Marlin: [BUG] Bulge on linear advance speed change

Bug Description

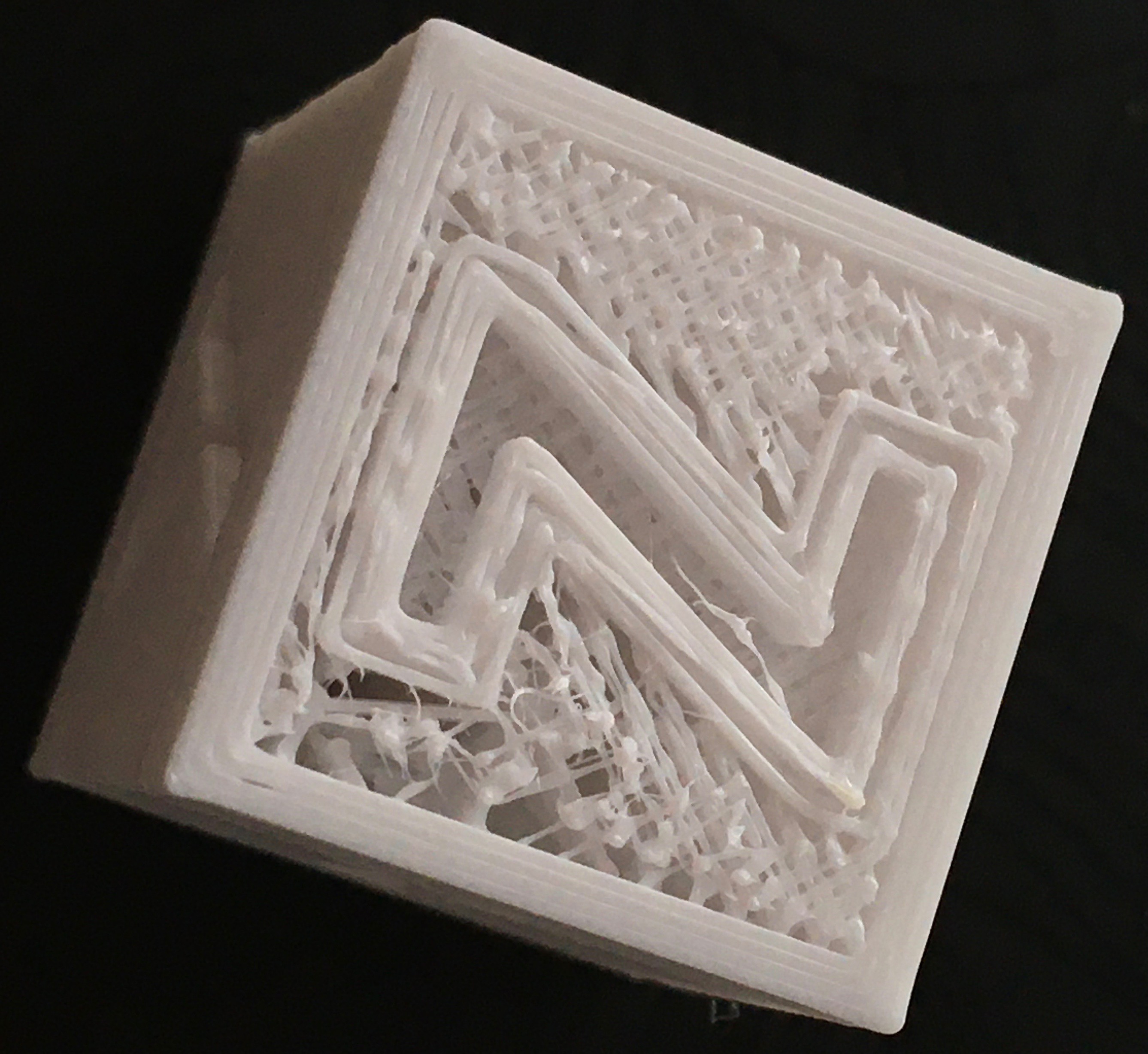

When using linear advance on my bowden system, no matter what value, even between 0 and 5, there is a big drop of plastic at the point where the speed changes, even tho the 3 segments are changed correctly (my correct k value is around 0.5)

My Configurations

Marlin.zip

(Marlin bugfix as of 21 Jan)

Cr10S, skr 1.3, TMC 2209

Scurve acceleration, Standard jerk

Expected behavior: [What you expect to happen]

Linear transition between slow and fast speed

Actual behavior: [What actually happens]

Big drop left at the speed change

All 169 comments

In your slicer it will help to tell it not to subdivide curves too finely. Too many small segments lead to planner starvation because the G-code input cannot feed the queue fast enough.

I am directly referring to the official linear advance test.

There is not even a minimal difference in the bulge between 0 and 3.

Tried with scurve off: No difference.

there is a big drop of plastic at the point where the speed changes

Tried with scurve off: No difference.

I think I have the same issue.

While calibrating my linear advance settings, I also noticed a bulge at the speed change.

I used the official linear advance test found here: https://marlinfw.org/tools/lin_advance/k-factor.html

While trying around I also tried very low acceleration settings and noticed something strange:

At the point where the print head is supposed to accelerate, it actually decelerates first before speeding up. This can be clearly seen and heard. I don't think this behavior is correct. Maybe you want to try it out for yourself? These are the speed settings I used:

; Settings Speed:

; Slow Printing Speed = 900 mm/min

; Fast Printing Speed = 3600 mm/min

; Movement Speed = 7200 mm/min

; Retract Speed = 2400 mm/min

; Printing Acceleration = 40 mm/s^2

In order to track down spurious issues, after first testing the latest bugfix-2.0.x code it can help to go back in time to find a version of Marlin that doesn't exhibit the issue. Through a process of bisection you can quickly locate the day when the issue first arises. We can then examine the code changes from that time period and see which changes are the most likely problem.

I can confirm this also - when moving from the first slow segment into the middle fast segment on each line, it not only decelerates, it also briefly moves the extruder backward just before the normal surge forward. It's been a long time since I last tried to set up LA, so I couldn't even begin to guess when it last worked.

It never worked correctly to me.

My i3 plus 3D printer which shows the strange behavior is running a Marlin firmware version 1.1.4. (You can find the the firmware project here https://github.com/Silverquark/i3PlusPlus)

If the bug was never fixed in between, this would probably mean it has been around since at least mid 2017.

briefly moves the extruder backward

Yeah, Linear Advance is allowed to do that.

It's been a while since @Sebastianv650 has been around, but I'm sure if LA was seriously broken he would have harshly criticized us by now!

briefly moves the extruder backward

Yeah, Linear Advance is allowed to do that.

Sure, if it's moving from a fast segment to a slow segment in the calibration pattern, E moving backward slightly makes perfect sense, since it has to bleed-off some pressure just before the slow segment starts. On the transitions from slow to fast on each line, one would expect only a forward E surge, to boost the pressure just before the fast segment starts.

That's how it worked when LA v1.5 was introduced (and I seem to recall that that's more or less how it worked in the old implementation that preceded it).

But now, a slow-to-fast transition is getting both a backward move and a forward surge, one after the other, which cancel each other out. Thus the start of the fast segment never fills-out. I did not take note of the behavior of fast-to-slow transitions, but I'll hazard a guess that an inverse pair of moves happens there, since the fast-to-slow bulges never smooth out.

Since @Sebastianv650 hasn't stopped by to yell at anyone, I can only assume he has moved on to some other project.

The last I remember hearing from @Sebastianv650 was https://github.com/MarlinFirmware/Marlin/issues/10272#issuecomment-534905221 where it looked like he had moved on to other things.

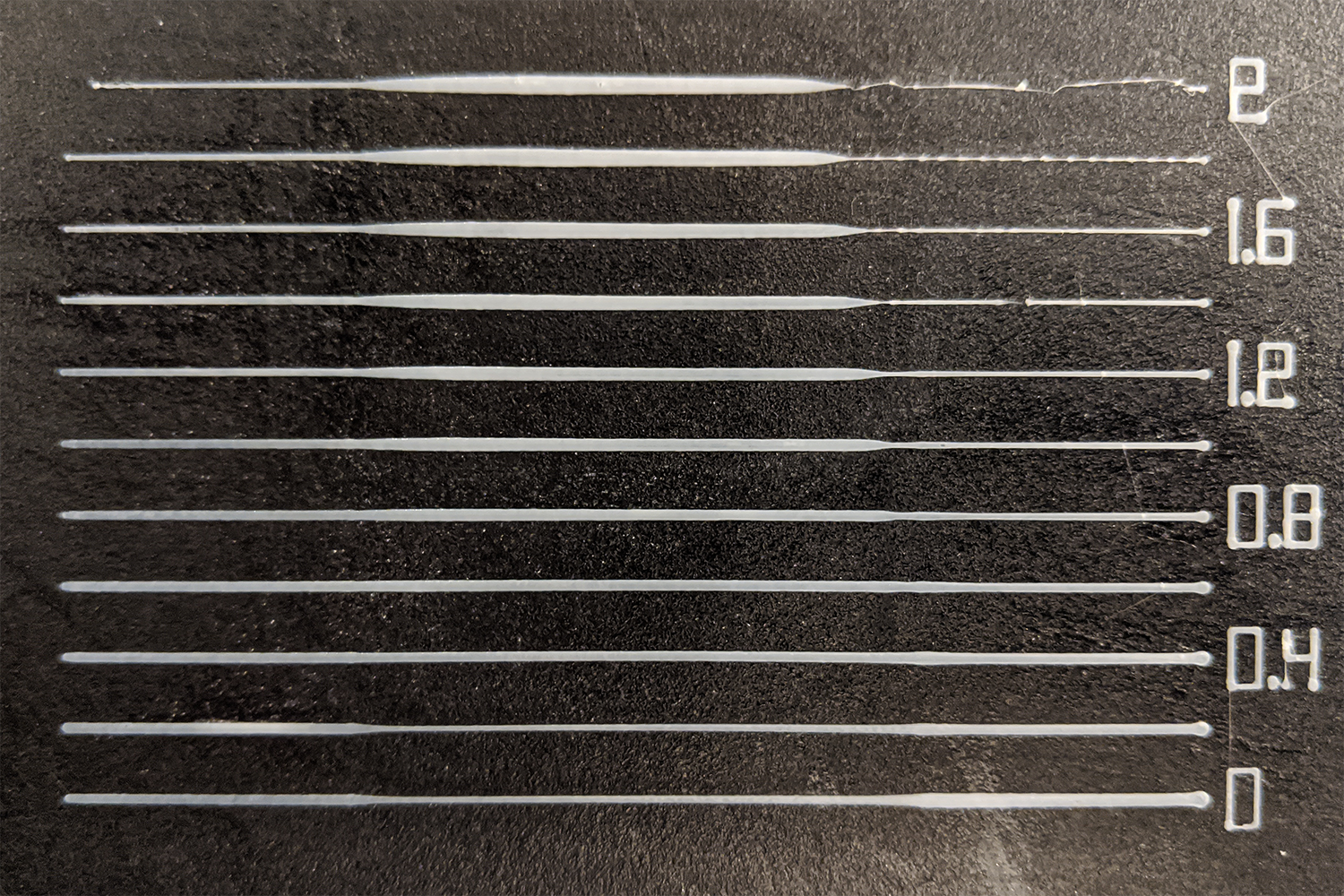

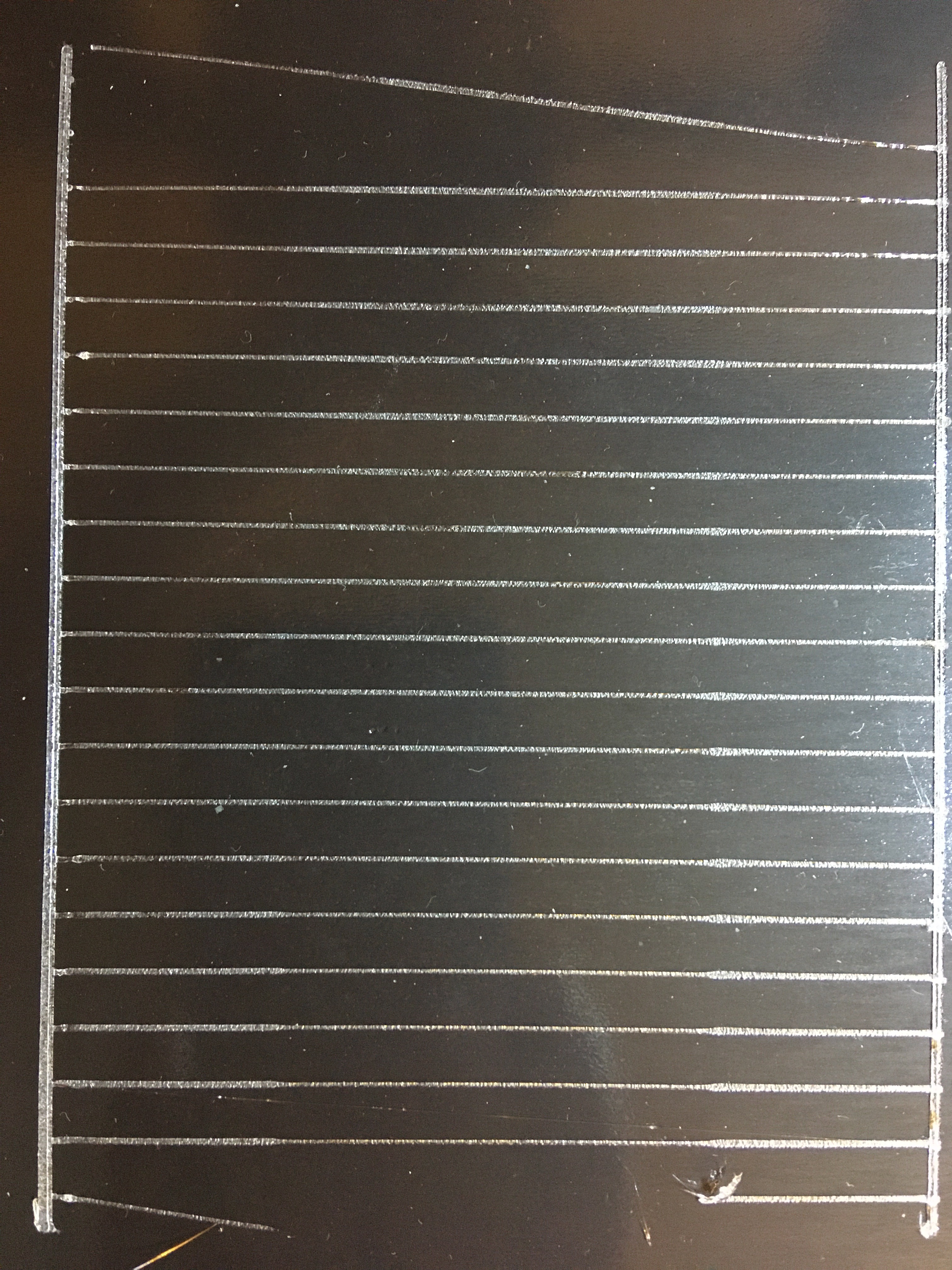

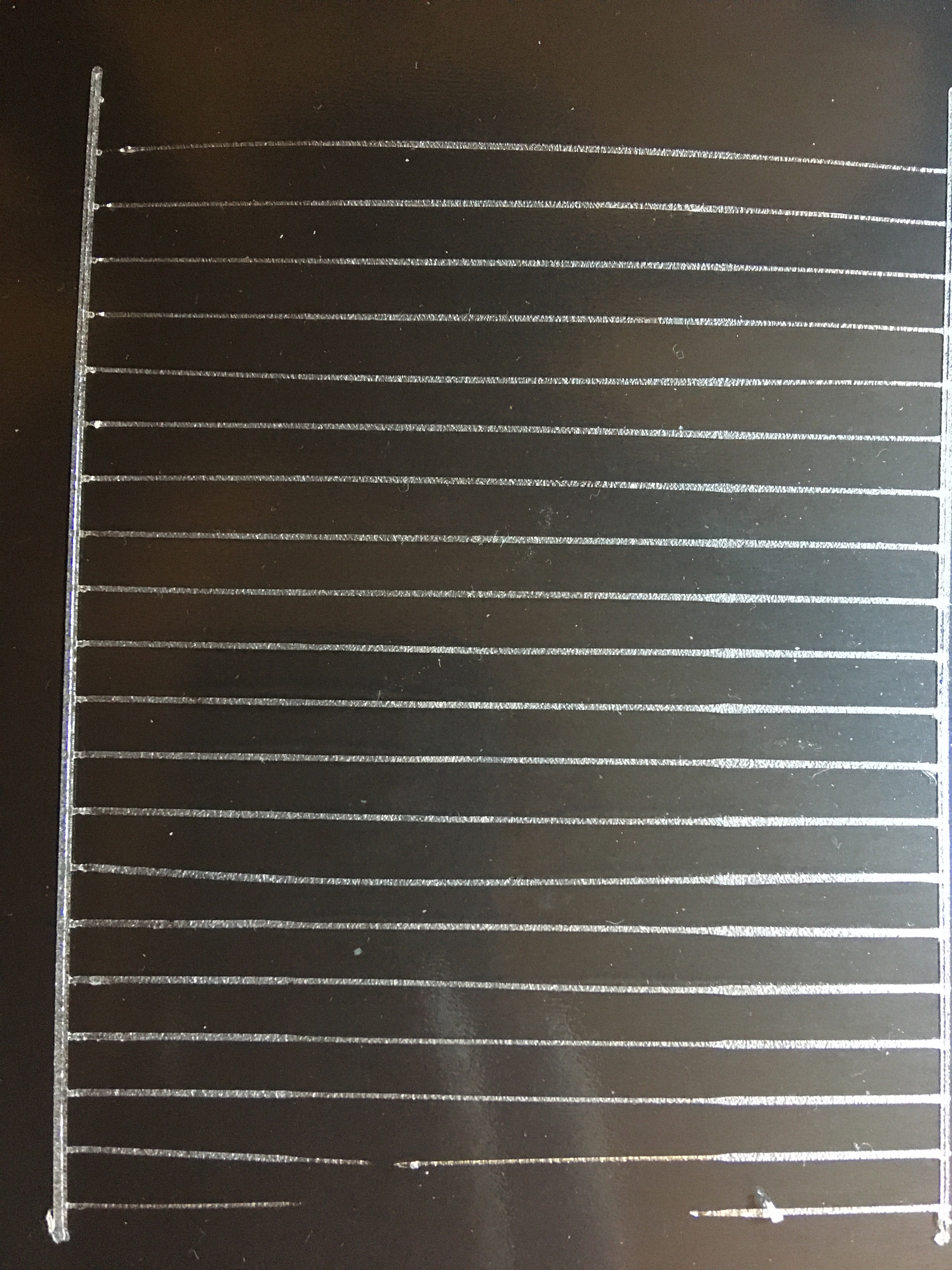

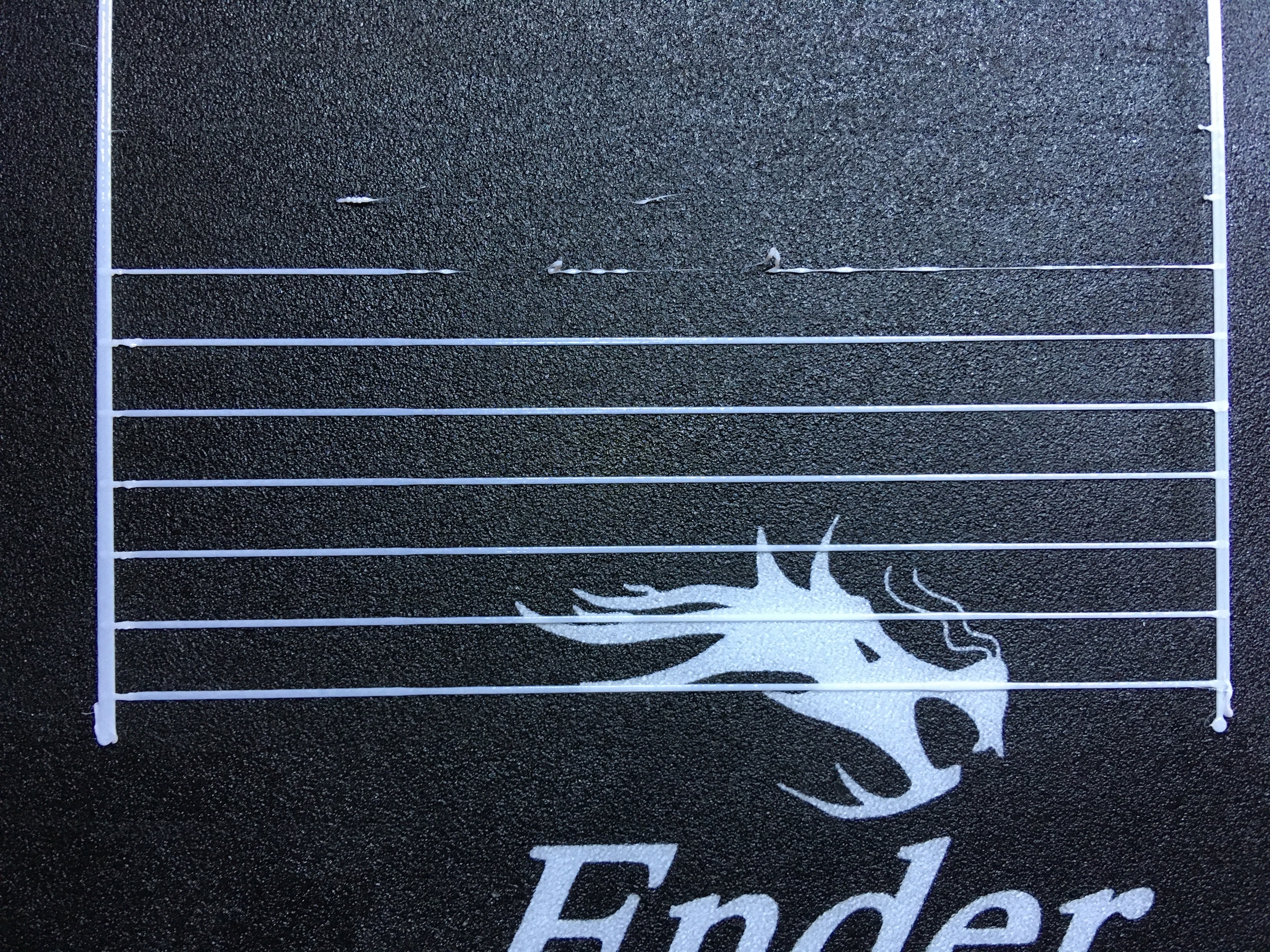

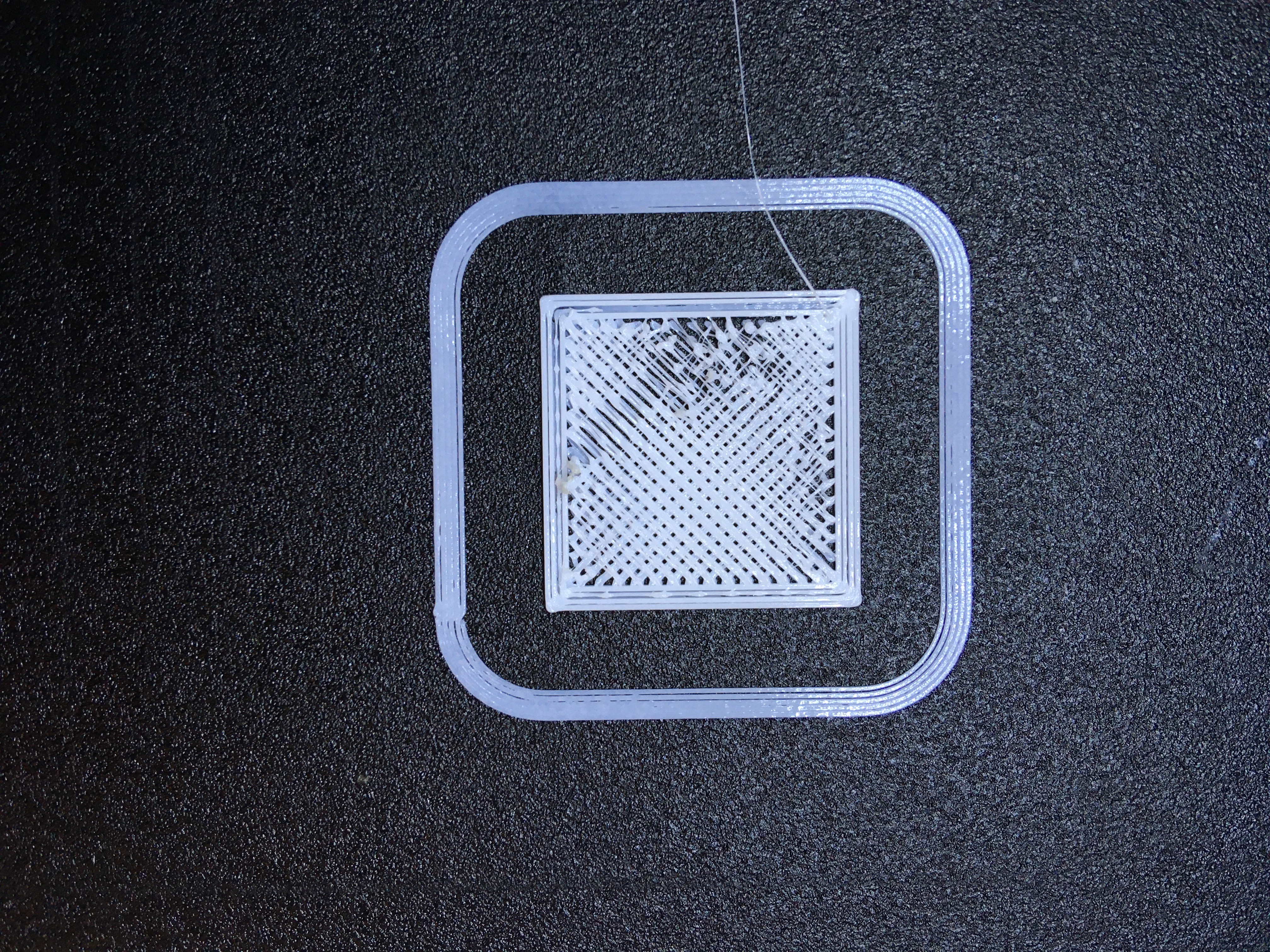

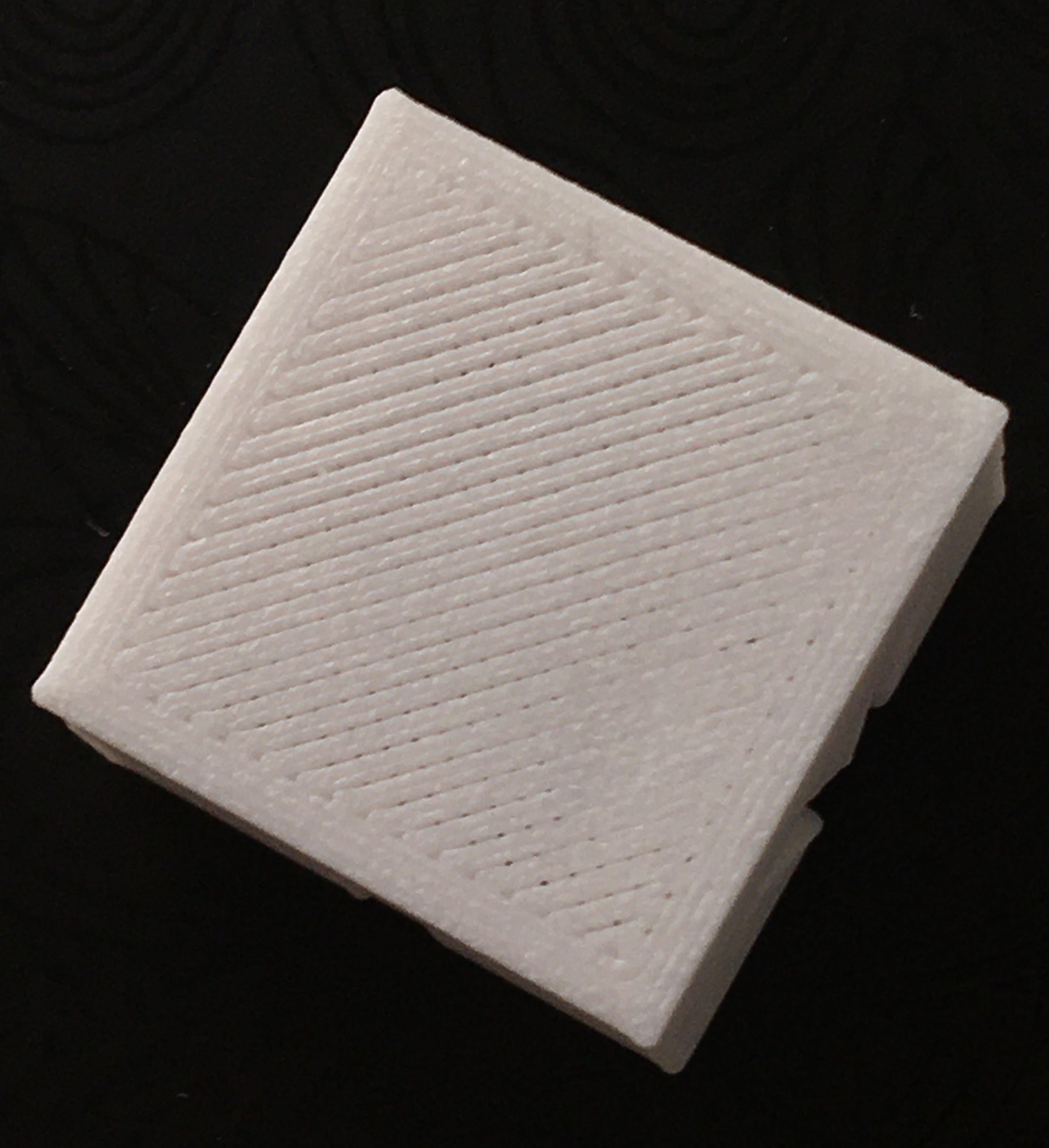

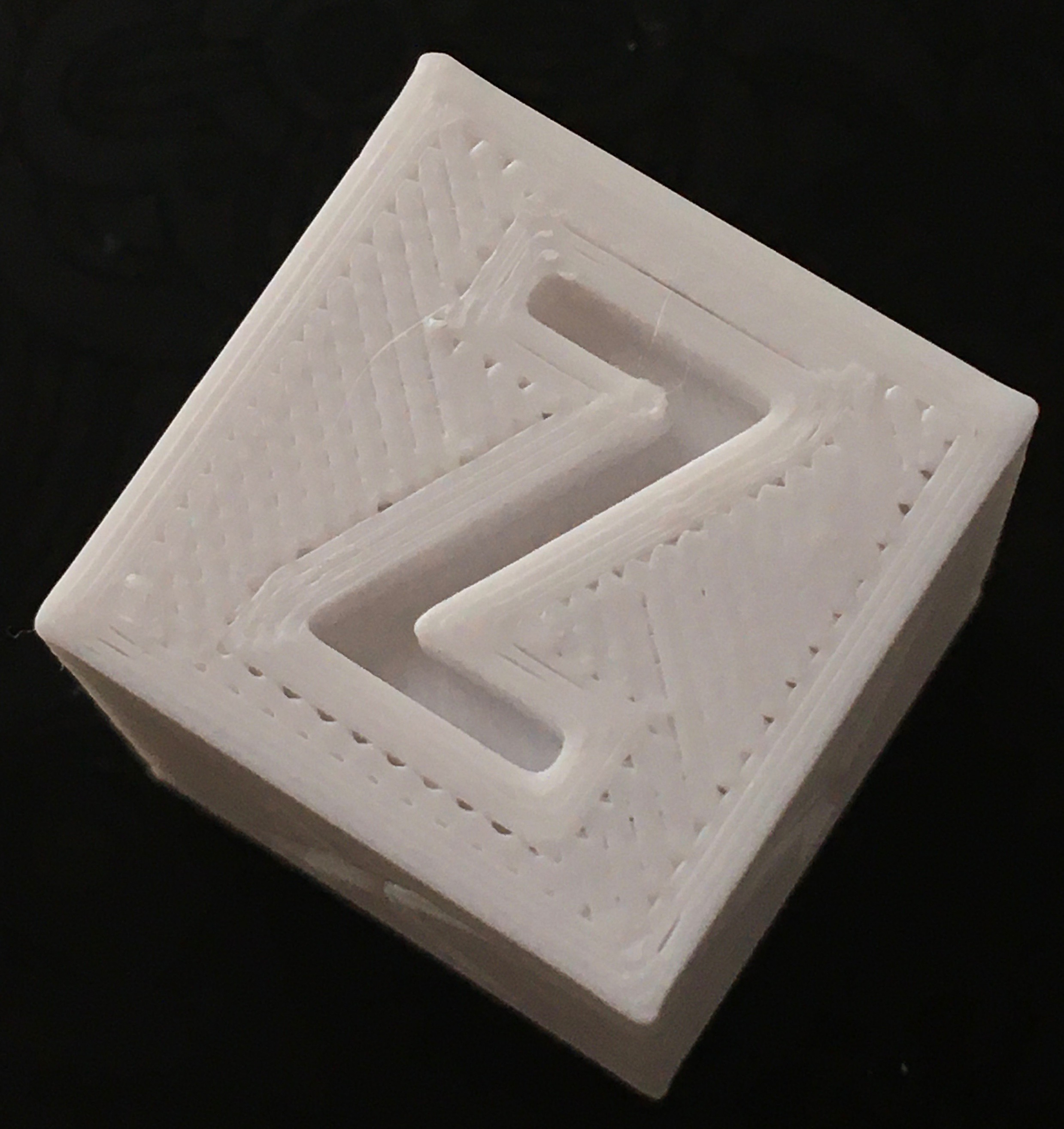

@Liger0 Can you upload a picture of the bulge? I think I have a similar problem, but I'm not sure because the description is a bit vage. This is an image ob the bulge on my pattern:

Yes that's exactly like yours, just a little bigger and visible on all the lines all the way from 0 to 5.

Good. What extruder do you use? Bowden, direct drive or flexdrive? I've got the problem on a stock Ender 3 Pro, which uses a Bowden.

I had this really noticeably on stock bowden Ender 3, and still can see it - even if very slightly - with direct drive now. (K=0.9, K=0.18)

I use bowden.

I have this issue as well, the bulge exists all the way up to 1.8K or so. Running marlin 1.1.9 on an Ender 3.

Same issue here with SKR pro 1.1, 2208s, Bowden and latest bug fix from today. It’s been an issue for a VERY long time even back to the AVR days in my past setup. This has been seen across my i3 variants with both Bowden and direct drive. I have just lived with it and assumed I was just not calibrating something properly. Which is still a likely possibility. :)

-William

…it looked like he had moved on to other things.

I guess that means we'll have to actually understand his code now! I was hoping to maybe get him to throw us a hint in a short comment. Has anyone looked at Prusa Firmware to see if their algorithm is significantly different?

_Anyways…_

Just so everyone is on the same page here:

- S-curve acceleration is not deemed to be compatible with Linear Advance. You can experiment with it, so it's not completely blocked, but Linear Advance expects to be working alongside of Linear Acceleration. So, please test with S-Curve Acceleration disabled and compare those results.

S-curve acceleration is not deemed to be compatible with Linear Advance. You can experiment with it, so it's not completely blocked, but Linear Advance expects to be working alongside of Linear Acceleration. So, please test with S-Curve Acceleration disabled and compare those results.

Oh really? I've only heard it being used along with S-curve, I'll go test this rq.

@thinkyhead

So I tested it with S-curve disabled, if there was a difference, it was marginal. There is still a bulge at the slow down transition. This, eventually goes away but then your slower speeds are much thinner, if there at all.

I tested V1 last night and found that the opposite problem exists, where the fast portion is not fed fast enough.

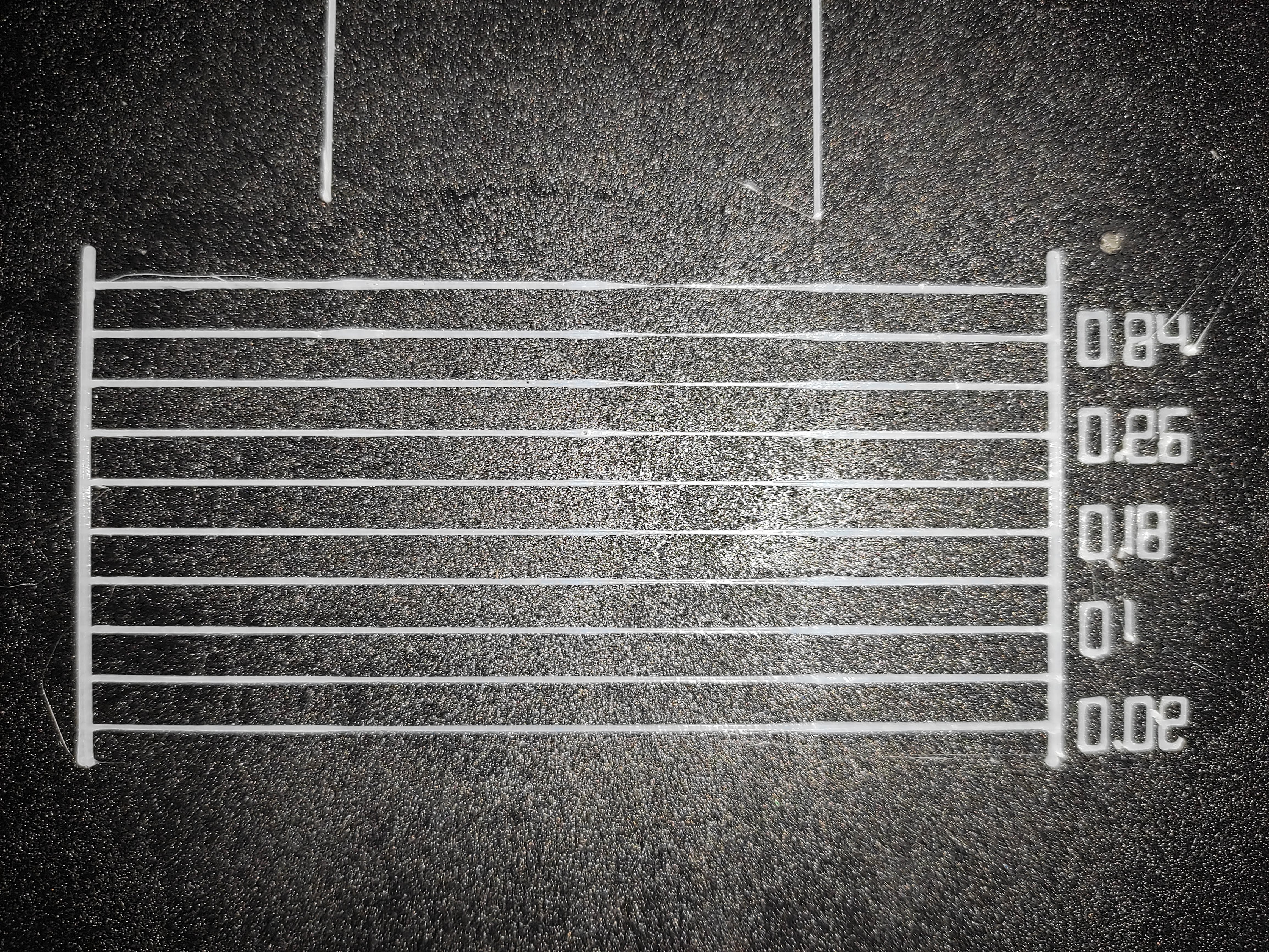

Just to see what happens, I tested it with different accelerations.

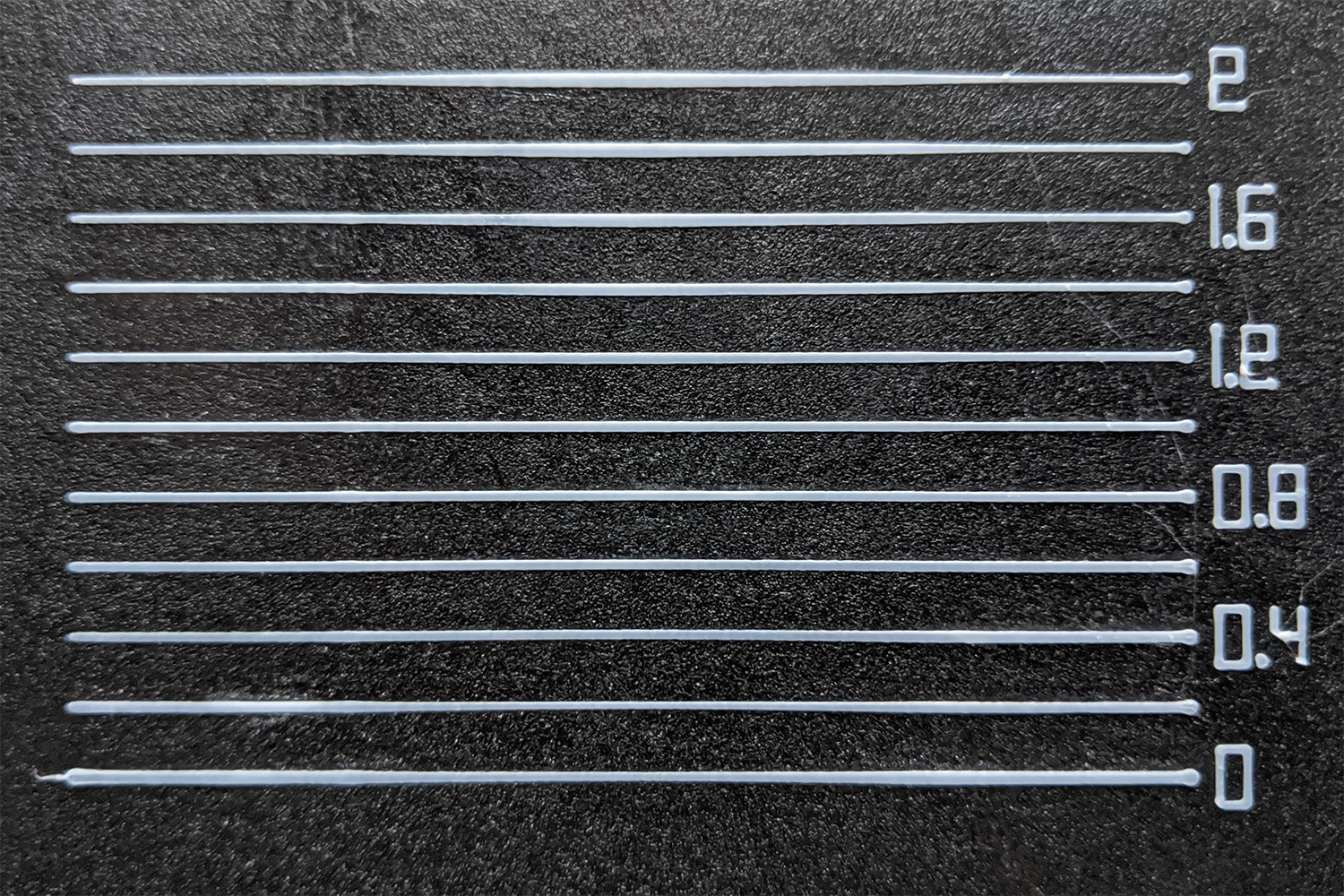

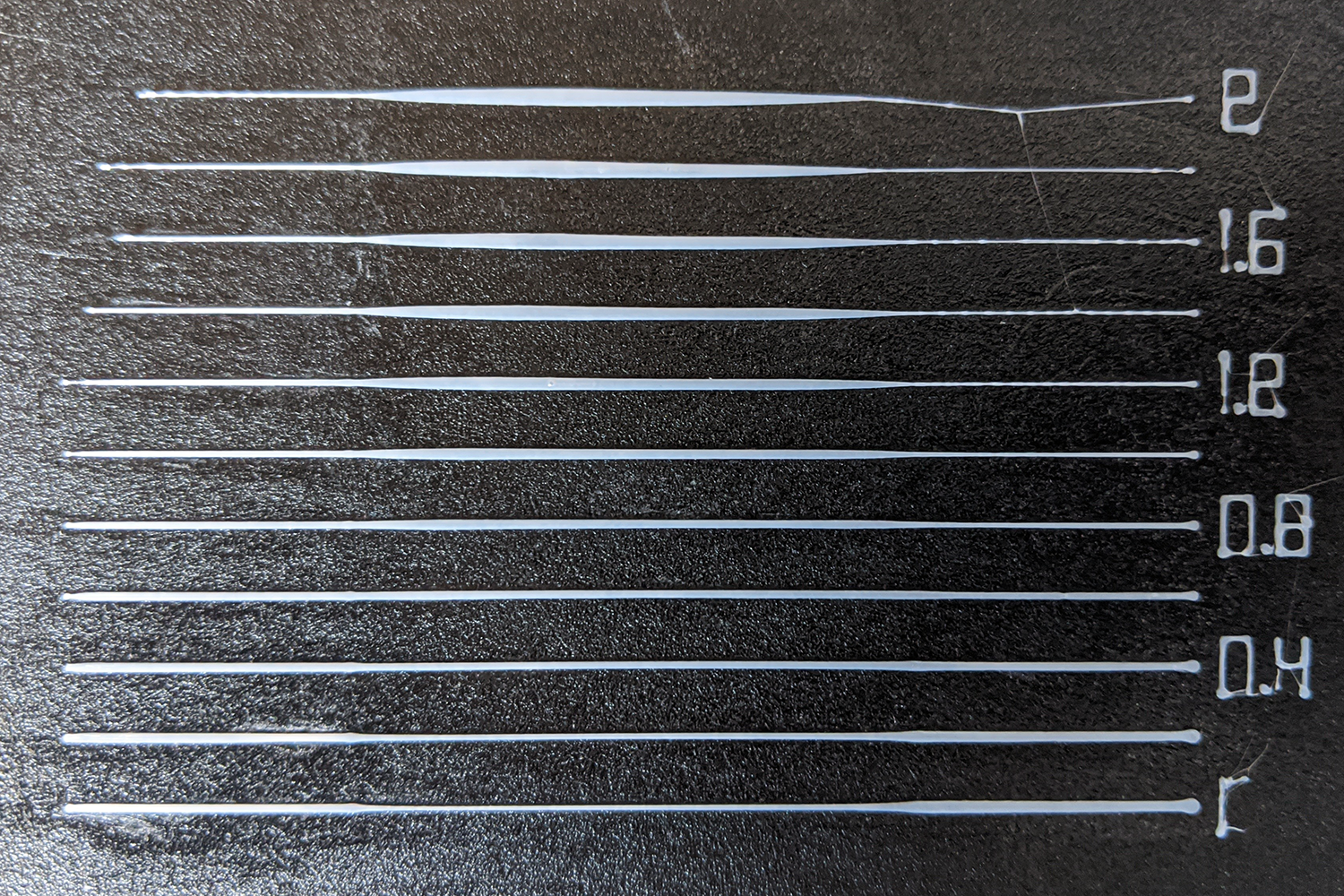

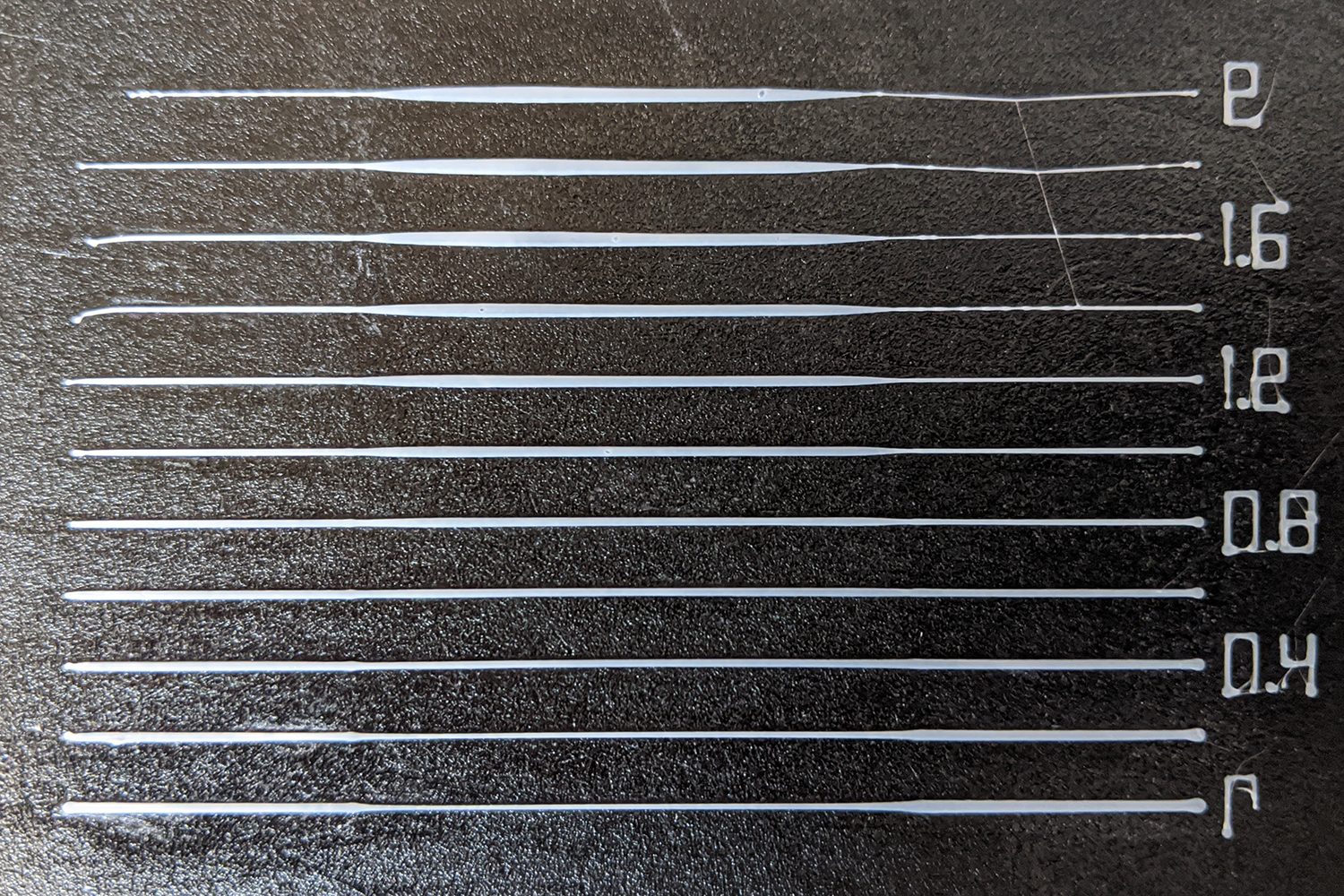

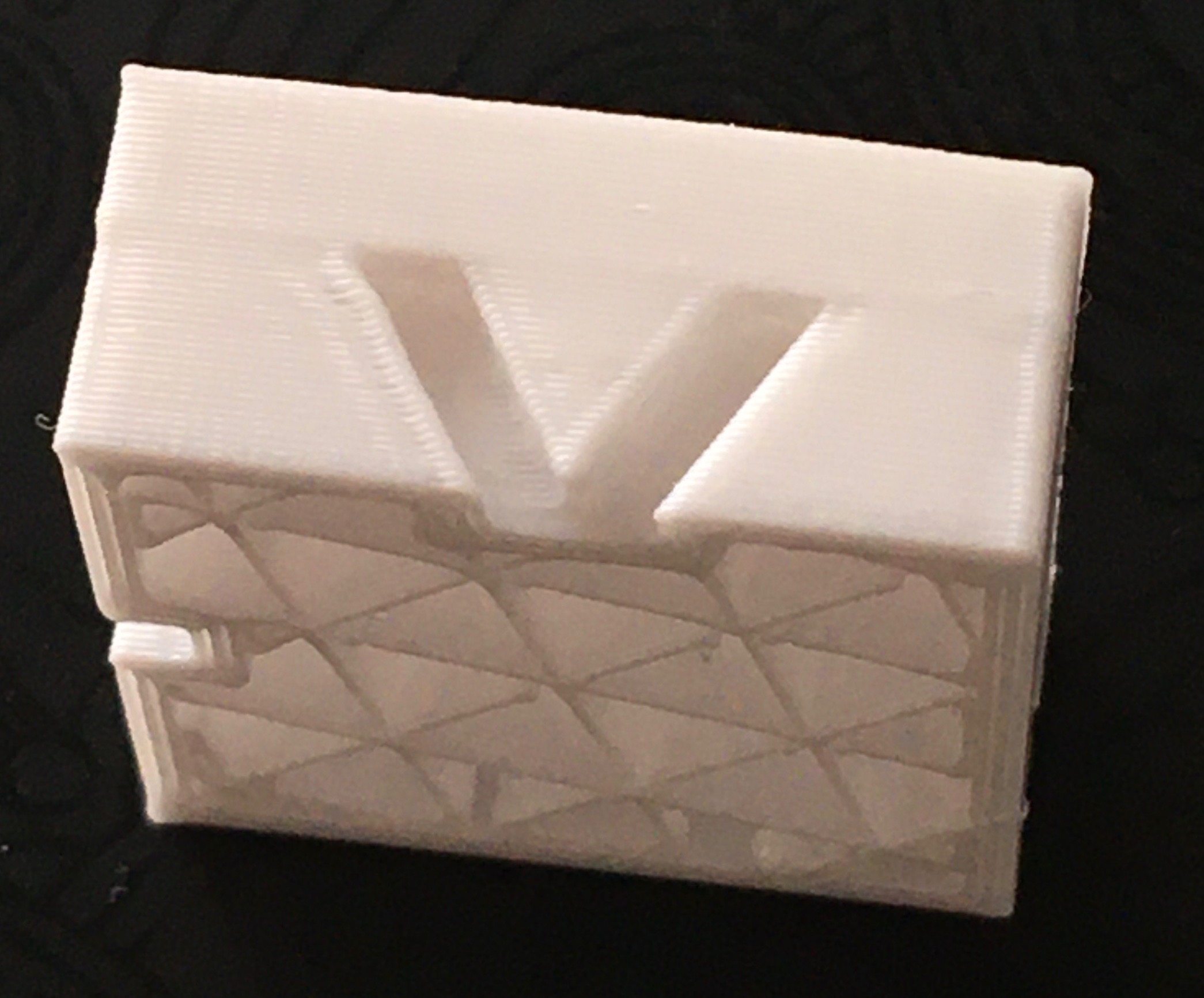

80 mm/s² 🔽

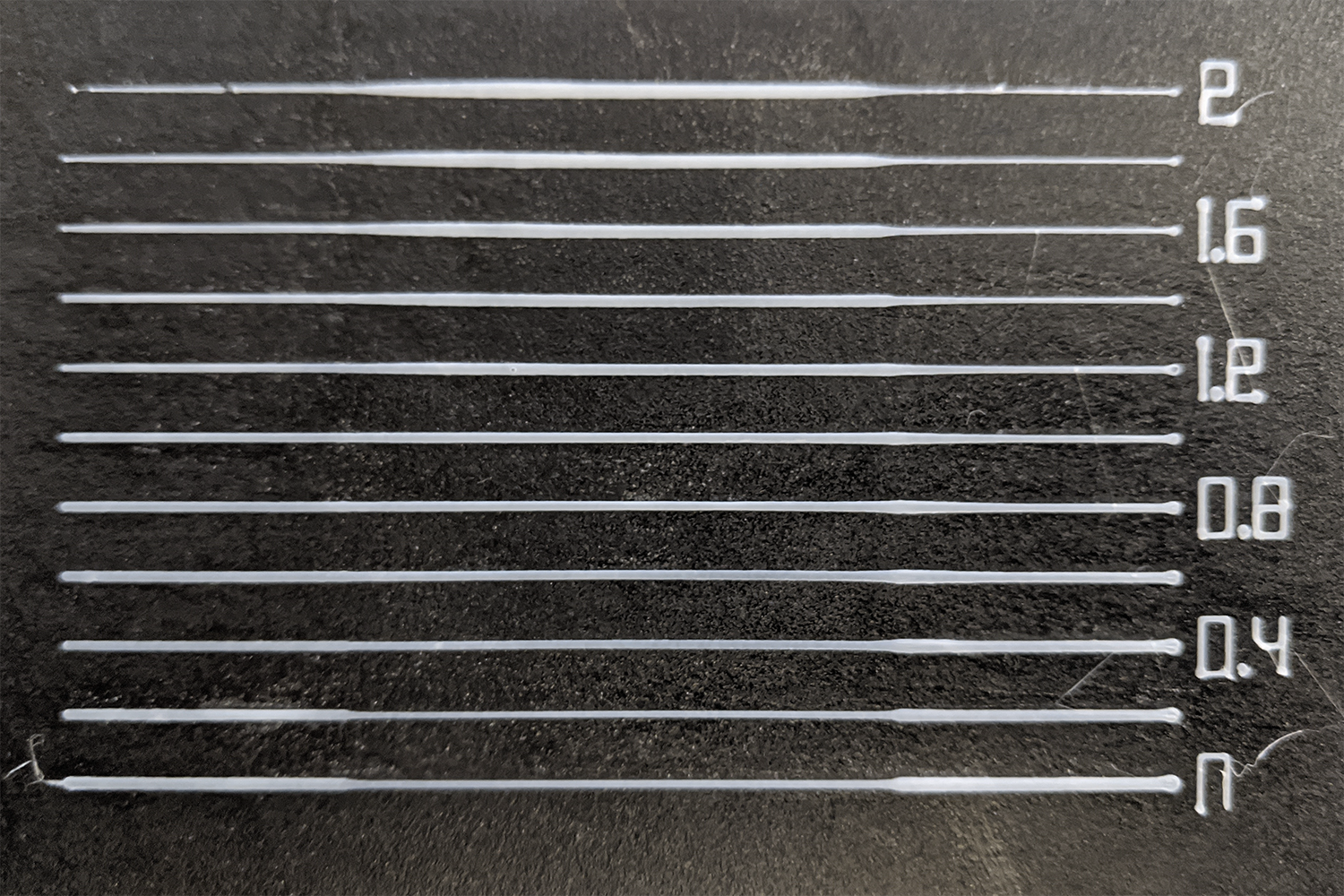

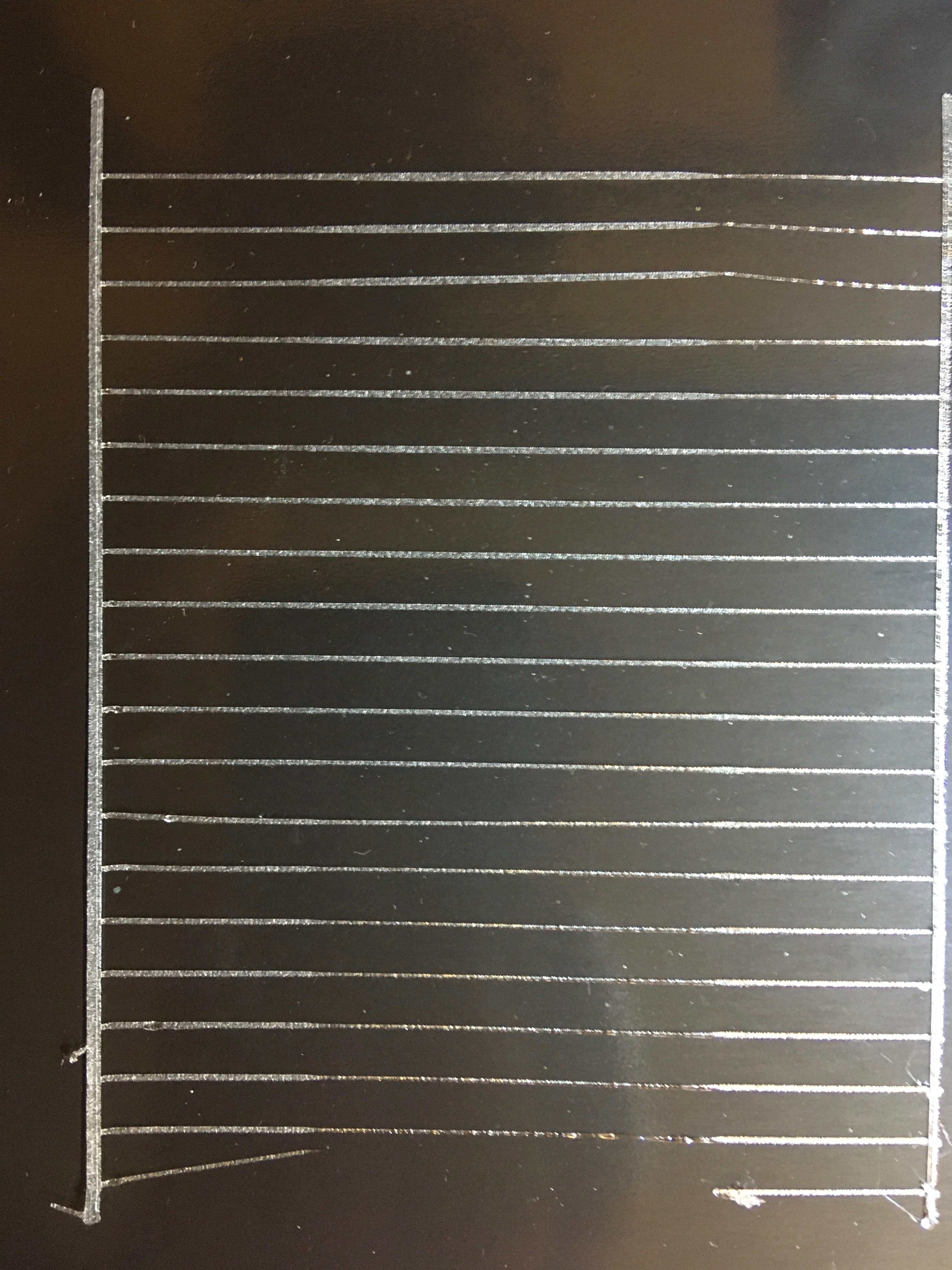

400 mm/s² 🔽

2000 mm/s² 🔽

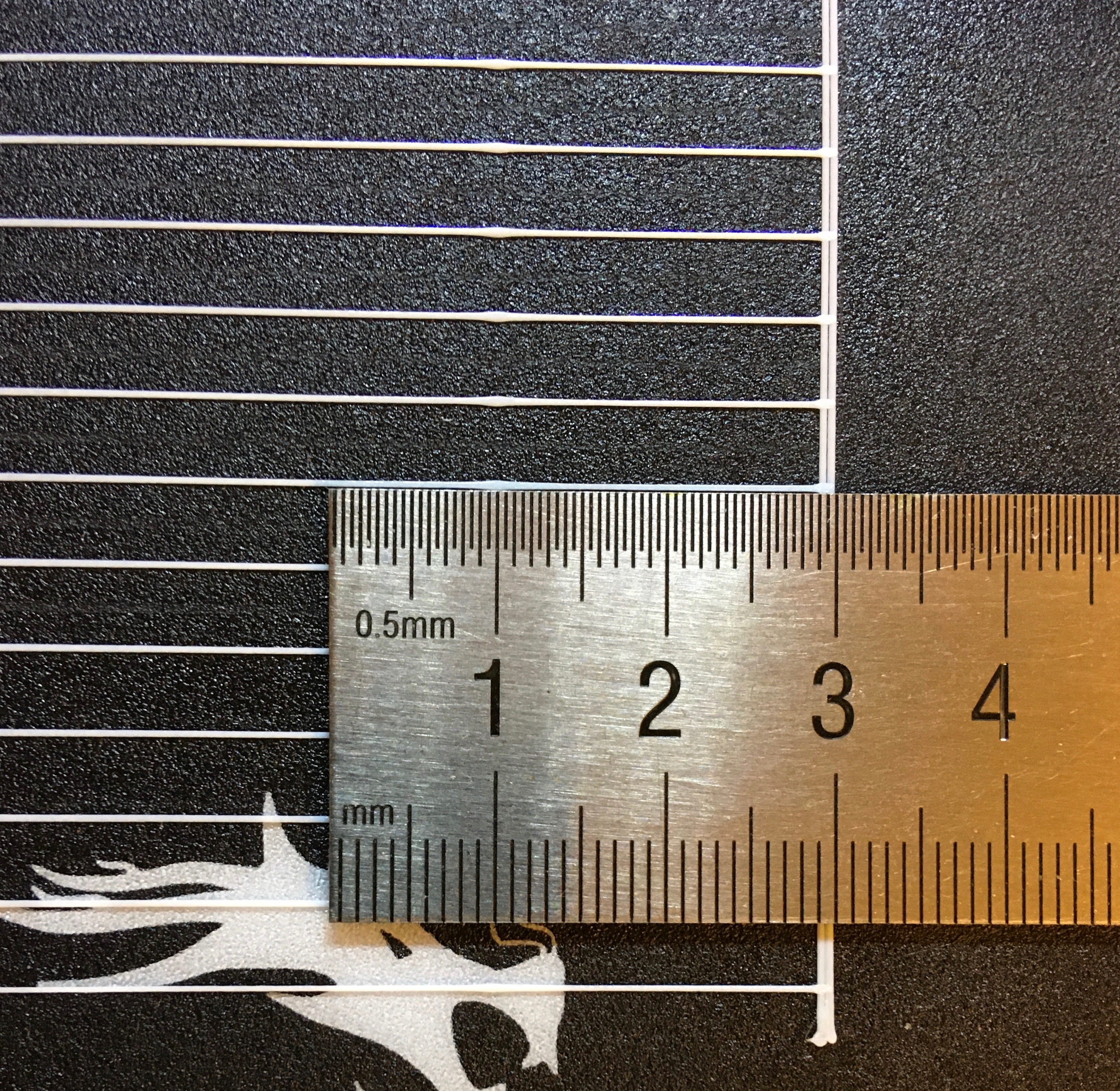

All other settings are identical (speed 20/80/20 mm/s, segment lengths and extrusion settings default, retraction 3 mm). As you can see, there is no bulge at 80 mm/s². At 400 mm/s², it's already very visible. This is a typical result for my printer. At 2000 mm/s², it's only slightly bigger than at 400.

Looking at where the bulge is placed shows, that most of it (maybe 80%) is directly after the speed change 20 mm before the end of the line. That is, after the deceleration phase, which I would have thought to be somewhat more critical.

@XDA-Bam Your 2k results are exactly what I'm seeing. So it seems for LA to work worth a damn, you have to slow your printer to a crawl; which seems to defeat the purpose.

@XDA-Bam Is S-Curve Acceleration on?

@XDA-Bam Is S-Curve Acceleration on?

From my tests, it won't matter, the results stay the same.

@qwewer0 No S-curve on those tests. Also, using either Jerk or JD does not make a difference, as far as I can tell.

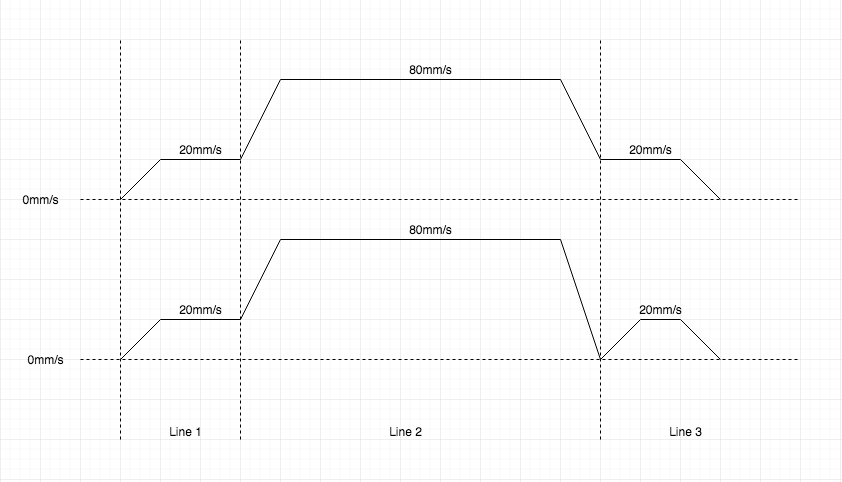

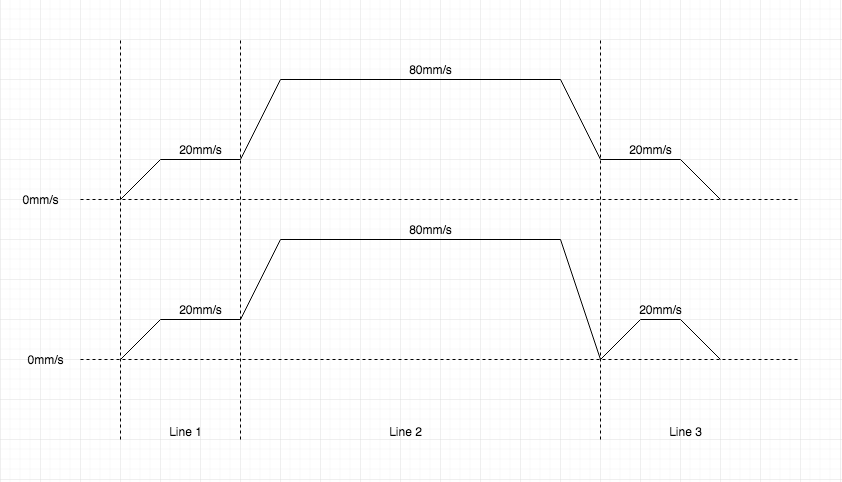

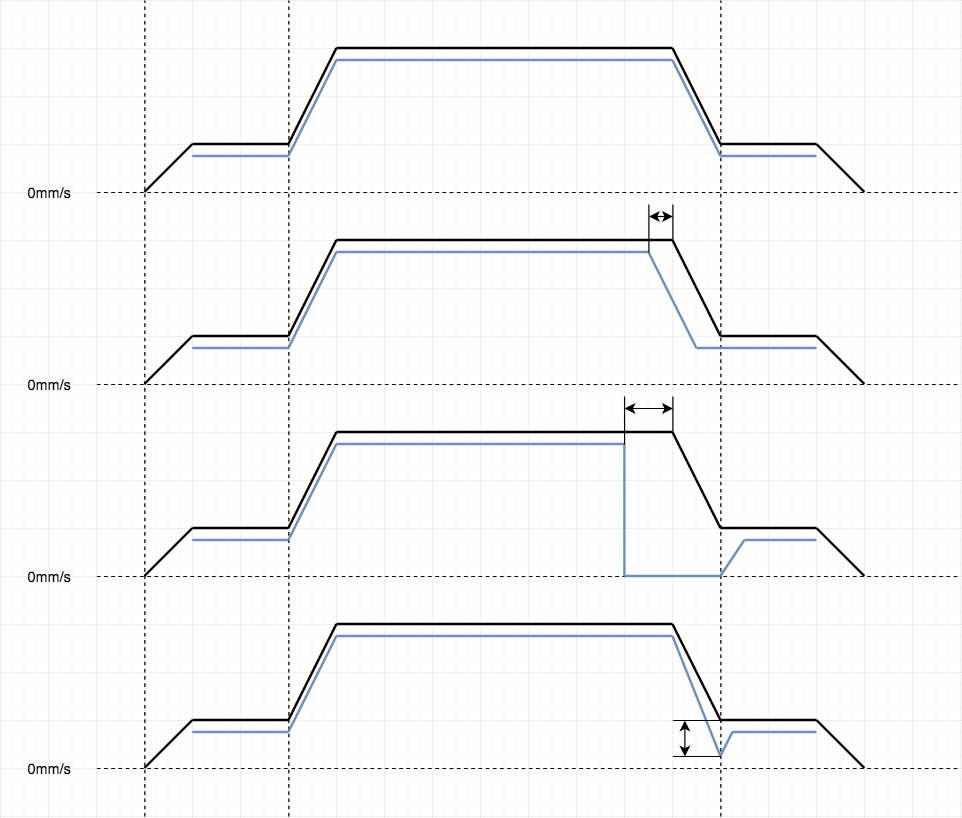

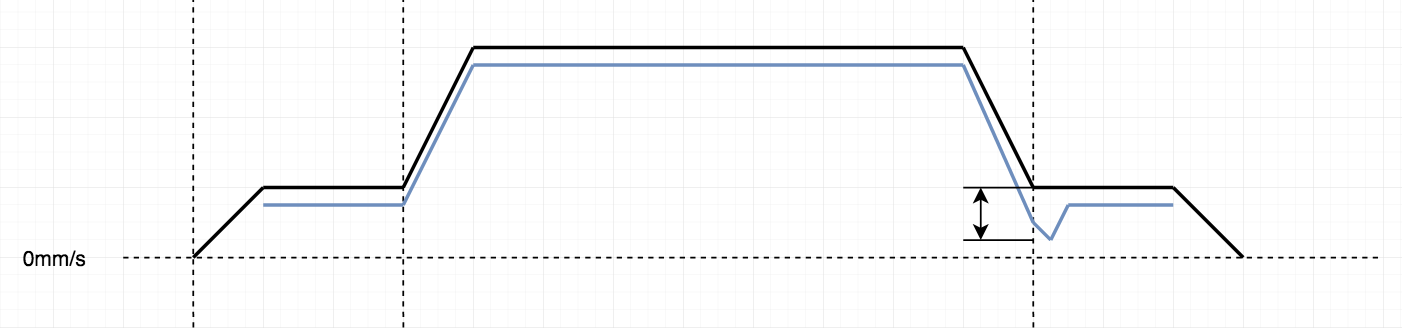

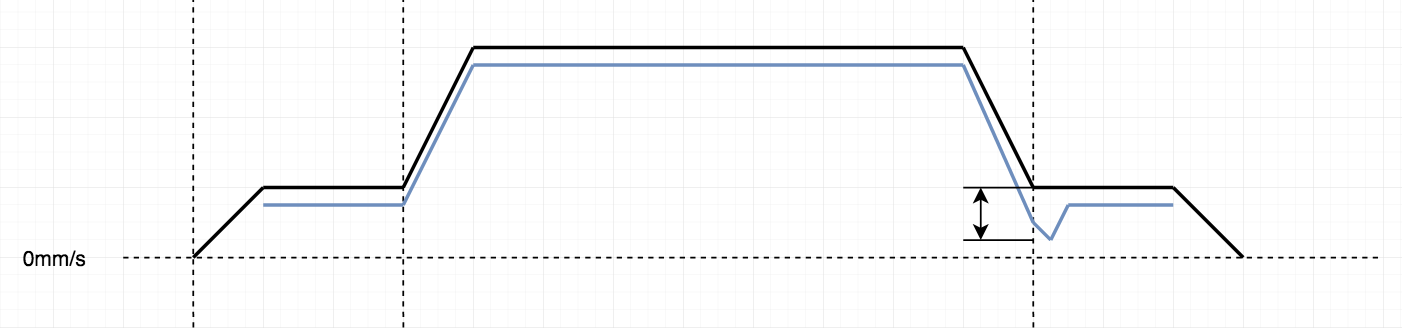

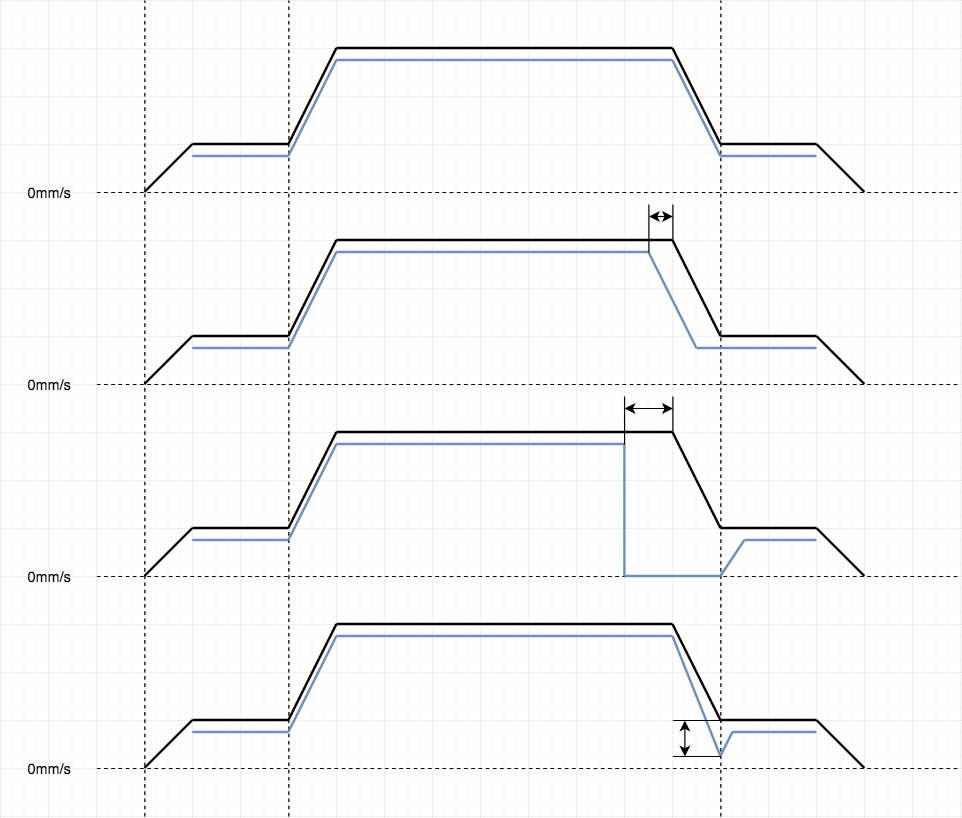

My understanding is, that the planner never moves faster than the nominal speed of a block. In case of the LA test pattern, that would mean the speed profile should look roughly like this:

So the deceleration happens right up to the 60 mm line, at which the second slow segment begins. For anybody accustomed to Marlin movement code: Is this correct?

I am seeing exactly the same result with bulge in the deceleration zone.

I have tried to switch all kind of features off (including s_curve, JD), but it does not seem to matter - the blob stays present.

Is it possible that the flow decrease happens too late in relation to the deceleration? It looks like the deceleration happens and while it being decreased the flow decrease follows - but a bit too late.

- Using an Ender 3 Pro with opgraded parts and newest marlin.

I'm also seeing this bulge on the LA calibration pattern regardless of K-value.

@thinkyhead Has anyone looked at Prusa Firmware to see if their algorithm is significantly different?

Looking at Prusa's stepper.cpp history, indeed they have put significant work into linear advance since merging LA v1.5 one year ago. They've made enough changes that their April 8, 2020 commit mentions "[...] removing the last vestiges of the original implementation [...]"

Same issue with my E3Pro, all stock, branch 2.0.x. Printing test pattern (from marlinfw site) with K=0..2 and 0.1 step produces good results (same width) on acceleration side (left) starting at K=1. But on entire range from 0 to 2 there is bulge on slow part on right. I think this issue is mostly with Bowden setups. When accelerating, it adds pressure to keep line width, but it is not retracting fast enough (or not enough volume) on slow down (because of Bowden). In my understanding, this happen because of same amount of filament is being pushed on acceleration and retracted on slow down. Probably, Bowden needs two separate K - one for acceleration, another for slowdown. May be this will work better.

I think this issue is mostly with Bowden setups. When accelerating, it adds pressure to keep line width, but it is not retracting fast enough (or not enough volume) on slow down (because of Bowden). In my understanding, this happen because of same amount of filament is being pushed on acceleration and retracted on slow down. Probably, Bowden needs two separate K - one for acceleration, another for slowdown. May be this will work better.

From what I'm seeing, the slowdown is not the problem. If you measure it, you will see that the blob occurs _after_ the slowdown (so, by default less than 20 mm before the end of the line). The blob appears when printing at constant speed in the beginning of the slow last segment. At least that's what I observe on my prints.

I also did a couple of experiments some weeks ago, by altering stepper.cpp and planner.cpp:

- Force LA to reduce the advance steps 2 mm earlier: Line thins during deceleration, but blob on short segment is still present.

- Force LA to reduce advance steps twice as fast: Line thins during decelration, but blob on short segment is still present.

- Increase or decrease

Konly for the deceleration phase: Various effects on line thickness, blob still present.

I'm not sure if the problem is sort of a delay, or if it rather is a hysteresis. I'm now looking into altering LA in the slow last segment, where the print head is essentially just cruising.

To diagnose the problem further, I changed a couple of lines in stepper.cpp to slow down the increase in advance steps. Lines 2273 - 2278 by default looks like this (comment omitted):

else if (step_events_completed < decelerate_after && LA_current_adv_steps < LA_max_adv_steps) {

LA_steps++;

LA_current_adv_steps++;

interval = LA_isr_rate;

}

For a 2x slowdown, I changed it to

else if (step_events_completed < decelerate_after && LA_current_adv_steps < LA_max_adv_steps) {

if (step_events_completed % 2 == 0) {

LA_steps++;

LA_current_adv_steps++;

}

interval = LA_isr_rate;

}

So we're only increasing LA_steps on every second step.

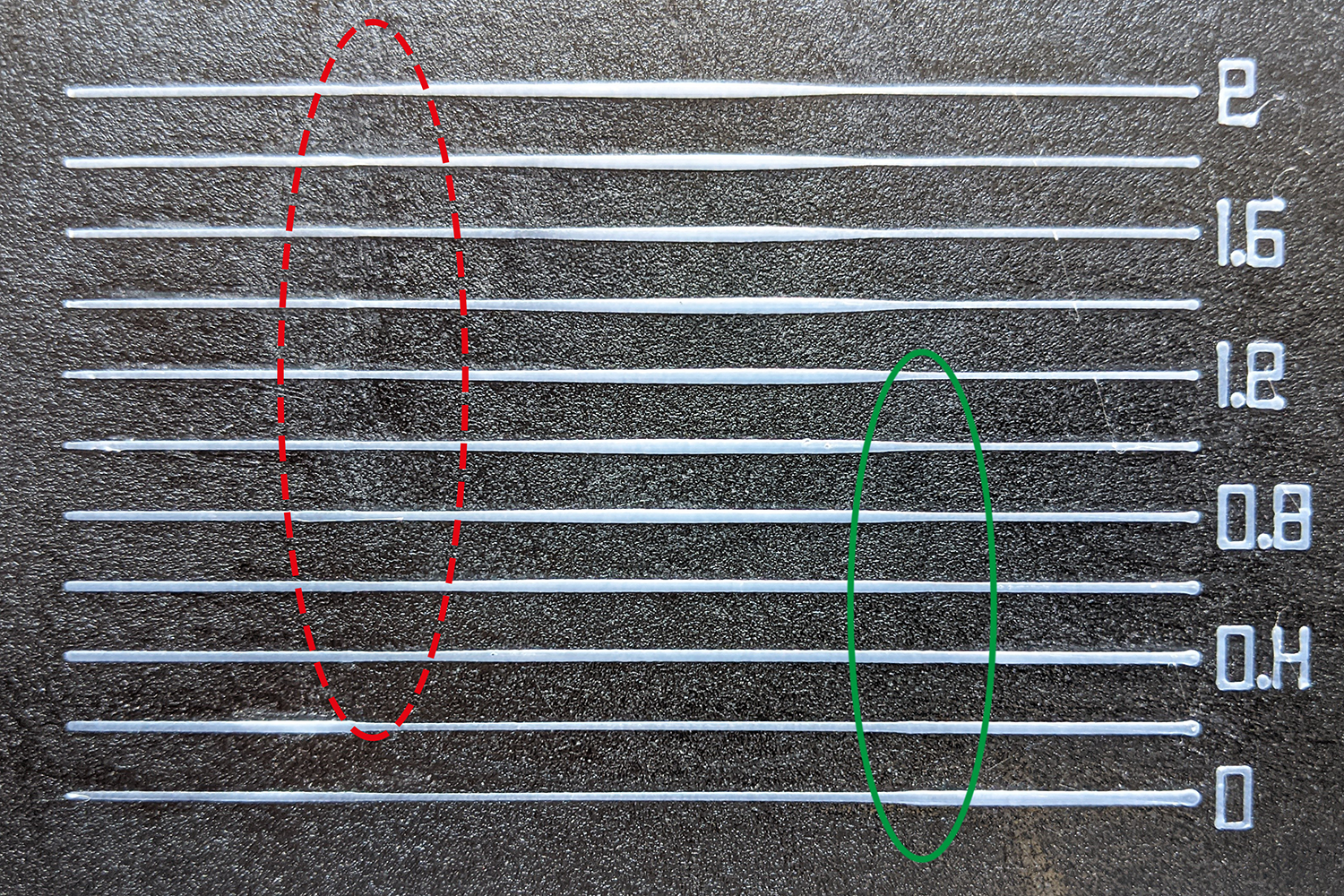

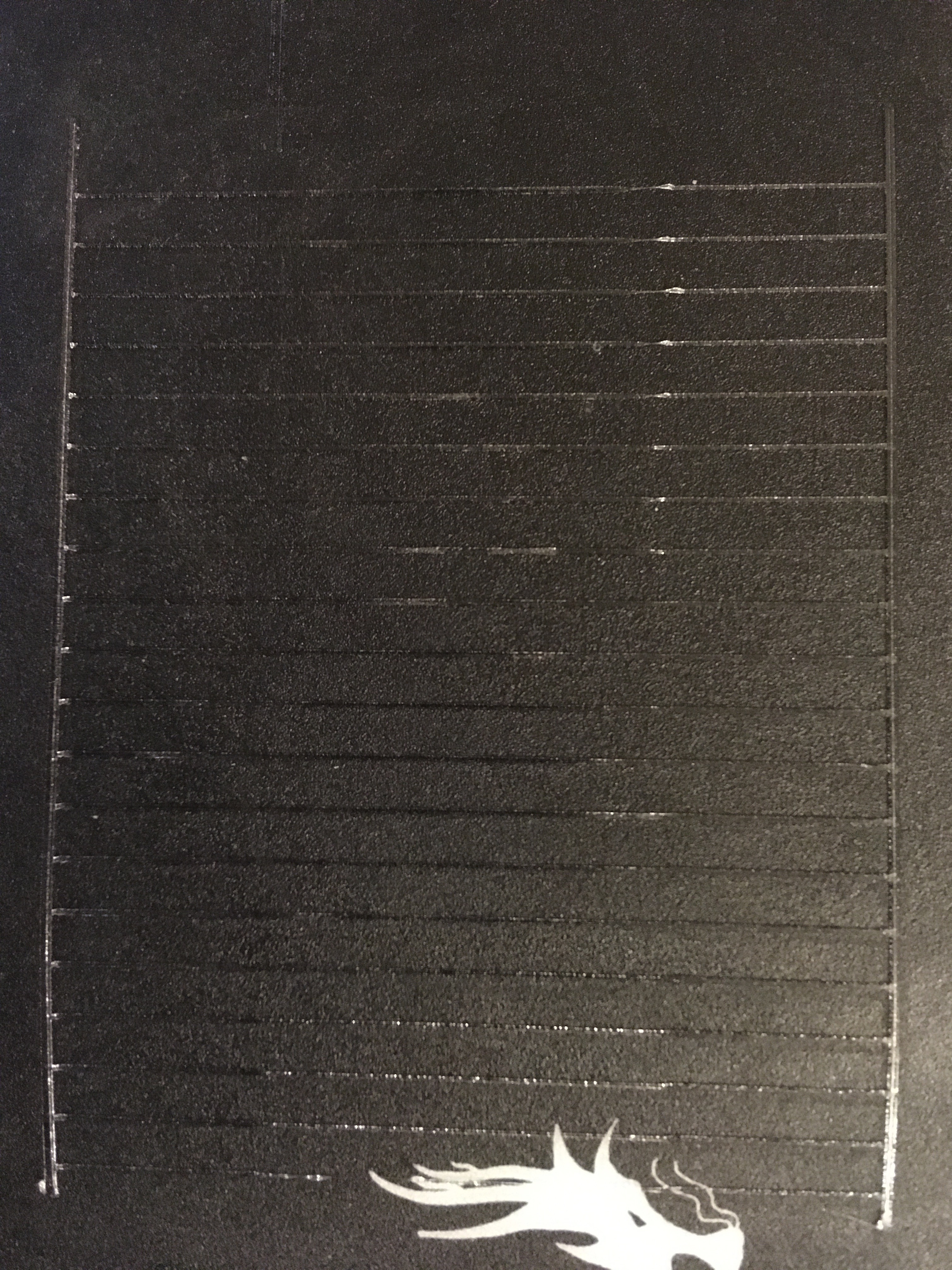

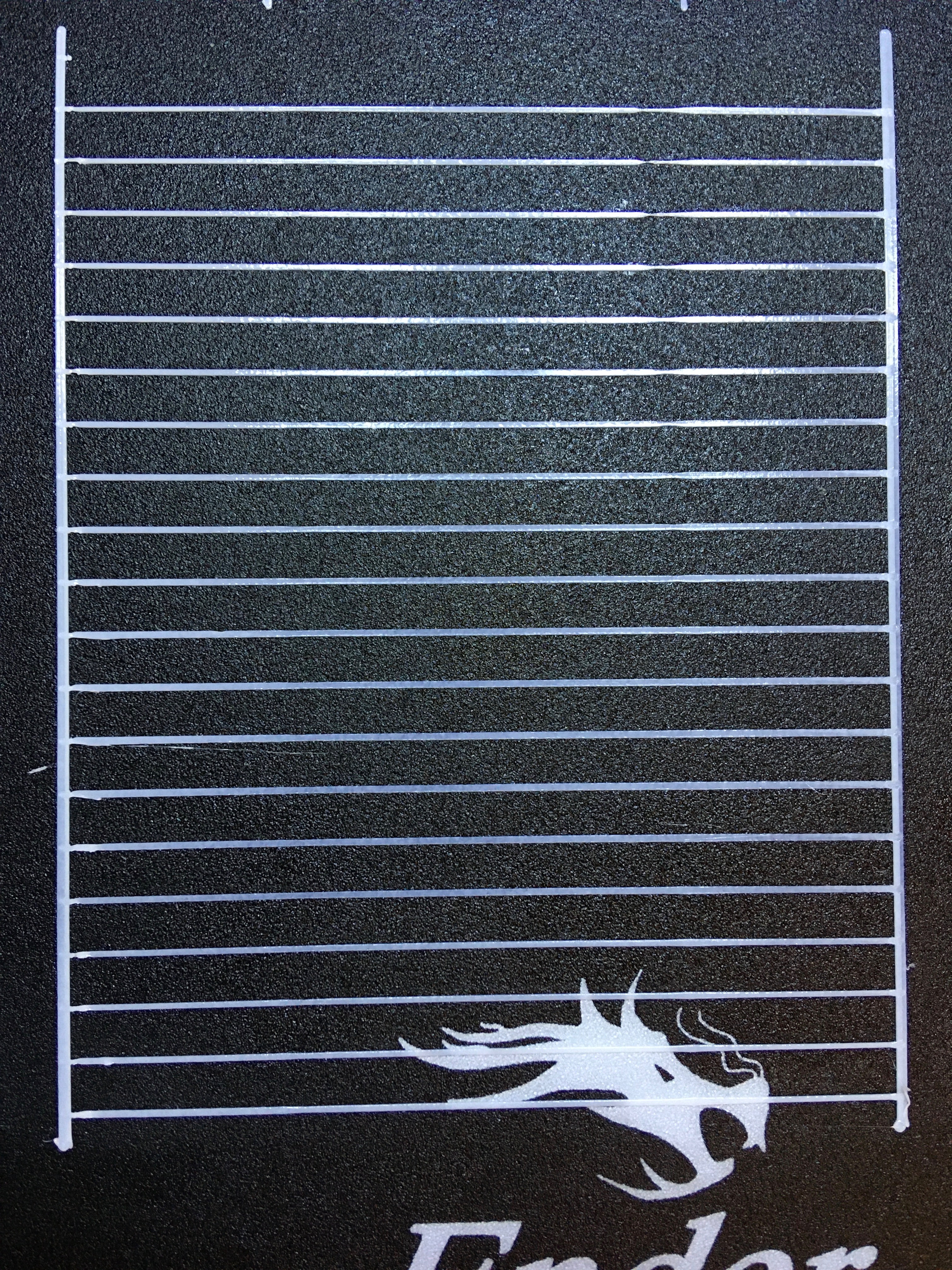

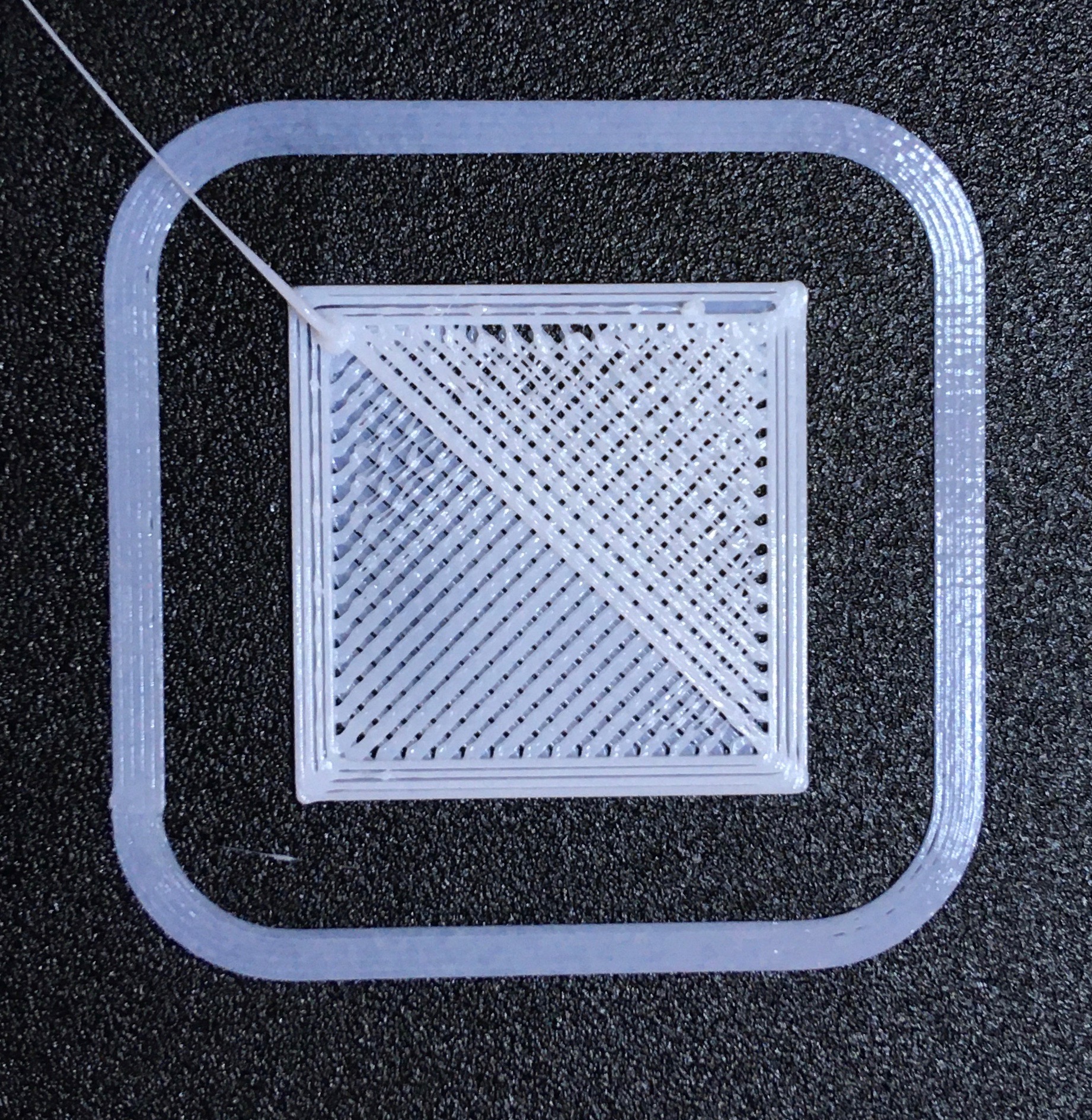

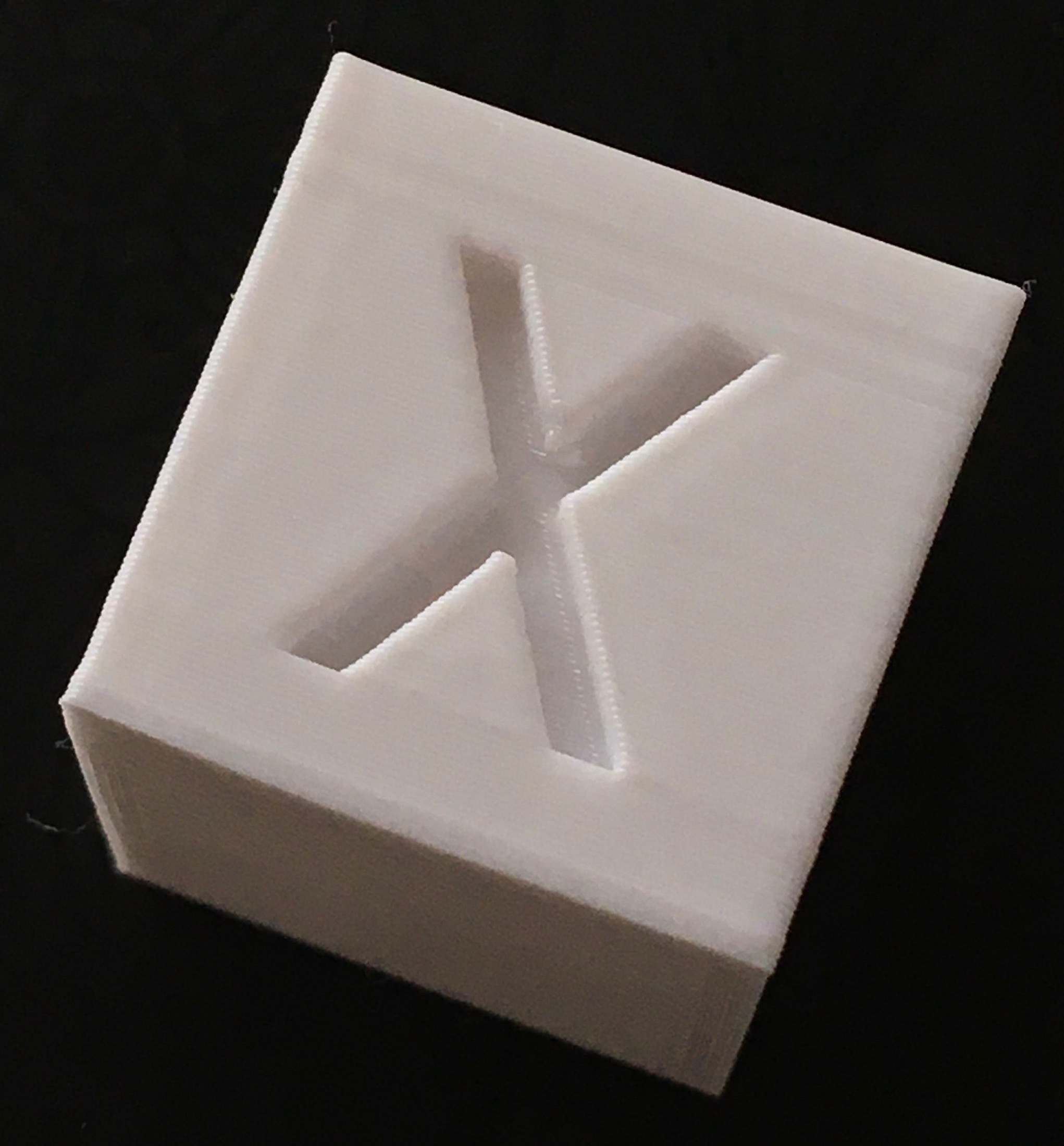

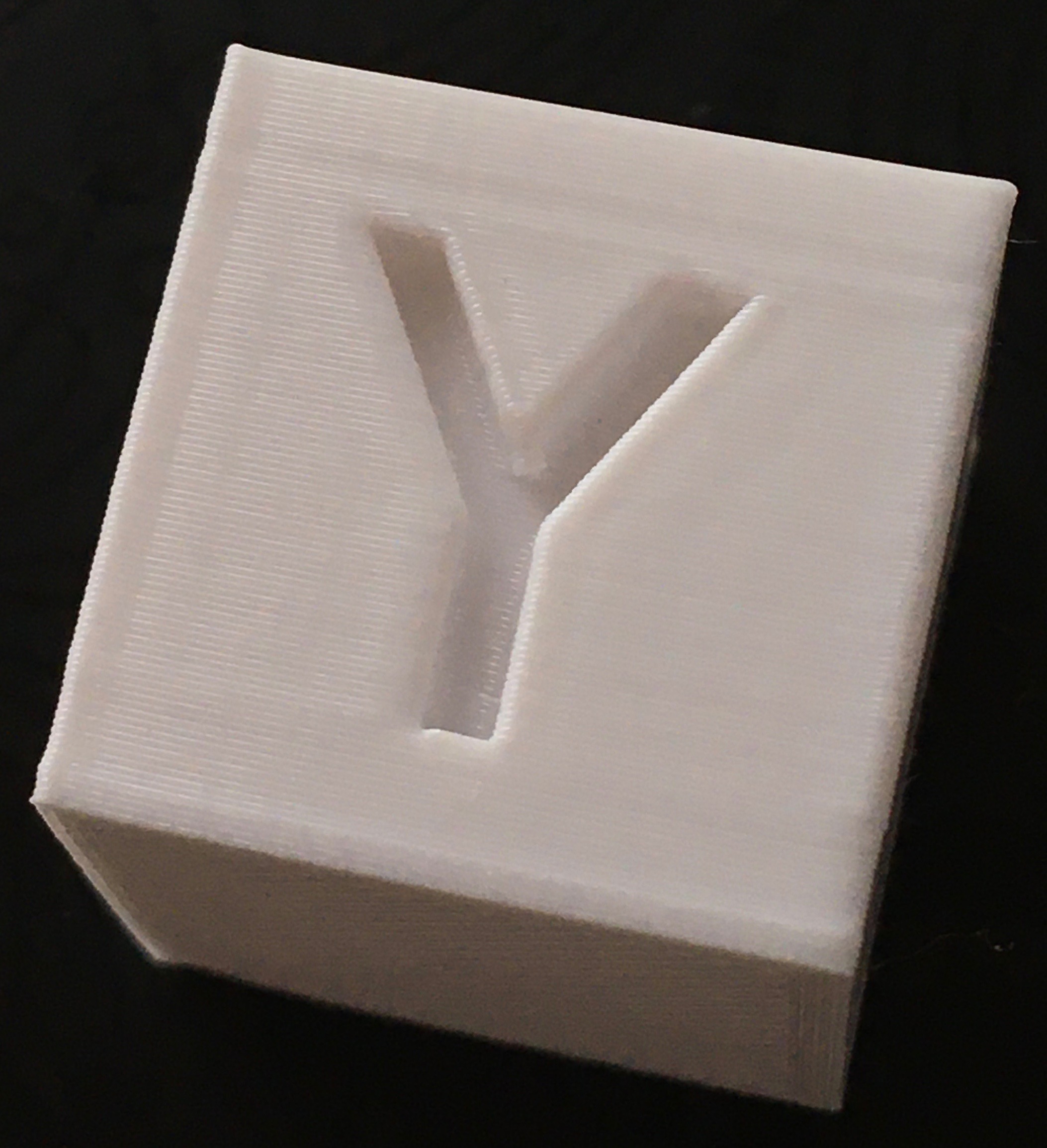

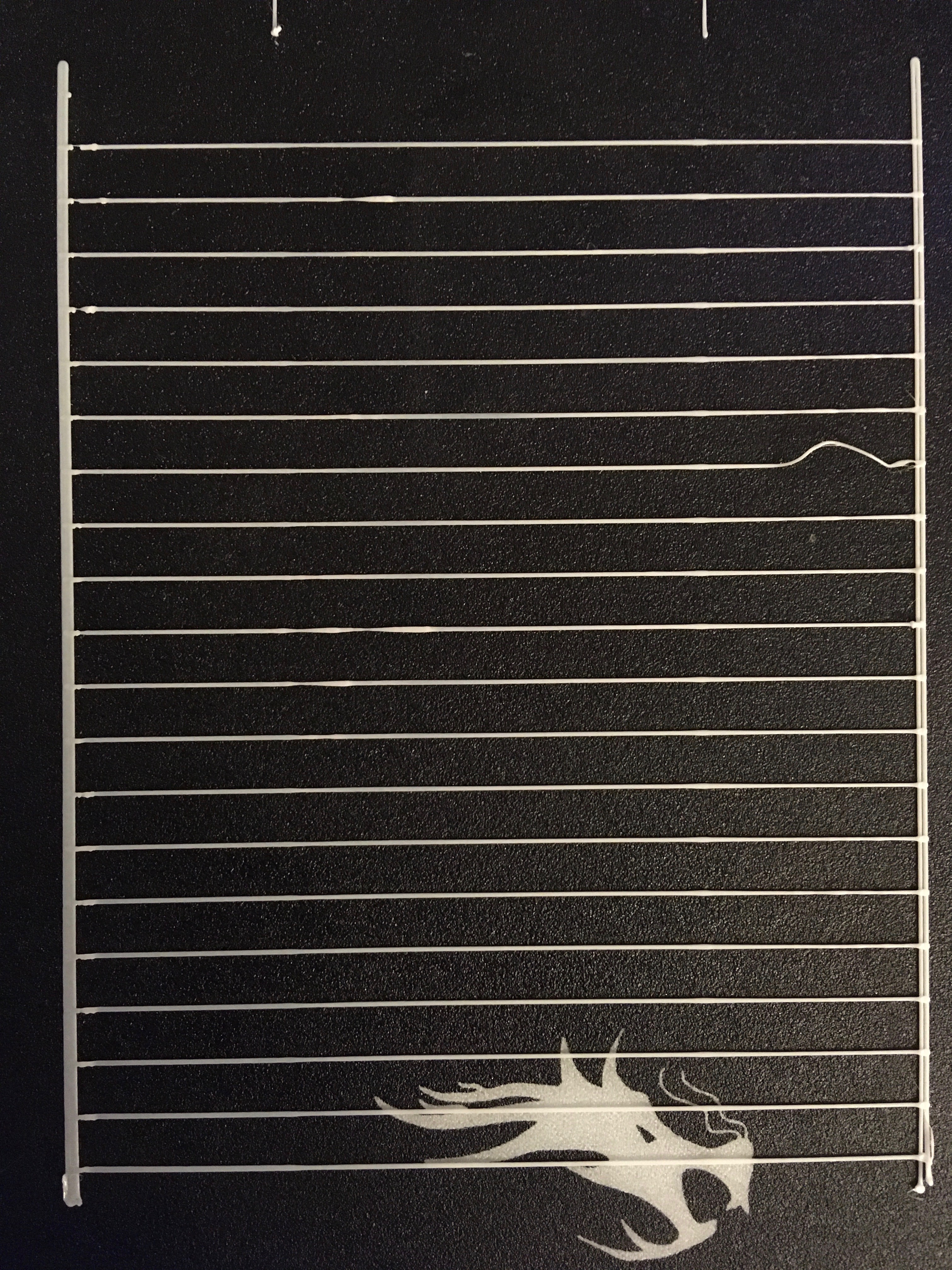

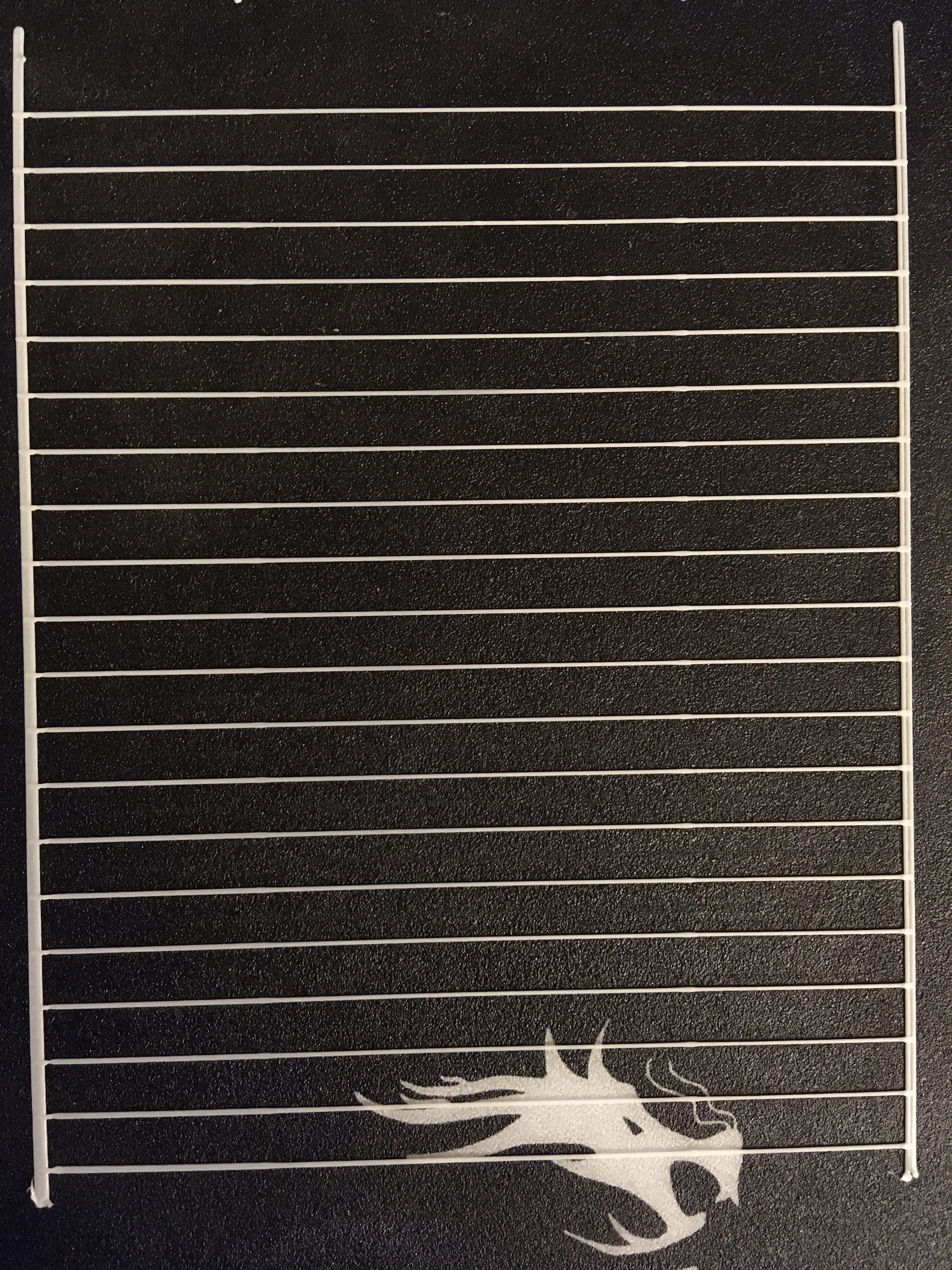

The resulting LA test pattern with the same GCode I used before looks like this:

Now there's two things to note, here:

- Green ellipse 🟢 : All blobs after the slowdown are gone. The lines are not perfectly even, but damn close. Also, note that this is the coarse initial test pattern, and further tuning might result in even cleaner lines.

- Dashed red ellipse 🔴 : As a side effect of the slower advance step increase, the faster segments now suffer in the beginning. This is expected and could be rectified by _only_ applying the slower advance increase after a deceleration phase.

Conclusions:

- 80-90% of the blob is located in the slow segment (-> after a deceleration phase, not during that phase). Therefore, any fix should affect mainly the beginning of slow segments which follow on a deceleration.

- It looks like LA is increasing the advance steps too fast for segments which are preceeded by faster segments (-> after a deceleration).

- The actual cause may be a bug in the code I don't see, or it may be a mechanical oddity of the extruder system.

- I originally suspected this to be a problem exclusive to bowden setups, but direct drive users reported the same bulges in this issue.

I'm not familiar with how LA works (yet), but from Your explanation I see that it's not that easy as I thought :) Anyway, for me it seems like this algorithm missing something from real world physics and this is why we have extra filament where we don't expect it. I just checked my test (from 0 to 2 with 0.1 step) and yes, all blobs appear right at the beginning of slow segment. Attached pic, sorry for poor quality.

It looks like LA is increasing the advance steps too fast for segments which are preceeded by faster segments (-> after a deceleration).

So, may be this is where second K for deceleration is needed? Seems acceleration and deceleration need different advance for some reason. And I think for different setups, it will be different. So, fixed difference won't work.

Hmm, may be I understand wrong, but this part works when accelerating?

else if (step_events_completed < decelerate_after && LA_current_adv_steps < LA_max_adv_steps) {

if (step_events_completed % 2 == 0) {

LA_steps++;

LA_current_adv_steps++;

}

interval = LA_isr_rate;

}

Shouldn't we modify this part instead? And may be decrease steps -=2 ? So we decrease advance twice faster?

if (step_events_completed > decelerate_after && LA_current_adv_steps > LA_final_adv_steps) {

LA_steps--;

LA_current_adv_steps--;

interval = LA_isr_rate;

}

Hmm, may be I understand wrong, but this part works when accelerating?

else if (step_events_completed < decelerate_after && LA_current_adv_steps < LA_max_adv_steps) { if (step_events_completed % 2 == 0) { LA_steps++; LA_current_adv_steps++; } interval = LA_isr_rate; }

Partly wrong: It is responsible for the acceleration and cruising phase. And the latter is the one we need to modify.

Shouldn't we modify this part instead? And may be decrease steps -=2 ? So we decrease advance twice faster?

if (step_events_completed > decelerate_after && LA_current_adv_steps > LA_final_adv_steps) { LA_steps--; LA_current_adv_steps--; interval = LA_isr_rate; }

No. I tested and mentioned this in my previous post, altough I may not have stated it clear enough. It does not eliminate the blob.

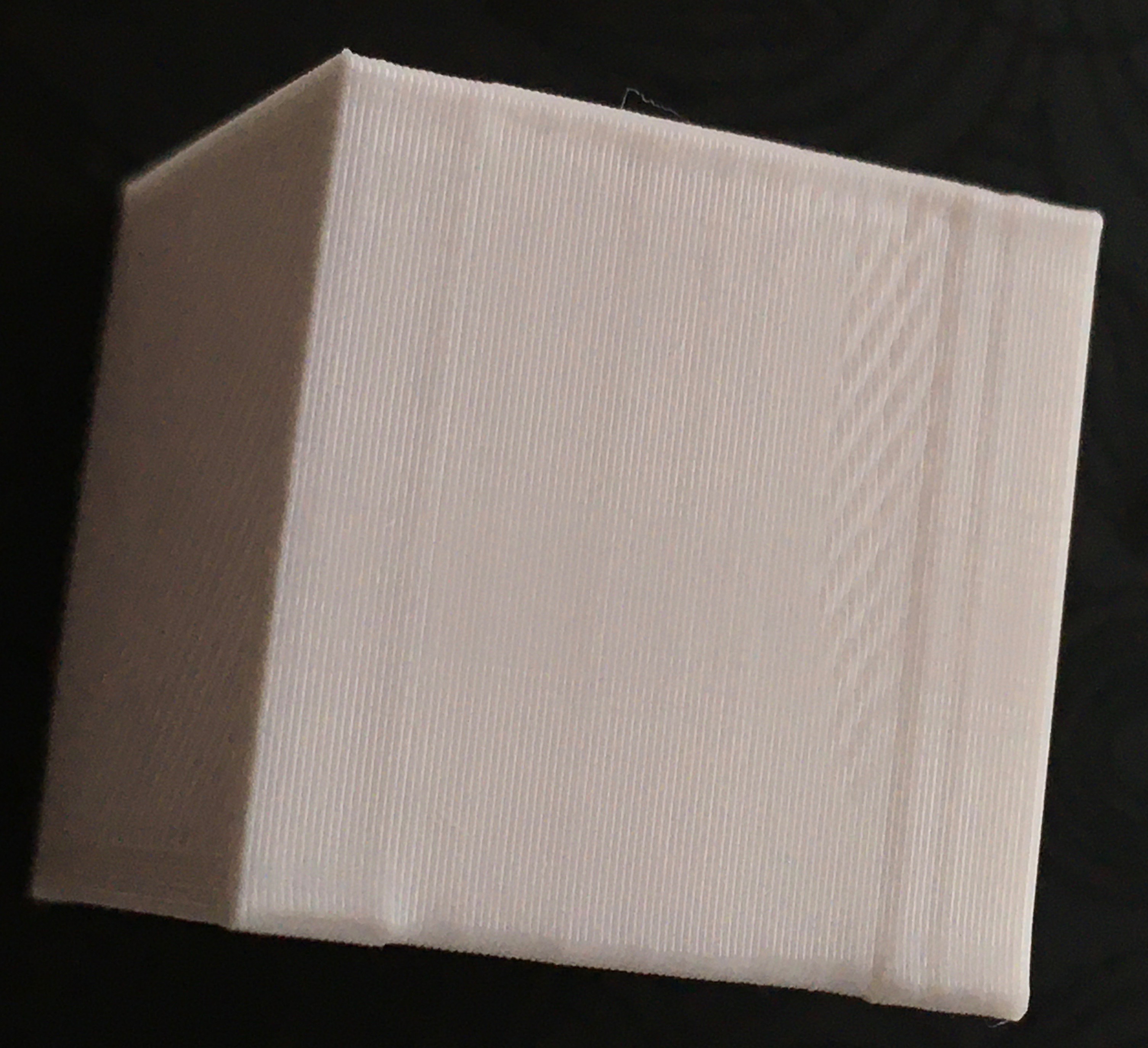

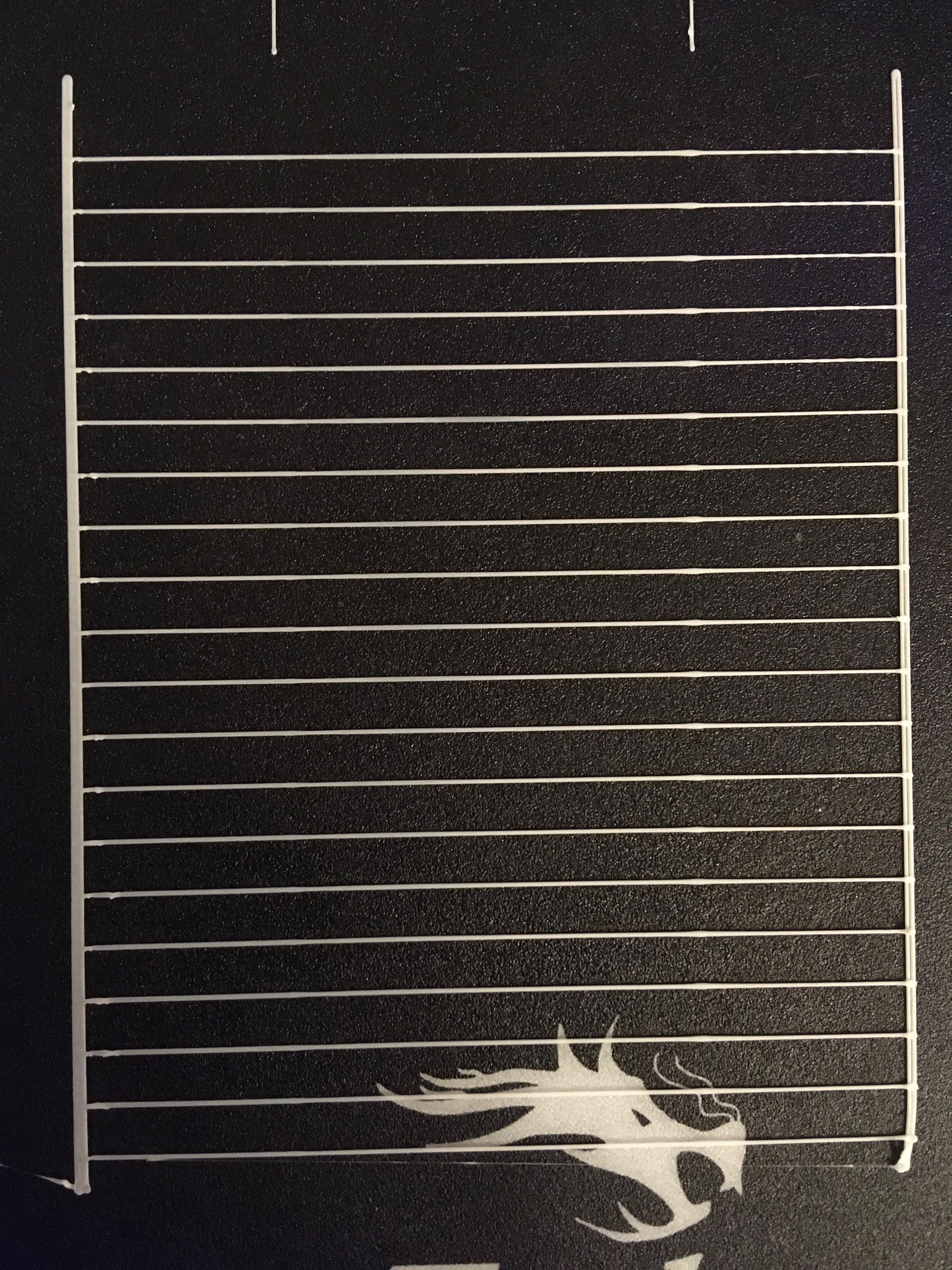

Here is the result for a doubled LA_steps-- & LA_current_adv_steps--:

It helps a bit (maybe 20% less volume to the blob), but it also creates a lack of filament right before the blob, at the end of the fast segment. The main problem is the beginning of the slow segment - so the beginning of a cruising phase.

- I originally suspected this to be a problem exclusive to bowden setups, but direct drive users reported the same bulges in this issue.

I will say, I converted my enders to direct drive to test LA, and while there may still be a bit of bulge in the test, (i've almost completely foregone using that test as a testing method) when running test towers comparing bowden to to direct drive, the direct drive towers act as one would assume. Corners bulge and Z seam bulge, then they smooth out into "sharp" corners and a, relatively, flat Z seam, and as the K value increases the corners and Z seam suck in.

When running the same test on the bowden setup, the corners and Z seam do not change, however, artifacts will begin to appear. I.E., under-extrusion due to high K values. Please note, 0 corner and Z seam change was noted from 0 to K 1.65 on bowden.

Apologies I can't help out with the firmware side of things, but hopefully that info is somewhat helpful.

XDA-Bam, I was sure that LA affect only acceleration and deceleration parts of segment. Now I see that it completely handles pressure advance on entire segment. So, now I reading source to get understanding how things work. But I have strong feeling, that after deceleration, at end of segment, there is some extra pressure left in nozzle. And this volume is being over extruded on slow part, in addition to normal amount. May be logging values of LA_* variables when segment is finished will shed some light? This is what I found: https://marlinfw.org/docs/features/lin_advance.html

During the block runtime, the pressure will be advanced until the precalculated needed extra step amount is reached or the deceleration is started. During deceleration we reduce the advance step amount until we reach the amount for final speed or the block comes to an end. This checks are necessary as Marlin uses an approximation for acceleration calculation as mentioned above. Therefore, for example, we might not reach the final pressure at end of move perfectly but that’s not important as this error will not cumulate.

So, yes, it is not cumulating, but may be producing this bulb?

At Your last test 0.6 line looks very good. And under extrusion at end of fast line happen because decreasing pressure advance two times faster than it should be for this part. It corresponds to 2xK for deceleration. I feel that decrease speed of LA_current_adv_steps should be slightly faster than increase, so when segment complete, there will be zero or slightly negative pressure in nozzle.

XDA-Bam, I was sure that LA affect only acceleration and deceleration parts of segment. Now I see that it completely handles pressure advance on entire segment. So, now I reading source to get understanding how things work. But I have strong feeling, that after deceleration, at end of segment, there is some extra pressure left in nozzle.

Yes, there is a small amount of pressure left. You can see from my tests, that if this pressure is reduced to near zero (either by reducing advance steps 2 mm earlier, or by reducing them twice as fast), the bulge is reduced a little bit. Maybe by 20%, maybe it's even 30%. But it is still there.

And this volume is being over extruded on slow part, in addition to normal amount.

According to my tests, this is definietly not what's happening. Look at the results again - the bulge is still there, even if all pressure is bled from the nozzle before the slow segment begins. I am fairly certain that the problem is the increase of advance steps in the beginning of the slow segment. And reducing this increase in the slow segment has eliminated the bulge. If that doesn't prove where the problem originates, I don't know what will.

But feel free to test yourself and hopefully you will come to the same conclusion. Four eyes do see more than two.

May be logging values of LA_* variables when segment is finished will shed some light?

That will certainly be helpful.

This is what I found: https://marlinfw.org/docs/features/lin_advance.html

...

So, yes, it is not cumulating, but may be producing this bulb?At Your last test 0.6 line looks very good. And under extrusion at end of fast line happen because decreasing pressure advance two times faster than it should be for this part. It corresponds to 2xK for deceleration.

Yes, that's why the underextrusion happens. And at that point, right at the 60 mm mark, there will be very little pressure left in the nozzle - we're printing with zero advance at high speeds. And yet, the bulge is still there in the small segment!

I feel that decrease speed of LA_steps should be slightly faster than increase, so when segment complete, there will be zero or slightly negative pressure in nozzle.

I agree somewhat: We will probably need to _also_ increase the reduction of advance steps while decelerating to totally fix our issue. But you can try - my tests show, that we won't get rid of the bulge this way. It helps, but only a small amount. We will also need to slow down the increase of advance steps directly after the deceleration, during the cruising phase.

Hmm... Here is our line:

G1 X85 Y37.5 E0.7982 F1200 ; print line

G1 X125 Y37.5 E1.5965 F4800 ; print line

G1 X145 Y37.5 E0.7982 F1200 ; print line

First (slow) segment starts from zero, and last segment starts from some non-zero speed? And LA doesn't take this into account and calculating advance steps like if we start from zero?

Not sure if LA assumes that we start from zero speed. But step_events_completed < decelerate_after (in this line) is certainly true at the 60 mm mark (beginning of second slow segment). And LA_current_adv_steps < LA_max_adv_steps seems to be true, too. Otherwise, my fix/hack with the slower step increase wouldn't work.

I assumed, that LA_current_adv_steps = LA_max_adv_steps at the beginning of the second slow segment: The final speed at the end of the fast segment is exactly the same as the speed at the beginning of the slow one. Consequently, the number of advance steps should be the same, right? 🤔

Of yourse, that would only be true, if the current advance steps are carried over from one segment to the next. If they are forgotton each time the segment changes, LA_current_adv_steps = 0 would be true at the beginning of the last slow one. Which is it?

Hmm.. that's good question. In my understanding, there should be no advance at all at beginning of second slow segment, as we are already at cruise speed and extruder feeds proper amount of filament. Here is how I see this:

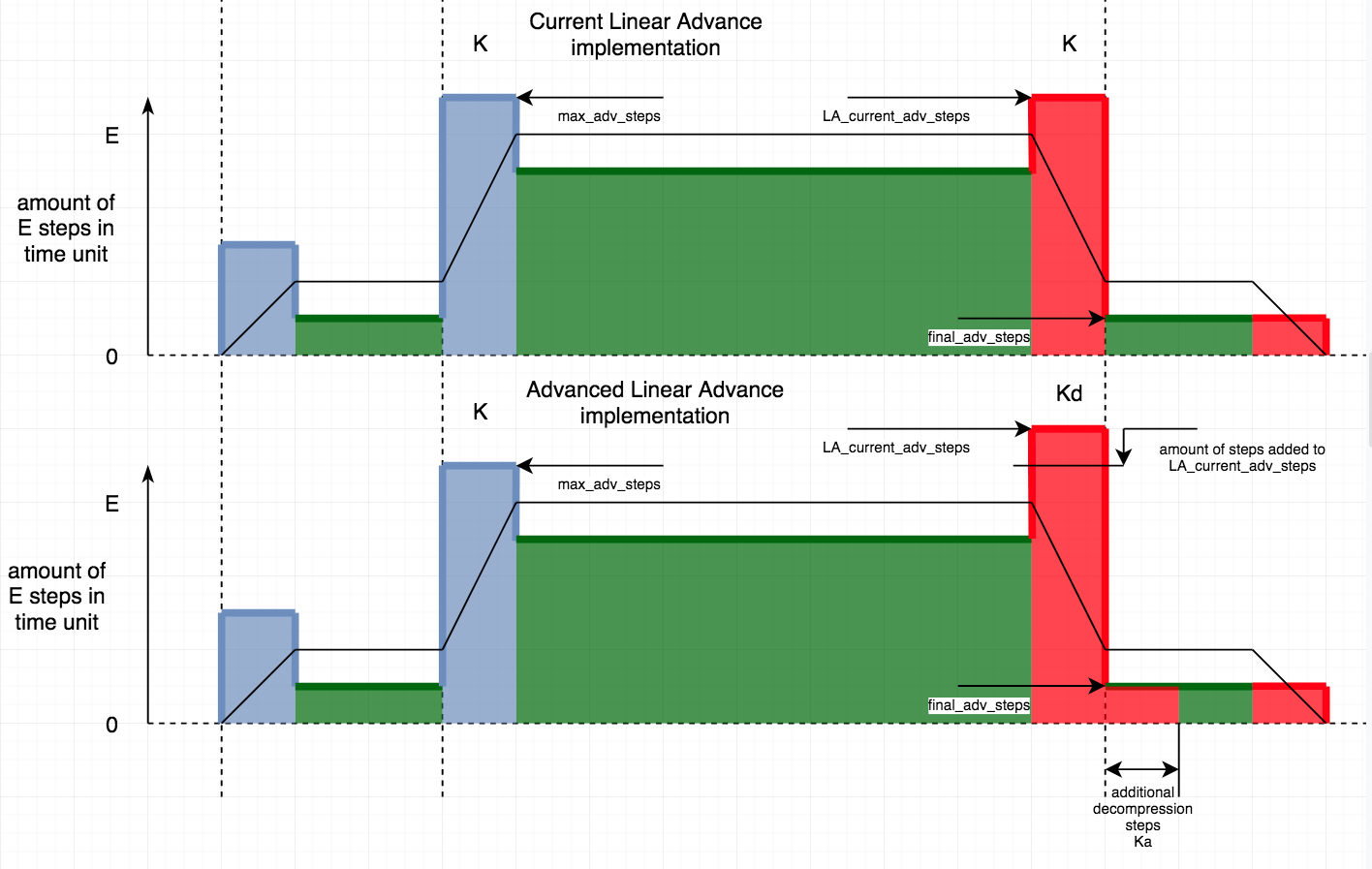

First graph show how it really goes, and second how LA interprets it and pushing some extra filament on beginning of second slow segment like if it was starting from zero. I don't know (yet) if this is what happen, but this my suggestion.

So, seems You're right - there should be no advance at beginning of second slow segment.

So, definitely, we need to log all LA_* values at start and end of each segment. This will give us more information on what's going on.

Hmm.. that's good question. In my understanding, there should be no advance at all at beginning of second slow segment, as we are already at cruise speed and extruder feeds proper amount of filament.

Not 100% sure, but yeah. Looks like there's a problem.

First graph show how it really goes, and second how LA interprets it and pushing some extra filament on beginning of second slow segment like if it was starting from zero. I don't know (yet) if this is what happen, but this my suggestion.

That's a nice way to visualize it.

So, this is what I see in planner:

#if ENABLED(LIN_ADVANCE)

if (block->use_advance_lead) {

const float comp = block->e_D_ratio * extruder_advance_K[active_extruder] * settings.axis_steps_per_mm[E_AXIS];

block->max_adv_steps = current_nominal_speed * comp;

block->final_adv_steps = next_entry_speed * comp;

}

#endif

and in stepper:

// Initialize the trapezoid generator from the current block.

#if ENABLED(LIN_ADVANCE)

#if DISABLED(MIXING_EXTRUDER) && E_STEPPERS > 1

// If the now active extruder wasn't in use during the last move, its pressure is most likely gone.

if (stepper_extruder != last_moved_extruder) LA_current_adv_steps = 0;

#endif

if ((LA_use_advance_lead = current_block->use_advance_lead)) {

LA_final_adv_steps = current_block->final_adv_steps;

LA_max_adv_steps = current_block->max_adv_steps;

initiateLA(); // Start the ISR

LA_isr_rate = current_block->advance_speed;

}

else LA_isr_rate = LA_ADV_NEVER;

#endif

So, final_adv_steps of fast segment must be same as max_adv_steps of last slow segment. In this case no extra E steps will be executed. But how we can check if this is true?

And yes, it seems that LA_current_adv_steps always starts from zero. Somehow, it must inherit value from previous block.

Is there any place at stepper/planner where we can pull LA_current_adv_steps from previous block?

s there any place at stepper/planner where we can pull LA_current_adv_steps from previous block?

No.

LA_current_adv_steps is a privat from stepper class - it's existing only once.

Maybe you can save it to an new variable when leaving/deleting or entering a block.

The second graph is looking as if the third block is not properly connected to the second. This will (for example) happen when the second block is already stepped when the third is planned (planner buffer not full enough).

is a privat from stepper class.

Maybe you can save it to an new variable when leaving/deleting a block.

Memory scope is always confuse me:( So, is it keeps its value since initialized at startup? Or being reset to zero each time? And if reset - when this happen? I can't find any assignment in code except declaration.

As to second graph - it is my vision of how advance is calculated. This blob looks like more E steps was executed at beginning of last segment as if it was starting from zero speed (with acceleration). So, it's not reflecting real motion :)

#if ENABLED(LIN_ADVANCE)

#if DISABLED(MIXING_EXTRUDER) && E_STEPPERS > 1

// If the now active extruder wasn't in use during the last move, its pressure is most likely gone.

if (stepper_extruder != last_moved_extruder) LA_current_adv_steps = 0;

#endif

When setting up a new block LA_current_adv_steps should have the value left over from the previous.

When setting up a new block LA_current_adv_steps should have the value left over from the previous.

Yes, that's what I thought. But here (https://marlinfw.org/docs/features/lin_advance.html) it says:

Therefore, for example, we might not reach the final pressure at end of move perfectly but that’s not important as this error will not cumulate.

That means to me that LA_current_adv_steps is being reset every block. Or am I getting it wrong? There is no other place in code where it sets value of LA_current_adv_steps. So, how do I find out value of LA_current_adv_steps at block setup? If I properly understand how things work, at beginning of last slow segment LA_current_adv_steps must equal LA_max_adv_steps so no extra E steps executed. But not sure if this is true.

Yes, that's what I thought. But here (https://marlinfw.org/docs/features/lin_advance.html) it says:

Don't go by what the documentation says it should do. Go by what the code is actually doing 😉

When setting up a new block

LA_current_adv_stepsshould have the value left over from the previous.

In that case, it's probably best to check whether this is actually the case when printing the LA test pattern. So, as @sbasmanov suggested, we need to debug it while running. I'm still waiting for a cable to be able to set this up on my printer, so I can't help with that right now.

My guess is that the error is not accumulating because the error is transferred to the new block via LA_current_adv_steps. In the new block that number of additional steps is done to reach the new value. (At least, i guess, that is the plan.)

I'm still waiting for skr board, as mine (original) behave very strange - after two-three times I update firmware it may stop booting at all, so I have to connect Pi, erase, flash bootloader and only after it will work again. So, I don't want to touch it while it works :)

But I think we can try to simulate this situation if we can figure out at block setup if we already at cruise speed and there is no need to accelerate. If this is possible, we can put 'LA_current_adv_steps=LA_max_adv_steps' right after setup, after line 2150: https://github.com/MarlinFirmware/Marlin/blob/6c994002af1ef13004490b5e15501e6cdc70dd88/Marlin/src/module/stepper.cpp#L2150

In the new block that number of additional steps is done to reach the new value. (At least, i guess, that is the plan.)

That looks like real. So, probably in case when no acceleration is needed and head already at cruising speed, we don't want these extra steps to be executed. Am I right? That means LA_current_adv_steps==LA_max_adv_steps must be true.

My guess is that the error is not accumulating because the error is transferred to the new block via

LA_current_adv_steps. In the new block that number of additional steps is done to reach the new value. (At least, i guess, that is the plan.)

I think it doesn't accumulate, because we increase LA_current_adv_steps until we reach LA_max_adv_steps in _each_ block. At that point, the error will be zero again. Maybe we're saying the same thing, not sure.

However, regardless of the error we start out with at the beginning of a block (which is only non-zero, if LA_final_adv_steps has not been reached), the code always increases LA_current_adv_steps until the desired value is reached. So, if LA_final_adv_steps has not been reached in the last block, LA_current_adv_steps will be too high in the current one - and we will also begin to increase it right away. In that case, our advance will be consistently too high from some point in the deceleration phase of the last block, until a couple of steps _after_ we reach LA_max_adv_steps in our current block. That's not good.

I assume that the opposite case - LA_final_adv_steps being undercut and LA_current_adv_steps being too low at the start of the next block - should never happen. At least I don't currently see how it could.

So, if LA_final_adv_steps has not been reached in the last block, LA_current_adv_steps will be too high in the current one - and we will also begin to increase it right away.

It will not increase as it will increment only when LA_current_adv_steps < LA_max_adv_steps and LA_max_adv_steps should be same as LA_final_adv_steps from previous block.

Anyway, I think that value of LA_current_adv_steps is not root of problem. Remember, when You decreased it twice faster? It was definitely reaching LA_final_adv_steps before end of block. And that didn't affected blob significantly. That means, even if LA_current_adv_steps reached LA_final_adv_steps and next block have same value of LA_max_adv_steps (so no extra E steps), there is still too much pressure in nozzle. And this is where I think that pressure should go lower than needed in next block. Here is what I mean:

May be we should adjust final_adv_steps in planner, so it is less than max_adv_steps of next block?

if (block->use_advance_lead) {

const float comp = block->e_D_ratio * extruder_advance_K[active_extruder] * settings.axis_steps_per_mm[E_AXIS];

block->max_adv_steps = current_nominal_speed * comp;

block->final_adv_steps = next_entry_speed * comp;

For test it could be:

if(next_entry_speed < current_nominal_speed) block->final_adv_steps = next_entry_speed * comp * 0.5;

else block->final_adv_steps = next_entry_speed * comp;

At least we will see how it will affect blob (and where).

It will not increase as it will increment only when LA_current_adv_steps < LA_max_adv_steps and LA_max_adv_steps should be same as LA_final_adv_steps from previous block.

True, in our case it should not increase it further. LA_current_adv_steps might still be too high (>LA_max_adv_steps), though. This was more of a general idea - it might not happen in our case, but it looks like a possible bug in LA.

Anyway, I think that value of LA_current_adv_steps is not root of problem. Remember, when You decreased it twice faster? It was definitely reaching LA_final_adv_steps before end of block. And that didn't affected blob significantly.

True. But that only tells us that LA_current_adv_steps = LA_final_adv_steps is reached at the end of the fast block. It does not tell us what happens to LA_current_adv_steps at the beginning of the second slow block. I still think that our problem originates there.

That means, even if LA_current_adv_steps reached LA_final_adv_steps and next block have same value of LA_max_adv_steps (so no extra E steps), there is still too much pressure in nozzle.

But my tests also show, that LA_current_adv_steps seems to be increased at the beginning of the last slow block, because halving the increase rate got rid of the blobs 🤔 It shouldn't happen - you're right. But it seems to me, that it does happen nonetheless. Maybe you should test it, too. Maybe there was a problem with my machine or test method.

True. But that only tells us that LA_current_adv_steps = LA_final_adv_steps is reached at the end of the fast block. It does not tell us what happens to LA_current_adv_steps at the beginning of the second slow block. I still think that our problem originates there.

If I understand properly, Stepper class is not initialized on start of each block. It means that LA_current_adv_steps keeps its value where it was at end of previous block. And look at planner, how it calculates values for current block:

block->max_adv_steps = current_nominal_speed * comp;

block->final_adv_steps = next_entry_speed * comp;

So, for fast block, final_adv_steps will be same as max_adv_steps for slow block, when it will come to this point at planner. So, here will be no additional E steps.

But my tests also show, that LA_current_adv_steps seems to be increased at the beginning of the last slow block, because halving the increase rate got rid of the blobs 🤔 It shouldn't happen - you're right. But it seems to me, that it does happen nonetheless. Maybe you should test it, too. Maybe there was a problem with my machine or test method.

Well, we don't know if it increasing or not until we log this values. Now we can only guess :) Here is what I think about this: when accelerating, we increase E speed in advance, that means more filament coming to extruder. To handle this, more heat is needed to melt increased amount of filament. This raises nozzle temperature to compensate this. When we slowing down, we lowering extrusion speed, but nozzle (and filament) can't cool down with same speed. So, extra filament still coming from nozzle even if we are at right (slower) extruder speed. What I'm trying to say, that K for advance when accelerating and K when decelerating is not same. We should reduce extrusion amount slightly more than we added in advance on acceleration. I think it will be small difference in K1,K2 on direct setup, but significant on Bowden.

Here is how I think pressure (blue line) is rising and lowering when E speed is changed:

And there is another caveat - isr interval is calculated at planner for entire block. If we want to try decreasing LA_current_adv_steps with different speed (compared to how it was increased), we should adjust this interval as well, to let isr count down to `LA_final_adv_steps'.

ps: I'll definitely do my tests as soon as I get my skr board. As I mentioned before, my creality board behaves very strange, so I don't want to brick it now, when I don't have replacement. So, if You have time for tests, try to change final_adv_steps value calculation as I proposed above? Oh, and here https://github.com/MarlinFirmware/Marlin/blob/6c994002af1ef13004490b5e15501e6cdc70dd88/Marlin/src/module/stepper.cpp#L2267 we need to adjust decrement, to reach lowered LA_final_adv_steps. I think it could be:

if (step_events_completed > decelerate_after && LA_current_adv_steps > LA_final_adv_steps) {

if (step_events_completed % 2 == 0) {

LA_steps-=2;

LA_current_adv_steps-=2;

} else {

LA_steps--;

LA_current_adv_steps--;

}

interval = LA_isr_rate;

}

Yes, it will reach LA_final_adv_steps faster than needed, but for test may be will work :)

So, for fast block, final_adv_steps will be same as max_adv_steps for slow block, when it will come to this point at planner. So, here will be no additional E steps.

I agree that this should be the case. That's what I would expect seeing the code. Also agree that we need to debug to see if it is as expected when actually printing.

What I'm trying to say, that K for advance when accelerating and K when decelerating is not same. We should reduce extrusion amount slightly more than we added in advance on acceleration. I think it will be small difference in K1,K2 on direct setup, but significant on Bowden.

Mostly agree. Not sure if this will "cure" the blobs, but we will see.

So, if You have time for tests, try to change final_adv_steps value calculation as I proposed above?

Tested it a couple of weeks ago. I forced K +-0.4 and +-0.5 (more or less randomly chosen) for the deceleration phase only. Both changes seemed to make the blobs worse and had unwanted side effects (slow lines super thin or super thick). I'm not totally happy with the tests though. Might repeat them in the coming days.

The 'LA_steps-=2;'-stuff is also something I tested and which resulted in this image. So, a little better but not solved.

Looking forward to your new board and my damn cable 😀

The 'LA_steps-=2;'-stuff is also something I tested and which resulted in this image. So, a little better but not solved.

Seems twice faster is too much. We need to decrease LA_steps with something like x0.8 x1.2 of normal speed or fire isr more frequently. But this will have effect only with lowering of LA_final_adv_steps for fast segment, so at end we remove little more pressure than needed. And because LA_current_adv_steps will be low as well, it will start incrementing at beginning of slow segment to get to proper level.

Anyway, my board arrive in two weeks (I hope), so there is enough time to think :)

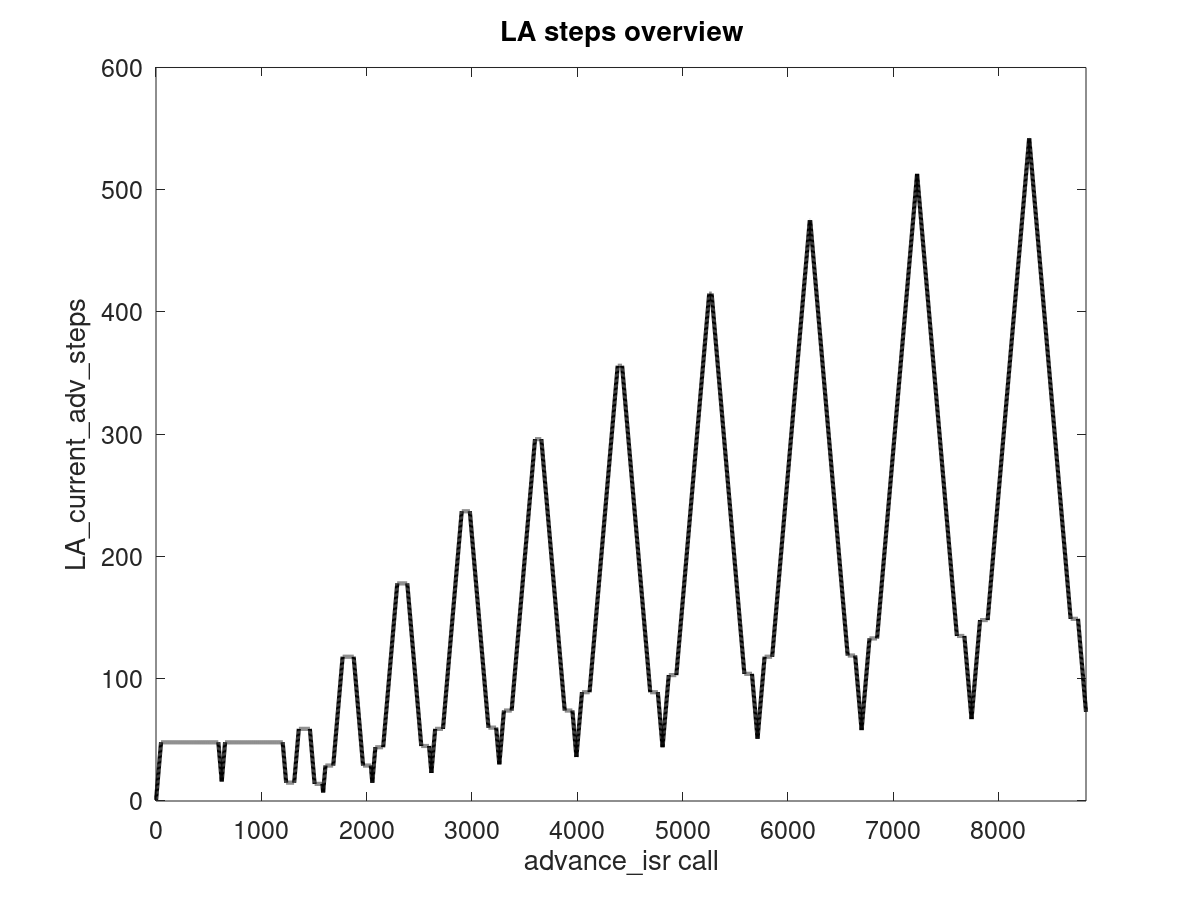

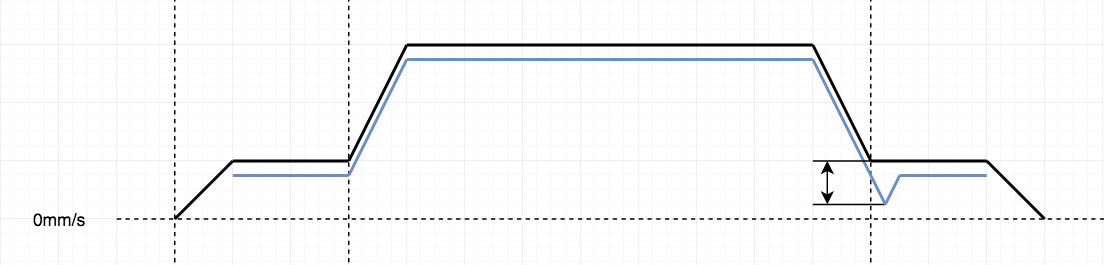

Got the cable and did some initial testing. This is what LA_current_adv_steps looks like for each call of Stepper::advance_isr during printing a pretty typical test pattern (20/40/20 mm segment length, 20 mm/s slow, 80 mm/s fast, accel. 750 mm/s², K=0 - 2.0 in 0.2 steps):

The two long plateaus at the beginning should be the nozzle purging / priming. Notice that there are 11 calibration lines (K=0 to 2.0), but only 10 peaks follow - I guess K=0 does not produce any changes to LA_current_adv_steps, which kind of makes sense. Other than the fact that the lowest LA_current_adv_steps reached inbetween each of the calibration lines increases continously, it looks good to me.

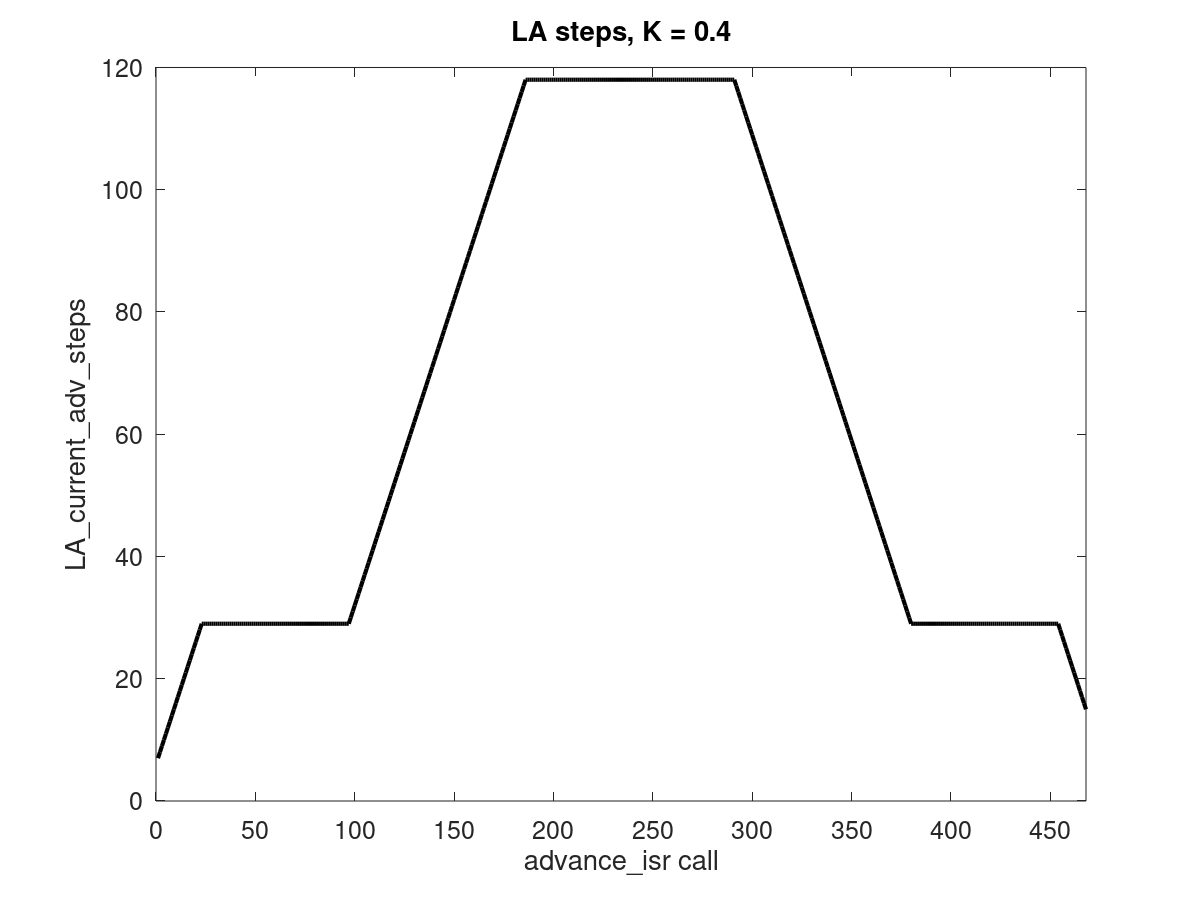

Now, investigating one peak in more detail. Let's pick the second one after the plateaus, which should be K=0.4:

I have to say - this is more boring than expected 😄 Looks to me as it should. No unexpected increases, no bumps or drops, all good.

The value of the low plateaus before and after the peak, corresponding to the slow segments, are both "29". Therefore, LA_current_adv_steps seems to reach LA_final_adv_steps just fine. It's also pretty clear that it reaches LA_max_adv_steps for the first couple of peaks and probably doesn't for the later ones - there is no visible plateau at the top of those.

Oh, such useful information. Many thanks. I expected something similar :) While I still digging back & forth in code to get understanding in details, here is what I found so far:

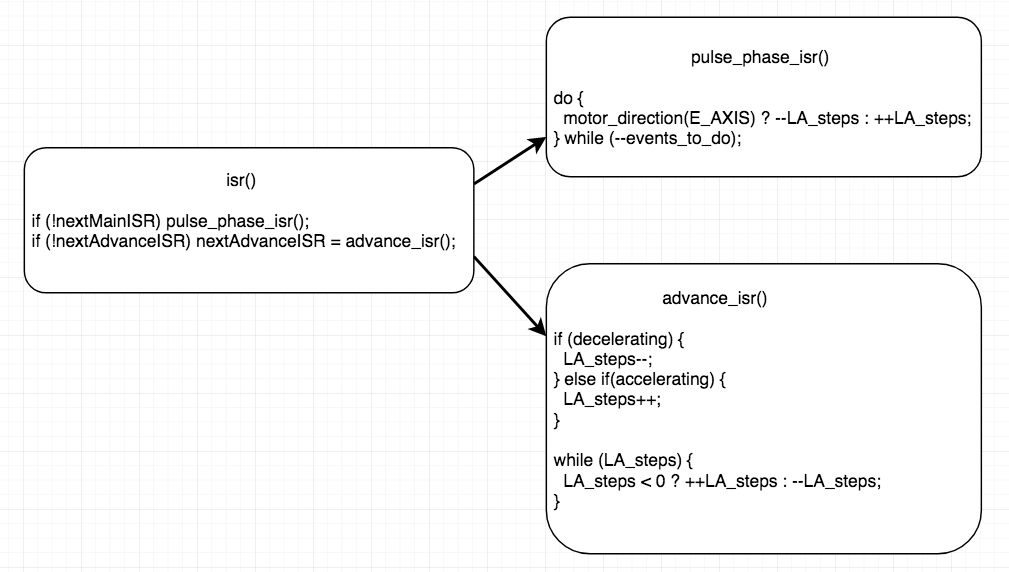

So, pulse_phase_isr is just altering LA_steps and not doing actual pulses. Next, advance_isr is called and this is where it fires all pending pulses. In case we're accelerating/decelerating it additionally alters LA_steps adding/removing extra pulses. While cruising, LA_steps altered only at pulse_phase_isr.

Ok, another thing. There is advance_speed that is being calculated using K (and lot of other stuff). And according to this speed, advance_isr frequency is set. And of course, this speed is absolutely same for acceleration and deceleration. And this is where I think problem comes from: on acceleration we fed a lot of filament in Bowden tube and now, when we lowering speed, this filament straightens up which is resulting in that bulge. I'm still thinking we could try setting final_adv_steps to x0.8 (with if(next_entry_speed < current_nominal_speed) ) value and see if LA_current_adv_steps will count down to it. https://github.com/MarlinFirmware/Marlin/issues/16880#issuecomment-634761609

ps: what cable, board and software you're using to get values from running board? I definitely need same :)

It's also pretty clear that it reaches LA_max_adv_steps for the first couple of peaks and probably doesn't for the later ones - there is no visible plateau at the top of those.

Yes, with higher K it starts going down without reaching cruise value. With high enough K it starts retracting (LA_steps becomes negative).

ps: what cable, board and software you're using to get values from running board? I definitely need same :)

I'm running a stock Ender 3 Pro (Creality Melzi v1.1.4 board, ATMega 1284p, A4988 drivers) and got a no-name USB-ASP as programmer. Serial console is done via the regular Ender 3 mini USB port. "The cable" I was waiting for was a USB extender, so I don't have to lay my printer flat to reach my PC's front USB 😉

Ok, so, flashed my board with two different values. Once, avrdude lost connection right in the middle. But this time boot loader survived, so I restarted flashing :)

if(next_entry_speed < current_nominal_speed) \

block->final_adv_steps = next_entry_speed * comp * 0.8;

else block->final_adv_steps = next_entry_speed * comp;

And

if(next_entry_speed < current_nominal_speed) \

block->final_adv_steps = next_entry_speed * comp * 0.5;

else block->final_adv_steps = next_entry_speed * comp;

I wonder, how far I can go? x0.1? :)

Go limbo 😉

But looks like the bulge is mostly unchanged, but slow second segment just becomes thicker and thicker. Mostly like in my old tests. I suppose LA_current_adv_steps is increased immediately after the second slow segment begins, because at that moment, it is lower than LA_max_adv_steps. Will also debug this soon.

Just want to weigh in.

I had this issue and it was bad.

I have now changed filament and thereby changed the retraction, temperature, adjusted flowrate a bit etc.

now the bulge is almost gone.

The machine has not been altered in the meantime, which makes me believe that it is possible to change settings/filament and achieve fine results in the calibration pattern.

BUT, the bulge is still there - it is just very small now.

Don’t know what was causing it of all the changes.

But looks like the bulge is mostly unchanged, but slow second segment just becomes thicker and thicker. Mostly like in my old tests. I suppose LA_current_adv_steps is increased immediately after the second slow segment begins, because at that moment, it is lower than LA_max_adv_steps. Will also debug this soon.

Seems I know why it doesn't affect bulge. Because LA_current_adv_steps never reach such low final_adv_steps. We should definitely change advance_speed to higher value when decelerating. And this https://github.com/MarlinFirmware/Marlin/blob/6c994002af1ef13004490b5e15501e6cdc70dd88/Marlin/src/module/stepper.cpp#L1917 seems right place to do it.

Next test.

if(next_entry_speed < current_nominal_speed) \

block->final_adv_steps = next_entry_speed * comp * 0.8;

else block->final_adv_steps = next_entry_speed * comp;

and

LA_isr_rate = (int) (current_block->advance_speed * 0.8);

We're on right way? :)

ps: how to log LA_ values from isr?

Looks promising!

ps: how to log LA_ values from isr?

Just add

SERIAL_ECHO(LA_current_adv_steps);

SERIAL_EOL();

or

SERIAL_ECHOPAIR("Final steps: ",LA_final_adv_steps);

SERIAL_EOL();

after those have been set/changed.

Shouldn't it be LA_isr_rate = (int) (current_block->advance_speed * 1.25);, meaning /0.8 instead of *0.8? We want LA to reduce the steps quicker not slower, right?

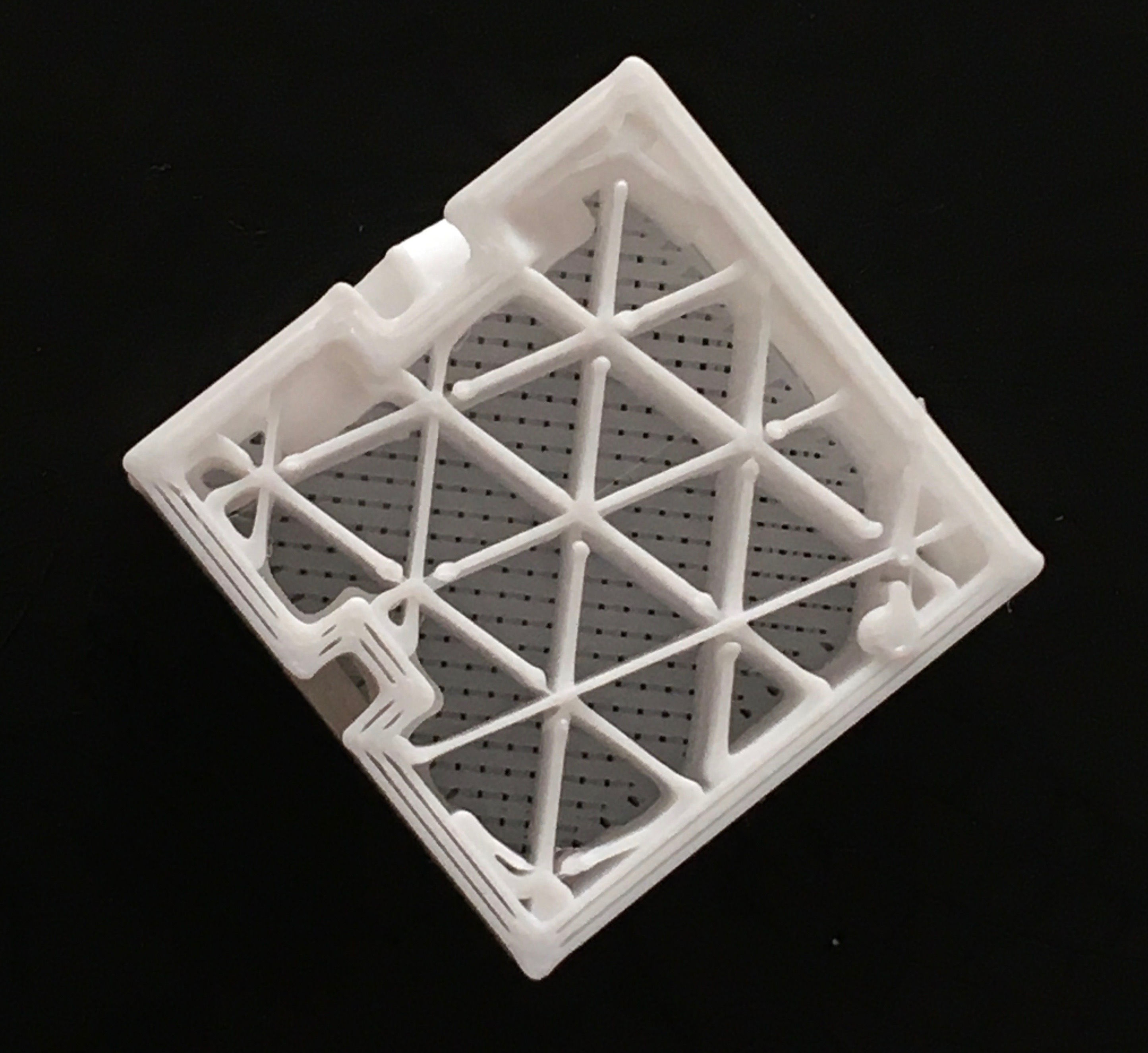

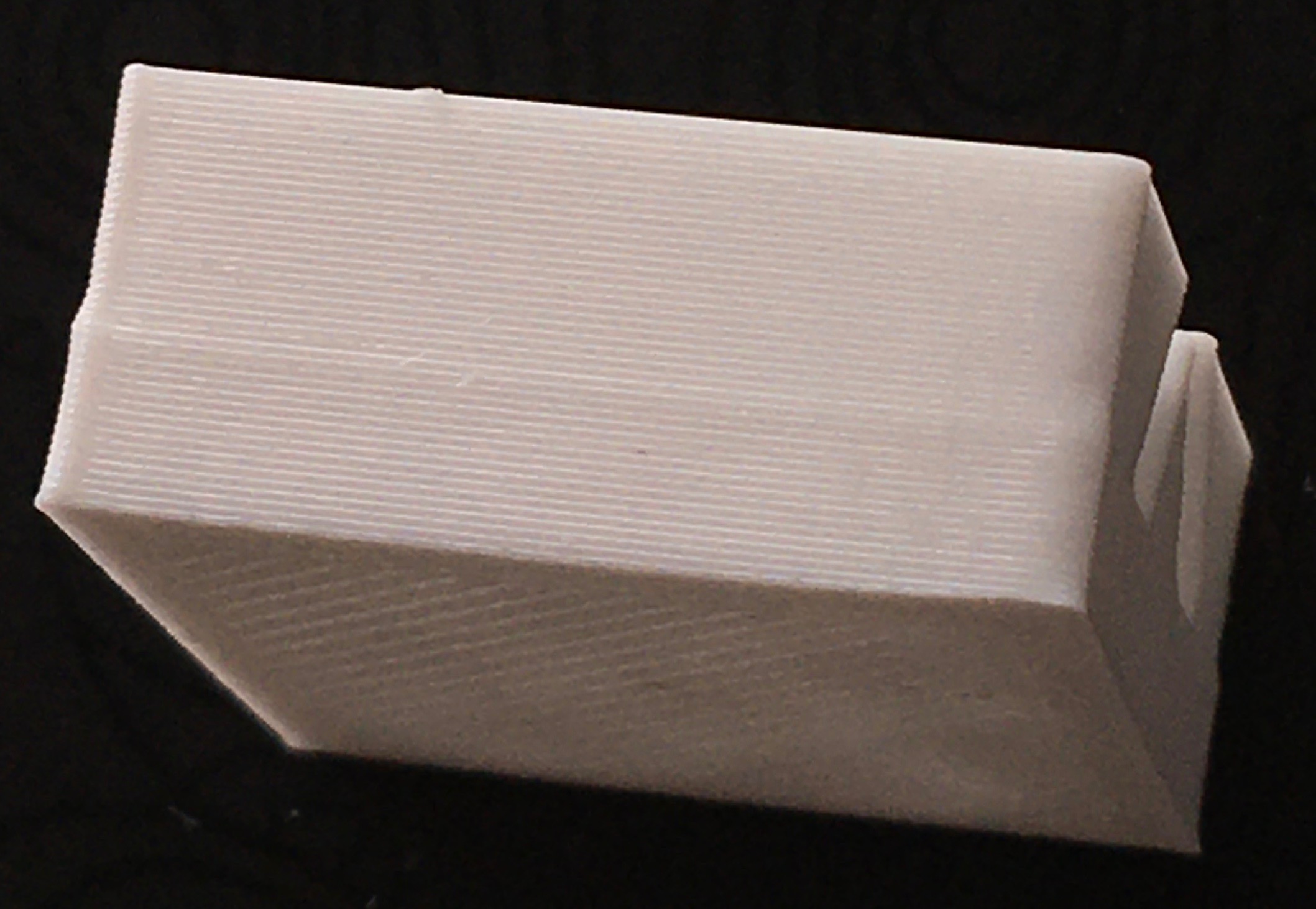

I set values to x0.5 and made two pictures:

Here is visible places with bad adhesion - probably not enough filament.

And this how it looks after I took it off from bed:

Notice last 5 lines - it makes under extrusion with K >1.5 :)

So, on last pic lines 0.9 and 1.0 look like it should be.

Shouldn't it be LA_isr_rate = (int) (current_block->advance_speed * 1.25);, meaning /0.8 instead of *0.8? We want LA to reduce the steps quicker not slower, right?

This is timer interval, so shorter values mean more frequent call. May be I made mistake when been talking about speeds :)

OK, makes sense. Maybe we should not correct so hard (0.5 seems quite extreme). Could be cleaner to use a factor of 0.7 or so and additionally slow down the increase of LA_current_adv_steps in the following segment by adding

else if (step_events_completed < decelerate_after && LA_current_adv_steps < LA_max_adv_steps) {

LA_steps++;

LA_current_adv_steps++;

if (current_block->initial_rate == current_block->nominal_rate)

interval = (int) (LA_isr_rate * 1.428f); // =1/0.7f

else

interval = LA_isr_rate;

}

So, the bottom line: it seems that on Bowden setups pressure drops slower than increasing, so extra E steps should be executed (comparing to acceleration). I think solution is:

- adding second K, let's say Kd (deceleration)

- adding

deceleration_advance_speedto block structure - calculating

final_adv_stepswith Kd - setting

advance_isr()rate withdeceleration_advance_speedon deceleration to match steps withfinal_adv_steps

I think there is another way to check pressure drop speed: print 3 segments with K=0, 20-40-20 with same feedrate (F) but with different line width, let's say 0.8 (means more E steps) in middle. Then measure distance, where last segment become normal width. I bet it will be somewhere at ~18mm from end :)

OK, makes sense. Maybe we should not correct so hard (0.5 seems quite extreme). Could be cleaner to use a factor of 0.7 or so and additionally slow down the increase of LA_current_adv_steps in the following segment by adding

I took 0.5 to get contrast.

Hmm.. Not sure if increasing isr intervals will do the trick, but worth trying. May be together this will produce expected result. But anyway, this changes have to be user adjustable. We can't just hardcode them :)

But anyway, this changes have to be user adjustable. We can't just hardcode them :)

Of course. Also, I'd argue that this is a hysteresis behaviour, so I would introduce something like K_hyst and define K_accel = K as well as K_decel = K-K_hyst. Other vars as you suggested. That way, K_hyst can default to zero for all configs and users only need to tune it, if The Blob ™️ appears.

I think there is another way to check pressure drop speed: print 3 segments with K=0, 20-40-20 with same feedrate (F) but with different line width, let's say 0.8 (means more E steps) in middle. Then measure distance, where last segment become normal width. I bet it will be somewhere at ~18mm from end :)

Either I don't understand how G-code works, or I don't understand something else :) Tried to print this code:

G1 E3 F1500 ; un-retract

G1 X85 Y37.5 E0.7982 F1200 ; print line

G1 X125 Y37.5 E3.193 F1200 ; print line

G1 X145 Y37.5 E0.7982 F1200 ; print line

G1 E-3 F1500 ; retract

with E for middle part twice more, but got this result:

But even if it tried to push twice more filament into middle segment, I don't see where it ends :)

Of course. Also, I'd argue that this is a hysteresis behaviour, so I would introduce something like K_hyst and define K_accel = K as well as K_decel = K-K_hyst.

Well, this can be any way. I was thinking about second K: 0 < K < 1 And it will 1 by default. Math is not my strongest side, so may be somebody with more math skills will give us advice :)

The Blob ™️

The LA Blob ™️ - most famous blob :)

So, what to do next? Writing patch or looking for other ways to solve this? I admit that I may be getting things wrong, so may be there are more proper and elegant way to fix the blob.

I'd say next step would be to program a "clean" solution and make a pull request to bugfix-2.0.x branch.

But I also just tried your changes with a factor of 0.7 and got the following result:

I think that doesn't look like it should. Also, either my extruder or my X stepper sounds really unhealthy on the lines with K>0. Maybe we are disrespecting some acceleration or jerk limit by hardcoding these values? 🤔

Just to be sure, this is what I changed: In planner.cpp, I changed line 1182 to

if(next_entry_speed < current_nominal_speed)

block->final_adv_steps = next_entry_speed * comp * 0.7f;

else

block->final_adv_steps = next_entry_speed * comp;

In stepper.cpp, I changed line 1917 to

LA_isr_rate = (int) (current_block->advance_speed * 0.7f);

That should be equal to your changes, right?

Hmm.. Yes, changes are same, but totally different picture. Why there are blobs in the beginning and at the end of fast segment? I can't explain this. As to sound, make sure there is no backlash on X axis. Extruder usually clicking when can't feed filament.

Only difference I see that I'm running 2.0.x branch, not bugfix. And I have different jerk/acceleration settings:

M201 X1500 Y1500 Z100 E1500

M203 X500.00 Y500.00 Z10.00 E50.00

M204 P800.00 R500.00 T800.00

M205 S0.00 T0.00 B20000 X20.00 Y20.00 Z0.40 E20.00

I put this in test script just before G92 E0. And of course, filament & temperature makes sense. I'm using transparent petg at 240C. May be for your filament you need something like 0.9 ? Seems viscosity greatly affects how pressure changes. Oh, and try to print from 0.4 to 0.6 with 0.02 increment?

What E jerk you have? Because LA respects this, it will limit execution speed for entire block. This is why your first line (K=0) is solid. Mine is always broken because of fast acceleration.

I have now changed filament and thereby changed the retraction, temperature, adjusted flowrate a bit etc.

now the bulge is almost gone.

Pizzahd88, yes, this is true. Different filaments & settings produce different results. But we want to print with any filament, right? :) Not to stick to just one, but be able to use anything and adjust printer accordingly.

Yeah, our settings are different. For testing, I'm running the default config:

#define DEFAULT_AXIS_STEPS_PER_UNIT { 80, 80, 400, 93 }

#define DEFAULT_MAX_FEEDRATE { 500, 500, 5, 25 }

#define DEFAULT_MAX_ACCELERATION { 500, 500, 100, 5000 }

#define DEFAULT_ACCELERATION 500

#define DEFAULT_RETRACT_ACCELERATION 500

#define DEFAULT_TRAVEL_ACCELERATION 500

#define DEFAULT_EJERK 5.0

That means, my E-jerk is way too low. Forgot that, sorry 🤦♂️ I'll test again, probably tomorrow.

Have you adjusted e-steps as well? That makes significant difference. So, try my settings (just put them in script) and see how that will work.

This is funny: I found that M900 have second parameter L - other_extruder_advance_K which exists only in M900 and configuration_store. Looks like unfinished work or it is reserved for something else? May be it was planned as K for deceleration?

Another interesting thing. Planner, _populate_block()

accel = CEIL((esteps ? settings.acceleration : settings.travel_acceleration) * steps_per_mm);

block->acceleration = accel / steps_per_mm;

block->advance_speed = (STEPPER_TIMER_RATE) / (extruder_advance_K[active_extruder] * block->e_D_ratio * block->acceleration * settings.axis_steps_per_mm[E_AXIS_N(extruder)]);

I wonder, why it might be using travel acceleration in advance_speed? Anyway, field advance_speed should be renamed to something more meaningful (like prusa did):

block->comp_speed = (STEPPER_TIMER_RATE) / (extruder_comp_K[active_extruder] * block->e_D_ratio * settings.acceleration * settings.axis_steps_per_mm[E_AXIS_N(extruder)]);

block->decomp_speed = (STEPPER_TIMER_RATE) / (extruder_decomp_K[active_extruder] * block->e_D_ratio * settings.acceleration * settings.axis_steps_per_mm[E_AXIS_N(extruder)]);

So, comp_speed means compression speed and decomp_speed - decompression speed. Similar with K. Makes sense?

So, comp_speed means compression speed and decomp_speed - decompression speed. Similar with K. Makes sense?

Sounds good. We do need to check, whether extruder max. speed, max. accel and jerk are still being respected. For example, this line needs to be adapted for the two K factors:

https://github.com/MarlinFirmware/Marlin/blob/6c994002af1ef13004490b5e15501e6cdc70dd88/Marlin/src/module/planner.cpp#L2186

It should be possible to split it and allow seperate max accel and max decel. There's probably more places where similar checks are run and need to be changed.

Update on my testing: The rattling / ringing sound is still there, but it actually does not seem to come from the steppers directly. It sounds like something on the X-carriage or the hotend cage is picking up vibrations from harsh stepping. At the given speed, it seems to be occasionally hitting a resonance frequency 🤷♂️

Setting the correct extruder jerk and trying multiple factors from 0.8 down to 0.4 lead to this for 0.4:

You can see: I'm beginning to get slight underextrusion just before the second slow segment and the blob. That's already starting to show a tiny bit at a factor of 0.5, so going down below ~0.55 is not useful for me and the solution as it is now won't eliminate the blob without introducing strong underextrusion in front of it.

I think we also need to intervene in the beginning of the second slow segment. Because as it is now, we successfully reduce pressure before the 60 mm mark during the deceleration phase. At that point, LA_current_adv_steps = LA_final_adv_steps(segm. 2). But immediatley after the 60 mm mark, LA_max_adv_steps(segm. 3) becomes our target value and LA_max_adv_steps(segm. 3) > LA_final_adv_steps(segm. 2). That means LA is starting to increase LA_current_adv_steps again, thereby increasing pressure and producing The Blob ™️.

OK, I tested some more, running a factor of 0.6 on deceleration K and the deceleration ISR:

- Reducing the frequency of

LA_steps++andLA_current_adv_steps++here by a factor of 2 or 4 for blocks which start at cruising speed helps very little. - Totally eliminating

LA_steps++andLA_current_adv_steps++for blocks which start at cruising speed reduces the thickness of the last slow segment, but even then, the blobs are still there! - Doubling or quadrupling the stepper ISR interval here also has little effect on the blob and at the higher value (4x) thins out the last slow segment.

I think, in the end the problem is that we are extruding too much filament overall. Any solution that eventually increases LA_current_adv_steps back to the default LA value , even if it does so slower or later, won't fix our problem. We need to add a "retract" motion at the end of the deceleration phase, which takes the tension out of the filament inside the bowden tube. For a later acceleration, we would then have to "un-retract" the same amount to tension the filament inside the tube again.

Huh, just got back home :)

We do need to check, whether extruder max. speed, max. accel and jerk are still being respected. For example, this line needs to be adapted for the two K factors:

It should be possible to split it and allow seperate max accel and max decel. There's probably more places where similar checks are run and need to be changed.

I didn't noticed that accel updated with respect to ejerk. Anyway, we don't have to care about anything related to acceleration, as we keep this part as is. The only change is deceleration, do no need to worry about ejerk and other stuff. Because advance_speed set only in one place in planner, we can do following:

#if ENABLED(LIN_ADVANCE)

if (block->use_advance_lead) {

#if ENABLED(LIN_ADVANCE_SECOND_K)

block->comp_speed = (STEPPER_TIMER_RATE) / (extruder_comp_K[active_extruder] * block->e_D_ratio * block->acceleration * settings.axis_steps_per_mm[E_AXIS_N(extruder)]);

block->decomp_speed = (STEPPER_TIMER_RATE) / (extruder_decomp_K[active_extruder] * block->e_D_ratio * block->acceleration * settings.axis_steps_per_mm[E_AXIS_N(extruder)]);

#else

block->comp_speed = block->decomp_speed = (STEPPER_TIMER_RATE) / (extruder_comp_K[active_extruder] * block->e_D_ratio * block->acceleration * settings.axis_steps_per_mm[E_AXIS_N(extruder)]);

#endif

#if ENABLED(LA_DEBUG)

if (extruder_advance_K[active_extruder] * block->e_D_ratio * block->acceleration * 2 < SQRT(block->nominal_speed_sqr) * block->e_D_ratio)

SERIAL_ECHOLNPGM("More than 2 steps per eISR loop executed.");

if (block->advance_speed < 200)

SERIAL_ECHOLNPGM("eISR running at > 10kHz.");

#endif

}

#endif

After this, we have to update code where final_adv_steps and LA_isr_rate is set and that's it. When no second K defined - it will use same values. I'll write diff later today.

The rattling / ringing sound is still there, but it actually does not seem to come from the steppers directly. It sounds like something on the X-carriage or the hotend cage is picking up vibrations from harsh stepping. At the given speed, it seems to be occasionally hitting a resonance frequency

Yes, there are few speeds that create that resonance. Check backlash of X-carriage. May be it is too tight or little loose. I tried to tighten/loose bottom wheel with micro steps and found place where it is not resonating on common speeds.

I think, in the end the problem is that we are extruding too much filament overall. Any solution that eventually increases LA_current_adv_steps back to the default LA value , even if it does so slower or later, won't fix our problem. We need to add a "retract" motion at the end of the deceleration phase, which takes the tension out of the filament inside the bowden tube. For a later acceleration, we would then have to "un-retract" the same amount to tension the filament inside the tube again.

Well, I seen few places where advance_speed of current block compared to stored value and if different (block changed?) it fires advance_isr() to fire queued pulses. May be this is where blob produced. I'll try later today to dump LA_steps value just before while() loop in isr and see how it changes. Seems we are getting some extra E steps from somewhere else. So, I have few ideas to check, will do that later today and post results here.

As to retract - I would like to avoid it completely. I've tried to print on higher speeds with high enough K and it was retracting at end of every segment. E motor was spinning like hell and clicking like crazy. So, retract is last resort.

The rattling / ringing sound is still there, but it actually does not seem to come from the steppers directly. It sounds like something on the X-carriage or the hotend cage is picking up vibrations from harsh stepping. At the given speed, it seems to be occasionally hitting a resonance frequency

Now I know what you mean :) After adding ECHO in interrupt, it sounds very scary :) UART operations are very expensive, so this slows everything.

Ok, so, here is what I see in log:

Beginning of first segment:

block_phase_isr(): final_adv_steps=15 max_adv_steps=15 isr_rate=3283

advance_isr(): current_adv_steps=7 steps=1 - counting from 7 (previous block) to 15. step either 1 or 0.

Then it goes like this for entire line:

advance_isr(): current_adv_steps=15 steps=1 (E steps added in main isr())

Beginning of fast segment:

block_phase_isr(): final_adv_steps=60 max_adv_steps=60 isr_rate=3283

advance_isr(): current_adv_steps=16 steps=1 - starts incrementing up to 60, steps value 1 or 2.

So, most interesting part - deceleration:

block_phase_isr(): final_adv_steps=15 max_adv_steps=60 isr_rate=3283

and advance_isr():

current_adv_steps=59 steps=-1

current_adv_steps=58 steps=-1

current_adv_steps=57 steps=0

current_adv_steps=56 steps=-1

current_adv_steps=55 steps=0

current_adv_steps=54 steps=-1

current_adv_steps=53 steps=0

current_adv_steps=52 steps=-1

current_adv_steps=51 steps=0

current_adv_steps=50 steps=-1

current_adv_steps=49 steps=0

current_adv_steps=48 steps=-1

current_adv_steps=47 steps=0

current_adv_steps=46 steps=-1

current_adv_steps=45 steps=0

current_adv_steps=44 steps=-1

current_adv_steps=43 steps=-1

current_adv_steps=42 steps=0

current_adv_steps=41 steps=-1

current_adv_steps=40 steps=0

current_adv_steps=39 steps=-1

current_adv_steps=38 steps=-1

current_adv_steps=37 steps=0

current_adv_steps=36 steps=-1

current_adv_steps=35 steps=-1

current_adv_steps=34 steps=0

current_adv_steps=33 steps=-1

current_adv_steps=32 steps=-1

current_adv_steps=31 steps=-1

current_adv_steps=30 steps=0

current_adv_steps=29 steps=-1

current_adv_steps=28 steps=-1

current_adv_steps=27 steps=-1

current_adv_steps=26 steps=-1

current_adv_steps=25 steps=0

current_adv_steps=24 steps=-1

current_adv_steps=23 steps=-1

current_adv_steps=22 steps=-1

current_adv_steps=21 steps=-1

current_adv_steps=20 steps=-1

current_adv_steps=19 steps=-1

current_adv_steps=18 steps=0

current_adv_steps=17 steps=-1

current_adv_steps=16 steps=-1

current_adv_steps=15 steps=-1

block_phase_isr(): final_adv_steps=15 max_adv_steps=15 isr_rate=3283

current_adv_steps=15 steps=0

current_adv_steps=15 steps=1

and third slow segment continue...

So, look at how it decelerates - it giving reverse direction impulses interleaving with zero (empty) steps. Zero comes from main isr still incrementing LA_steps, while LA decrementing. That means it actually retracting. It was line with K=0.1.

For line with K somewhere near 1, values are:

final_adv_steps=243 max_adv_steps=243 isr_rate=1048

and when it counting down, even if not reached final_adv_steps:

current_adv_steps=67 steps=-1

current_adv_steps=66 steps=-1

current_adv_steps=65 steps=-1

isr final_adv_steps=60 max_adv_steps=60 isr_rate=1048

current_adv_steps=65 steps=0

current_adv_steps=65 steps=1

current_adv_steps=65 steps=1

current_adv_steps=65 steps=1

current_adv_steps=65 steps=1

it makes no extra steps on slow segment. So, logic is correct and it works as expected.

I think, in the end the problem is that we are extruding too much filament overall. Any solution that eventually increases LA_current_adv_steps back to the default LA value , even if it does so slower or later, won't fix our problem. We need to add a "retract" motion at the end of the deceleration phase, which takes the tension out of the filament inside the bowden tube. For a later acceleration, we would then have to "un-retract" the same amount to tension the filament inside the tube again.

So, as you can see it is already retracting. What we can do is to continue this retraction on beginning of slow segment. This can be done only by changing final_adv_steps to lower value and executing advance_isr more frequently (in proportion to max_adv_step-final_adv_steps difference). I don't see any other way. May be somebody else will have better ideas?

With two K we can print two test patterns, on first change both K to same value, on second pattern - only second K (having first K chosen with best value). This way it's possible to find point, where line will straight and no bulbs.

Ok, here is some news:

- got white petg filament

- updated code so it is using same K to lower final_adv_steps as well

planner.h

// Advance extrusion

#if ENABLED(LIN_ADVANCE)

bool use_advance_lead;

uint16_t advance_speed, // STEP timer value for extruder speed offset ISR

max_adv_steps, // max. advance steps to get cruising speed pressure (not always nominal_speed!)

final_adv_steps; // advance steps due to exit speed

float e_D_ratio;

float decomp_isr_K;

#endif

planner.cpp

#if ENABLED(LIN_ADVANCE)

if (block->use_advance_lead) {

const float comp = block->e_D_ratio * extruder_advance_K[active_extruder] * settings.axis_steps_per_mm[E_AXIS];

block->max_adv_steps = current_nominal_speed * comp;

block->final_adv_steps = next_entry_speed * comp;

if(current_nominal_speed >= next_entry_speed) {

block->decomp_isr_K = (block->max_adv_steps - block->final_adv_steps) / (block->max_adv_steps - block->final_adv_steps * extruder_advance_K[active_extruder]);

block->final_adv_steps = next_entry_speed * comp * extruder_advance_K[active_extruder];

} else {

block->decomp_isr_K = 1;

}

}

#endif

Added isr K to update isr rate at deceleration in stepper.cpp:

#if ENABLED(LIN_ADVANCE)

if (LA_use_advance_lead) {

// Wake up eISR on first deceleration loop and fire ISR if final adv_rate is reached

if (step_events_completed <= decelerate_after + steps_per_isr || (LA_steps && LA_isr_rate != current_block->advance_speed)) {

initiateLA();

if(current_block->decomp_isr_K) {

LA_isr_rate = current_block->advance_speed * current_block->decomp_isr_K;

} else {

LA_isr_rate = current_block->advance_speed;

}

}

}

else if (LA_steps) initiateLA();

#endif

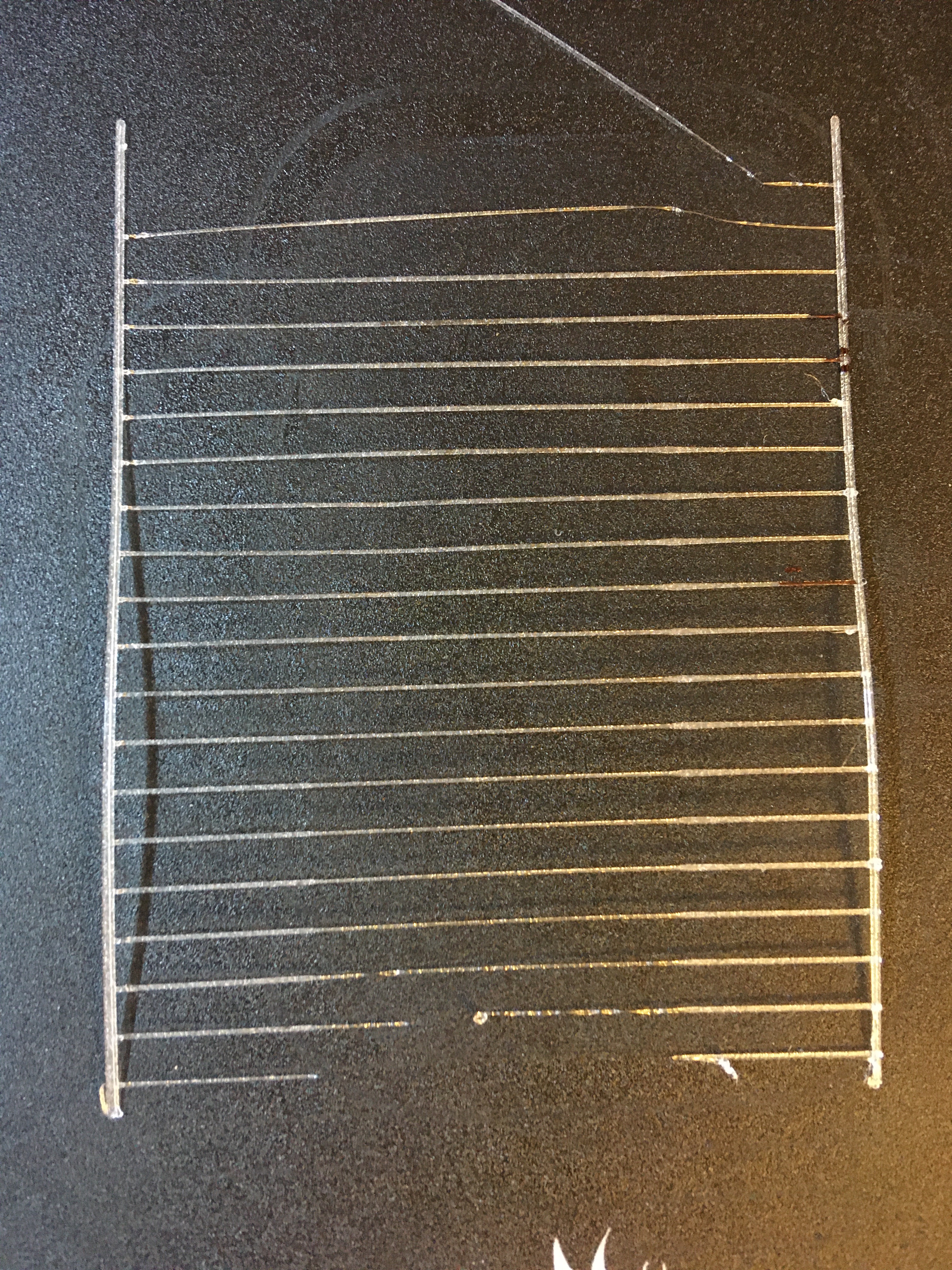

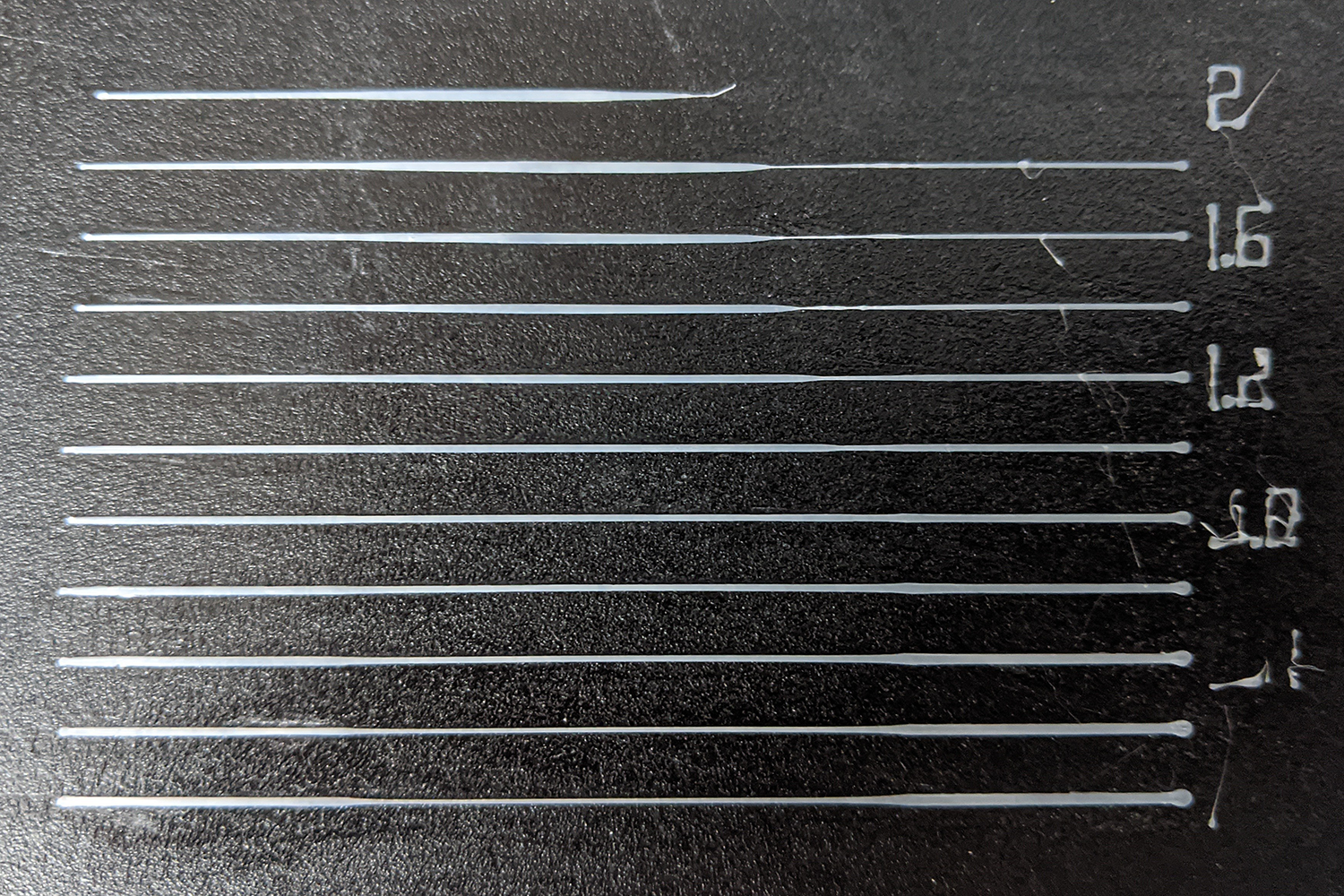

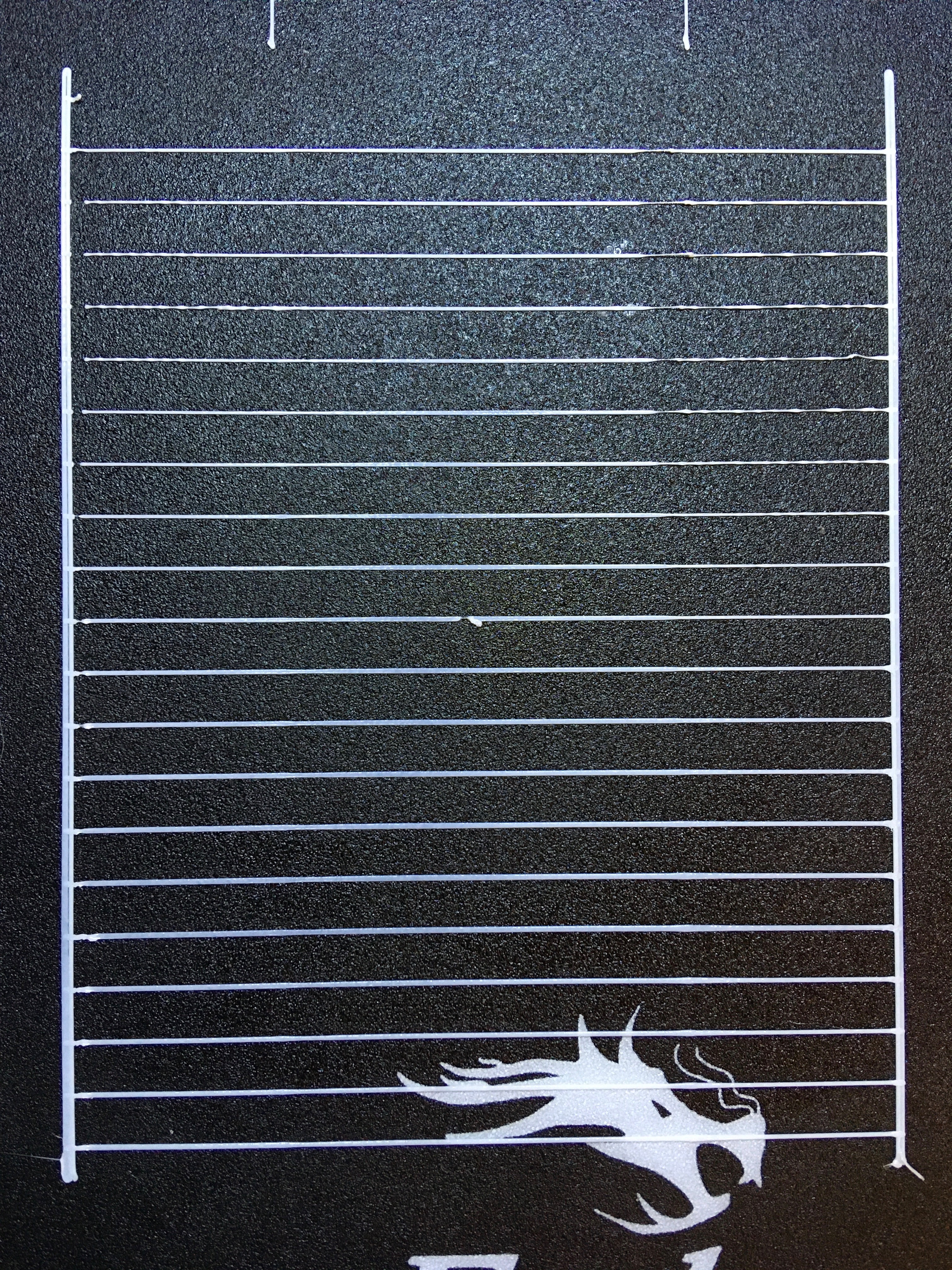

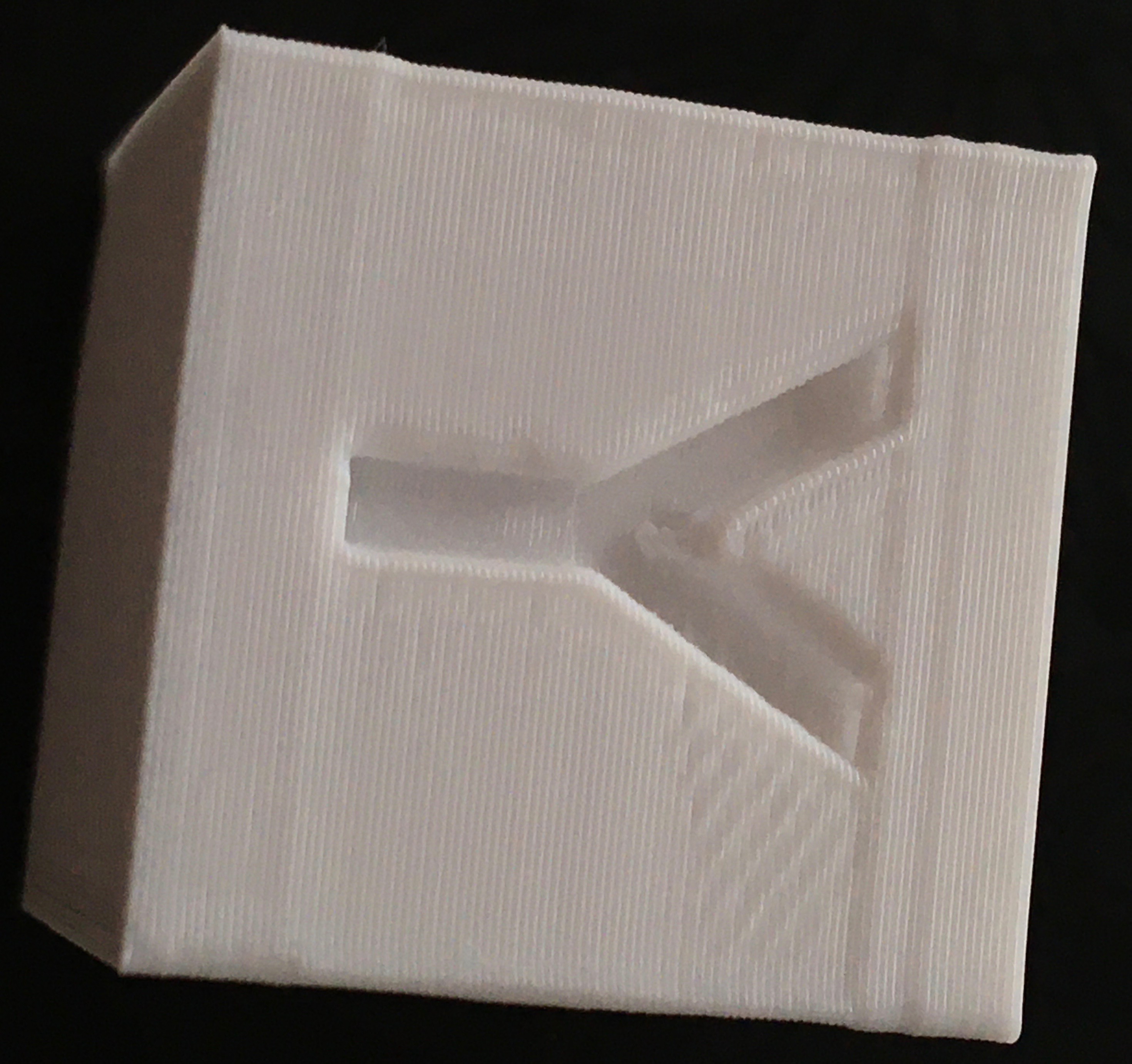

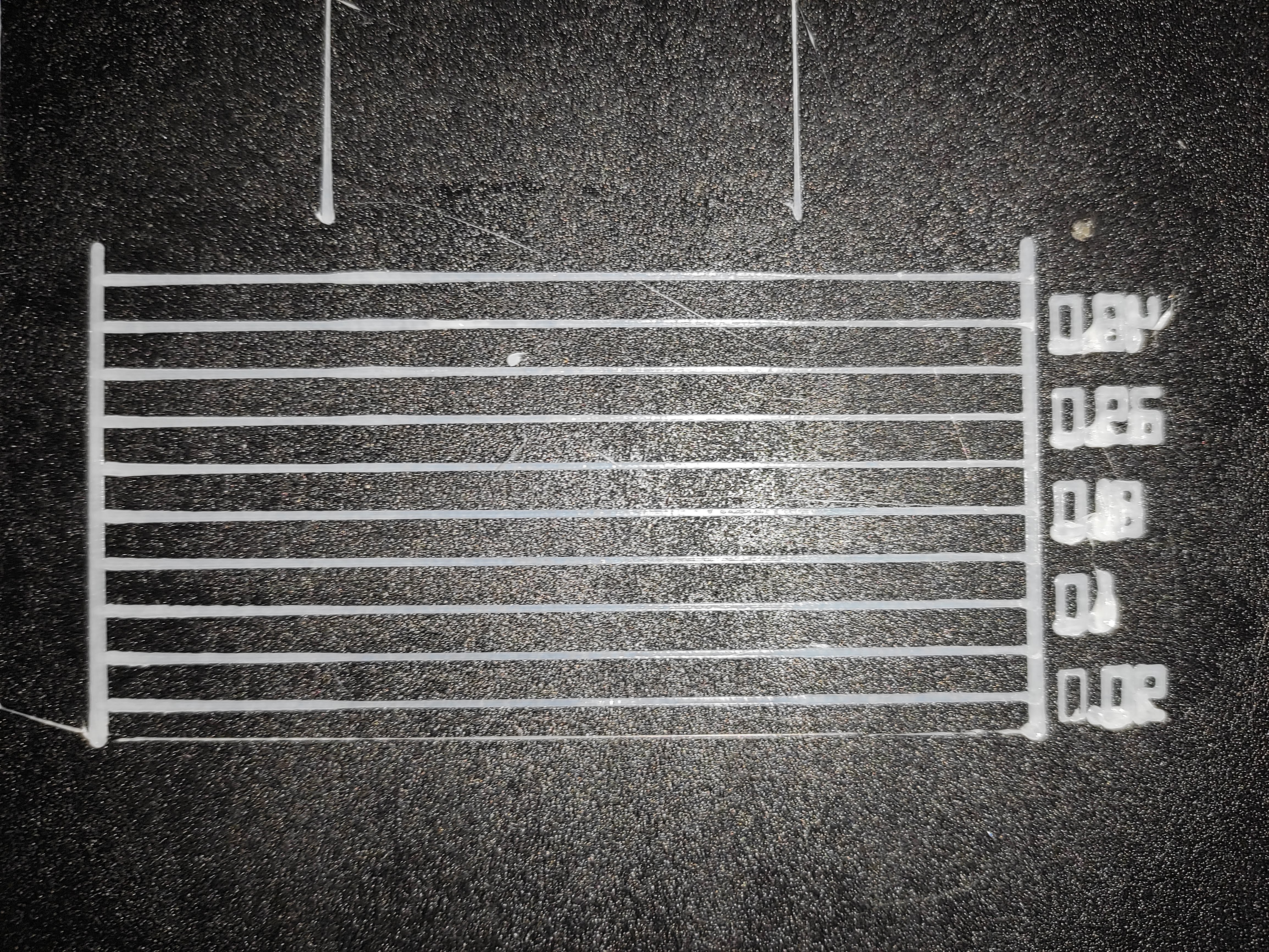

And what I got so far:

K from 0 to 2, step 0.1. Line with K=0.9 looks perfect :)

So, for me it proves the need of second, independent K that will affect how far final_adv_steps of current block will go beyond max_adv_steps of next block. And definitely it must count back to max_adv_steps in next block to avoid this:

Any thoughts?

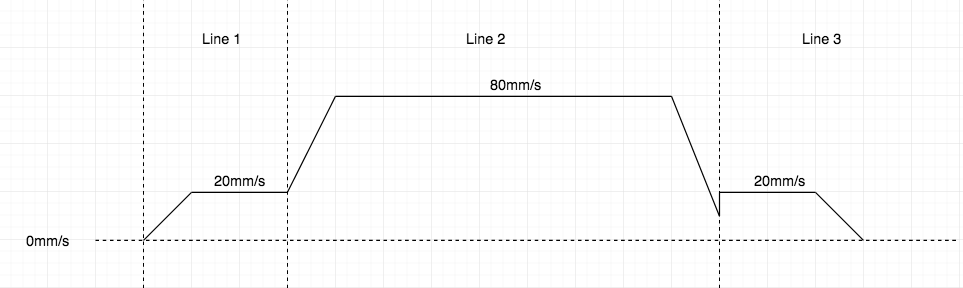

I did more different tests and now I see three ways to fight with bulge :)

So, graphs - black line is axis speed, blue line is E speed. Not real, just for illustration.

- This is how LA works right now. Adding more E pulses on acceleration and more -E (reverse) on deceleration. Same amount, symmetry.

- We can try start LA decompression (issuing -E pulses) slightly before axis deceleration. May be this will work.

- We can completely stop E before axis deceleration, so no retraction will be made at all. This (partially) works for straight lines, but needs precise calculation.

- This is what I tried to test with lower final_adv_steps and it somehow works, but I'm not sure about corners and chained segments with same speed. Needs more testing.

So, may be somebody else have other ideas? May be I missing something?

But in any case I think we need to rewrite LA code first, to split acceleration & deceleration parts completely, so they can be adjusted independently.

Very nice. There's certainly many other possibilities, but one I already thought about is the following (sorry, no nice graphs 😄 ):

- Reduce LA steps like in original LA (your 1.), but keep reducing into the slow segment. Then, there could be a short hold period, where LA setps are kept constant. This is optional and maybe useless. Afterwards, we allow LA to increase steps to the default again. This would look similar to your 4., but the lowpoint of LA steps would be a bit inside the last slow segment.

I think this (5.) will be very effective against the bulge. But I didn't have the time to test, yet. It would be very cool if you could check that, too. Otherwise, I will see if I get to it next week.

I also think that all methods, where we change LA setps earlier or later than LA does now will be tricky to implement in a robust way. Especially on very short segments, things will begin to overlap and we have to decide which logic (i.e. original LA increasing steps, where we would already decrease) has higher priority.

Well, to implement this logic (5) we have to add extra isr code that will detect, should it do normal acceleration/cruise or continue retract. This looks very complex, so this is why I tried to stay within single block. But why not to try (5). Anyway, this will require additional K and completely rewrite LA code. So, I’ll try to make a test in next few days and post results here.

Oh, nice graph :)

Oh, nice graph :)

Indeed 👍

It may not require "total rewrite". Might be enough to define an offset LA_offset_steps, which is calculated only if the block has a deceleration phase (zero otherwise). The offset is then substracted from LA_final_adv_steps and LA_max_adv_steps (which are identical for the problematic case) to set our new, lower target for LA_current_adv_steps. As soon as LA_current_adv_steps reaches this target, the offset is reset to zero, which causes the steps to increase again.

If it works like this, it's not gonna too complex. But I may have overlooked some potential pitfalls.

which is calculated only if the block has a deceleration phase (zero otherwise).

Not only. Don't forget about corners, when two blocks with same speed, but different direction. I see that the only case when we don't need this compensation - when next block have higher speed. Probably we could add condition in advance_isr() if this offset is not zero, it will decrement LA_steps. Otherwise regular logic will work. Ok, I'll try this.

Here is code:

https://github.com/MarlinFirmware/Marlin/blob/e4d8336175ee09b28d23220f446d07451ca3de43/Marlin/src/module/planner.cpp#L1143

#if ENABLED(LIN_ADVANCE)

if (block->use_advance_lead) {

const float comp = block->e_D_ratio * extruder_advance_K[active_extruder] * settings.axis_steps_per_mm[E_AXIS];

block->max_adv_steps = current_nominal_speed * comp;

block->final_adv_steps = next_entry_speed * comp;

if(current_nominal_speed >= next_entry_speed) {

block->advance_offset = next_entry_speed * (extruder_advance_K[active_extruder] < 1 ? extruder_advance_K[active_extruder] : 1);

} else {

block->advance_offset = 0;

}

}

#endif

Used same K just because don't have another K in M900 yet. Just multiply next_entry_speed by K, while it 0 < K < 1. Not sure if this is correct way, but will go for test.

https://github.com/MarlinFirmware/Marlin/blob/e4d8336175ee09b28d23220f446d07451ca3de43/Marlin/src/module/stepper.cpp#L1735

#if ENABLED(LIN_ADVANCE)

if (LA_use_advance_lead) {

// Wake up eISR on first deceleration loop and fire ISR if final adv_rate is reached

if (step_events_completed <= decelerate_after + steps_per_isr || (LA_steps && LA_isr_rate != current_block->advance_speed)) {

initiateLA();

LA_isr_rate = current_block->advance_speed;

LA_offset_steps = current_block->advance_offset;

}

}

else if (LA_steps) initiateLA();

#endif

if (LA_use_advance_lead) {

if (step_events_completed > decelerate_after && LA_current_adv_steps > LA_final_adv_steps) {

LA_steps--;

LA_current_adv_steps--;

interval = LA_isr_rate;

}

else if(LA_offset_steps > 0) {

LA_offset_steps--;

LA_steps--;

LA_current_adv_steps--;

interval = LA_isr_rate;

}

else if (step_events_completed < decelerate_after && LA_current_adv_steps < LA_max_adv_steps) {

//step_events_completed <= (uint32_t)accelerate_until) {

LA_steps++;

LA_current_adv_steps++;

interval = LA_isr_rate;

}

else

interval = LA_isr_rate = LA_ADV_NEVER;

}

else

interval = LA_ADV_NEVER;

And result

So if I didn’t make any mistakes in code, seems it affects bulge with K close to 1.

And this is with

block->advance_offset = next_entry_speed;

-E steps being accumulated, so there is no filament at all :)

OK, I also found the time to test this. I implemented it a little bit differently. After line

https://github.com/MarlinFirmware/Marlin/blob/6c994002af1ef13004490b5e15501e6cdc70dd88/Marlin/src/module/planner.cpp#L1182

I added

if(next_entry_speed < current_nominal_speed)

block->advance_offset = block->final_adv_steps * 0.25f;

else

block->advance_offset = 0;

Thereby, the offset is always a fraction of final_adv_steps. Allowable range is [0,1]. For this test, K is the same for accel and decel. But effectively, this offset is the equivalent of a smaller K for deceleration. In stepper.cpp I then extended

https://github.com/MarlinFirmware/Marlin/blob/6c994002af1ef13004490b5e15501e6cdc70dd88/Marlin/src/module/stepper.cpp#L1917

by

LA_offset_steps = current_block->advance_offset;

just like you did. But the main stepping logic at

https://github.com/MarlinFirmware/Marlin/blob/6c994002af1ef13004490b5e15501e6cdc70dd88/Marlin/src/module/stepper.cpp#L2267

looks a bit different:

if (step_events_completed > decelerate_after && LA_current_adv_steps > LA_final_adv_steps - LA_offset_steps) {

LA_steps--;

LA_current_adv_steps--;

interval = LA_isr_rate;

}

else if (step_events_completed < decelerate_after && LA_offset_steps > 0) {

LA_steps--;

LA_current_adv_steps--;

LA_offset_steps--;

interval = LA_isr_rate;

}

else if (step_events_completed < decelerate_after && LA_current_adv_steps < LA_max_adv_steps) {

...

Basically, it allows the advance steps to already be less than LA_final_adv_steps in the fast segment, but this does not come into play unless LA_isr_rate is modified. With this setup, results for an offset factor of 0.25f look like this:

That looks okay-ish, but the slow segment is a bit on the thin side. Also, there seems to be some effect during the acceleration phase of the fast segment. I don't understand how that could happen, because the offset shouldn't affect it.

Ignoring this problem, I then went on to tinker with LA_isr_rate like you did in your version (1.). I changed

https://github.com/MarlinFirmware/Marlin/blob/6c994002af1ef13004490b5e15501e6cdc70dd88/Marlin/src/module/stepper.cpp#L1917

to

LA_isr_rate = (int) (current_block->advance_speed * 0.9f);

and lowered my offset factor to 0.20f. That means that LA_current_adv_steps < LA_final_adv_steps should already be reached slightly before the end of the fast segment. It should continue to go lower a couple steps into the slow segment and then rise again. The result looks like this:

I'd say that is pretty damn good for K around 0.6. With a tiny bit more tuning, maybe an LA_isr_rate factor of 0.93f or something and an offset factor of 0.22f it's probably bang on.

I'm pretty optimistic about this solution. It kinda combines the best of two worlds: Your approach (1.) and my offset 😄 It needs two factors to work instead of one, so it will be harder to tune. But the results look very promising. You should try it! 👍

Yeah, this looks good. Meanwhile, I added second K to parser, so we can run scripts with different settings, instead of hardcoding them. Not storing into EEPROM but enough for tests.

Here is diff. Sorry, just put changed files to single folder, because in work folder I touched many files, so no extra garbage will go to diff. This is from 2.0.x, but I think will apply to bugfix with some fuzz.

M900.diff.zip

I'll try your code later today.

if (step_events_completed > decelerate_after && LA_current_adv_steps > LA_final_adv_steps - LA_offset_steps) {

this is same as if you do block->final_adv_steps-=offset in planner but little more expensive. And yes, timer have to be adjusted. I just calculated it dumb way:

block->decomp_isr_K = (block->max_adv_steps - block->final_adv_steps) / (block->max_adv_steps - block->final_adv_steps * extruder_advance_Kd[active_extruder]);

I don't know how, but seems this

else if (step_events_completed < decelerate_after && LA_offset_steps > 0) {

may affect fast block. Needs investigation. In my code the idea was that first if() will do its usual work for normal deceleration, second else if(LA_offset_steps > 0) will start working after first finished (step_events_completed > decelerate_after && LA_current_adv_steps > LA_final_adv_steps is not true anymore) and after LA_offset_steps will go down to zero, third if() start adding E steps. So, by adding final_adv_steps-offset in first condition, together with adjusting timer, you just implemented (4). So, I tried combining 4 & 5 like this:

And it was retracting very hard, so after few lines it stopped feeding filament at all :) Probably I messed with K somewhere and this is why I got this result. I will review my calculations and try again.

I don't know how, but seems this

else if (step_events_completed < decelerate_after && LA_offset_steps > 0) {

may affect fast block.

Yeah, could be. I thought that LA_offset_steps should still be zero from the first block and would only change during the second once

LA_offset_steps = current_block->advance_offset;

is run, but maybe there's something I'm overlooking. We could probably define something like block->previous_did_decelerate in the planner, copy to LA_previous_did_decelerate in the stepper and then add to the check:

else if (step_events_completed < decelerate_after && LA_offset_steps > 0 && LA_previous_did_decelerate) {

We could probably define something like block->previous_did_decelerate in the planner, copy to LA_previous_did_decelerate in the stepper and then add to the check