Cura: XY Gradient infill as demonstrated by CNC Kitchen

As demonstrated by CNC Kitchen in this video, gradient infill on the XY would be a very nice (and probably easy) feature to add to Cura.

https://www.youtube.com/watch?v=hq53gsYREHU

He provided open source python script here:

https://github.com/CNCKitchen/GradientInfill

This would make cura the only slicer to support it built-in without having to hack anything.

A combo of XY and Z gradient infill would be even better!

All 9 comments

The concept is brilliantly simple.

Btw, it has already been implemented in PrusaSlicer as an experimental build.

Since it relies on adjusting the speed of the extruder, it may perhaps not work as well with Bowden extruders. I wonder if it would be feasible to manipulate the XY speed instead of the extruder speed?

I think it would be best to have it implemented as a full infill pattern otherwise it might messup Linear Advance (marlin) or Pressure Advance (klipper)

This also caught our attention this weekend. His script adjusts extrusion rather than speed, so is optimized for direct drive machines. Bowden machines running Marlin will operate a little differently and need more tuning. We will continue to investigate...

That method might not work on more complicated infills like gyroid, which probably requires the whole geometry to be re-generated with smoothly varied densities. Would be incredible, though!

Yes, this could be very useful, and of course will probably work only with selected infill type.

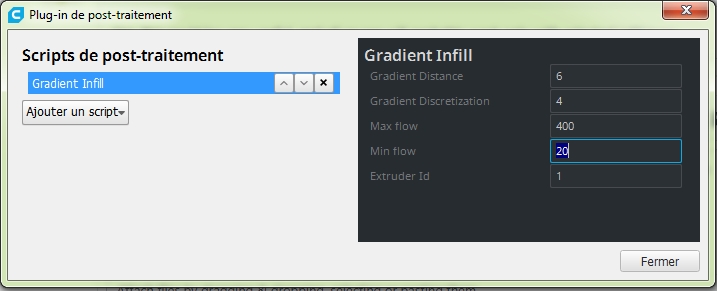

For testing purpose I've converted CNC Kitchen Python script into a Cura Postprocessing plug in Script.

Unfortunalty as mentionned by @mahtDFR ( and also in the CNC Kitchen publication ) This solution seems to be not very efficient on a Bowden machines running under Marlin. If someone wants to make more tests on a different machine : https://github.com/5axes/GradientInfill/blob/master/GradientInfill.py

The suggestion would be more of having this infill pattern as another type of infill without playing with the extrusion.

Bowden machines running Marlin will operate a little differently and need more tuning. We will continue to investigate...

Using the gradient Infill on a machine whitout a direct drive must definetly manage a speed variation to get a correct result.

* Sample test print with a Gradiant distance of 8 mm and a infill percentage of 45% *

It would also be different between Marlin's Linear Advance users and not I guess, that has to be considered as there is a Cura LA extension.

Also LA can be used on both bowden and Direct drive.

Most helpful comment

For testing purpose I've converted CNC Kitchen Python script into a Cura Postprocessing plug in Script.

Unfortunalty as mentionned by @mahtDFR ( and also in the CNC Kitchen publication ) This solution seems to be not very efficient on a Bowden machines running under Marlin. If someone wants to make more tests on a different machine : https://github.com/5axes/GradientInfill/blob/master/GradientInfill.py