Marlin: [FR] Dual X Carriage tool settings

Would it be possible to add settings in configuratin_adv in the #define DUAL_X_CARRIAGE section to determine which tool (extruder) is on X1 and X2?

e.g.

#define X1_CARRIAGE_TOOL {T0, T1} // extruder E0 , E1 .....

#define X2_CARRIAGE_TOOL {T2, T3} // extruder E2 , E3 .....

I would like to test a 4-material print.

All 25 comments

This is on the list of things that have been discussed, with 3 tools on each for a max of 6 extruders in the works. We have hardware being worked up to develop with. So yes, but itll be awhile as hardware is still in development to work with. If a manufacturer is willing to contribute some to those of us working on it, it would speed things along greatly. Currently @Roxy-3D and myself are slowly chasing this with others looking at the board in development for other purposes as well.

Hi, I'm not a manufacturer, but I can contribute a little.

I'll be happy if it moves my request forward.

How do I credit?

Right now the primary constraint is the rest of the code for the board. Bootloader and HAL are in progress. Once that's done, we will need to go over mechanical design mounting a diamond hotend to a Trex 2+ carriage (the machine were both starting with) along with figuring out management for all 6 spools.

Hi, which board will you use for testing?

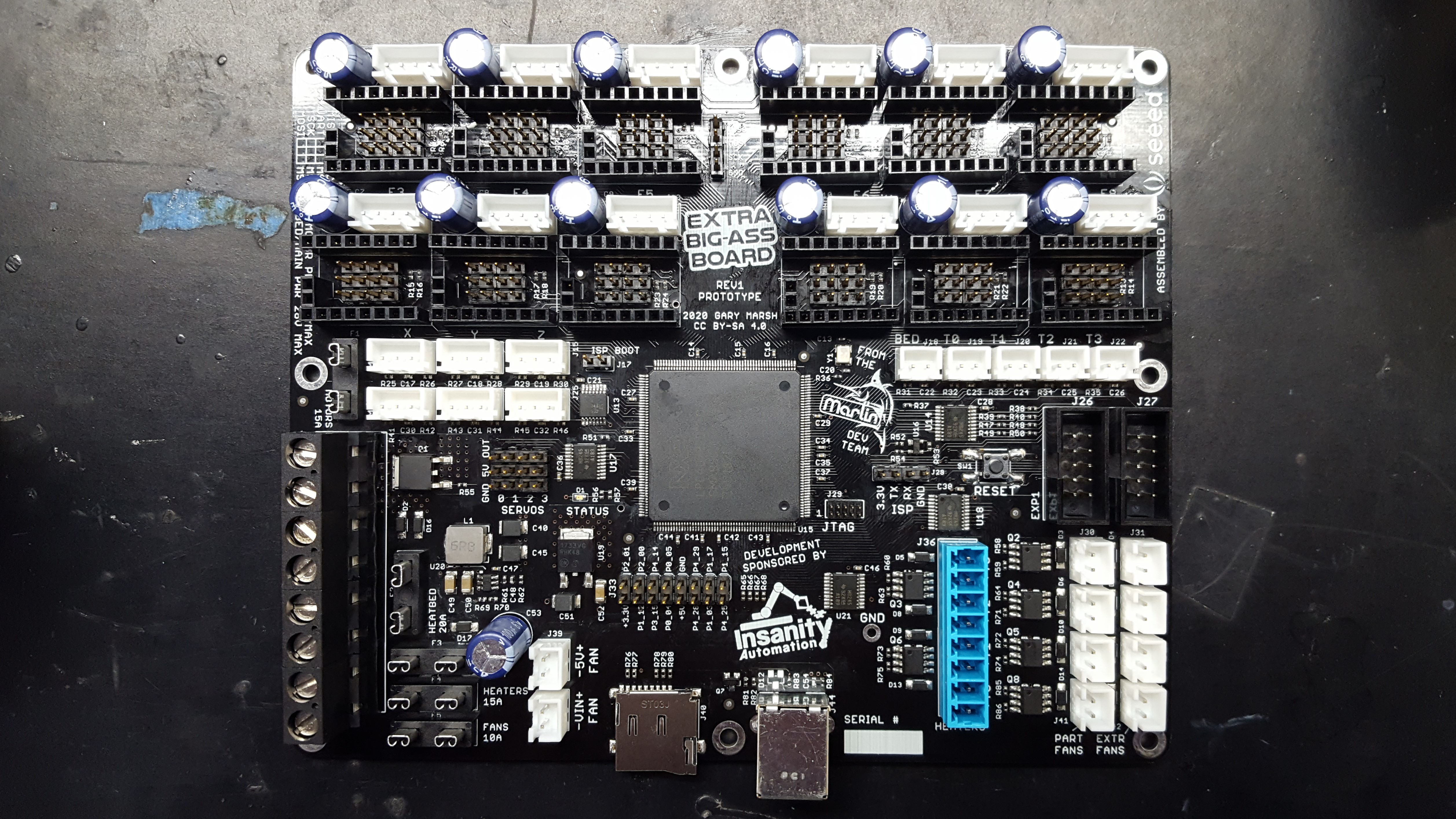

Custom design Gary Marsh did for us. We have 5 prototypes atm with LPC 4078 chips

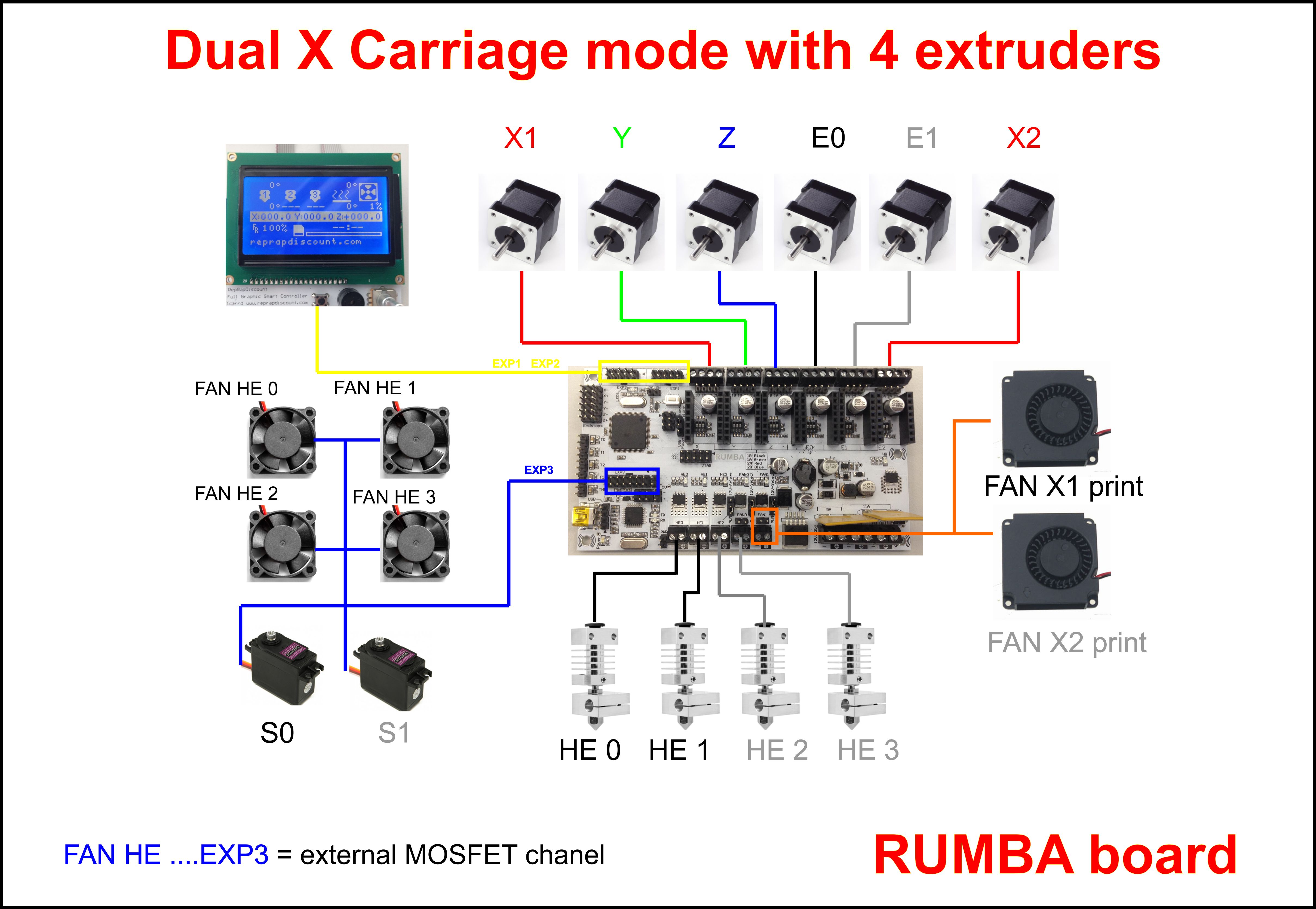

I have a RUMBA board where I use all the HW.

( I am considering using BIGTREETECH GTR V1.0 Control Board 32Bit + M5 V1.0 Expansion board )

I use dual X carriage stepper X1 and X2 and two servos

which I use for switching extruders E0 and E1 including nozzles.

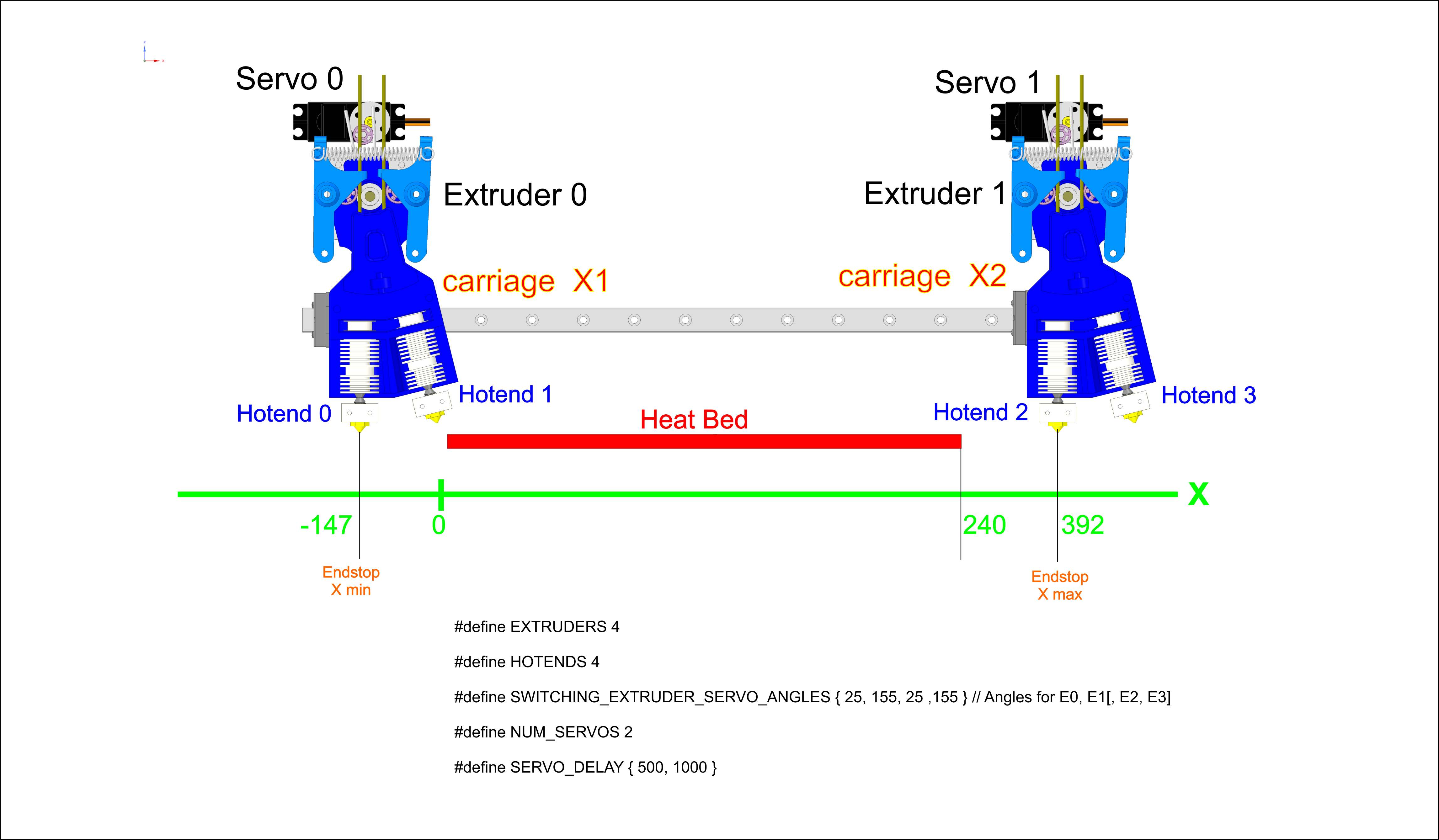

All I need is to assign tools T0 + T1 for carrier X1 and tools T2 + T3 for carrier X2, and unfortunately this is not possible in the current Marlin. If I can, I can start testing the IDEX and HOTEND_OFFSET_X tool settings

What you want to do isn't very much code. But it is complicated enough that I don't want to attempt anything without having a machine to code against and test the changes. The good news is, what you want to do is a subset of what we plan on doing. What you want should fall out naturally. The bad news is, it will probably be 3 or 4 months before we have something you can use.

I've got a GTR10 with expansion here and considered using it, but we all have alot of tasks going and efficiency in them is important! It'll get there, but unless there's financial incentive that portion isn't going to jump the queue.

Unless I am tripping, I think we have some sort of SINGLENOZZLE or Switching Nozzle support for Dual X Carriage at this time, which gets us most of the way, since I assume whatever is feeding each carriage is something like that.

Not currently unfortunately. Toolchange isn't smart enough to split extruders from physical tools yet. It's been discussed a few times so it's something were definitely moving towards.

Hi,

The current Marlin can do the tool T0 to carrier X1 and T1 to X2.

Is it really a problem to insert the condition that T0 or T1 will be on X1 and the tool T2 or T3 will be on carrier X2?

My friend and I could try it out and give feedback.

Hey! Ready for my machine to try this prompt. I was working on it and it's great to come across. I can try the software. His equipment is ready. I use 4 extruders and dualx systems. I tried to activate SINGLENOZZLE but I encountered an error. I want to try it soon. Yours.

Thank you for your comments on the above feature. This closes the query.

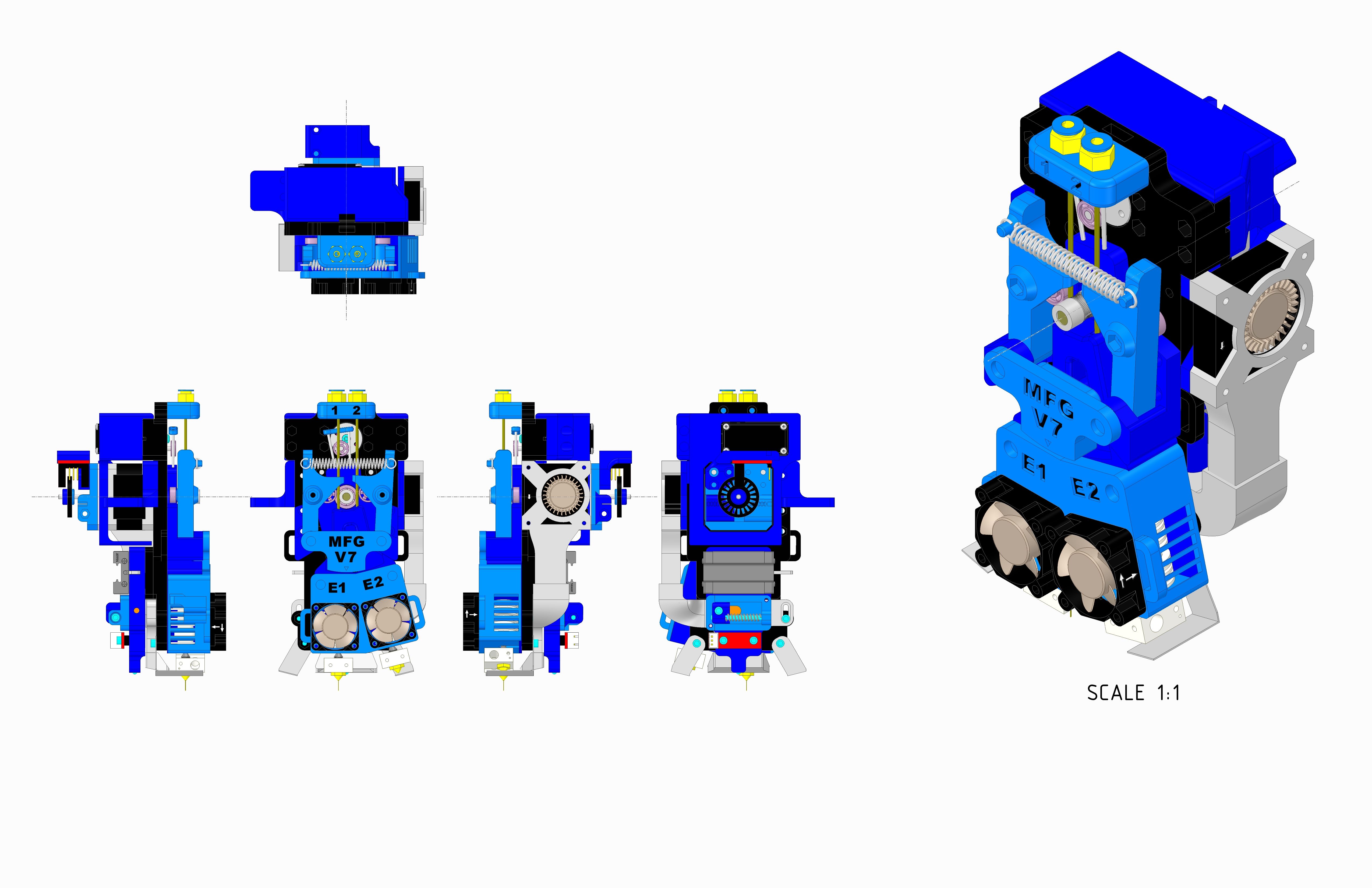

This is project 4 Extruders on IDEX

Edited by Marlin from Stephen's friend.

configuration.zip

To first test, we need to divide the tools into individual carriages

#define X1_CARRIAGE_TOOL {T0, T1} // extruder E0 , E1

#define X2_CARRIAGE_TOOL {T2, T3} // extruder E2 , E3

Demonstration of the V-extruder function.

https://www.youtube.com/watch?v=BOaIMiyzaks

https://www.youtube.com/watch?v=DsCdpfjLS2g

That looks like a DUAL_X_CARRIAGE plus SWITCHING_EXTRUDER plus EXTRUDERS 4 setup. These options are intended to be usable together, but since that capability was first enabled we have not had a lot of testers and coders working on refining it.

Hi, The subroutines were edited by Stephen.

I'm not a programmer.

I just have HW here and I'm testing

Hi this is Stephen. The changes made can probably be made by just comparing the original Marlin files over the ZIP DrumClock provided, however listing below for the sake of time or that somebody can spot something quickly.

SanityCheck.h

/**

* A Dual Nozzle carriage with switching servo

*/

#if ENABLED(SWITCHING_NOZZLE)

//#if ENABLED(DUAL_X_CARRIAGE)

// #error "SWITCHING_NOZZLE and DUAL_X_CARRIAGE are incompatible."

//#elif ENABLED(SINGLENOZZLE)

#if ENABLED(SINGLENOZZLE)

#error "SWITCHING_NOZZLE and SINGLENOZZLE are incompatible."

#elif DISABLED(DUAL_X_CARRIAGE) && EXTRUDERS != 2

#error "SWITCHING_NOZZLE requires exactly 2 EXTRUDERS."

#elif DISABLED(DUAL_X_CARRIAGE) && NUM_SERVOS < 1

#error "SWITCHING_NOZZLE requires NUM_SERVOS >= 1."

#elif ENABLED(DUAL_X_CARRIAGE) && EXTRUDERS != 4

#error "SWITCHING_NOZZLE along with DUAL_X_CARRIAGE requires exactly 4 EXTRUDERS."

#elif ENABLED(DUAL_X_CARRIAGE) && NUM_SERVOS < 2

#error "SWITCHING_NOZZLE along with DUAL_X_CARRIAGE requires NUM_SERVOS >= 2."

#endif

tool_change.cpp and motion.cpp

I would continue to use the original Marlin source files here. No matter what changes I had attempted here, I could not map the tools to the carriages. T1 always gets assigned to the X2 carriage, no matter what code changes I attempted in these two files.

status_screen_DOGM.cpp

I was having issues in two methods with 4 tools/extruders so just got around the display portion of this and we used the serial port or OctoPrint for tool temp monitoring and switching.

Hi! @ElectroFlux-SS and @Ziyayildizz3 👍👍

I'm glad there are more of us who are thinking about this mode. 😊😊

As one of the ones who has been through nearly all the underlying IDEX code, there is no trivial method to do this currently. Im focused purely on projects that pay the bills right now so itll be quite awhile until this gets more attention. One of the big items is that active extruder is currently used everywhere for determining the X stepper to use and its position index. That will need to be broken up. And it needs to be done in a way that expands to Y for the quad carriage setup.

there is no trivial method to do this currently

This small change will allow for more extruders, where the odd ones are located on one of the X carriages and the even ones located on the other X-carriage:

- if (movement_extruder()) X2_DIR_WRITE(v); else X_DIR_WRITE(v); \

+ if (movement_extruder() & 1) X2_DIR_WRITE(v); else X_DIR_WRITE(v); \

I modified line 360 in ... src\module\stepper.cpp ... as follows:

else if (movement_extruder () & 1) X2_DIR_WRITE (v); else X_DIR_WRITE (v); \

Replacement of T0 and T1 will be successful.

When attempting to replace the T2 or T3, the X2 carriage constantly strikes the X-MAX endstop sensor.

Behaviour (pronterface terminal) :

M218

SENDING:M218

echo:Hotend offsets: 0.00,0.00,0.000 292.00,0.00,0.000 0.00,0.00,0.000 292.00,0.00,0.000

G28

SENDING:G28

echo:Active Extruder: 0

X1 = print position

X2 = parking position

T1

SENDING:T1

echo:Active Extruder: 1

X1 = move to parking osition

X2 = move to print position

T2

SENDING:T2

echo:Active Extruder: 2

X2 = move to parking osition

X2 = attempt to move through the X-MAX endstop

X1 = still in parking position

T3

SENDING:T3

echo:Active Extruder: 3

X2 = attempt to move through the X-MAX endstop

X1 = still in parking position

T0

SENDING:T0

echo:Active Extruder: 0

X2 = attempt to move through the X-MAX endstop

X1 = move to print position

Please be able to set T0, T1 to carriage X1 and T2, T3 to carriage X2

Hi,

Is anyone solving this question or should I close it?

Looks like there's no interest in it and nothing's happening.

This GitHub system is a bit strange.

I don't know if anyone is solving it or not or if it is already solved.

There is simply no feedback!

Keep in mind that all the code here is contributed by unpaid volunteers who work on it in their free time.

I've added a Help Wanted label to hopefully attract attention of someone who has the hardware, interest, and ability to fix/implement the change.

At present, we have nearly 400 feature requests, and nearly 100 bug reports, so some patience is required.

HI @thinkyhead @InsanityAutomation

I have a printer ready with IDEX and if possible,

I would like to try modified Marlin modules for the intended project.

So far, everything is functional except for the division of tools into individual carriages.

Setting tools on carriages:

X1 = T0, T1

X2 = T2, T3

Here is my settings: https://github.com/DrumClock/Marlin/tree/GTR-2xMFG-V7

I'm very happy to help with testing, but I can't modify the program.