Cura: [4.4.1] Purge tower coordinates don't take into account hotend offset

Application version

4.4.1

Platform

Win10 x64

Printer

Custom dual extrusion

Reproduction steps

- Second hotend +20mm offset

- Enable purge tower

- Try to slice

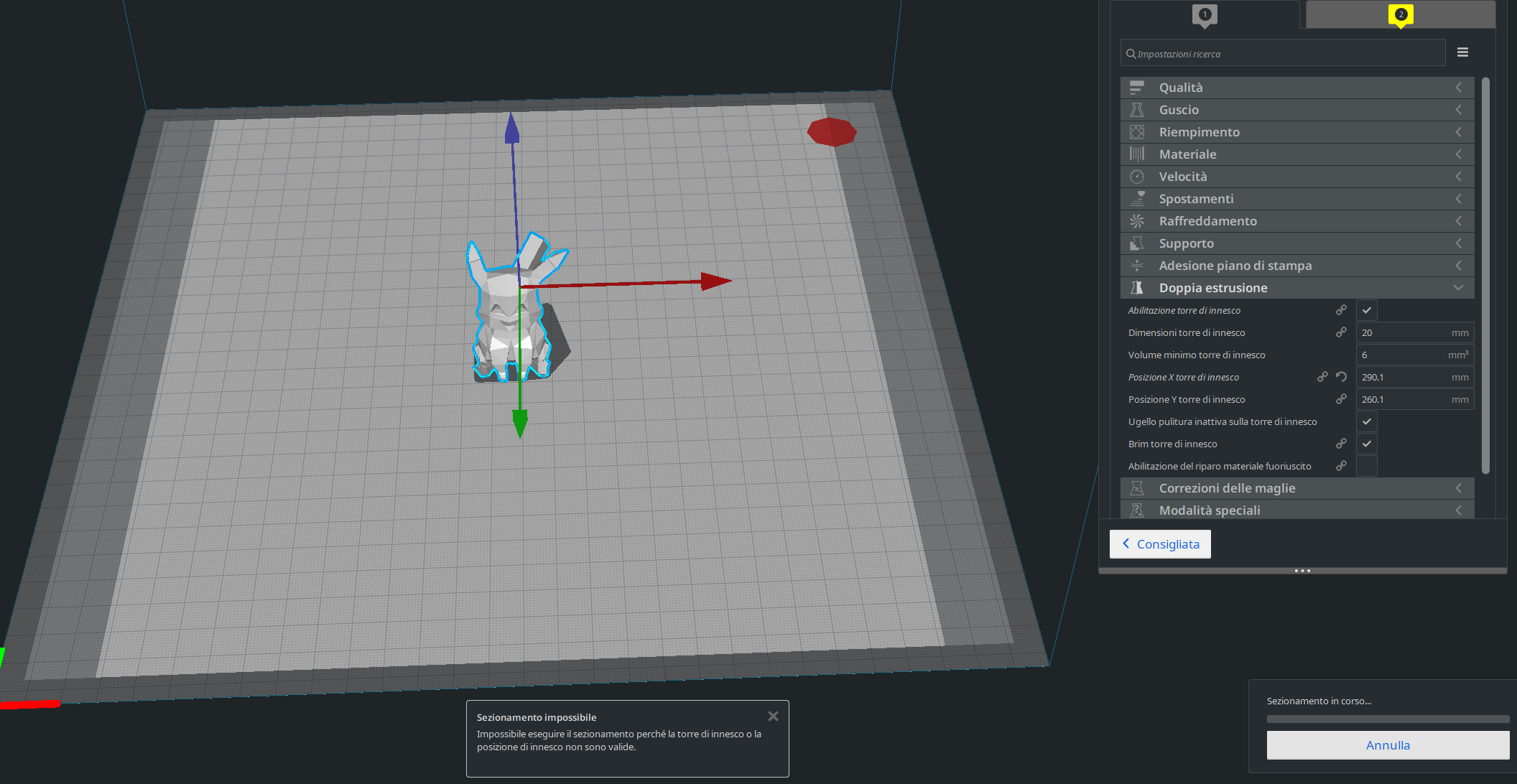

Screenshot(s)

Actual results

The purge tower is calculated on a place that the primary hotend (on the left) can't reach (right side)

Expected results

The tower should be on a printable area

All 7 comments

By the look of it you have altered the default X value, as the circular indicates there's a difference from the default profile value.

As a workaround to get you printing, you can edit the position of the prime tower by inputting custom X and Y positions. It looks as if you need to subtract 20mm or so from the default value of your Prime tower X position (i.e. change 290.1 to 270 so that the prime tower is within the printable area). But perhaps you knew that already. Regardless, it shoudn't be placing prime towers in the non-printable area by default. As stated in the issue template, can you please upload a zipped 3mf of your project and log files too, then I can try to reproduce your issue to see if it is a bug. If so, we can devote some time to it.

The circular arrow meant that I was using the preset automatically calculated default which is wrong instead of a fixed custom value I did subtract by 20 in the profile.

purge tower outside.zip

Ah I see. I've reproduced the error successfully, so will investigate further.

Fixed it. It was indeed not taking the nozzle offsets into account for the default value in fdmprinter. We didn't notice this because we override the prime tower position for our printers anyway, due to the bed clips that Ultimaker printers have in that corner.

Just to be sure since I have no idea how the software works, but I did read in the change done the line

max(map(abs, extruderValues('machine_nozzle_offset_x'))

and I am unsure what the abs function/variable does, so as I did put a project that was using an ABS material I got to think about it.

This fix will work on all materials, right?

Thank you.

abs() in most programming languages is a function to calculate the "absolute value" of what you pass to it; abs(-10) = 10, abs(4) = 4. In other words, it remove the minus sign from the value if there is one.

To set your mind at ease: it has nothing to do with the material named Acrylonitrile Butadiene Styrene here.

I documented the steps in that function in the commit message, since it's not immediately apparent even to a programmer. Basically this abs() function is called on all of the extruder values for the X offset, so they are all positive then. And then it takes the highest of them.