Slic3r: Model looks normal in 3D view on Plater, but misses some after slicing

Version

add2895f38df40f79ff06552a179a3a88f3bf5e7

Operating system type + version

Arch Linux 4.13.11-1-ARCH

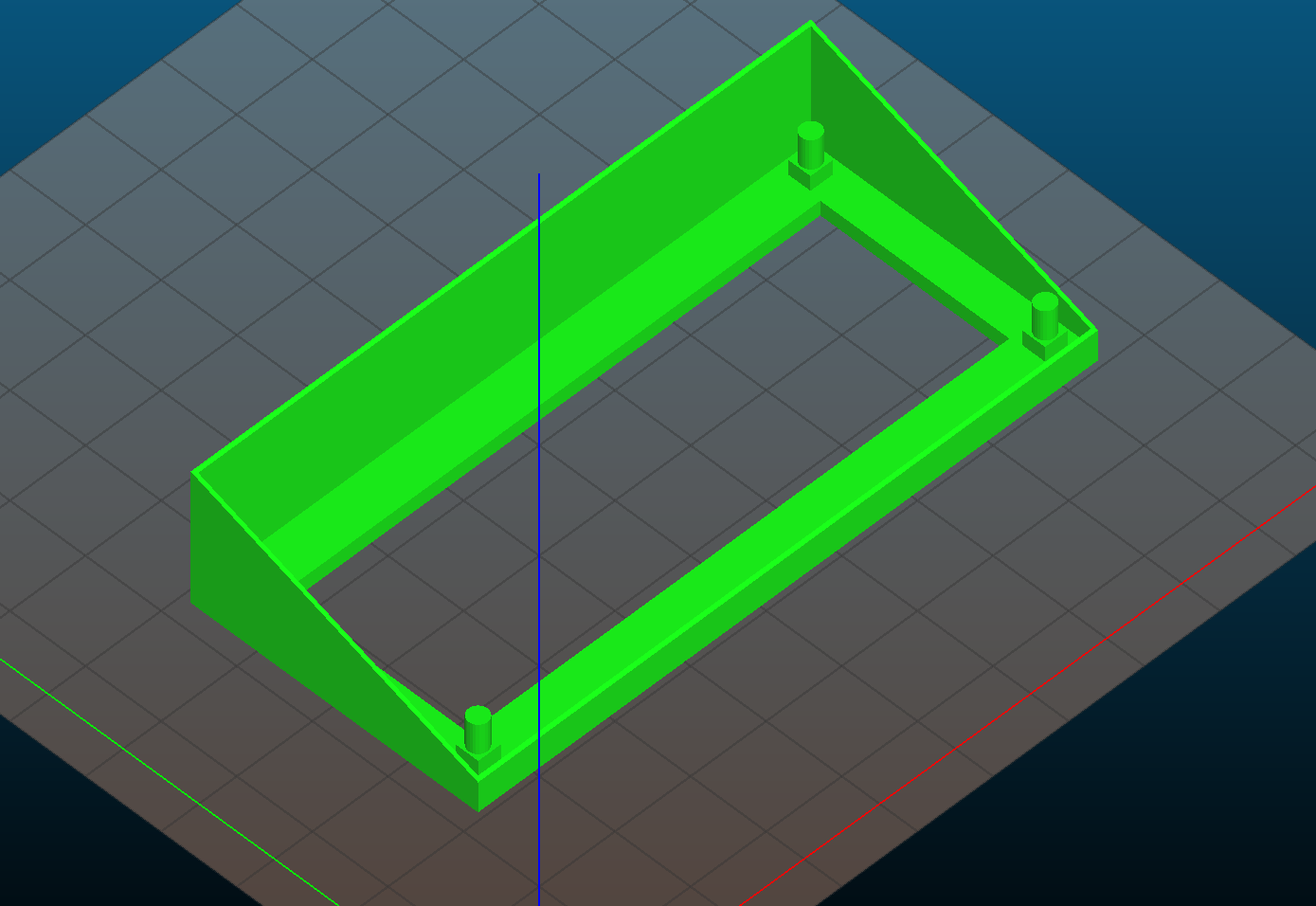

Behavior

The model is sliced incorrectly,

The source file:

print.obj.gz

All 10 comments

Would be nice to have the Ctrl-E config export.

Works after a pass through Netfabb's online service. I wonder what it did that caused it to render properly.

The config file.

Also I tried the same model in Cura 3.0.3 - it was able to slice it just fine, if that helps.

# generated by Slic3r 1.3.0-dev on 2017-11-04 13:47:07

adaptive_slicing = 0

adaptive_slicing_quality = 75%

avoid_crossing_perimeters = 0

bed_shape = -5x-5,115x-5,115x115,-5x115

bed_temperature = 30

before_layer_gcode =

between_objects_gcode =

bottom_infill_pattern = rectilinear

bottom_solid_layers = 4

bridge_acceleration = 0

bridge_fan_speed = 100

bridge_flow_ratio = 1

bridge_speed = 10

brim_connections_width = 0

brim_width = 0

compatible_printers =

complete_objects = 0

cooling = 0

default_acceleration = 0

disable_fan_first_layers = 1

dont_support_bridges = 1

duplicate_distance = 6

end_filament_gcode = "; Filament-specific end gcode \n;END gcode for filament\n"

end_gcode = M104 S0 ; turn off hotend/extruder heater\nM140 S0 ; turn off bed heater\nG91 ; Switch to use Relative Coordinates\nG1 E-2 F300 ; retract the filament a bit before lifting the nozzle to release some of the pressure\nG1 Z1 ; raise Z 1mm from current position\nG1 E-2 F300 ; retract filament even more\nG90 ; Switch back to using Absolute Coordinates\nG1 X20 ; move X axis close to tower but hopefully far enough to keep the fan from rattling\nG1 Y120 ; move bed forward for easier part removal\nM84 ; disable motors\nM107 ; turn off fan. Some say M107 doesn't work for them but if the hotend is cool enough it should work

external_perimeter_extrusion_width = 0.4

external_perimeter_speed = 15

external_perimeters_first = 1

extra_perimeters = 1

extruder_clearance_height = 20

extruder_clearance_radius = 20

extruder_offset = 0x0

extrusion_axis = E

extrusion_multiplier = 1

extrusion_width = 0.4

fan_always_on = 1

fan_below_layer_time = 60

filament_colour = #000000

filament_cost = 17

filament_density = 0

filament_diameter = 1.75

filament_max_volumetric_speed = 0

filament_notes = ""

filament_settings_id =

fill_angle = 45

fill_density = 0%

fill_gaps = 1

fill_pattern = rectilinear

first_layer_acceleration = 0

first_layer_bed_temperature = 40

first_layer_extrusion_width = 0.42

first_layer_height = 0.2625

first_layer_speed = 20

first_layer_temperature = 200

gap_fill_speed = 20

gcode_arcs = 0

gcode_comments = 1

gcode_flavor = reprap

has_heatbed = 1

host_type = octoprint

infill_acceleration = 0

infill_every_layers = 1

infill_extruder = 1

infill_extrusion_width = 0.4

infill_first = 0

infill_only_where_needed = 0

infill_overlap = 25%

infill_speed = 20

interface_shells = 0

interior_brim_width = 0

layer_gcode =

layer_height = 0.0875

match_horizontal_surfaces = 0

max_fan_speed = 99

max_layer_height = 0.30625

max_print_speed = 30

max_volumetric_speed = 0

min_fan_speed = 100

min_layer_height = 0.0875

min_print_speed = 10

min_skirt_length = 0

notes =

nozzle_diameter = 0.4

only_retract_when_crossing_perimeters = 0

ooze_prevention = 0

output_filename_format = [input_filename_base].gcode

overhangs = 1

perimeter_acceleration = 0

perimeter_extruder = 1

perimeter_extrusion_width = 0.4

perimeter_speed = 20

perimeters = 2

post_process =

pressure_advance = 0

print_host = 10.0.0.28:5000

print_settings_id =

printer_notes =

printer_settings_id =

raft_layers = 0

regions_overlap = 0

resolution = 0

retract_before_travel = 2

retract_layer_change = 0

retract_length = 5

retract_length_toolchange = 10

retract_lift = 0

retract_lift_above = 0

retract_lift_below = 0

retract_restart_extra = 0

retract_restart_extra_toolchange = 0

retract_speed = 40

seam_position = aligned

sequential_print_priority = 0

serial_port =

serial_speed = 250000

shortcuts = support_material

skirt_distance = 5

skirt_height = 1

skirts = 1

slowdown_below_layer_time = 10

small_perimeter_speed = 15

solid_infill_below_area = 70

solid_infill_every_layers = 0

solid_infill_extruder = 1

solid_infill_extrusion_width = 0.4

solid_infill_speed = 15

spiral_vase = 0

standby_temperature_delta = -5

start_filament_gcode = "; Filament gcode\n"

start_gcode = M109 S[first_layer_temperature]\nG21 ;metric values\nG90 ; absolute positioning - this line was added in case Cura doesn't include it by default\nM82 ; \nG28 ; home all axes\nG92 E0 ; reset extrusion distance\nG1 Z5 F1200 ; raise nozzle 5mm\nG1 E12; Purge 12mm of filament \nG92 E0; reset extrusion distance

support_material = 0

support_material_angle = 0

support_material_buildplate_only = 0

support_material_contact_distance = 0.2

support_material_enforce_layers = 0

support_material_extruder = 1

support_material_extrusion_width = 0.4

support_material_interface_extruder = 1

support_material_interface_extrusion_width = 0

support_material_interface_layers = 3

support_material_interface_spacing = 0

support_material_interface_speed = 100%

support_material_pattern = pillars

support_material_spacing = 2.5

support_material_speed = 25

support_material_threshold = 60

temperature = 210

thin_walls = 1

threads = 8

toolchange_gcode =

top_infill_extrusion_width = 0.4

top_infill_pattern = rectilinear

top_solid_infill_speed = 15

top_solid_layers = 4

travel_speed = 110

use_firmware_retraction = 0

use_relative_e_distances = 0

use_volumetric_e = 0

vibration_limit = 0

wipe = 1

xy_size_compensation = 0

z_offset = 0

z_steps_per_mm = 0

Cura tries to do more with file repair than Slic3r does, so that doesn't

mean much.

As I noted, Slic3r does just fine after the model gets a pass through

netfabb. I will have to try to compare what Slic3r thinks the model looks

like with both versions. The fixed version is also larger iirc.

Currently I am leaning towards GIGO, but the input code needs to be looked

at to make sure there isn't a bug in it.

On Nov 4, 2017 8:49 AM, "Eugene Dzhurinsky" notifications@github.com

wrote:

The config file example.

Also I tried the same model in Cura 3.0.3 - it was able to slice it just

fine, if that helps.generated by Slic3r 1.3.0-dev on 2017-11-04 13:47:07

adaptive_slicing = 0

adaptive_slicing_quality = 75%

avoid_crossing_perimeters = 0

bed_shape = -5x-5,115x-5,115x115,-5x115

bed_temperature = 30

before_layer_gcode =

between_objects_gcode =

bottom_infill_pattern = rectilinear

bottom_solid_layers = 4

bridge_acceleration = 0

bridge_fan_speed = 100

bridge_flow_ratio = 1

bridge_speed = 10

brim_connections_width = 0

brim_width = 0

compatible_printers =

complete_objects = 0

cooling = 0

default_acceleration = 0

disable_fan_first_layers = 1

dont_support_bridges = 1

duplicate_distance = 6

end_filament_gcode = "; Filament-specific end gcode \n;END gcode for filament\n"

end_gcode = M104 S0 ; turn off hotend/extruder heater\nM140 S0 ; turn off bed heater\nG91 ; Switch to use Relative Coordinates\nG1 E-2 F300 ; retract the filament a bit before lifting the nozzle to release some of the pressure\nG1 Z1 ; raise Z 1mm from current position\nG1 E-2 F300 ; retract filament even more\nG90 ; Switch back to using Absolute Coordinates\nG1 X20 ; move X axis close to tower but hopefully far enough to keep the fan from rattling\nG1 Y120 ; move bed forward for easier part removal\nM84 ; disable motors\nM107 ; turn off fan. Some say M107 doesn't work for them but if the hotend is cool enough it should work

external_perimeter_extrusion_width = 0.4

external_perimeter_speed = 15

external_perimeters_first = 1

extra_perimeters = 1

extruder_clearance_height = 20

extruder_clearance_radius = 20

extruder_offset = 0x0

extrusion_axis = E

extrusion_multiplier = 1

extrusion_width = 0.4

fan_always_on = 1

fan_below_layer_time = 60

filament_colour = #000000

filament_cost = 17

filament_density = 0

filament_diameter = 1.75

filament_max_volumetric_speed = 0

filament_notes = ""

filament_settings_id =

fill_angle = 45

fill_density = 0%

fill_gaps = 1

fill_pattern = rectilinear

first_layer_acceleration = 0

first_layer_bed_temperature = 40

first_layer_extrusion_width = 0.42

first_layer_height = 0.2625

first_layer_speed = 20

first_layer_temperature = 200

gap_fill_speed = 20

gcode_arcs = 0

gcode_comments = 1

gcode_flavor = reprap

has_heatbed = 1

host_type = octoprint

infill_acceleration = 0

infill_every_layers = 1

infill_extruder = 1

infill_extrusion_width = 0.4

infill_first = 0

infill_only_where_needed = 0

infill_overlap = 25%

infill_speed = 20

interface_shells = 0

interior_brim_width = 0

layer_gcode =

layer_height = 0.0875

match_horizontal_surfaces = 0

max_fan_speed = 99

max_layer_height = 0.30625

max_print_speed = 30

max_volumetric_speed = 0

min_fan_speed = 100

min_layer_height = 0.0875

min_print_speed = 10

min_skirt_length = 0

notes =

nozzle_diameter = 0.4

only_retract_when_crossing_perimeters = 0

ooze_prevention = 0

output_filename_format = [input_filename_base].gcode

overhangs = 1

perimeter_acceleration = 0

perimeter_extruder = 1

perimeter_extrusion_width = 0.4

perimeter_speed = 20

perimeters = 2

post_process =

pressure_advance = 0

print_host = 10.0.0.28:5000

print_settings_id =

printer_notes =

printer_settings_id =

raft_layers = 0

regions_overlap = 0

resolution = 0

retract_before_travel = 2

retract_layer_change = 0

retract_length = 5

retract_length_toolchange = 10

retract_lift = 0

retract_lift_above = 0

retract_lift_below = 0

retract_restart_extra = 0

retract_restart_extra_toolchange = 0

retract_speed = 40

seam_position = aligned

sequential_print_priority = 0

serial_port =

serial_speed = 250000

shortcuts = support_material

skirt_distance = 5

skirt_height = 1

skirts = 1

slowdown_below_layer_time = 10

small_perimeter_speed = 15

solid_infill_below_area = 70

solid_infill_every_layers = 0

solid_infill_extruder = 1

solid_infill_extrusion_width = 0.4

solid_infill_speed = 15

spiral_vase = 0

standby_temperature_delta = -5

start_filament_gcode = "; Filament gcode\n"

start_gcode = M109 S[first_layer_temperature]\nG21 ;metric values\nG90 ; absolute positioning - this line was added in case Cura doesn't include it by default\nM82 ; \nG28 ; home all axes\nG92 E0 ; reset extrusion distance\nG1 Z5 F1200 ; raise nozzle 5mm\nG1 E12; Purge 12mm of filament \nG92 E0; reset extrusion distance

support_material = 0

support_material_angle = 0

support_material_buildplate_only = 0

support_material_contact_distance = 0.2

support_material_enforce_layers = 0

support_material_extruder = 1

support_material_extrusion_width = 0.4

support_material_interface_extruder = 1

support_material_interface_extrusion_width = 0

support_material_interface_layers = 3

support_material_interface_spacing = 0

support_material_interface_speed = 100%

support_material_pattern = pillars

support_material_spacing = 2.5

support_material_speed = 25

support_material_threshold = 60

temperature = 210

thin_walls = 1

threads = 8

toolchange_gcode =

top_infill_extrusion_width = 0.4

top_infill_pattern = rectilinear

top_solid_infill_speed = 15

top_solid_layers = 4

travel_speed = 110

use_firmware_retraction = 0

use_relative_e_distances = 0

use_volumetric_e = 0

vibration_limit = 0

wipe = 1

xy_size_compensation = 0

z_offset = 0

z_steps_per_mm = 0—

You are receiving this because you commented.

Reply to this email directly, view it on GitHub

https://github.com/alexrj/Slic3r/issues/4182#issuecomment-341898373, or mute

the thread

https://github.com/notifications/unsubscribe-auth/AAB8CsvegL1qcZrB_ix0cinckWDGbysSks5szGtUgaJpZM4QR4jC

.

Self-intersecting faces.

That "missing" area mesh isn't properly connected to the posts. There are 10 shells that are all individually manifold.

Here's a picture after applying split:

Okay, that makes sense, it's the first time I tried to use FreeCAD to model something, and apparently I did something wrong. Thanks for the help1

@lordofhyphens which tool did you use to figure that out?

Meshlab with the face view turned on showed a line going right through one of the pegs.

It also has a "show self-intersecting faces" feature.

In FreeCAD you want to do a boolean union on all of the components and extract the resulting mesh, IIRC.

I regrouped the model a bit, so now it exports just fine. So at least I know - if something doesn't slice from the STL/OBJ exported by FreeCAD, and looks _okay_ after fixing the mesh - it's likely that the model itself is broken.

Thanks a lot again :)

No problem. Happens a lot; solid 3D modeling is surprisingly finicky. One of the reasons that most things out of Sketchup are garbage (and by extension 95% of models on Thingiverse are garbage until proven otherwise ;) )