Marlin: [BUG] Y axis only moving 25% of what it should

Bug Description

I just installed an SKR Mini E3 v2.0 on my Ender 5 and flashed with the latest bugfix.

Oddly, my Y axis is moving only 25% of what it should. My e-steps are 80,80,400.

This has been discussed with @txt4nk from BigTreeTech at:

https://github.com/bigtreetech/BIGTREETECH-SKR-mini-E3/issues/266#issuecomment-643467988 -- he seems just as stomped as me.

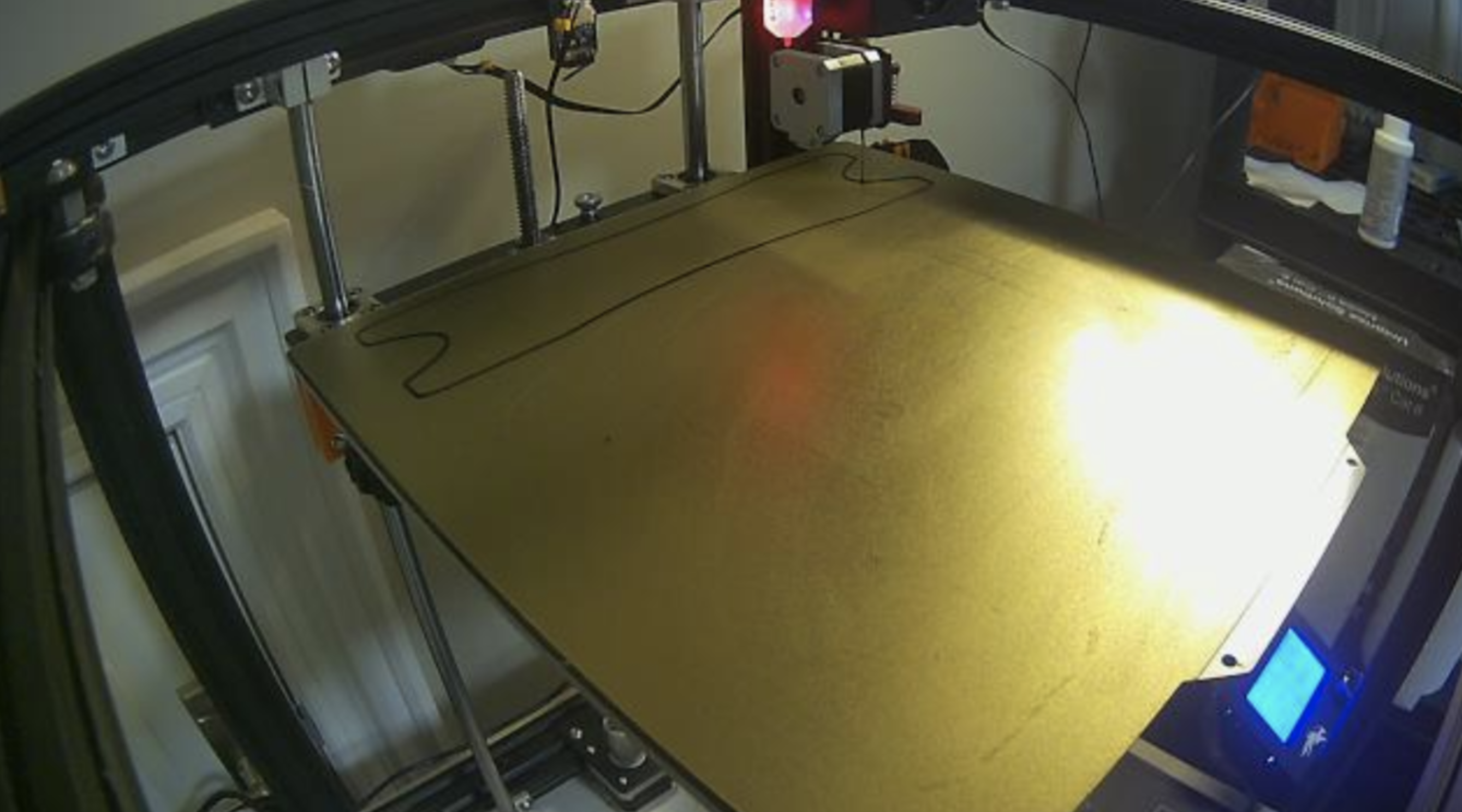

The following line should be around the entire bed.

My Configurations

See: https://github.com/cmer/creality_ender5_config_and_notes/tree/master/marlin-2.0.x

Steps to Reproduce

The same happens wether I print a sliced model, or if I manually move the Y axis with the printer screen.

Expected behavior: Y axis able to navigate the entire 220mm

Actual behavior: Every Y axis movement is 25% of what it should be. Maximum Y distance is 55mm.

All 12 comments

Just as an additional note, the first firmware I supplied was from scratch using the latest bugfix and example configurations. I went through the firmware and couldn't see anything blatantly obvious. I've got an ender 5 on an E3 Mini V1.2, so I modified my personal firmware and updated the board to the V2.0, and the result is the same.

@txt4nk just to clarify you were also able to reproduce the issue on an E3 Mini v2 board?

Negative, my V2.0 board is on the way. But taking in to account that A. a known working configuration on a V1.2 was used and you are still getting this result. B. Your printer was working just find on your previous board, which tells me it is not a printer issue.. I dont see how this is not a bug.

Send: M122 S1

Recv: X Y Z E

Recv: Address 0 0 0 0

Recv: Enabled false false false false

Recv: Set current 580 650 580 650

Recv: RMS current 550 642 550 642

Recv: MAX current 776 905 776 905

Recv: Run current 17/31 20/31 17/31 20/31

Recv: Hold current 8/31 10/31 8/31 10/31

Recv: CS actual 10/31 10/31 10/31 10/31

Recv: PWM scale 33 33 33 33

Recv: vsense 1=.18 1=.18 1=.18 1=.18

Recv: stealthChop true true true true

Recv: msteps 16 16 16 16

Recv: tstep max max max max

Recv: PWM thresh.

Recv: [mm/s]

Recv: OT prewarn false false false false

Recv: off time 4 4 4 4

Recv: blank time 24 24 24 24

Recv: hysteresis

Recv: -end 2 2 2 2

Recv: -start 1 1 1 1

Recv: Stallguard thrs 0 0 0 0

Recv: DRVSTATUS X Y Z E

Recv: sg_result 54 54 54 54

Recv: stst

Recv: olb

Recv: ola

Recv: s2gb

Recv: s2ga

Recv: otpw

Recv: ot

Recv: 157C

Recv: 150C

Recv: 143C

Recv: 120C

Recv: s2vsa

Recv: s2vsb

Recv: Driver registers:

Recv: X 0xC0:0A:00:00

Recv: Y 0xC0:0A:00:00

Recv: Z 0xC0:0A:00:00

Recv: E 0xC0:0A:00:00

Recv:

Recv:

Recv: Testing X connection... OK

Recv: Testing Y connection... OK

Recv: Testing Z connection... OK

Recv: Testing E connection... OK

Send: M503

Recv: echo: G21 ; Units in mm (mm)

Recv: echo: M149 C ; Units in Celsius

Recv:

Recv: echo:; Filament settings: Disabled

Recv: echo: M200 S0 D1.75

Recv: echo:; Steps per unit:

Recv: echo: M92 X80.00 Y80.00 Z400.00 E93.00

Recv: echo:; Maximum feedrates (units/s):

Recv: echo: M203 X500.00 Y500.00 Z5.00 E25.00

Recv: echo:; Maximum Acceleration (units/s2):

Recv: echo: M201 X500.00 Y500.00 Z100.00 E5000.00

Recv: echo:; Acceleration (units/s2): P<print_accel> R<retract_accel> T<travel_accel>

Recv: echo: M204 P500.00 R500.00 T500.00

Recv: echo:; Advanced: B<min_segment_time_us> S<min_feedrate> T<min_travel_feedrate> J<junc_dev>

Recv: echo: M205 B20000.00 S0.00 T0.00 J0.08

Recv: echo:; Home offset:

Recv: echo: M206 X0.00 Y0.00 Z0.00

Recv: echo:; Auto Bed Leveling:

Recv: echo: M420 S0 Z0.00

Recv: echo:; Material heatup parameters:

Recv: echo: M145 S0 H200 B60 F255

Recv: echo: M145 S1 H240 B70 F255

Recv: echo:; PID settings:

Recv: echo: M301 P21.73 I1.54 D76.55

Recv: echo:; Z-Probe Offset (mm):

Recv: echo: M851 X-45.00 Y-14.00 Z-1.40

Recv: echo:; Stepper driver current:

Recv: echo: M906 X580 Y650 Z580

Recv: echo: M906 T0 E650

Recv:

Recv: echo:; Driver stepping mode:

Recv: echo: M569 S1 X Y Z

Recv: echo: M569 S1 T0 E

Recv: ok

Okey bud, do you mean by Y axis the heated bed? also if you have a newer vesion of the Ender 5 your Z axis Steps/mm should be 1600. because the sleadscrew moves 2mm per rotation.

I think you meant to say Z instead of Y

No it is his Y.. its the front/back horizontal movement.

And the new lead screw version of the ender 5 is 800/mm, not 1600.

I oddly got it to work. I don't understand why. I rebuilt my config file by hand from the vanilla Marlin config file. This commit works for me: https://github.com/cmer/creality_ender5_config_and_notes/commit/83aae28058b7ae6b8cf9e455c590fd0e5217a67a -- You can see the diff with my old config files.

I will update this thread if I find out why it didn't work before.

The core of the issue is the improper setting of the slave addresses for the serial communications.

In "Configuration_adv.h"

This needs to be changed:

#define X_SLAVE_ADDRESS 0

#define Y_SLAVE_ADDRESS 0

#define Z_SLAVE_ADDRESS 0

#define X2_SLAVE_ADDRESS 0

#define Y2_SLAVE_ADDRESS 0

#define Z2_SLAVE_ADDRESS 0

#define Z3_SLAVE_ADDRESS 0

#define Z4_SLAVE_ADDRESS 0

#define E0_SLAVE_ADDRESS 0

#define E1_SLAVE_ADDRESS 0

#define E2_SLAVE_ADDRESS 0

#define E3_SLAVE_ADDRESS 0

#define E4_SLAVE_ADDRESS 0

#define E5_SLAVE_ADDRESS 0

#define E6_SLAVE_ADDRESS 0

#define E7_SLAVE_ADDRESS 0

To this:

#define X_SLAVE_ADDRESS 0

#define Y_SLAVE_ADDRESS 2

#define Z_SLAVE_ADDRESS 1

#define X2_SLAVE_ADDRESS 0

#define Y2_SLAVE_ADDRESS 0

#define Z2_SLAVE_ADDRESS 0

#define Z3_SLAVE_ADDRESS 0

#define Z4_SLAVE_ADDRESS 0

#define E0_SLAVE_ADDRESS 3

#define E1_SLAVE_ADDRESS 0

#define E2_SLAVE_ADDRESS 0

#define E3_SLAVE_ADDRESS 0

#define E4_SLAVE_ADDRESS 0

#define E5_SLAVE_ADDRESS 0

#define E6_SLAVE_ADDRESS 0

#define E7_SLAVE_ADDRESS 0

The core of the issue is the improper setting of the slave addresses for the serial communications.

@coolio986 — That is an issue for the MarlinFirmware/Configurations repository, and any fixes you submit should target the specific configuration(s) which need these settings.

The examples for the SKR E3 Mini 2.0 already set these.

This family is a little confusing, because 1.0/2.0 use hardware serial with slave addresses, but 1.2 uses software serial and needs them all set to 0.

This issue has been automatically locked since there has not been any recent activity after it was closed. Please open a new issue for related bugs.

Most helpful comment

The examples for the SKR E3 Mini 2.0 already set these.

This family is a little confusing, because 1.0/2.0 use hardware serial with slave addresses, but 1.2 uses software serial and needs them all set to 0.