does not scratch the bed

ok got it

i looked at the config and could not find any numbers we can use

so its the boring way :-/

ok :(

so now I should home with G28 and then move it to the Center manualy and then M114?

No

G28

then G0 X0 Y0

then move manual to get it to precise center

then M114

G0 X0 Y0 moves it to where it thinks the center is

when you move it manual we can get the difference when you send M114

can I do it with Prepare -> move axis as well?

yes you can do it from lcd too, but i never done it that way as i always have my printer next to pc

let me check on my printer if its says the same, but i use marlin 2.0

on mine menu is motion -> move axis

ok so now the nozzle is perfectly in the Center

X:9.30 Y:12.30 Z:2.20 E:0.00 Count X:744 Y:984 Z:880

I had to move down z a bit

oki....

define X_MIN_POS -100 + 9,3 = -90,7

define Y_MIN_POS -100 + 12,3 = -87,7

upload and this time when you send G0 X0 Y0 it should be in perfect center, or much closer than before

error :D

static assertion failed: Movement bounds ([XY]_MIN_POS, [XY]_MAX_POS) are too narrow to contain [XY]_BED_SIZE.

of course there is the option that i got my math wrong and that is moves more away from center

this is why when you setup a printer first time it takes more work to get things right

why is there an error?

Scheiße... let me think how we fix the error

how big is the bed when you messure it?

it now says the bed is to small for the movement we want

it does a lot of checking on the config to make sure its right

in the datasheet it says x210 y210 z250

but I can messure it as well

define X_BED_SIZE 210

define Y_BED_SIZE 210

still same error

static assertion failed: Movement bounds ([XY]_MIN_POS, [XY]_MAX_POS) are too narrow to contain [XY]_BED_SIZE.

let me think for a bit

what if you try

define X_MIN_POS -109.3

define Y_MIN_POS -112.3

of course since the bed is 210 and not 200 it might not be in center

define X_BED_SIZE 200

define Y_BED_SIZE 200

define X_MIN_POS -109.3

define Y_MIN_POS -112.3

I did this:

define X_BED_SIZE 200

define Y_BED_SIZE 200

define X_MIN_POS -109.3

define Y_MIN_POS -112.3

error: floating constant in preprocessor expression

its better to start with the 4 lines i just wrote

we will get max bed size next

do I have to make -109,3 or -109.3?

of course.... needs to be whole numbers, my mistake

define X_MIN_POS -109

define Y_MIN_POS -112

back in 5 mins

i uploaded this:

define X_BED_SIZE 200

define Y_BED_SIZE 200

// Travel limits (mm) after homing, corresponding to endstop positions.

define X_MIN_POS -109

define Y_MIN_POS -112

define Z_MIN_POS 0

define X_MAX_POS 100

define Y_MAX_POS 100

define Z_MAX_POS 160

but when I send G28 and G0 X0 Y0 it isnt in perfectly in the center

did it get closer to center?

or did it move away from center?

away but maybe should I do :

define X_BED_SIZE 210

define Y_BED_SIZE 210

?

no dont change that yet

did it get more close to center this time? or did it get worse?

with this I think it get worse

define X_BED_SIZE 200

define Y_BED_SIZE 200

// Travel limits (mm) after homing, corresponding to endstop positions.

define X_MIN_POS -109

define Y_MIN_POS -112

define Z_MIN_POS 0

define X_MAX_POS 100

define Y_MAX_POS 100

define Z_MAX_POS 160

oki... let me correct the numbers for you so we get bigger bed in firmware

define X_BED_SIZE 210

define Y_BED_SIZE 210

define X_MIN_POS -105

define Y_MIN_POS -105

define Z_MIN_POS 0

define X_MAX_POS 105

define Y_MAX_POS 105

define Z_MAX_POS 250

i hope its error free

it is

should I upload it?

upload to printer

then G28, then G0 X0 Y0

how close to center is it now?

I think it is Closer but still a bit away

move to center with display

and then M114 or read numbers from display

X:4.60 Y:6.90 Z:2.10 E:0.00 Count X:368 Y:552 Z:840

define X_MIN_POS -109

define Y_MIN_POS -107

does it give compile error?

it doesnt :D

do we have to Change These as well?

define X_MAX_POS 105

define Y_MAX_POS 105

define Y_MIN_POS -111

hope still error free

no we dont need to change the other numbers

we only need to change the MIN numbers to trick the printer to travel a bit more from endstop so when we tell it to go to 0,0 it will stop at 0,0

y min -111 works as well

ok... upload again

then G28, then G0 X0 Y0

Closer to Center but still a bit away

use display to get it to center and then M114

remember it only take whole numbers and no decimal so we might not get precise on center, but we want to get as close we can

I moved it to the Center --> M114= X:4.40 Y:7.70 Z:2.20 E:0.00 Count X:352 Y:616 Z:880

almost the same as before.... strange.... will think and see if i can find out

I mean it is Pretty close. What if we leave it like this?

we can leave it yes, it is just strange to me that you have to move it almost the same to get it to center

hmm ok what next?

last test

define X_MIN_POS -101

define Y_MIN_POS -98

if that is error free try and upload it and then as before G28, G0 X0 Y0 move it to center and M114

but next test is to see if nozzle start at correct height

error:

static assertion failed: Movement bounds ([XY]_MIN_POS, [XY]_MAX_POS) are too narrow to contain [XY]_BED_SIZE

:D

then back to this

define X_MIN_POS -109

define Y_MIN_POS -107

ok

no need to upload

on pronterface: send G28, then G0 X0 Y0.... makre sure nozzle is clean

then take a bit of paper under the nozzle

heat nozzle to 210, then put paper under nozzle and move Z down until it starts to grap the paper

then M114

done :

X:0.00 Y:0.00 Z:1.90 E:0.00 Count X:0 Y:0 Z:760

so its now at 0.1mm (thickness of paper) but it still thinks its 1.9mm up

let me look at config and see where we change number this time

define Z_PROBE_OFFSET_FROM_EXTRUDER -1.7

we need to change that to

define Z_PROBE_OFFSET_FROM_EXTRUDER -3.6

hope it compiles error free

then upload and repeat same steps again

we tell it that probe triggers 3.6mm under the nozzle and this will make it move 1.9 mm closer to bed compared to last time

with hot nozzle we want it to be 0.1mm above bed when it think Z is 0

this also takes a few attempts

my partner is on her way home so i will be out for 4-5 hours when she is here

now when I do g28 g0 x0 y0 its still a few cm About the bed

yes but you have to heat up nozzle and use a clean bit of paper and then move it down until it starts to grap paper

then M114 again

ok X:0.00 Y:0.00 Z:2.10 E:0.00 Count X:0 Y:0 Z:840

so it got worse...

define Z_PROBE_OFFSET_FROM_EXTRUDER 0

upload and repeat the steps with paper.... but i need to check config to see if eeprom is enabled or else it will never change

it is... so after upload send first M502 then M500

this will make sure default settings is used and saved so we dont use old settings

ok and now G28 and g0 x0 y0 and m114?

have you sent M502 and M500 ?

yes M502,M500,G28,g0 x0 y0, M114 = X:0.00 Y:0.00 Z:0.40 E:0.00 Count X:0 Y:0 Z:160

great the numbers to better :-D

ok what next :D

define Z_PROBE_OFFSET_FROM_EXTRUDER -0.4

upload

M502

M500

G28

G0 X0 Y0

check with paper and hot nozzle....

then M114... Z should be 0

have to go...

back in 4-5 hours

ok thank you for your help so far :D

now m114 = X:0.00 Y:0.00 Z:0.60 E:0.00 Count X:0 Y:0 Z:240

We will get it. Next will be some test prints to get it perfect

try this print: https://www.thingiverse.com/thing:2177790

and if the nozzle is to far up it will not stick to bed, to get the nozzle closer just change

define Z_PROBE_OFFSET_FROM_EXTRUDER -0.4

to

define Z_PROBE_OFFSET_FROM_EXTRUDER -0.5

then send M502 and M500 to make sure it uses the new settings

what slicer do you use? will have a look at your start code

the start gcode looks wrong

;Sliced at: {day} {date} {time}

;Basic settings: Layer height: {layer_height} Walls: {wall_thickness} Fill: {fill_density}

;Print time: {print_time}

;Filament used: {filament_amount}m {filament_weight}g

;Filament cost: {filament_cost}

;M190 S{print_bed_temperature} ;Uncomment to add your own bed temperature line

;M109 S{print_temperature} ;Uncomment to add your own temperature line

G21 ; milimeters

G90 ; absolute coords

G1 Z10 ; move the extruder up out of the way

G28 ; Home all axes

M565 Zx.x ; set the Z offset value

G29 ; probe bed

G28 X0 Y0 ; home X and Y

G1 Z5.00 F4800 ; get ready to move by lifting the extruder

G1 X100 Y110 F4800 ; move to centre of the bed

G1 Z0.3 ; Move extruder to 0.3mm above the centre of the bed

;Put printing message on LCD screen

M117 Printing...

it looks more like a copy from a gcode

if you remove all the comments in the start it will end like this

G21 ; milimeters

G90 ; absolute coords

G1 Z10 ; move the extruder up out of the way

G28 ; Home all axes

M565 Zx.x ; set the Z offset value

G29 ; probe bed

G28 X0 Y0 ; home X and Y

G1 Z5.00 F4800 ; get ready to move by lifting the extruder

G1 X100 Y110 F4800 ; move to centre of the bed

G1 Z0.3 ; Move extruder to 0.3mm above the centre of the bed

M117 Printing...

the comments is not used by the printer

could you copy the start and stop gcode from the slicer?

So the original start Code in cura is:

G21 ;metric values

G90 ;absolute positioning

M82 ;set extruder to absolute mode

M107 ;start with the fan off

G28 X0 Y0 ;move X/Y to min endstops

G28 Z0 ;move Z to min endstops

G1 Z15.0 F{travel_speed} ;move the platform down 15mm

G92 E0 ;zero the extruded length

G1 F200 E3 ;extrude 3mm of feed stock

G92 E0 ;zero the extruded length again

G1 F{travel_speed}

;Put printing message on LCD screen

M117 Printing...

But I cant see any autobedleveling there

no problem

so you use cura?

i have a little time before dinner, so just wanted to check slicer

where did you get cura profile from? its also missing setting temp

I copied from any site I cant remember ...

what should the start gcode look like

depends on what slicer you use

but i will goggle for settings, just hope i find it

http://community.robo3d.com/index.php?threads/auto-bed-leveling-in-cura.2994/ ??

G21 ; milimeters

G90 ; absolute coords

G1 Z10 ; move the extruder up out of the way

G28 ; Home all axes

M565 Zx.x ; set the Z offset value

G29 ; probe bed

G28 X0 Y0 ; home X and Y

G1 Z5.00 F4800 ; get ready to move by lifting the extruder

G1 X100 Y110 F4800 ; move to centre of the bed

G1 Z0.3 ; Move extruder to 0.3mm above the centre of the bed

always go direct to factory first if possible

will try and extract settings from my link

what is this: http://www.anycubic3d.com/support/show/594036.html ?

I cant see any start gcode? :D

its cura for your printer,

The diver Cura_15.04.6_Win is for ANYCUBIC I

yes I have cura 15.04.

the link has everything setup for your printer

but dinner time soon so will have to get back later

no the link does not have your printer build in, i just tried to install it and your printer is not there

but i will try and find slicer profile after dinner

It is mentioned in the Manual how to set it up: You have to choose other and then prusa mendel i3 and then Change some Settings. But I dont know how to set up autobedleveling in cura

oki will read the manual, but we still need start and stop code from them if possible

but dinner now :-D

no problem

what about this:

G21 ; milimeters

G90 ; absolute coords

G1 Z10 ; move the extruder up out of the way

G28 ; Home all axes

M565 Zx.x ; set the Z offset value

G29 ; probe bed

G28 X0 Y0 ; home X and Y

G1 Z5.00 F4800 ; get ready to move by lifting the extruder

G1 X100 Y110 F4800 ; move to centre of the bed

G1 Z0.3 ; Move extruder to 0.3mm above the centre of the bed

;Put printing message on LCD screen

M117 Printing...

where is that from?

Cura 15.04

in the manual there isnt any start gcode mentioned

:-( we will have to look later

okkk :D

just before i start to eat, does this make sense for you

https://manual.prusa3d.com/Guide/How+to+import+profiles+to+Cura+%28Windows+%26+macOS%29/703

not really. First of all I am using cura 15.04 its an older version. And it worked fine before I upgraded to marlin and installed the bltouch.

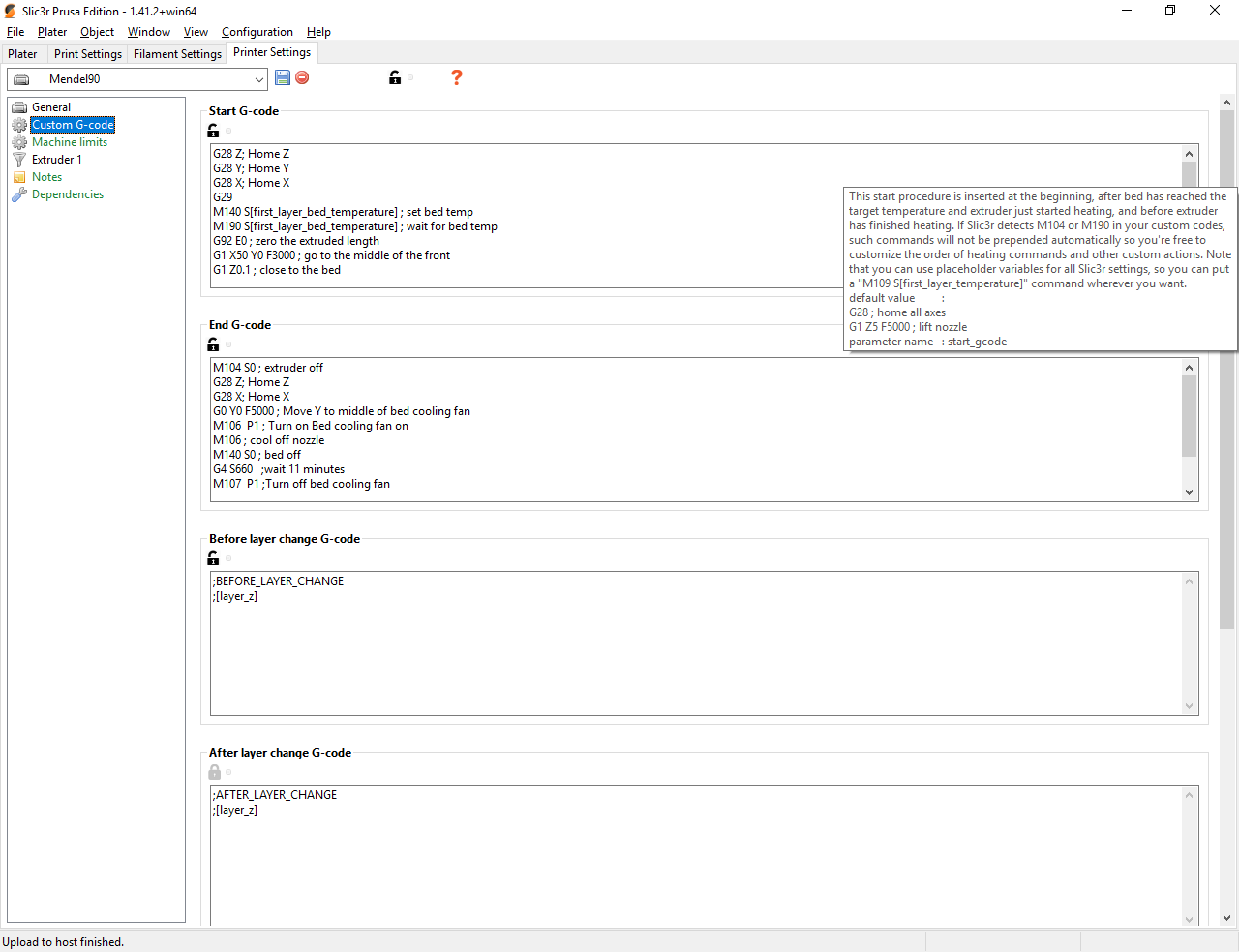

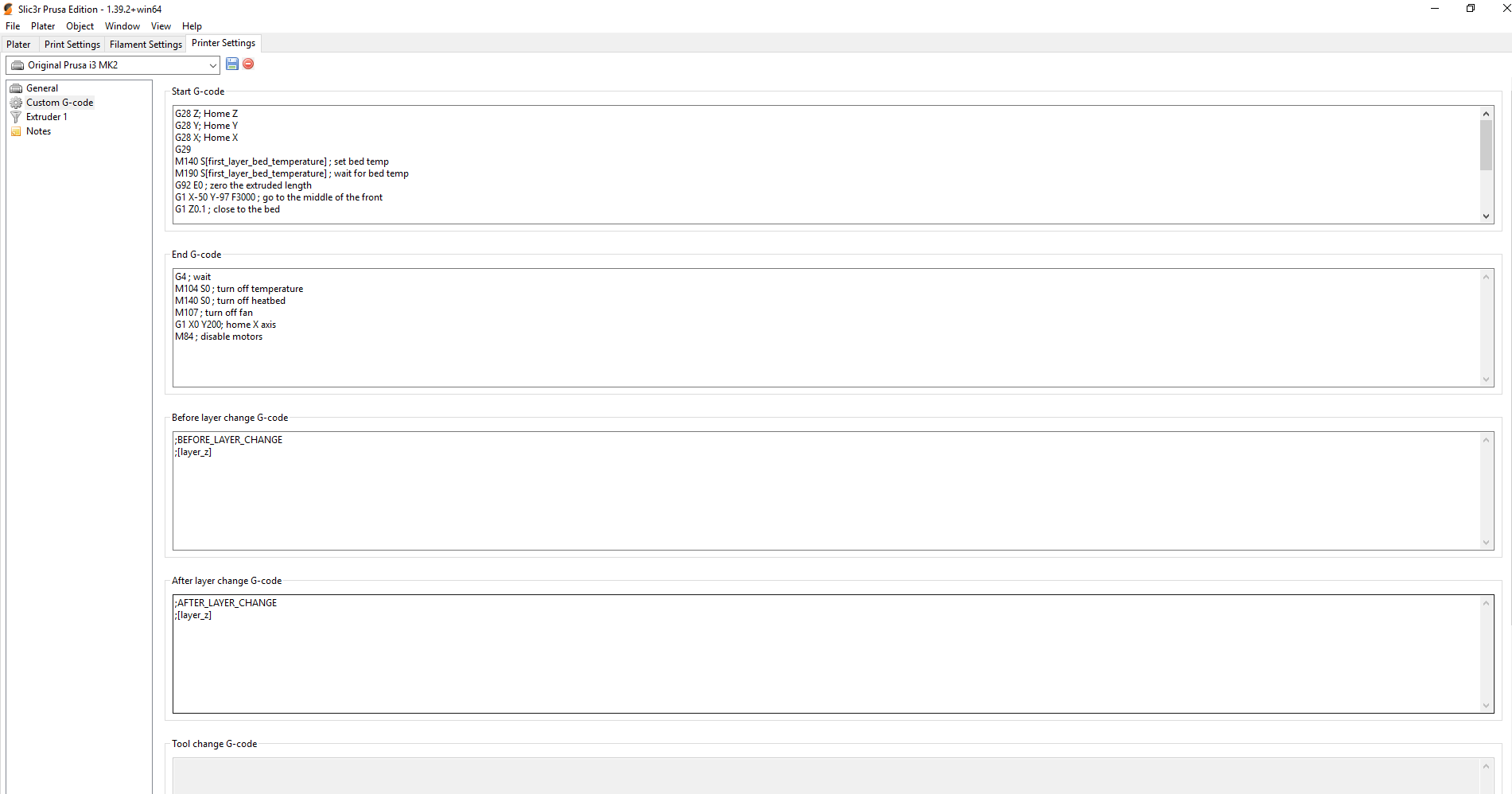

my start code from slic3r:

G28 Z; Home Z

G28 Y; Home Y

G28 X; Home X

G29

M140 S[first_layer_bed_temperature] ; set bed temp

M190 S[first_layer_bed_temperature] ; wait for bed temp

G92 E0 ; zero the extruded length

G1 X50 Y0 F3000 ; go to the middle of the front

G1 Z0.1 ; close to the bed

M104 S[first_layer_temperature] ; set extruder temp

M109 S[first_layer_temperature] ; wait for extruder temp

G1 X100 E10 F200 ; make a thick line to prime extruder

G92 E0 ; zero the extruded length

G1 Z0.3 ; lift Z

G4 S2 ;wait 2 sec to bleed off excess pressure

endcode:

M104 S0 ; extruder off

G28 Z; Home Z

G28 X; Home X

G0 Y0 F5000 ; Move Y to middle of bed cooling fan

M106 P1 ; Turn on Bed cooling fan on

M106 ; cool off nozzle

M140 S0 ; bed off

G4 S660 ;wait 11 minutes

M107 P1 ;Turn off bed cooling fan

M107 ; carriage fan off

G28 Y; home Y

M84 ; disable motors

when i get back i will need to find out what should be when it says [first_layer_bed_temperature] its not the same in cura, and there are other lines that need changes

ok

I just reinstalled cura and this is the start gcode it comes with:

G21 ;metric values

G90 ;absolute positioning

M82 ;set extruder to absolute mode

M107 ;start with the fan off

G28 X0 Y0 ;move X/Y to min endstops

G28 Z0 ;move Z to min endstops

G1 Z15.0 F{travel_speed} ;move the platform down 15mm

G92 E0 ;zero the extruded length

G1 F200 E3 ;extrude 3mm of feed stock

G92 E0 ;zero the extruded length again

G1 F{travel_speed}

;Put printing message on LCD screen

M117 Printing...

short break before desert... yes you can use slic3r.... i can help you with that as i use it too

but back in an hour

ok

My start code adjusted for cura an your printer

G28 Z; Home Z

G28 Y; Home Y

G28 X; Home X

G29

M140 S{print_bed_temperature} ; set bed temp

M190 S{print_bed_temperature} ; wait for bed temp

G92 E0 ; zero the extruded length

G1 X-50 Y-97 F3000 ; go to the middle of the front

G1 Z0.1 ; close to the bed

M104 S{print_temperature}; set extruder temp

M109 S{print_temperature}; wait for extruder temp

G1 X0 E10 F200 ; make a thick line to prime extruder

G92 E0 ; zero the extruded length

G1 Z0.3 ; lift Z

G4 S2 ;wait 2 sec to bleed off excess pressure

stop code

M104 S0 ; extruder off

G28 X; Home X

G28 Y; home Y

M84 ; disable motors

back in 20 mins and we can have a look at slic3r if you want

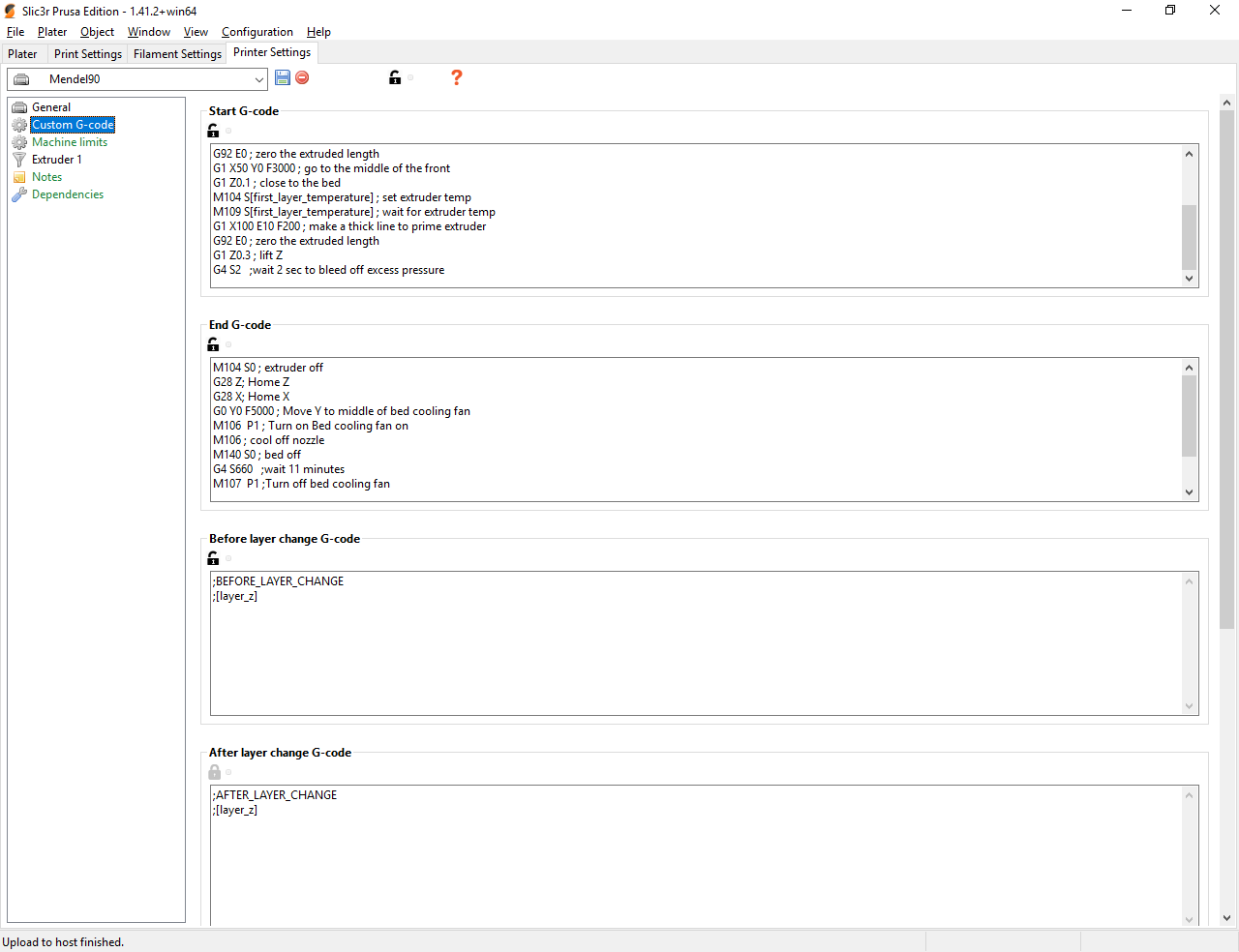

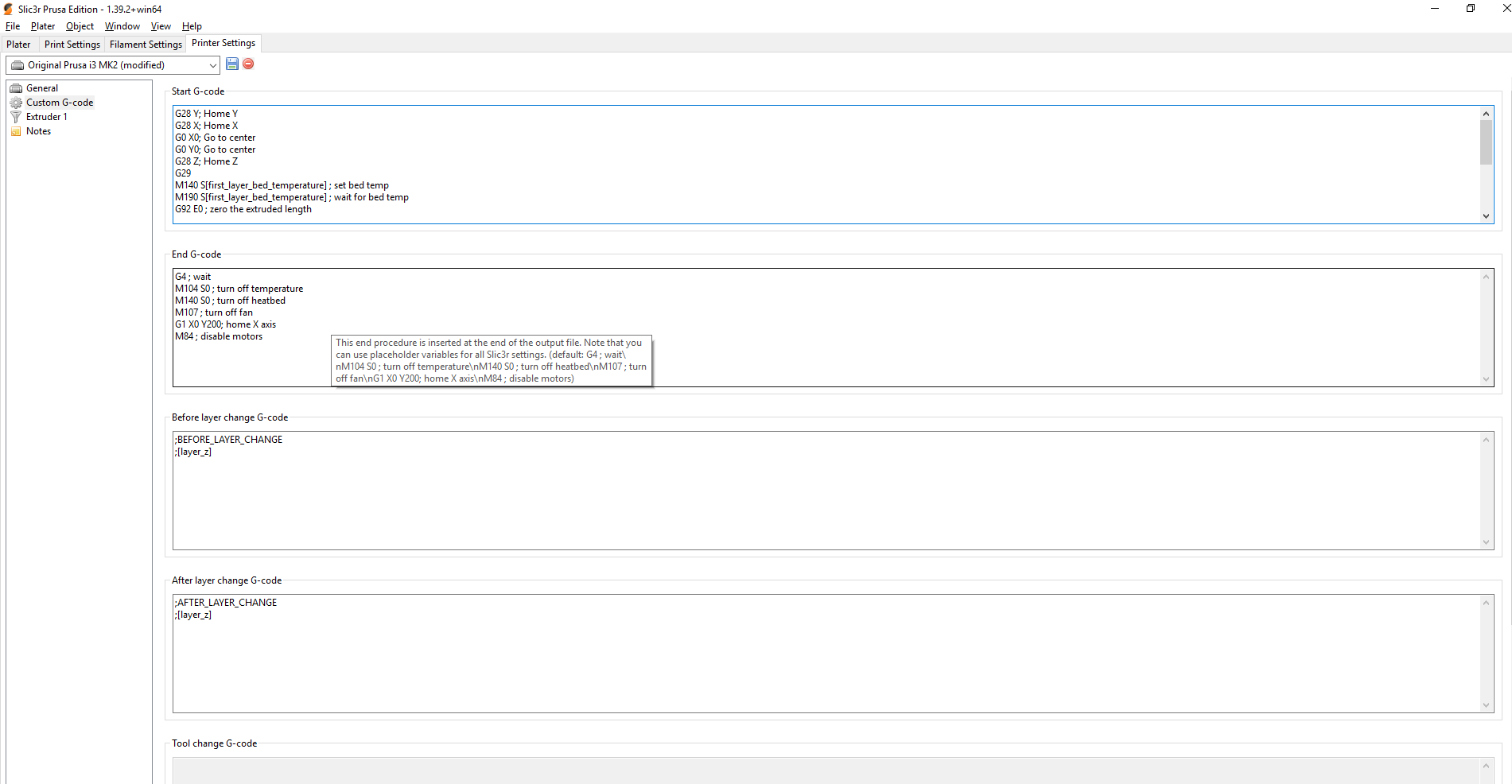

about slic3r PE

get it here: https://www.prusa3d.com/drivers/drivers-changelog/#mk25

V2.1.6 to start with, when its starting up it will ask you which printer to install, pick mk2.5 with 0.4 mm nozzle

all you nedd after its starts up next is to adjust start and stop gcode

and you have my start code gcode, but it needs adjustment for your printer

G28 Z; Home Z

G28 Y; Home Y

G28 X; Home X

G29

M140 S[first_layer_bed_temperature] ; set bed temp

M190 S[first_layer_bed_temperature] ; wait for bed temp

G92 E0 ; zero the extruded length

G1 X-50 Y-97 F3000 ; go to the middle of the front

G1 Z0.1 ; close to the bed

M104 S[first_layer_temperature] ; set extruder temp

M109 S[first_layer_temperature] ; wait for extruder temp

G1 X0 E10 F200 ; make a thick line to prime extruder

G92 E0 ; zero the extruded length

G1 Z0.3 ; lift Z

G4 S2 ;wait 2 sec to bleed off excess pressure

stop code

M104 S0 ; extruder off

G28 X; Home X

G28 Y; home Y

M84 ; disable motors

Ok i am Back. I will try both in a few minutes

I tried your cura start gcode, it seems good but 1) it doesnt do a bed Level and 2) the nozzle is to close to the bed a bit

What values to Change?

hi, just got out of bed so i will need to have breakfast first

but value to change is

define Z_PROBE_OFFSET_FROM_EXTRUDER -0.4

try and change it to

define Z_PROBE_OFFSET_FROM_EXTRUDER -0.3

upload

M502

M500

try test print again

will have to think about bed level, its in start code, look for G29

could you attach configuration.h and configuration_adv.h in a zip file?

Configuration.zip

besides the Problems from above it does some wierd Things.

It crashes in the x axxis on the opposite site of the endstop for a second. It prints the Pentagon shape for a while but then it prints on a single line.

and it moves Pretty wierd. I ll try to make a video

oki, i will start to look through the config files to see if we missed anything

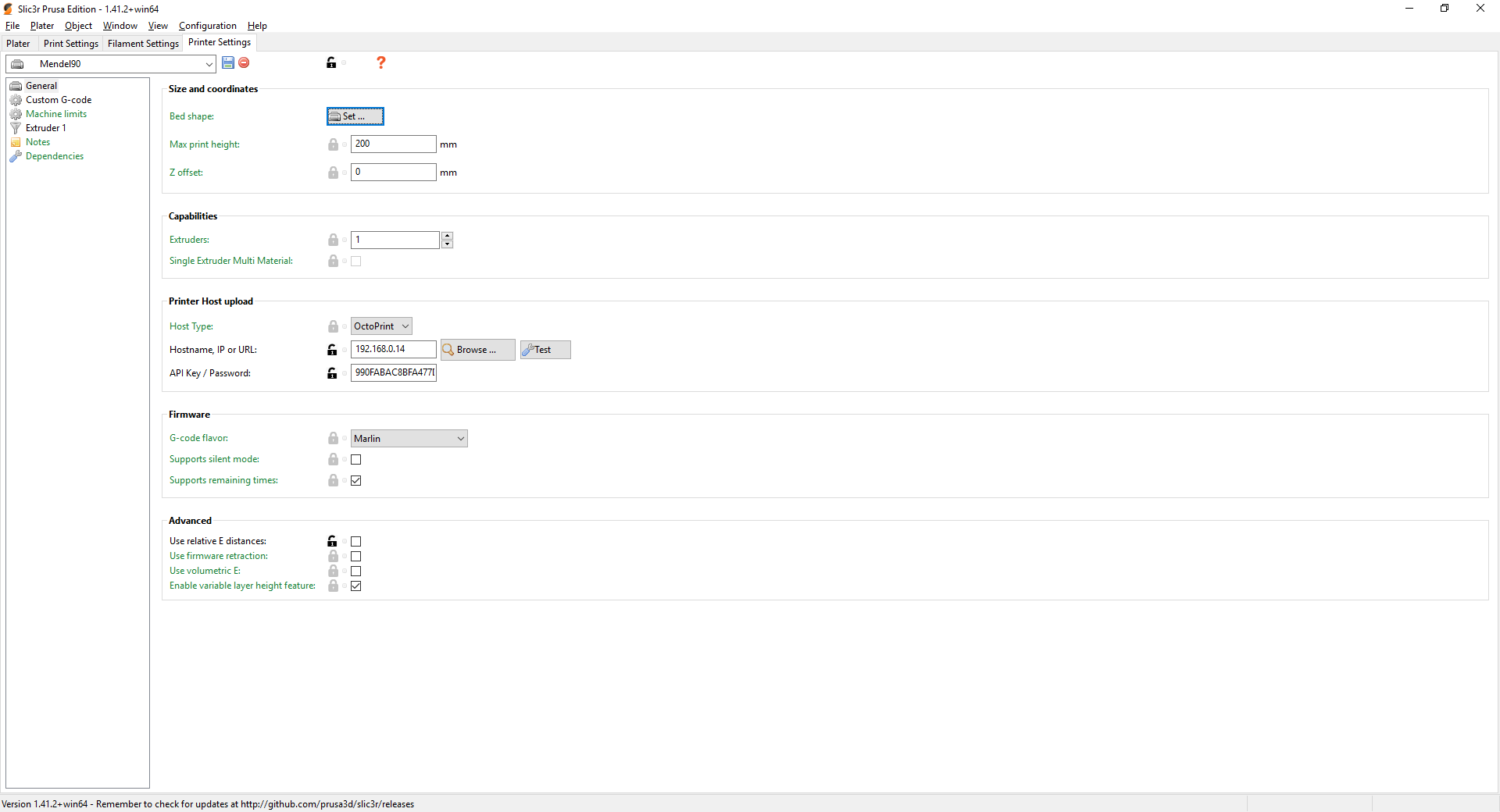

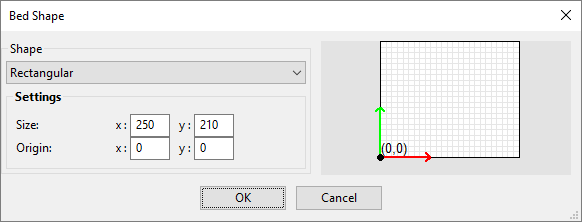

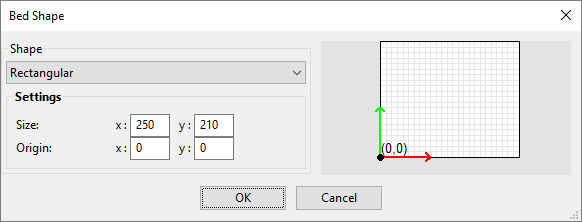

ohh

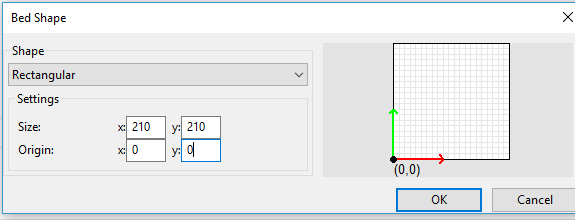

is the slicer set to have 0,0 in center?

then this is the place to change it, click the botton next to bed shape

enter 105 in both box's for bed origin, you see different numbers for bed shape as i use a different bed

yes

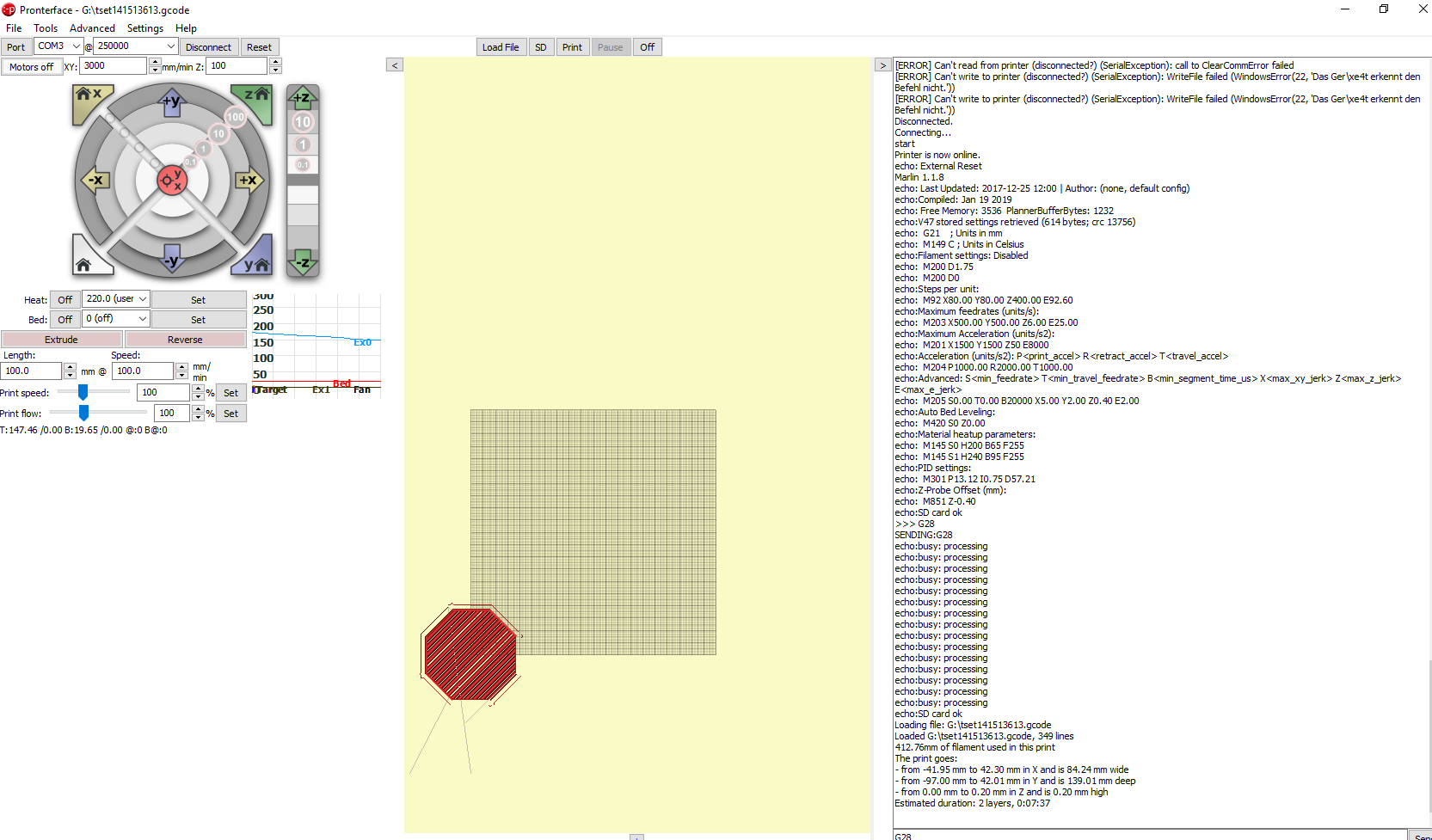

quick experiment

send G28 to printer then G29 from pronterface, what happens?

both from pronterface? first G28 then G29?

yes

G29 should make it probe the bed, if it does not we need help finding out

G29 does probe the bed it Looks good. G28 homes X and Y and Z one time. But on G28 the bltouch gets triggered to late and the nozzle touches the bed too much.

so the pin in bltouch does not come out in good time before it hits bed?

I am not shure why but I just repeated the testprint and now it does probe the but

so the pin in bltouch does not come out in good time before it hits bed?

no the pin is down but it gets triggered to late, but only on G28

I am not shure why but I just repeated the testprint and now it does probe the but

now its heating let me see whats coming next.

strange, maybe @Roxy-3D know what is going on, ie why the probe is triggered to late

maybe we need to enable some extra debug output so we can get more details on what is going on

when I try to print it again without pronterface connected it sais G28 Z forbidden on the LCD and it doesnt probe

anyone that follows this: config is here: https://github.com/MarlinFirmware/Marlin/issues/12948#issuecomment-455856838

but does it print when you do it from pc? just so we know if it makes any difference

are you kidding me now G28 is just fine. What is this?

but does it print when you do it from pc? just so we know if it makes any difference

wait I ll try it with pronterface

https://github.com/MarlinFirmware/Marlin/issues/5824

so i think it has something to do with same homing...

what it means is that you are to close to the bed when you try G28

is this normal?

no, pronterface thinks 0,0 is in the corner

i will look where to change that

The nozzle pushed down the bed a bit. But now G28 is fine

no, pronterface things 0,0 is in the corner

ok wait i ll print it trough cura

I tried it with cura and it said on the LCD: G28 Z forbidden and then home Z first

I ll Change the Settings and try it with pronterface

So we need to change start code a bit to make it happen

but lets get pronterface correct also, trying to figure out what of the 2 last lines to change

are you opening the gcode from cura in pronterface?

yes the gcode I was trying to print before

oki, dont worrie, i'm just slow to find out things

here is the gcode

gcode used.zip

cura still thinks 0,0 is down the corner i think

have you tried slic3r pe?

Wait i ll try it. Which start gcode?

the one i have posted last night

ok its downloading. But is my bed like the prusa mk2.5?

nope, but it does not matter

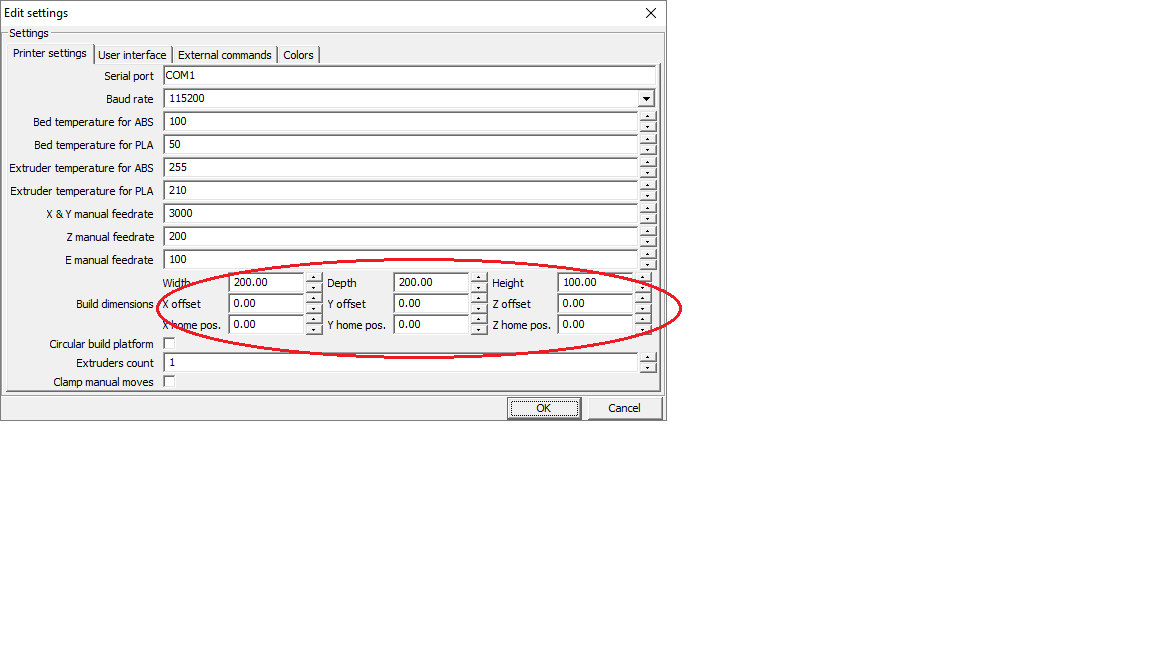

how to set 0,0 in center: https://github.com/MarlinFirmware/Marlin/issues/12948#issuecomment-455857670

ok wait a sec

and in same place where you set 0,0 in center you change bed size

remember V2.1.6

ohh i downloaded 2.2.2. Wait ill download 2.1.6 :D

if you are confused about the difference between slicer and pronterface here is the short explanation

slicer(cura or slic3r pe or any other program) prepares the model, so its the slicer that decides where on the bed printer is going

pronterface is just a control program that sends instructions to the printer, it does not change the gcode

why i want to test slic3r pe is because i know that program better and we can see if there is any change in the gcode when you load it in pronter face

but its sunday, lets take it easy, no reason for stress

ok I tried it. It doesnt home Z and it doesnt probe the bed. So its printing in mid air.

Gcode:

testsli3r.zip

now I try this gcode through pronterface

post picture of start code in slic3r pe

first delete all gcode and then insert the one i gave last night

mine looks like this, and you cant use it since you wanted 0,0 in center

this is all:

G28 Z; Home Z

G28 Y; Home Y

G28 X; Home X

G29

M140 S[first_layer_bed_temperature] ; set bed temp

M190 S[first_layer_bed_temperature] ; wait for bed temp

G92 E0 ; zero the extruded length

G1 X-50 Y-97 F3000 ; go to the middle of the front

G1 Z0.1 ; close to the bed

M104 S[first_layer_temperature] ; set extruder temp

M109 S[first_layer_temperature] ; wait for extruder temp

G1 X0 E10 F200 ; make a thick line to prime extruder

G92 E0 ; zero the extruded length

G1 Z0.3 ; lift Z

G4 S2 ;wait 2 sec to bleed off excess pressure

it said at the beginnig on the LCD: G28 Z forbidden

this is very strange

G28 Z should home Z first

but maybe we need to change it so it homes Z last

ok just change G28Z and G28X ?

why is it forbidden?

G28 Y; Home Y

G28 X; Home X

G0 X0; Go to center

G0 Y0; Go to center

G28 Z; Home Z

G29

M140 S[first_layer_bed_temperature] ; set bed temp

M190 S[first_layer_bed_temperature] ; wait for bed temp

G92 E0 ; zero the extruded length

G1 X-50 Y-97 F3000 ; go to the middle of the front

G1 Z0.1 ; close to the bed

M104 S[first_layer_temperature] ; set extruder temp

M109 S[first_layer_temperature] ; wait for extruder temp

G1 X0 E10 F200 ; make a thick line to prime extruder

G92 E0 ; zero the extruded length

G1 Z0.3 ; lift Z

G4 S2 ;wait 2 sec to bleed off excess pressure

its forbidden because it does not know where probe is on bed before X and Y is homed

ok should I switch G28 Z and X

i have changed the code so it now homes X and Y and then goes to center before it homes Z

ok

no use the code i just gave you.... see the changes?

brb, need to start a print

no dont see changes

before:

G28 Z; Home Z

G28 Y; Home Y

G28 X; Home X

G29

after:

G28 Y; Home Y

G28 X; Home X

G0 X0; Go to center

G0 Y0; Go to center

G28 Z; Home Z

G29

see it now?

nah but I ll copy this

stop

you need to understand it or else you dont know what is going on

all:

G28 Y; Home Y

G28 X; Home X

G0 X0; Go to center

G0 Y0; Go to center

G28 Z; Home Z

G29

M140 S[first_layer_bed_temperature] ; set bed temp

M190 S[first_layer_bed_temperature] ; wait for bed temp

G92 E0 ; zero the extruded length

G1 X-50 Y-97 F3000 ; go to the middle of the front

G1 Z0.1 ; close to the bed

M104 S[first_layer_temperature] ; set extruder temp

M109 S[first_layer_temperature] ; wait for extruder temp

G1 X0 E10 F200 ; make a thick line to prime extruder

G92 E0 ; zero the extruded length

G1 Z0.3 ; lift Z

G4 S2 ;wait 2 sec to bleed off excess pressure

before the first bit of the start code was:

G28 Z; Home Z

G28 Y; Home Y

G28 X; Home X

G29

now its

G28 Y; Home Y

G28 X; Home X

G0 X0; Go to center

G0 Y0; Go to center

G28 Z; Home Z

G29

i moved home Z down just before G29

and after home of Y and X asked the nozzle to go to center of bed

before:

G28 Z; Home Z

G28 Y; Home Y

G28 X; Home X

G29after:

G28 Y; Home Y

G28 X; Home X

G0 X0; Go to center

G0 Y0; Go to center

G28 Z; Home Z

G29

here I can see it but in your post from last night I do not see any changes

you got it right in slic3r pe

no these changes was not there last night because i did not know of the forbidden error

we have now changed it so it should not give this error

i ll try it wait

how does bed setup look like?

i have another bed remember that

your number should be

210 210

105 105

yes they are

now it homes z fine and probes the bed fine. But it still does wierd Things. it s

newtestsli3r.zip

ill crashes for a sec in the x axis oposite side of the endstop. and it doesnt make that Pentagon shape. I ll capture a video

i think what is giving us so much pain is that you want 0,0 in center

can we have 0,0 in lower left corner instead?

of course. i dont want 0,0 in center :D

i thought you wanted that :-D but oh well it's easy to change let me look through config

define BED_CENTER_AT_0_0

change to

//#define BED_CENTER_AT_0_0

define LEFT_PROBE_BED_POSITION -25

define RIGHT_PROBE_BED_POSITION 100

define FRONT_PROBE_BED_POSITION -93

define BACK_PROBE_BED_POSITION 100

change to

define LEFT_PROBE_BED_POSITION 25

define RIGHT_PROBE_BED_POSITION 100

define FRONT_PROBE_BED_POSITION 93

define BACK_PROBE_BED_POSITION 100

define X_MIN_POS -109

define Y_MIN_POS -107

define Z_MIN_POS 0

define X_MAX_POS 105

define Y_MAX_POS 105

define Z_MAX_POS 250

change to

define X_MIN_POS 109

define Y_MIN_POS 107

define Z_MIN_POS 0

define X_MAX_POS 105

define Y_MAX_POS 105

define Z_MAX_POS 250

try and compile and see if error free (should be)

upps....

define X_MIN_POS 0

define Y_MIN_POS 0

define Z_MIN_POS 0

define X_MAX_POS 210

define Y_MAX_POS 210

define Z_MAX_POS 250

erro :D static assertion failed: LEFT_PROBE_BED_POSITION can't be reached by the Z probe.

define X_MIN_POS 0

define Y_MIN_POS 0

define Z_MIN_POS 0

define X_MAX_POS 210

define Y_MAX_POS 210

define Z_MAX_POS 250

define LEFT_PROBE_BED_POSITION 25

define RIGHT_PROBE_BED_POSITION 100

define FRONT_PROBE_BED_POSITION 93

define BACK_PROBE_BED_POSITION 100

//#define BED_CENTER_AT_0_0

define LEFT_PROBE_BED_POSITION 75

define RIGHT_PROBE_BED_POSITION 210

define FRONT_PROBE_BED_POSITION 93

define BACK_PROBE_BED_POSITION 210

try that

i guess next is error on front :-D

no it compiles fine. I uploaded it

whats next?

define FRONT_PROBE_BED_POSITION 7

define BACK_PROBE_BED_POSITION 210

still without error?

this works_:

define FRONT_PROBE_BED_POSITION 93

define BACK_PROBE_BED_POSITION 210

this aswell

define FRONT_PROBE_BED_POSITION 7

define BACK_PROBE_BED_POSITION 210

go with the last

define FRONT_PROBE_BED_POSITION 93

define BACK_PROBE_BED_POSITION 210

upload

then M502

then M500

then we are sure it uses latest settings

then send one line at a time

G28 Y

G28 X

G0 X0

G0 Y0

G28 Z

G29

this works

G28 Y

G28 X

G0 X0 --> bed runs in endstop

upppps again

G28 Y

G28 X

G0 X105

G0 Y105

G28 Z

G29

we also need to change start code latyer

G0 X105 --> still running in bed endstop

did you do G28 X first?

yes

i ll do it again

send config as zip again... something is wrong with config if it goes in to endstop

looks correct

send G28 X

then G28 Y

send M114

what does it say?

X:0.00 Y:0.00 Z:10.00 E:0.00 Count X:0 Y:0 Z:4000

and nozzle is in the front left corner

Send G0 X105

where does it move?

bed runs further --> in the endstop

bed should not move... only the nozzle

send G28 X again so we can get it back in the corner

now send G0 Y105

where does it move now?

again in the bed endstop

with G28 the nozzle homes

there is something serious wrong

did the bed or nozzle move?

with G28 X the nozzle

with G0 Y105 the bed

oki, send G28 so its in the corner

let me know when that is done

with G28 it homes all axis after z home the nozzle stays not in the Corner but on the left side

now send: G0 X10

nozzle should move 10mm away from endstop

is X endstop in left side?

no bed runs in endstop again with G0 X10

yes x endstop is on the left side of the Extruder

bed should not move, only nozzle

yes but it does move :(

we need to check connections... but lets take it slowly

first send M84, this will stop the steppers

next move bed and nozzle with your hand slowly away from endstops so we can get to them with finger

if go on the LCD to prepare move axis and move X axxis it mooves the nozzle

ok I mooved it away

have you done as i told? brb, need to make coffee

yes bed and nozzle is on the opposite side of the endstops now

Send M119, what does it say?

x_min: open

y_min: open

z_min: open

now with finger press x endstop and send M119 again

x_min: TRIGGERED

y_min: open

z_min: open

when I press on bed endstop:

x_min: open

y_min: TRIGGERED

z_min: open

then endstops are connected right

send G28 again so we have it in the corner and machine thinks its in the corner

then send M84 and move nozle and bed so its in center

ok wait with G28 its not in the corner

it moves to the Corner then it moves a bit in the Center and the home Z with the bltouch

yes... it moves to center so its sure that probe is over bed

just send G28 and then M84

ok

then with hand move bed and nozzle so its in center

now machine does still think its in corner

send G0 X10, now what does move and in what direction

bed runs in endstop again

it should only move 10mm

strange

Why can I move the bed with the LCD just fine?

but it was the bed that moved and not the nozzle?

Yes the nozzle stands still

we are not moving the bed right now, so if you move X on lcd and bed moves motors are connected wrong

if I moove X it mooves the nozzle

if I move Y it moves the bed

now i'm confused

we send G0 X10 and you say the bed moves.... X is not the bed

Yes :/

with G0 X10 the bed moves in the endstop

and that is wrong... it should be nozzle moving and not bed and it should only move 10mm

Yes I know but it doesnt do it :/

how is this possible

Configuration_adv.zip

thats the latest config

send G28, then M84, move it with hand to center

now send G0 Y10, does the bed or nozzle move?

bed and again in the endstop

so if we ask it to move X it moves Y

if we ask it to move Y it moves Y

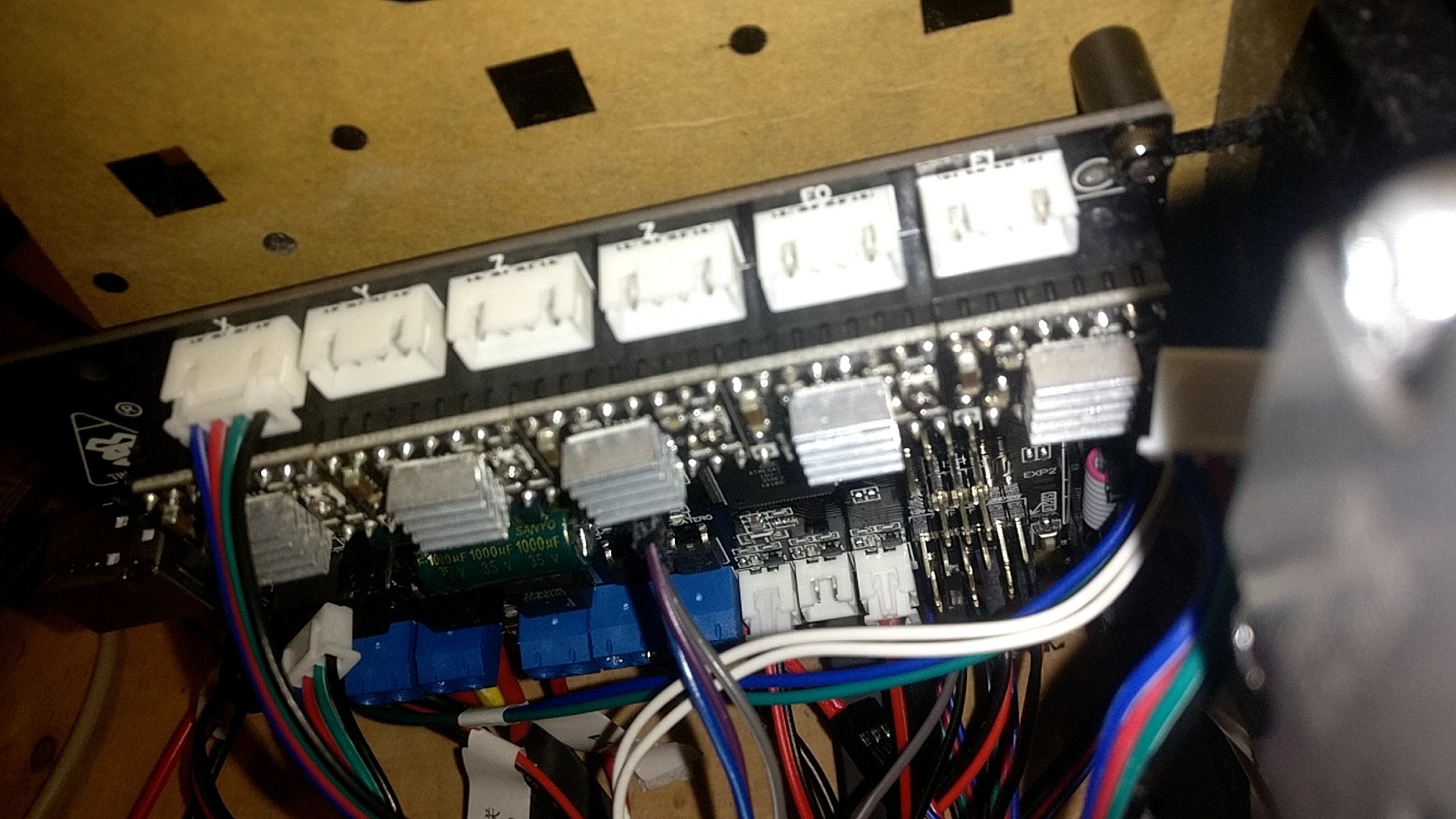

are there 2 motors connected in Y plug on electronics board?

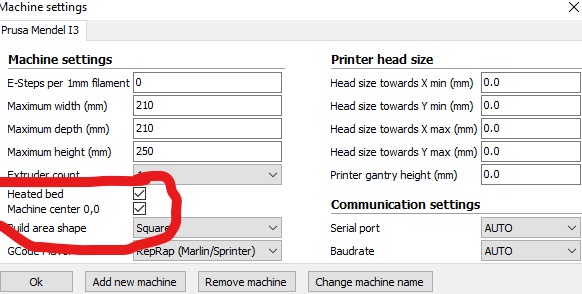

the last picture

I send all commands with pronterface should I try sending them with Arduino ide ?

no

i'm thinking

one of your links from yesterday, https://github.com/duisenberg/AnyCubic-I3/blob/master/Firmware/Marlin_1.1.5/Configuration.h

one difference is this line

define MOTHERBOARD BOARD_RAMPS_13_EFB

your is #define MOTHERBOARD BOARD_RAMPS_14_EFB

ok

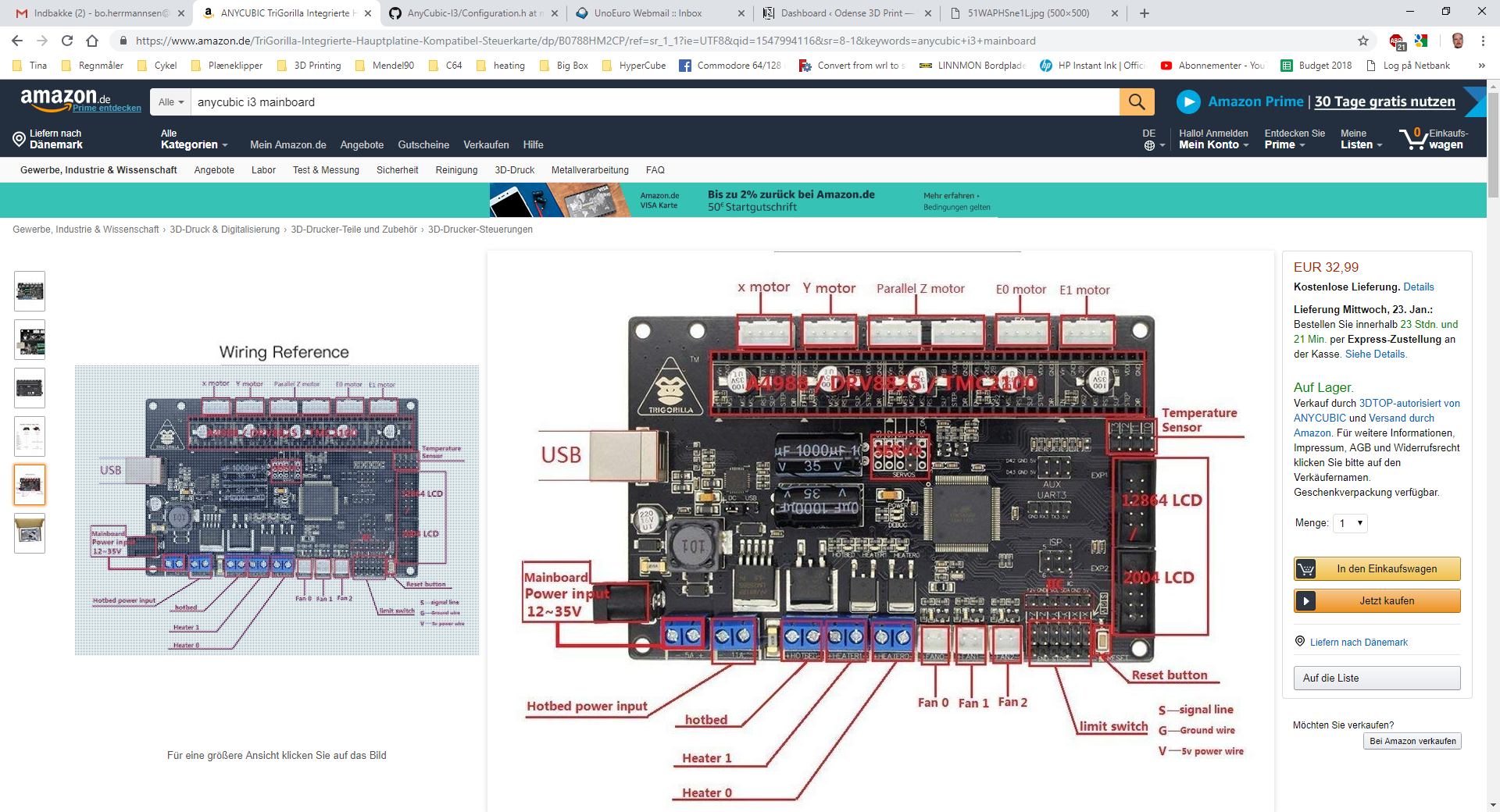

this is my mainboard: https://www.amazon.de/TriGorilla-Integrierte-Hauptplatine-Kompatibel-Steuerkarte/dp/B0788HM2CP/ref=sr_1_1?ie=UTF8&qid=1547994116&sr=8-1&keywords=anycubic+i3+mainboard

Because I blew up the old one :/

but this happened half a year ago

sure motors are connected correct?

the pictures are not the same

no they are connected like this:

that is not the same

yes should I connect it like your picture?

but X and Y are the same

3 first motors are the same, but not the rest

power off electronics, you must never take out a motor with power on

takke off all steppers but leave X connected... and make sure that it is X connected and not Y

could you take a picture and post it?

we need to check this very close and find out why it moves Y when we tell it to move X

now power up again

make sure Z is a little up from bed so it does not crash, you can turn Z rod with your hand

send G28 X.... only Z should move

upps

only X should move

yes

X does home

send G0 X10, what happens ?

nothing

what with G0 X-10

?

nothing aswell

power down and take out X stepper driver and put in Y stepper driver where X was

we need to check that X driver is not blown

waiiitt

same result G28 X moves home G0 X10 nothing

X did home fine so driver is fine, just me getting a bit desperat to find out what is wrong

now power down

take X motor out and put in Y motor and now send G28 Y

then send G0 Y10

G28 --> bed homes fine

G0 Y10 --> bed runs in endstop

aha.... so it moves Y in wrong direction

brb

change

define INVERT_Y_DIR false

to

define INVERT_Y_DIR true

upload

then G28 Y

then G0 Y10

now when I do G28 Y the bed runs away from the endstop and crashes in the opposite side

oki, so change it back

define Y_HOME_DIR -1

change to

define Y_HOME_DIR 1

upload and try again, hope it does not crash this time

what i did was telling it that the endstop is in the max end

if i'm correct when we send G0 Y10 it should move away from endstop and not crash in to it

error: #error "Enable USE_YMAX_PLUG when homing Y to MAX."

change back to #define Y_HOME_DIR -1

your board does not have Y max plug

need to think very hard now

ok :/

upload firmware

then G28 Y

then G0 Y-10

2 things can happen, either Y does not move after home or it moves away from endstop

wait so I upload with home dir -1 and #define INVERT_Y_DIR false

yes

with this G0 Y-10 nothing happens

and G0 Y10 makes it go in to endstop..... very strange

Yes :/

define MOTHERBOARD BOARD_RAMPS_14_EFB

try and change to

define MOTHERBOARD BOARD_RAMPS_13_EFB

it will proberly not make a difference but i just wanted to try it

Yes no difference

i have made a small list of things we have discovered so far, does the list look correct?

endstops are connected correct

X and Y homes ok

when sending G28 X followed by G0 X10 nothing happens

when sending G28 Y followed by G0 Y10 it crashes in to Y endstop

change

define MOTHERBOARD BOARD_RAMPS_13_EFB

back to

define MOTHERBOARD BOARD_RAMPS_14_EFB

i have made a small list of things we have discovered so far, does the list look correct?

endstops are connected correct

X and Y homes ok

when sending G28 X followed by G0 X10 nothing happens

when sending G28 Y followed by G0 Y10 it crashes in to Y endstop

yes

now power down and connect X so we have both X and Y connected

how many Z motors ? 1 or 2 ?

2 Z motors

connect both of them in to Z stepper connectors(2 middle plugs)

power up

send G28 and it should home fine

then send Go Z10... if it works it should move Z up 10mm

G0 not Go

ok

when I do G28 it seems fine but I think only one Z Motor is moving

strange

power down and move one Z motor to E1

and then try again

i just read the adv config file and it uses 2 stepper drivers so that is why only of them moved i think

what if I send G0 Z10 it moves the bed aswell

it should not move Y (bed)

Yes I know :?

and I am still not understanding why with the LCD I can move every axis just fine :D

but did Z move up? and what direction did the bed move?

when i do G0 Z10 it only moves the bed in the endstop again

Z did not move at all?

So this means for

G0 Z10

G0 X10

G0 Y10

it Always movbes the bed in the endstop

what if I send G0 Z10 it moves the bed aswell

when you say that it suggest that both Z and Y moves

no Z doesnt move at all

for

G0 Z10

G0 X10

G0 Y10

it Always moves the bed and only the bed in the endstop

new list then

endstops are connected correct

X and Y homes ok

when sending G28 X followed by G0 X10 nothing happens

when sending G28 Y followed by G0 Y10 it crashes in to Y endstop

checked that both X and Y steppers are not blown

when sending G28 Z followed by G0 Z10 Z does not move and bed crash in to endstop

when homing and moving from the lcd everything works fine

i'm starting to think that its an error in firmware, where did you get it from?

i'm starting to think that its an error in firmware, where did you get it from?

from https://github.com/MarlinFirmware/Marlin/archive/1.1.8.zip

then it should be ok

this is very strange but we have narrowed things down, not sure if it helps creating a new issue and close this one

i was thinking about calling a new issue something like: Anycubic I3 homes fine but crash's Y endstop on any move with X and Y

then in new issue use the list i have made

reason for doing this is to make issue shorter and show people what we have tested so far

sorry for chiming in

@mpm1396 is using a Trigorilla board, this board has its own board definition in marlin

and the E1 driver pins get undefined, so they are not usable in marlin

you should probably use only one z driver for both z motors

ok so what do I have to do now?

what is the board deff then? i tried to look for an anycubic config file but there are none

using the wrong board would explain a bit :-D

the trigorialla board is just a Arduino mega and a ramps or am I wrong?

pins_TRIGORILLA_13.h or pins_TRIGORILLA_14.h

define MOTHERBOARD BOARD_TRIGORILLA_13 or #define MOTHERBOARD BOARD_TRIGORILLA_14

ok and the rest the same?

board can be basicly the same, but sometimes people say its just a ramps and mega in one board

but they forget that sometimes the maker changes the pins used..

yes just change

define MOTHERBOARD BOARD_RAMPS_14_EFB

to

define MOTHERBOARD BOARD_TRIGORILLA_14

error "Unknown MOTHERBOARD value set in Configuration.h"

when/if we get this working we should upload the config so that others dont have to search for it

anycubic have not put anything on their site, not even the firmware, so they break the license :-(

only thing they have put up is a hex file, not the source as they should

but if we upload the config we can help others

let me find the right board name

ok

why has he:

https://github.com/duisenberg/AnyCubic-I3/blob/master/Firmware/Marlin_1.1.5/Configuration.h

the ramps 13 as Motherboard defined?

i dont know why he has. its not main marlin anyway

so what #define MOTHERBOARD now?

oops, the board is not in marlin 1.1.8 its in 1.1.9

so download marlin 1.1.9 then?

@kAdonis but did i get the define correct?

@mpm1396 i think its better to go for 2.0, maybe

isnt marlin 2.0 in alpha or so. I mean for me it doesnt matter as long as we can get it to work

i use it.... no problems here

ok so just download it and copy config and config adv?

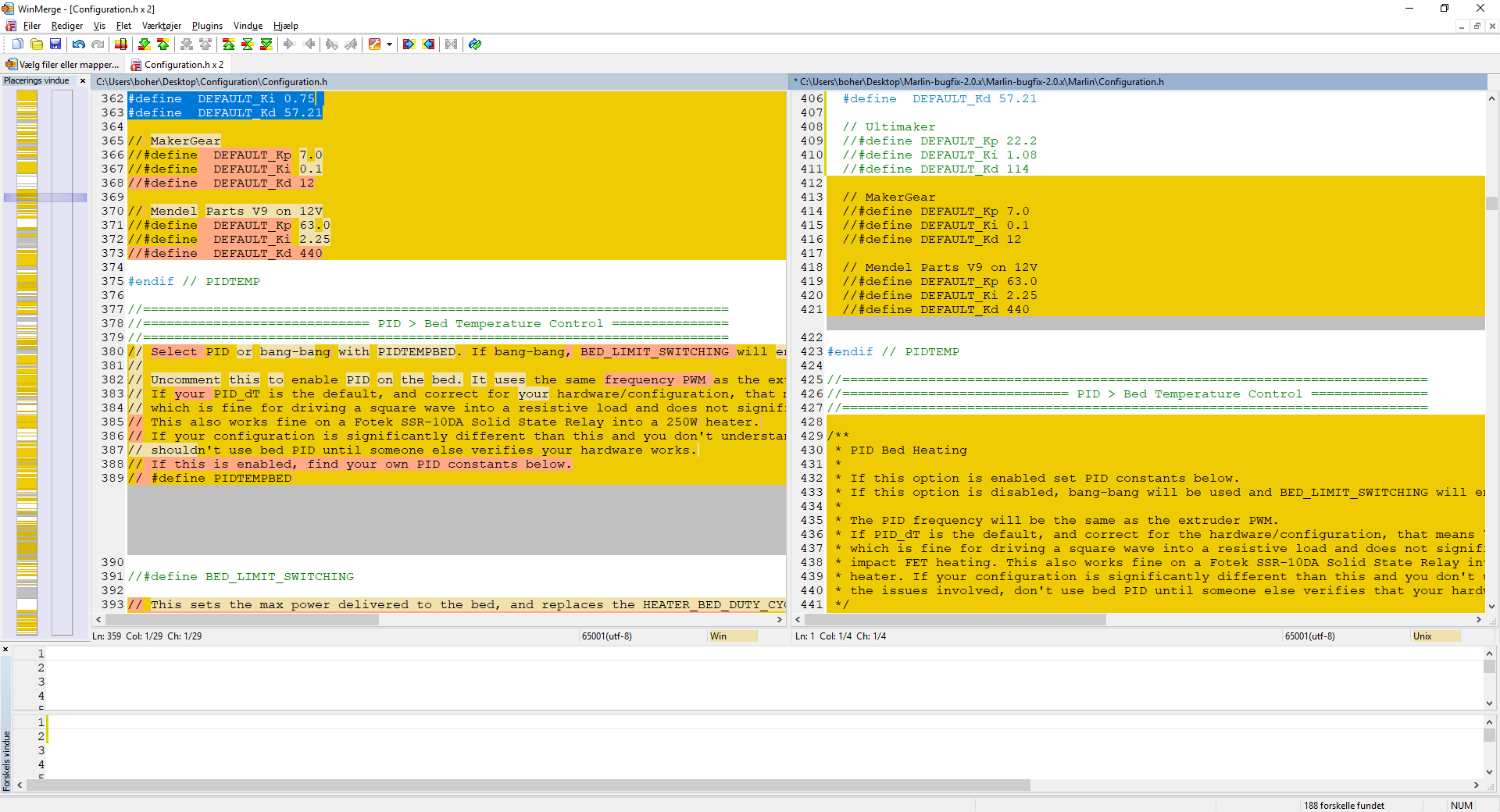

no you need to compare new and old config and move over settings

i can do it for you

can you post config as they are precise now, both files

Configuration.zip

Thank you so much :)

@boelle Yes

BOARD_TRIGORILLA_14 or BOARD_TRIGORILLA_13

I can't tell from the picture, I dont use the board

I also recommend marlin 2.0

in BOARD_TRIGORILLA_13 E1 is undefined!

@kAdonis its this board: https://www.amazon.de/TriGorilla-Integrierte-Hauptplatine-Kompatibel-Steuerkarte/dp/B0788HM2CP/ref=sr_1_1?ie=UTF8&qid=1548000760&sr=8-1&keywords=anycubic+i3+mainboard

i think its the _14

oki... we will get it

doing the work looks like this

old config on left, new on right

sorry, I dont know

ich kenne das Board auch nur vom Foto

ok then we have to try it i guess

und ich bin nur ein dumme däne 👍

i like Denmark

configuration.h: https://pastebin.com/PGyUWRA0

need to do the configuration_adv.h also

configuration_adv.h: https://pastebin.com/8vKqBbbF

but dinner time to so have to go for 1-2 hours

what areduino ide do you use?

what areduino ide do you use?

1.8.8

Oki. Still not back. Did it compile?

søn. 20. jan. 2019 17.53 skrev mpm1396 notifications@github.com:

what areduino ide do you use?1.8.8 from Windows store

—

You are receiving this because you were mentioned.

Reply to this email directly, view it on GitHub

https://github.com/MarlinFirmware/Marlin/issues/12948#issuecomment-455882661,

or mute the thread

https://github.com/notifications/unsubscribe-auth/ADp5r9L-6NqSROIMDtq99UzOQWjmpFC_ks5vFJ8LgaJpZM4aIkpm

.

I am not sure how to install 2.0 . I downloaded it from: https://github.com/MarlinFirmware/Marlin/archive/bugfix-2.0.x.zip

but where do I have to paste my configs?

Or how is this working because in the marlin folder there is now only config, config adv, makefile, and marlin.ino and two folders

paste config from the 2 links i posted in to marlin folder where you only see marlin.ino and 2 folders

then open marlin.ino in arduino ide

ok so it is normal that there are only 3 tabs in the Arduino ide now?

ok its uploaded now whats next?

Yes they have cleaned up marlin and made it more simple

søn. 20. jan. 2019 18.37 skrev mpm1396 notifications@github.com:

ok so it is normal that there are only 3 tabs in the Arduino ide now?

—

You are receiving this because you were mentioned.

Reply to this email directly, view it on GitHub

https://github.com/MarlinFirmware/Marlin/issues/12948#issuecomment-455886003,

or mute the thread

https://github.com/notifications/unsubscribe-auth/ADp5r-Ha_zp1fPZQr_MSOOqd8IPcmtxHks5vFKl0gaJpZM4aIkpm

.

Next is me coming back from dinner

søn. 20. jan. 2019 18.40 skrev mpm1396 notifications@github.com:

ok its uploaded now whats next?

—

You are receiving this because you were mentioned.

Reply to this email directly, view it on GitHub

https://github.com/MarlinFirmware/Marlin/issues/12948#issuecomment-455886134,

or mute the thread

https://github.com/notifications/unsubscribe-auth/ADp5r8P6vJ_xy5OkfGrc_29C31-ztW7Oks5vFKnzgaJpZM4aIkpm

.

ok :D

oki

try and send G28 and see if it still homes like before

forgot to ask, is everything connected like before we took off steppers?

remember not to have power on when connecting steppers or taking off steppers

its connected like before z left - z / z Right - E1

but on G28 only on z Motor moves

oki what happens when you send G28

should I connect them both to z now?

yes try that first

I think that still only one z Motor is moving but i am not sure. Is it possible to move only one at a time

did it home fine like before?

ok so now I checked it both z Steppers are working when connecting them both to Z

and it homes fine with G28 ?

ok it homes fine

the z Steppers are so much quieter now

whats next?

try and send M114 so we know where it think it is

G28 --> M114 = X:30.00 Y:100.00 Z:10.40 E:0.00 Count X:2400 Y:8000 Z:4160

oki..

Try G28 X and then G28 Y

it should go to corner

it does

now send G0 X105 Y105

should go near center

it does

yaaaaa progress

you still have the cross on bed?

yes

move it with display so its as close to center you can get

and then M114

X:110.30 Y:111.20 Z:1.00 E:0.00 Count X:8824 Y:8896 Z:400

in configuration.h change these 2 lines

define X_MIN_POS -10

define Y_MIN_POS -11

upload

send M502 and then M500

then send G28

and then G29

it should probe the bed

it does probe the bed

it goes Pretty close to the back Edge but it probs just fine

now we are going forward

as long the pin from probe are on the bed its ok... about 10mm from edge of bed

now maybe we should run PID tune so temps are better/stable

send M303 E-1 S100 C8

this will heat bed to 100C and it will go a bit over and under for 8 times and send some numbers back to you

wait what when I start the Printer it does say Marlin 1.1.8 again

I am Dump. I flashed 1.1.8 again

hehehe, it can happen to the best of us :-D

I had 2 Arduino ide s open (facepalm) I ll Flash 2.0 again

maybe move 1.1.8 to another place so you dont edit the wrong config and flash old firmware

ok 2.0 is flashed again. Now I should home and then moove it with the LCD to the Center and then M114??

yes just to confirm we are closer to center than first time

Try G28 X and then G28 Y

now send G0 X105 Y105

ok its near the center

we can never get it perfect center, as long we are 1mm from center in each direction we cant get it better

ok whats next

test bed temp control

send: M303 E-1 S100 C8

ok: PID Autotune start

:-)

you have the Ultrabase bed right?

as we get the config right i'm saving changes so that we can publish the config and help others

autotune might fail if bed cant get hot enough

yes Ultrabase.

Yes great Idea

what should now be the Output of the pid autotune?

it will say when its finished... it will go to 100C for bed temp

ok its at 65

if it can not get to 100 it will fail, no problem we just pick a lower number and try again

its on 80. I think the highest temp I have ever printed with was 90 or so but lets see

i pick 100 myself so i know how far it can go

ok its at 100 now

--> bias: 188 d: 66 min: 98.40 max: 100.05

it will now go a bit above 100 and a bit below 100 8 times before its complete

it figures out how much power is needed to keep temp at 100

ahh I understaind

it will give out lot of numbers before its done

but it will say when done

PID Autotune start

bias: 188 d: 66 min: 98.40 max: 100.05

bias: 217 d: 37 min: 98.56 max: 100.07

bias: 211 d: 43 min: 99.54 max: 100.13 Ku: 183.69 Tu: 15.07

Classic PID

Kp: 110.22 Ki: 14.62 Kd: 207.67

bias: 195 d: 59 min: 99.98 max: 100.49 Ku: 299.23 Tu: 16.55

Classic PID

Kp: 179.54 Ki: 21.70 Kd: 371.38

bias: 182 d: 72 min: 99.97 max: 100.54 Ku: 322.74 Tu: 13.11

Classic PID

Kp: 193.64 Ki: 29.55 Kd: 317.26

bias: 179 d: 75 min: 99.94 max: 100.45 Ku: 373.44 Tu: 10.65

Classic PID

Kp: 224.06 Ki: 42.08 Kd: 298.26

bias: 178 d: 76 min: 99.87 max: 100.34 Ku: 417.22 Tu: 10.32

Classic PID

Kp: 250.33 Ki: 48.50 Kd: 322.99

bias: 178 d: 76 min: 99.81 max: 100.35 Ku: 364.32 Tu: 10.16

Classic PID

Kp: 218.59 Ki: 43.04 Kd: 277.56

PID Autotune finished! Put the last Kp, Ki and Kd constants from below into Configuration.h

define DEFAULT_bedKp 218.59

define DEFAULT_bedKi 43.04

define DEFAULT_bedKd 277.56

find these lines and correct the values

#define DEFAULT_bedKp 218.59

#define DEFAULT_bedKi 43.04

#define DEFAULT_bedKd 277.56

ok done

now send: M303 E0 S255 C8

it will now do the same with the nozzle, but a bit higher temp

can I go up to 255? I do not have an allmetal hotend

ohhh

240 then as the max

ok :D

so

M303 E0 S240 C8

yes

its at 100 Degrees and the Extruder fan didnt start already

normal?

nope.... extruder fan should be on automatic

you have 2 fans on extruder right? one to cool plastic and one to cool hotned?

I switched the Printer of it was at 258 degrees

nope.... extruder fan should be on automaticyou have 2 fans on extruder right? one to cool plastic and one to cool hotned?

Yes

good... not sure why it should not go to 258

will need to check config_adv

define E0_AUTO_FAN_PIN 44

same as in old firmware

will check more

try and send M42 P44 S255 and see if fan moves

might just turn a few times

not moving:

SENDING:M42 P44 S255

Error:Protected Pin

[ERROR] Error:Protected Pin

no and i see why... in pins file

define TRIGORILLA_FAN2_PIN 44 // Anycubic Kossel: Hotend fan

need to think

in configuration_adv.h

change

define E0_AUTO_FAN_PIN 44

to

define E0_AUTO_FAN_PIN TRIGORILLA_FAN2_PIN

upload

M502

M500

try and set nozzle to 55 degree

the nozzle is still at 60 Degree but fan doesnt start

oki set nozzle to 0

send M106... does the plastic cooling fan turn on?

ok

yes it does turn on

send M107 and it turns off

yes

send M106 P1 any fans turning on?

no

try M106 P2

still no fans turning on?

no

wait i ll test the fan with my powersupply

oki, maybe its an issue with marlin,

but at least we have made big progress

thick we should close this one and this one: https://github.com/MarlinFirmware/Marlin/issues/12970

and then create a new issue called: E0_AUTO_FAN_PIN does not come on at 50C

and start posting your 2 config files as zip... remember to use the right files :-D

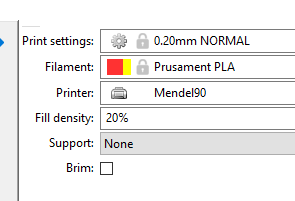

it think the fan is dead but i have another fan wait a sec

where is the heatsink fan connected?

in configuration_adv.h

there are 2 optioons for

define E0_AUTO_FAN_PIN

option 1): #define E0_AUTO_FAN_PIN TRIGORILLA_FAN2_PIN

option 2): #define E0_AUTO_FAN_PIN TRIGORILLA_FAN1_PIN

i got a hint from pins file

define TRIGORILLA_FAN1_PIN 7 // Anycubic Kossel: Unused

define TRIGORILLA_FAN2_PIN 44 // Anycubic Kossel: Hotend fan

the fan is connected to the fan 2 header

then option 1 is the correct one just like i thought first time

another way you could test was connecting plastic cooling fan to fan2 and set temp to 50 and see if plastic cooling fan comes on

think we should close this one and this one: #12970

and then create a new issue called: E0_AUTO_FAN_PIN does not come on at 50C

and start posting your 2 config files as zip... remember to use the right files :-D

its working --> the fan was dead

:-)

need to write an sms then i'm back

ok whats next?

let try tune on extruder again

M303 E0 S240 C8

fan should now come on when temp gets to 50

be right back, need to start a print

ok fan is on autotune started

it went up to 252 Degrees then down again. i didnt stop it this time

nope... it will go a little over and under

its trying to find out how much power it needs to get to 240

so a little over the first time is normal

change these in firmware configuration.h

#define DEFAULT_Kp 17.80

#define DEFAULT_Ki 0.84

#define DEFAULT_Kd 64.84

upload

M502

M500

will look in config if there is more needed before test print

done the values are in config.h whats next

have you uploaded also?

its uploading right now. This takes Always a gooood time :)

ok done

remember M02 and M500 after upload

but next we should check that printer moves correct mm when we tell it to

ok

so send G28

then send G0 X0, it should move 10mm away from endstop

it moves the x axis to the and stop and stops there so it doesnt run further

end stop* :D

hmm... Send G28 then M114

X:30.00 Y:100.00 Z:10.40 E:0.00 Count X:2400 Y:8000 Z:4160

oki, send G0 X20, X should only move 10mm toward endstop

yes it does

send G0 Y90

should also move 10mm toward endstop

yes it does

send G0 Z20.40 and z should move 10mm up

what color filament do you have in printer?

with G0 Z20.40 it does move up but it makes a wierd sound

White PLa

you have something black pen you can make a saml line on filament?

nevermind the sound

do you wanna calibrate the Extruder steps?

yep

make a mark 100mm away from extruder and next we heat up and ask it to extrude 50mm

but that link explains it very good

ok i marked 10 cm

I heated up to 210 degrees

now heat up and extrude 50mm

whats the extrude command again?

send M114 first... i need to know where extruder think it is

X:20.00 Y:90.00 Z:20.40 E:0.00 Count X:1600 Y:7200 Z:8160

G0 E50 F100

should move it slowly

and there should be 5cm left to mark on filament

Yes 5cm

turn heater off again

ok

now we need to do a test print to see if it start with correct first layer

ok cura or sli3r

slic3r but lost link to thiniverse

I got the first layer test.stl already

start gcode the same?

G28 Y; Home Y

G28 X; Home X

G0 X0; Go to center

G0 Y0; Go to center

G28 Z; Home Z

G29

M140 S[first_layer_bed_temperature] ; set bed temp

M190 S[first_layer_bed_temperature] ; wait for bed temp

G92 E0 ; zero the extruded length

G1 X-50 Y-97 F3000 ; go to the middle of the front

G1 Z0.1 ; close to the bed

M104 S[first_layer_temperature] ; set extruder temp

M109 S[first_layer_temperature] ; wait for extruder temp

G1 X0 E10 F200 ; make a thick line to prime extruder

G92 E0 ; zero the extruded length

G1 Z0.3 ; lift Z

G4 S2 ;wait 2 sec to bleed off excess pressure

no

G28 Y; Home Y

G28 X; Home X

G0 X105; Go to center

G0 Y105; Go to center

G28 Z; Home Z

G29

M140 S[first_layer_bed_temperature] ; set bed temp

M190 S[first_layer_bed_temperature] ; wait for bed temp

G92 E0 ; zero the extruded length

G1 X50 Y0 F3000 ; go to the middle of the front

G1 Z0.1 ; close to the bed

M104 S[first_layer_temperature] ; set extruder temp

M109 S[first_layer_temperature] ; wait for extruder temp

G1 X100 E10 F200 ; make a thick line to prime extruder

G92 E0 ; zero the extruded length

G1 Z0.3 ; lift Z

G4 S2 ;wait 2 sec to bleed off excess pressure

and bed like this?

bed like that yes

ok

i call my printer mendel90

yours should be mk2.5

its mk2

oki... does not make big difference

think we are good to try now

testsl3errerrerer.zip

here is the gcode: I try it now

hope it works

it should start with homing X and Y

then move to center and home Z

then it should do probe

then it will heat bed

then it will go to corner and heat up nozzle

then it will make a thick line close to the edge of bed to prime extruder, and then it will start print

its homing y and x and now its moving x and y realy slowly to the mid

Why is this so slow??

Now it homed z and it is probing the bed

we might need to change start code later if print works

did you see my list of what it should do?

yes it is now heating the nozzle but bltouch is blinking red like now after finishing probing

is pin up?

i dont use bl touch so not sure why its blinking

blinking means error I stopped the print and tried it again lets see

oki.... check that it does hit the bed every time and not out in the air next to bed

but i'm not sure why there should be an error, we need expert help on that

it Looks good but the nozzle is to close to the bed

there is no error any more

oki :-D

I stopped the print because the nozzle was Scratching the bad

bed*

but besides that it looked good

oki.... change #define Z_PROBE_OFFSET_FROM_EXTRUDER -0.4

to

define Z_PROBE_OFFSET_FROM_EXTRUDER 0

then upload

M502

M500

it should now be 0.4mm more up in the air

and yes it might move slow in start code but we can fix that

By now, I think many people are monitoring this thread to see if and when you reach 1000 posts. I am impressed by the dedication to helping. Kudos for @boelle.

but we can fix that

Yes :D

i think the biggest mistake is that the board in the printer was not there and we used the wrong one

ok uploaded it now its probing but now its not moving that slow

oki...

lets hope the print goes ok

no it is now even harder hitting the bed

define Z_PROBE_OFFSET_FROM_EXTRUDER -0.8

is that better?

i always get confused on how to set this number

its better but not enough i guess I ll try -1.2

yep... change it in small steps

you were right :D

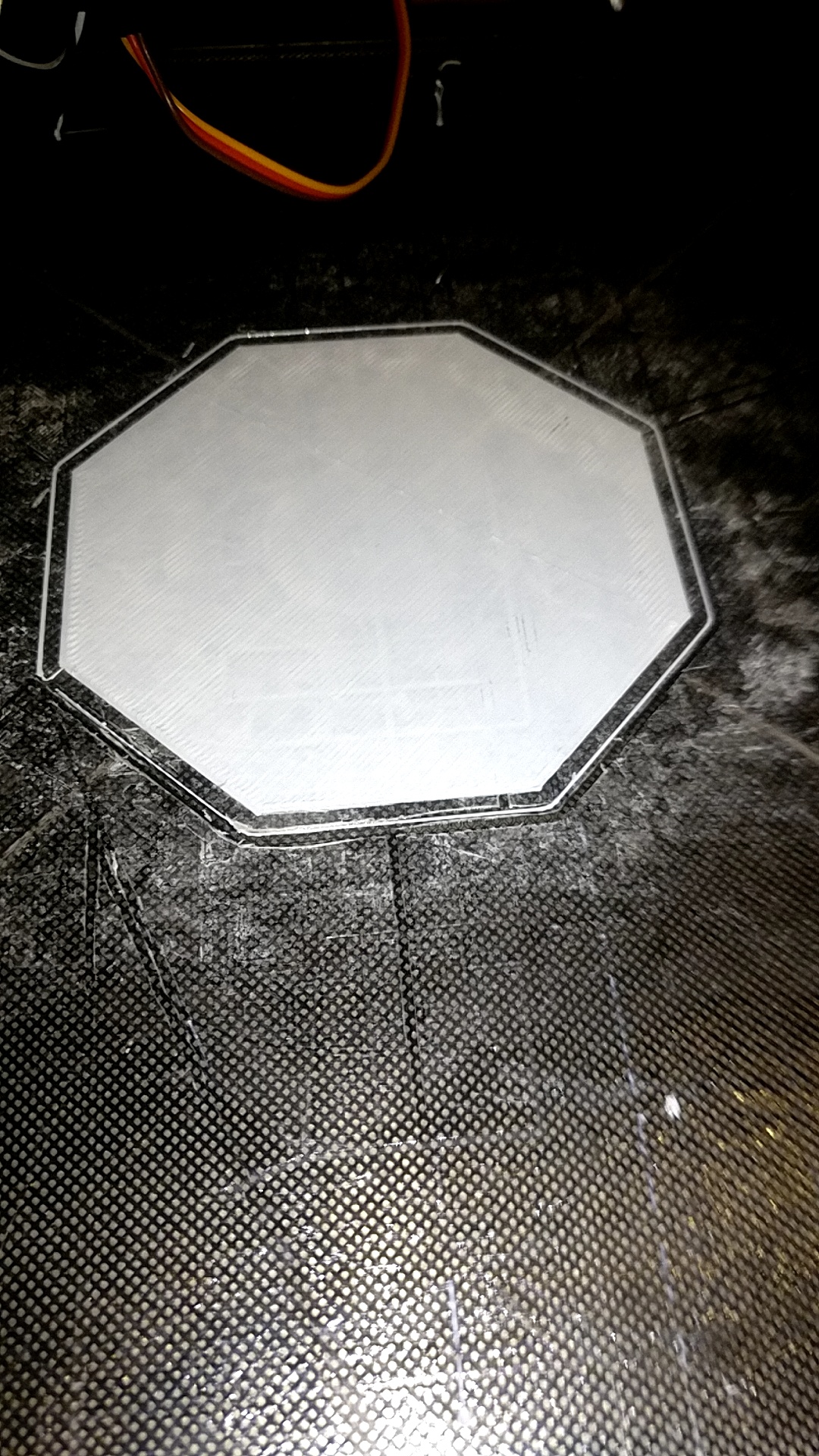

its working for Offset 2 now

let see a picture of test print :-D

Picture is coming wait

by the way... are there a fan to blow air on controller board?

Yes There is a fan at the board

Thank you soooooooo much for your Help.

If I got any qustions I now finally know sombody I can talk to. :D

try #define Z_PROBE_OFFSET_FROM_EXTRUDER -1.9

but otherwise it looks very good

i have a meeting tomorrow so we cant do any more testing today, but i think you have a working setup

goal with first layer is to get it smooth on both sides of the print

I ll try further tomorrow :D

you can even go with 2 decimal so -1.95

i will be here tomorrow afternoon

https://mattshub.com/2017/04/19/extruder-calibration/

go down to where you see the empty box

Calibrating extrusion multiplier

do you have calipers to messure precise?

I wanted to do this a while ago but I do Not have a digital caliper

:-( but yes... at least you are now good to go :-D

remember to close this issue and the other you opened before

you can still write to me via this issue even if closed

i will try and add your config to marlin now

configuration.h: https://github.com/MarlinFirmware/Marlin/pull/12972/commits/17ffbfd45902dc8516018801c80e13b474cbc4ad

configuration_adv.h: https://github.com/MarlinFirmware/Marlin/pull/12972/commits/d9610e456d97be5ccfa8f50aab5b161f4e65cc33

they do look correct yes?

Yes i think so. How can I Close this issue?

Look at bottom of page :)

man. 21. jan. 2019 07.04 skrev mpm1396 notifications@github.com:

Yes i think so. How can I Close this issue?

—

You are receiving this because you were mentioned.

Reply to this email directly, view it on GitHub

https://github.com/MarlinFirmware/Marlin/issues/12948#issuecomment-455957980,

or mute the thread

https://github.com/notifications/unsubscribe-auth/ADp5ryEC6O6MVA663TDJiQy_yhtRnvn4ks5vFVhigaJpZM4aIkpm

.

Ohh :D

So Ive noticied somthing, I am not sure if this is normal. I disconnected one threaded Z rod from the z motor (1) and I moved the other motor (2), the first motor (1) moves the same even if the printer is turned off

yep.... that is normal

2 motors connected in parallel, if you move one motor fast enough the other will move too

you forgot to close the other issue: https://github.com/MarlinFirmware/Marlin/issues/12970

ok btw. my first print failed, dont know why, the nozzle mooved in the object. I didnt watched it. Second print turned out beautiful.

if I want to adjust the z motor current wich driver poti do I have to turn?

if I only touch the z rods while moving them up it looses stepps ---> cureent is to low?

ok I turned all poti s a bit and it seems better now

This issue has been automatically locked since there has not been any recent activity after it was closed. Please open a new issue for related bugs.