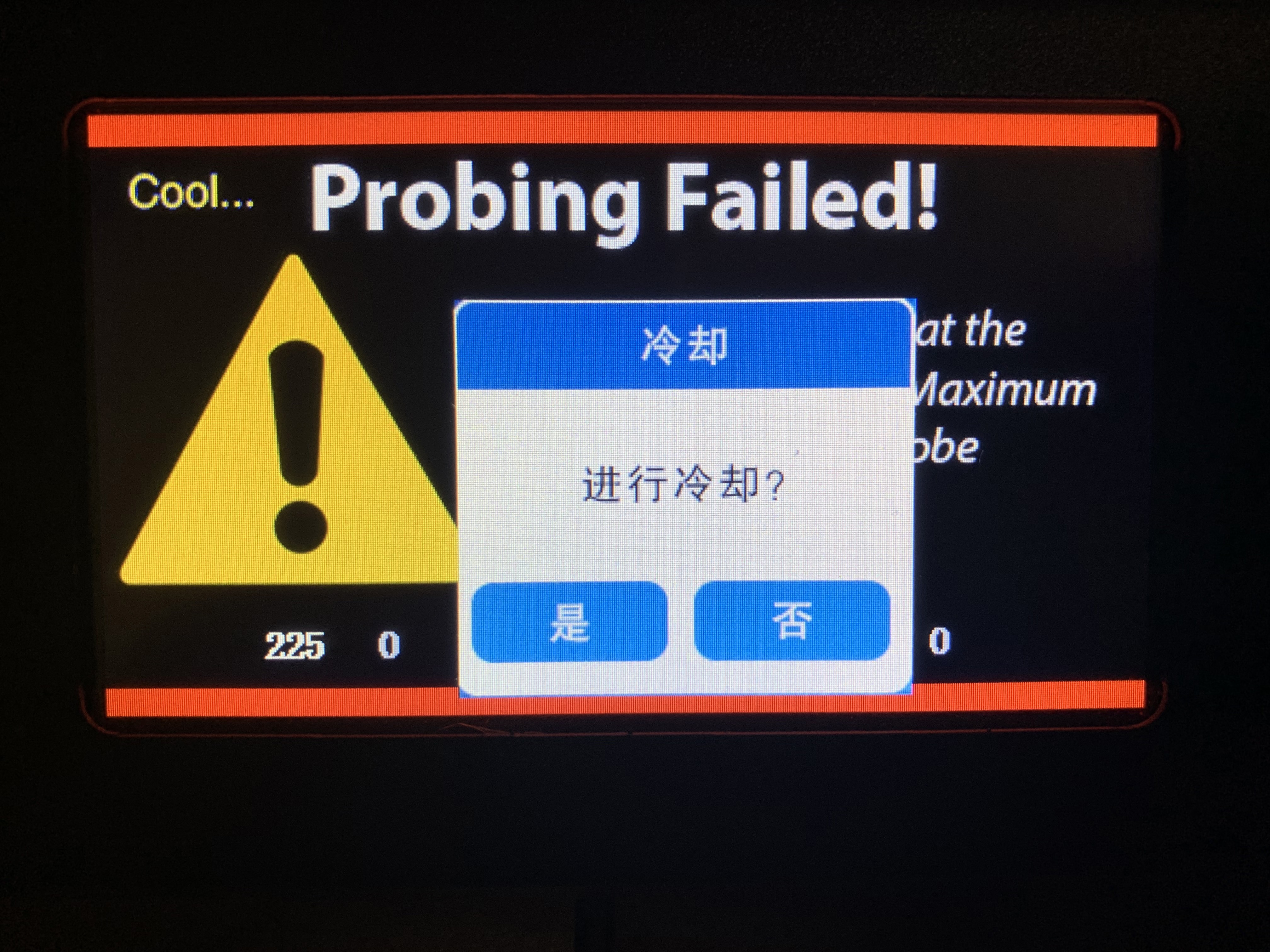

Marlin: [BUG] BLTouch v3.0 not working properly with marlin homing

Description

BL Touch new 3.0 units not working with marlin on homing. Probe responds to M codes for deployment, stowing, and shows no errors, but when it comes to levelling the probe doesn't seem to properly communicate that the Z endstop has been reached. Tried on three different 3.0 probes out of a batch of 100. Tried on old and new marlin builds and machines with existing BL touch 2.1 units that function fine with the same results.

Steps to Reproduce

- Install BL Touch 3.0

- Self test is OK and no flashing lights or errors.

- Start homing G28.

Expected behavior:

Probe should hit bed and be sucked up, triggering the Z endstop.

Actual behavior: [What actually happens]

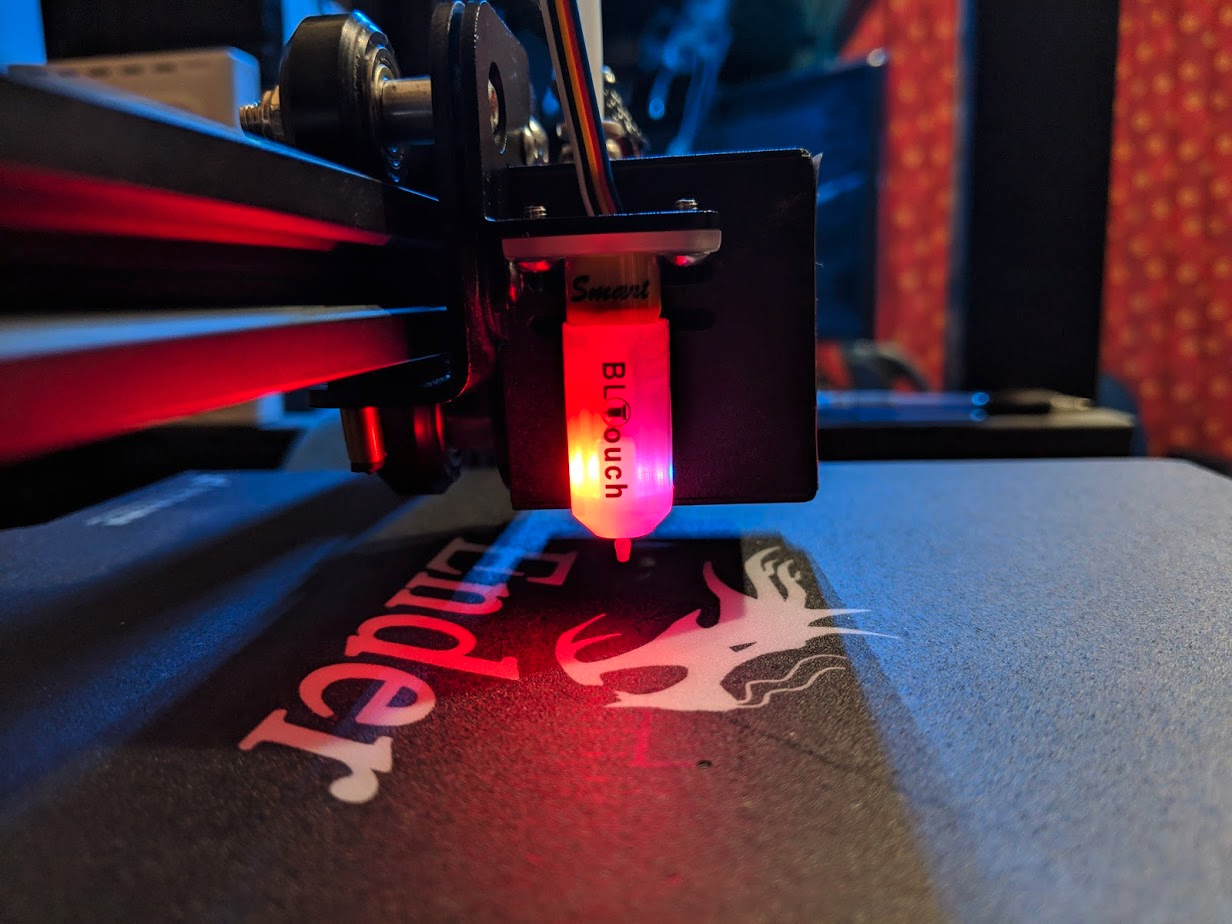

Probe deploys properly and Z lowers to meet bed. The probe touches the bed and sucks up into the unit as expected and glows red, but the Z axis continues to move downward as if it didn't recognize the action.

Additional Information

This is on the latest build of marlin.

Others on reddit report similar behaviour.

Tested three new units out of an order of 100.

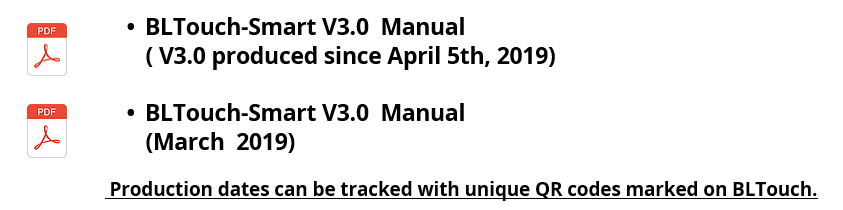

Here is the new DATASHEET for the 3.0 BL touch, which hasn't made it to Antclabs website yet.

This has been tested on machines that we know work with a BL touch 2.1. We home successfully with the 2.1, swap it for the 3.0 unit, homing fails, go back to 2.1 and its fine. That machine runs with marlin 1.1.9. Also tested on CR10S pro with InfinityAutomations firmware with the same results. No wiring connection issues.

All 549 comments

Are you able to deploy the probe, run M43 W and tap the pin with a finger and see if the input pulses at all? Your orders are much bigger than mine! I thought I got alot when I got 5!! lol

Are you able to deploy the probe, run M43 W and tap the pin with a finger and see if the input pulses at all? Your orders are much bigger than mine! I thought I got alot when I got 5!! lol

Unfortunately I am not - Requires Pins Debugging and unfortunately on the ender there is zero room for any more code, literally bytes away from maximum capacity on the memory. I don't have another testbed on me currently. Still awaiting a solution from Paris in S. Korea.

We are a pretty big shop with service and can burn through in a few weeks or so - people love the BL touch! I install probably at least one or two a day at the shop.

Here is a video of the behaviour. https://drive.google.com/file/d/1zcYgOuyuHnCjl3d1abK5lXgTjrE1WS-d/view?usp=sharing Just to reiterate - it will report a Z triggered on an M280 P0 S60.

So first thought is the sensor itself having swapped polarity on signal (black / white) lines. But the line "it will report a Z triggered on an M280 P0 S60." mostly rules that out. Next thought is pulse width. Id need to get one to hook up to my scope to see if thats different, and potentially shorter causing the endstop noise filtering to ignore it.

So first thought is the sensor itself having swapped polarity on signal (black / white) lines. But the line "it will report a Z triggered on an M280 P0 S60." mostly rules that out. Next thought is pulse width. Id need to get one to hook up to my scope to see if thats different, and potentially shorter causing the endstop noise filtering to ignore it.

Oh yeah the connections are fine - swapping in a 2.1 unit works perfectly, and we've tested four 3.0 units in a row now.

Paris did respond saying "After v2.2, because we use ceramic resonator, so we don't accept too large error than before." - Not sure what it means. I hope they didn't decrease the pulse width because it was already tiny at 5ms I believe. Also: On these tests, endstop noise filtering is not enabled.

Attached her is a better copy of the manual for the V3.0

BLTouchGuideV30.pdf

Seems to me there are some changes from V2.2 to V3.0:

V2.2 Servo Timing:

V3.0 Servo Timing:

Although at first glance it looks downward compatible, I would consider playing around with the M280 commands on the V3.0 to see if EACH one works as expected (except the S140 one).

Especially the 5V Logic ZMIN (option) position makes me a little suspicious - what the heck is it for? Anyway, it seems to me you can set "OpenDrain" or "5V Logic" with these two new positions, so maybe one would need a single M280 Px S150 before using the probe, but that is the default, shouldn't be needed. Still worth a try, maybe.

aris did respond saying "After v2.2, because we use ceramic resonator, so we don't accept too large error than before."

Sounds like they might be more exacting on the incoming PWM ratio that determines the servo angle. As they have moved to an external resonator for the MCU of the BLTouch, they don't need such a big leeway in detecting the desired angles setting - and that also gives them two additional new positions to use for two new "commands" (at 140° and at 150°.). If Marlin is slightly "off", something might go wrong.

In both the 2.2 and the 3.0 datasheets, they state the pulse witdh for detection is 10ms.

In both the 2.2 and the 3.0 datasheets, they state the pulse witdh for detection is 10ms.

Thanks for all your insights above. I agree that it appears (without a scope to confirm of course) that the two new commands are causing some difficulty - as if not issuing one of those commands after an M280 Px S10 command doesn't arm the unit for sensing.

Can someone explain to me exactly how marlin activates the BL touch for sensing during homing? Looking at the code there are five definitions for PWM positions:

#define BLTOUCH_DEPLOY 10

#define BLTOUCH_STOW 90

#define BLTOUCH_SELFTEST 120

#define BLTOUCH_RESET 160

#define _TEST_BLTOUCH(P) (READ(P##_PIN) != P##_ENDSTOP_INVERTING)

How and in what order does marlin use these in the sensing process? If the bl touch is deployed (10), does pushing it up automatically trigger an endstop event? And what is the purpose of Reset (160).

Actually, after giving this some more thought, this:

The probe touches the bed and sucks up into the unit as expected and glows red, but the Z axis continues to move downward as if it didn't recognize the action

points toward the probe actually performing its actions correctly. But it is the passing on of the touch-event to the controller board that is failing.

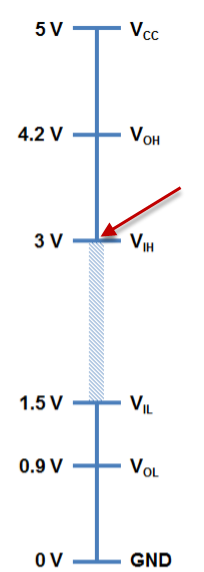

My thoughts: Configuration of pull-up action of the output stage in the probe is missing or insufficient. Even though it works for a 2.2 probe, maybe you don't have a pull-up strong enough (The probe is normal-state LOGIC-LOW according to the datasheet). You could actually measure (and compare to V2.2) with a multimeter in qiescent state.

And they explicitly state the following in the new datasheet, as if it were of dire importance:

#define ENDSTOPPULLUPS // BLTouch Smart V3.0 and Later #

From your description I would assume they have modified the output stage, therefore also the new commands to allow selecting the desired configuration and thus obviating the resistors or the little circuit board trace to cut when selecting 3.3V or 5V logic. Open-Drain works across all voltages, I suppose YOU should use the 5V Logic setting OR better, you should make sure you have actually activated your pull-ups on that input-pin. Which you have, according to your config files.

It's funny though: Why is (a little but further down) your

#define Z_MIN_PROBE_ENDSTOP_INVERTING false

whilst on my machine:

#define Z_MIN_PROBE_ENDSTOP_INVERTING true

Aha! Maybe. So on your machine the endstops are COM to ground, NC to input pin. On my machine, 'tis normal OPEN (normal closed is better I know but WTH, catch wiring faults that way). In that case maybe you should use the 5V logic setting of the probe instead of open-drain-default, (means you are missing the 140° init command) or consider changing #define Z_MIN_PROBE_ENDSTOP_INVERTING to true for the V3.0.

Worth a try?

Can you try a manual M280 Px S140 and then try a G28 Z? ?

But try the S10 and S90 first, to confirm you have the right "x"

I understand that perhaps the S140 setting might be needed EVERY time you deploy, but maybe it is kept in that state until next RESET or power cycle. Actually one should ask the ANTCLABS people all these things

It seems that you have contact with them, ask them to read this thread.

Tried all of the above, I definitely am addressing the right pin as M280 10 and 90 work great, and 60 returns a Z triggered when I look at the pinstates. I tried both S140 and S150 before homing but no luck, I am guessing its not programmed to save state. They responded to us on Sunday but we haven't heard back from them yet - I'll direct them to this thread!

In the mean time - If I needed to insert those commands just after deployment for Z probing, any idea where that line of code might be? I can just insert a bltouch_command(140) wherever that is, but its a matter of finding it.

Especially the 5V Logic ZMIN (option) position makes me a little suspicious - what the heck is it for?

Originally they had a solder jumper for 5v or 3.3v logic. Seems they replaced that with the angle command to avoid damage due to people soldering in order to be more compatible with some 32bit boards that are 3.3v instead of 5v logic for inputs.

Big question now is how we can get a couple of these in developers hands to mess with for awhile. perhaps the support rep can confirm vendors in the US these have been sent to that I may be able to get one from? Worst case, maybe someone can bring one to MRRF?

Especially the 5V Logic ZMIN (option) position makes me a little suspicious - what the heck is it for?

Originally they had a solder jumper for 5v or 3.3v logic. Seems they replaced that with the angle command to avoid damage due to people soldering in order to be more compatible with some 32bit boards that are 3.3v instead of 5v logic for inputs.

Big question now is how we can get a couple of these in developers hands to mess with for awhile. perhaps the support rep can confirm vendors in the US these have been sent to that I may be able to get one from? Worst case, maybe someone can bring one to MRRF?

You may be able to get one from antclabs themsevles if they can't figure it out - try giving them an email at their gmail, the address is on the datasheet attached to a post above.

it will report a Z triggered on an M280 P0 S60

This means the hardware is hooked up correctly.

The video shows that the Marlin software is not detecting the pulse from the BLTouch.

Long shot - Sometime enabling ENDSTOP_INTERRUPTS_FEATURE is helpful.

The basic BLTouch probing and homing sequences are the same:

- Deploy probe.

- Endstop code samples the probe input. This phase will be aborted if probing and Z get too low.

- When two consecutive active samples are detected the BLTouch is considered to have been activated.

- The probe is then stowed and the Z stepper(s) are stopped.

- Depending on the options selected, the Z axis may be re-positioned and steps 1-4 redone.

Is there US stock of the new BLTouch?

A quick look on Amazon didn't show anything claiming to be V3.0

Anyone willing to part with a V3.0? I can use PayPal to cover the cost & shipping.

Just sent an email out. Ill update here what I get back. So far, it sounds like we need to initialize the collector on startup and reset based on the state of the endstup pullup, and potentially add a config option to override and menu button to resend. From there, testing on it processing signals correctly needs to be performed.

Long shot - Sometime enabling ENDSTOP_INTERRUPTS_FEATURE is helpful.

One of the first things I tried unfortunately. No cheddar.

I'm not sure if US stock of BL touches, it appears we are basically at the release stage for them - at first I thought they were fakes, no reference on the website at all, but we're in touch with Paris and she says they are legit and redesigned.

Dont you love being patient zero? lol Pretty bad to get hit with that qty of them as well...

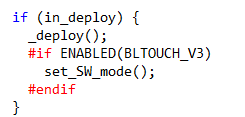

I'm just playing around here and hacking away at code, but I have some results that may offer some clues into the cause of the issues with 3.0:

In Marin_Main.cpp at line 3133 / 3171

#if HOMING_Z_WITH_PROBE && ENABLED(BLTOUCH)

// BLTOUCH needs to be deployed every time

if (axis == Z_AXIS && set_bltouch_deployed(true)) return;

bltouch_command(60);

#endif

If I manually add in a BL touch 60 command (Test) it will actually correctly sense the endstop properly, although it acts jankier because I am sure the code isn't supposed to work this way. But either way, it is putting the Bltouch in a state to report the endstop properly to marlin and indeed it gets sensed. If I change these values to 140 or 150 though, all that happens is the plunger gets sucked up, stays sucked up, and the Z axis keeps dropping.

I was the one who came up with the basic system in use today to reliably interface to the BLTouch. I'm very familiar with the low level hardware and software and I have the tools needed to see what the hardware is doing.

There a 90+% probability I can have a test image available within 6 hours of getting my hands on a unit.

Once I have code that works on a couple of different CPUs I'll do a PR so that people can grab a copy and try it. Once we get feedback from several people then we'll move the changes into the bugfix branches.

@Roxy-3D - do you still have the direct contact info?

@paulpenney - are you willing to part with one of your units? If yes please send it to:

Bob Kuhn

1034 Wisteria Trail

Austin, TX 78753

(512) 934-1943

I can use PayPal to send you $$ to cover your costs and/or return it to you..

From my experience with the V2.0 units:

- The 3.3V/5V option just selects what voltage the output pulse will be.

- You still need to supply 5V to the unit to have reliable operation.. Running the unit at 3.3V will result in unreliable operation.

Bob, I would try Paris @ [email protected] to see if she can ship you one, I'm sure that she has a lot of stake in getting this integrated with marlin as well considering that a lot of her customer base is people upgrading enders, CR10s, D9s and all the other marlin-based printers

As a quick update, antclabs did not respond to my email as of yet however another distributor who got hit with the same bundle of new sensors and is seeing the same problem is getting one over to me. I'll have it hooked up as soon as it gets here and hopefully have something working this weekend that we can merge giving everything that we've seen here. The aim will be to keep them plug and play with something that does not cause an issue with 2.1, and I have a bunch of those to swap back and forth however I will add a configuration option if needed. Given that these are being sold as direct replacements, there may be some merit to a run-time option if needed however I really hesitate to do that and hopefully I can find a way around it.

As a quick update, antclabs did not respond to my email as of yet however another distributor who got hit with the same bundle of new sensors and is seeing the same problem is getting one over to me. I'll have it hooked up as soon as it gets here and hopefully have something working this weekend that we can merge giving everything that we've seen here. The aim will be to keep them plug and play with something that does not cause an issue with 2.1, and I have a bunch of those to swap back and forth however I will add a configuration option if needed. Given that these are being sold as direct replacements, there may be some merit to a run-time option if needed however I really hesitate to do that and hopefully I can find a way around it.

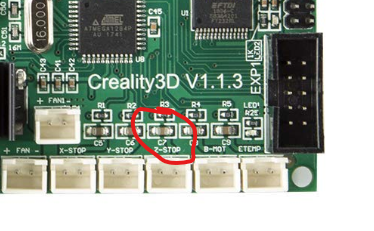

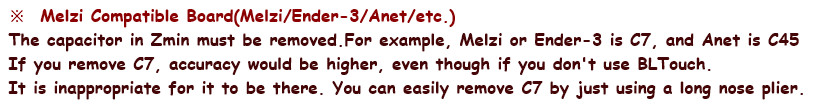

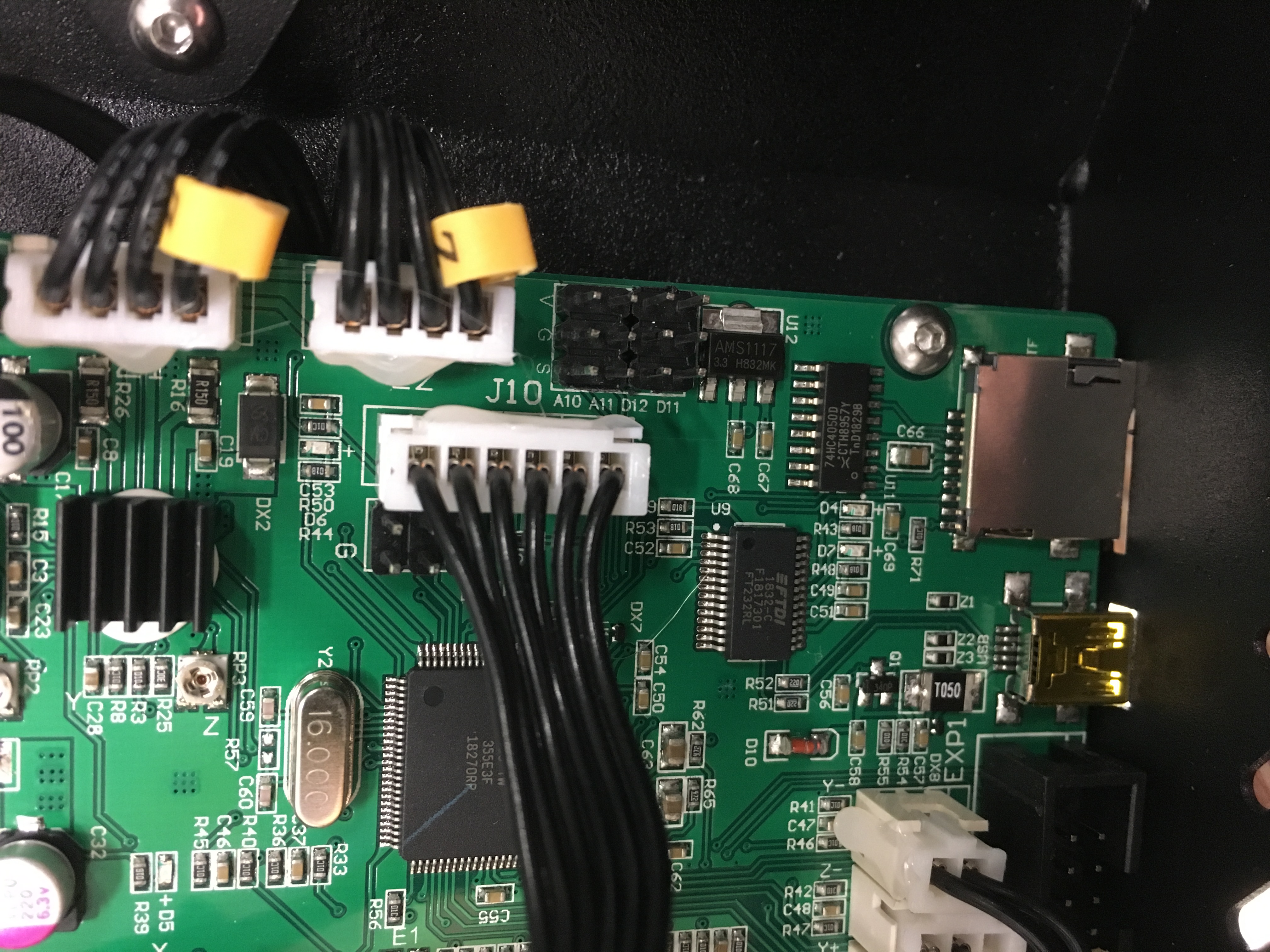

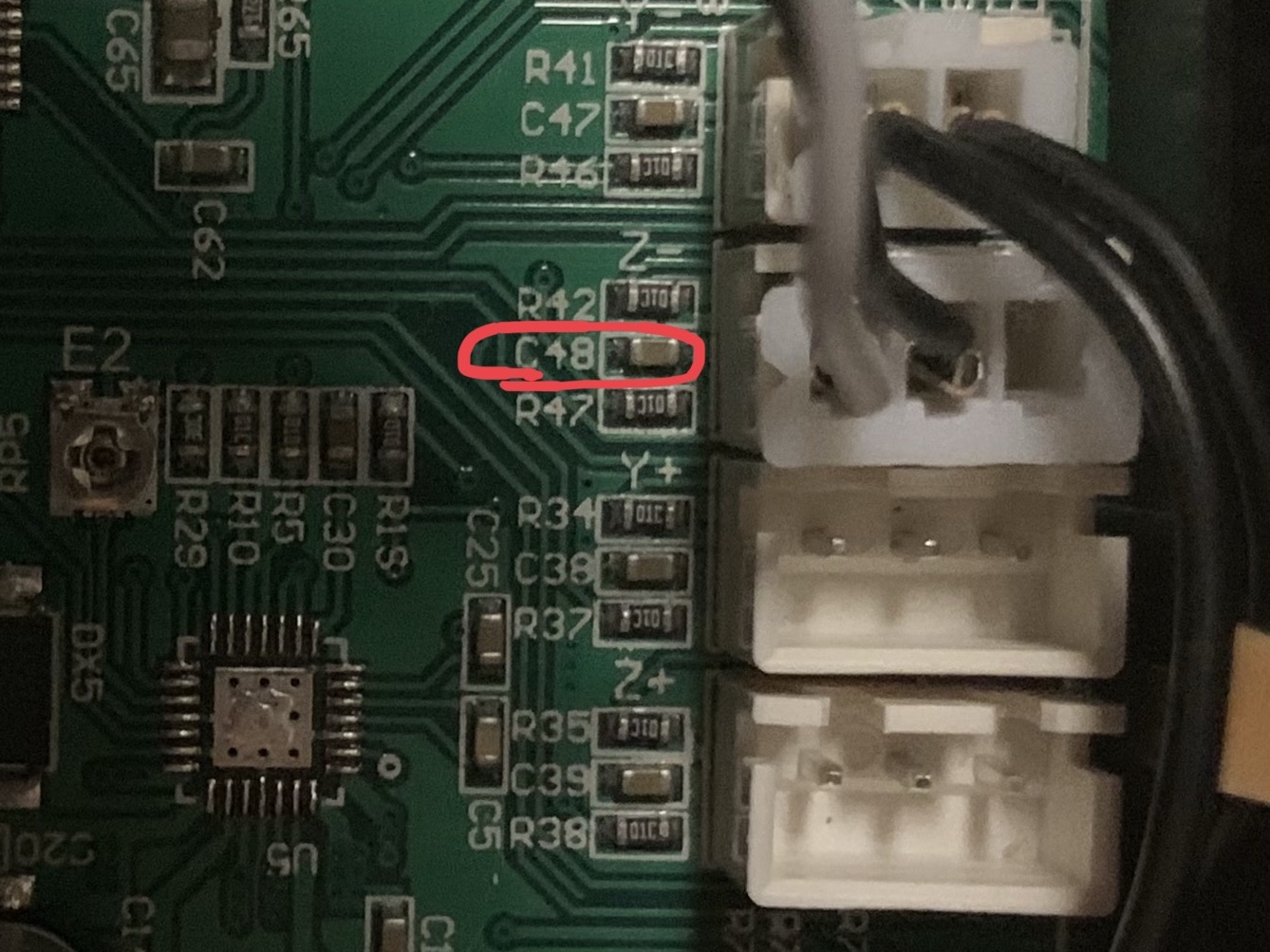

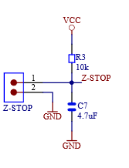

UPDATE: We got a positive response from Antclabs. The pin C7 capacitor leading to the Z endstop needs to be removed from the board with pliers. Doing this solved the problem, at least for the Enders. This is not the ideal solution though, as it permanently modifies the board, so we're hoping there is a software solution that will crop up.

Or maybe its a resistor. Anyways its the bigger yellow component.

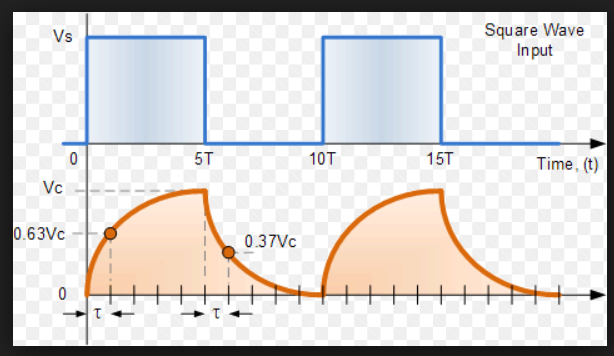

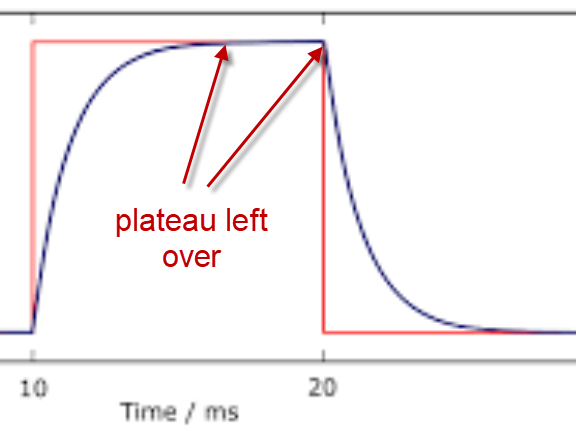

Removing a C7 capacitor. Hmmm. If removing it should help, it very probably (but not totally necessarily) is between ground and the output signal as a slight noise filter. WITH this capacitor, a 10ms signal might have less distinct rising and falling edges, thereby reducing the timeperiod in which the signal is above the logic 1 threshhold. Perhaps the samples that Marlin takes are then too far apart?

This reminds me of #13128 where the OP solved his noise problem by putting a small cap across the signal and ground. Works on that machine, but who knows how small that cap may be. Now ANTClabs have put a cap (same value or more?) on by default (did they read that thread?) and that seems to be detrimental for "normal" Marlin machines.

Could you post the original text of their reply and also post a foto of the V.30 PCB with the C7?

I can measure the component with my lcr-meter and put a scope on it before and after to see what it does to the pulse width. I should get the part here sometime tomorrow, but I'll do a little bit of logic testing to see what I can do with it un-modified first.

just a quick rig up to my scope, didn't really set up any triggering and this is an ancient analog scope without logging anyway. Definitely seeing the curve on the pulse. Overall length appears to be the same however the slope on front is definitely cutting into the duration.

I still don't see the problem.

Looks like about a 2mS rise time. If it's still a 10mS pulse then we should have 8mS at logic 1 which is well above the 5mS Marlin is designed to catch.

Strange - the pulse height is only 2V. I would expect more. What happens if you put a 1K pullup on it?

If the unit is in "Open-Drain" Mode per default, shouldn't the configured pull-up of the input-port-pin "pull it up" further?

Alternatively, would a switch to 5V mode, via 140° servo make the situation better?

Pull request is up! I dont have a 3.3v logic level board here to verify 100% with, but looks to work plug and play between versions now. Added menu items and everything.

So it actually was necessary to utilize the new BLTouch V3.0 mode commands. Sheesh, they sure risked it not working on a huge percentage of the printers out there (MARLIN pre todays bugfix vers), what got into them?

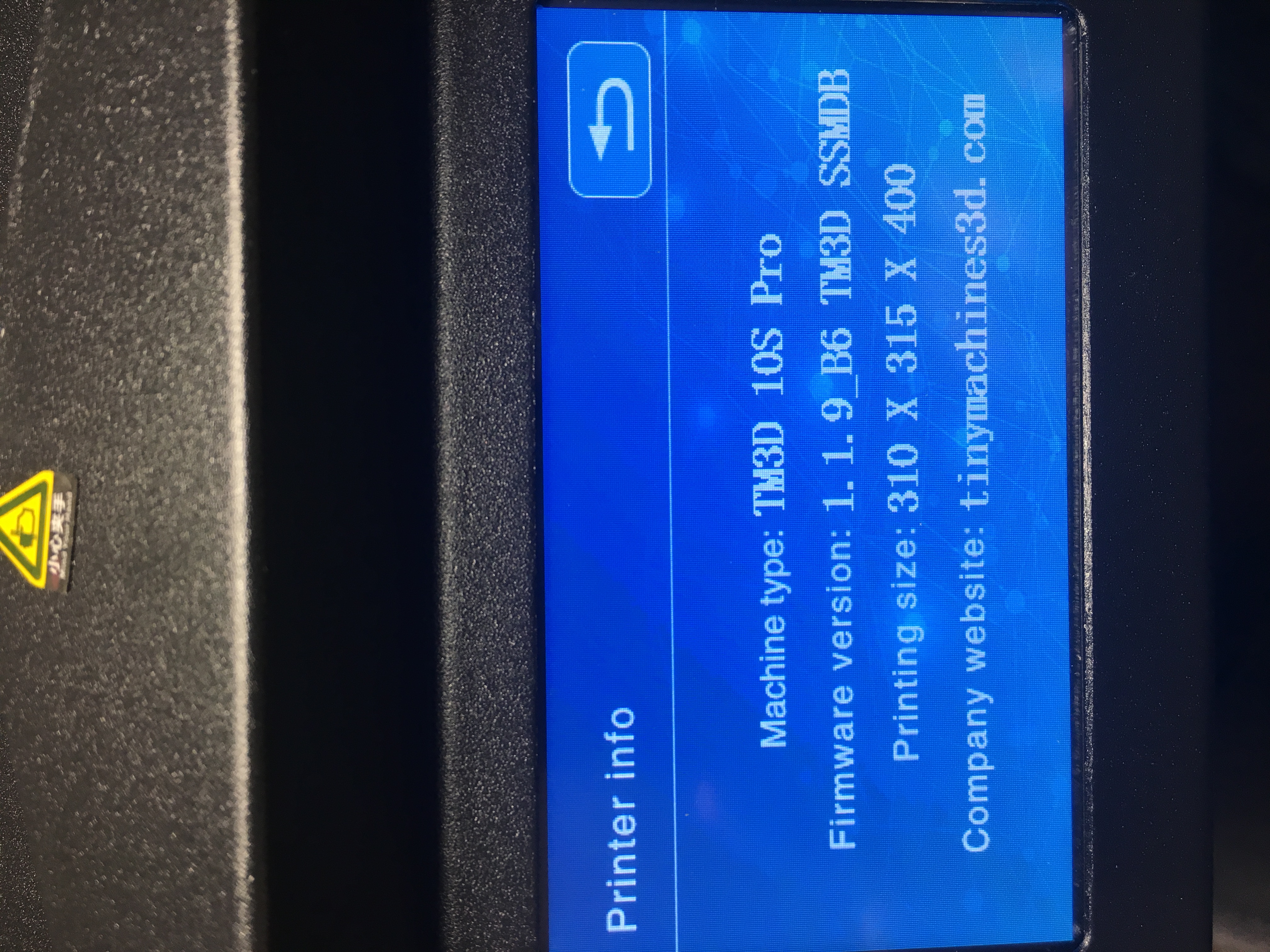

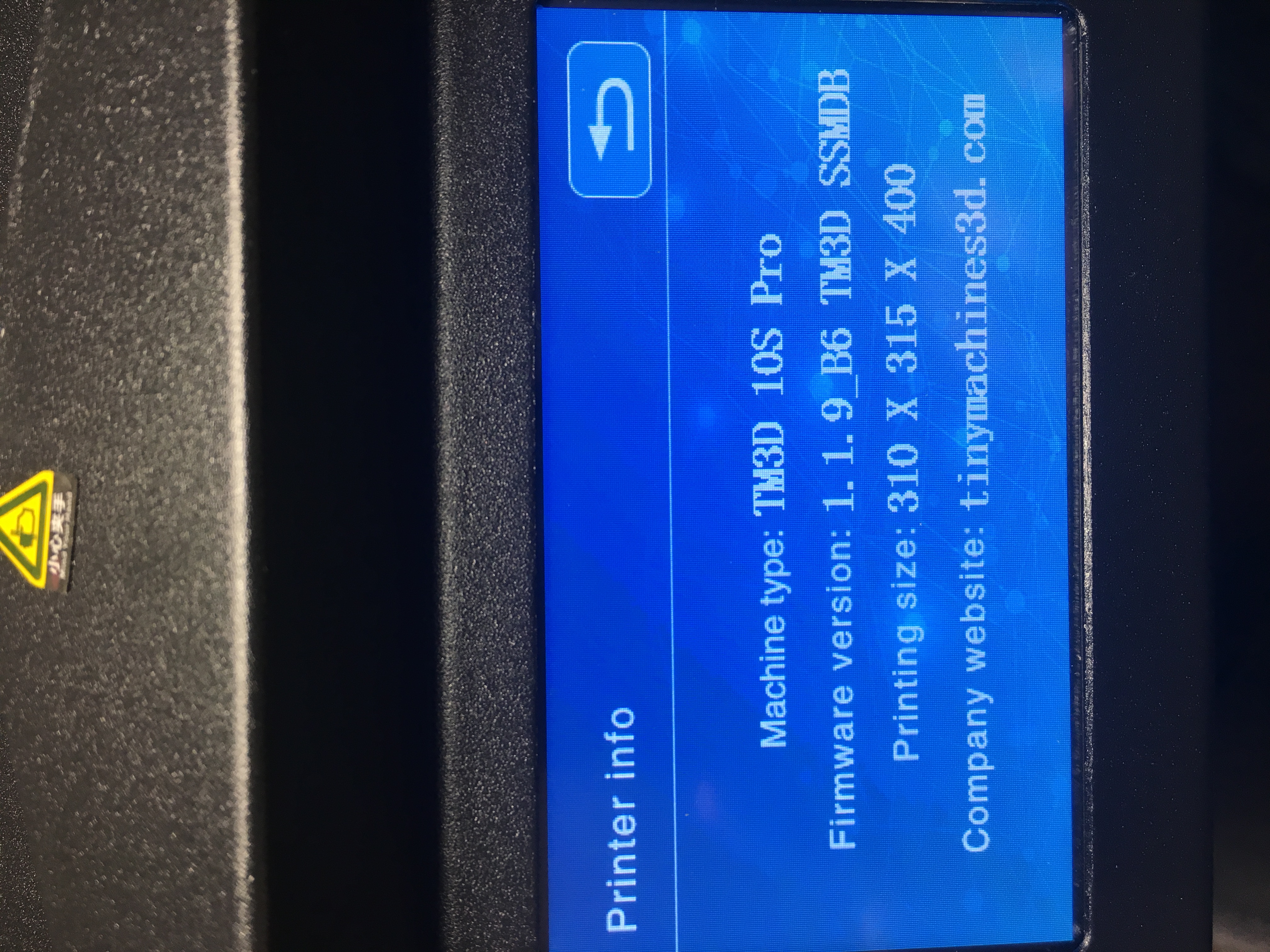

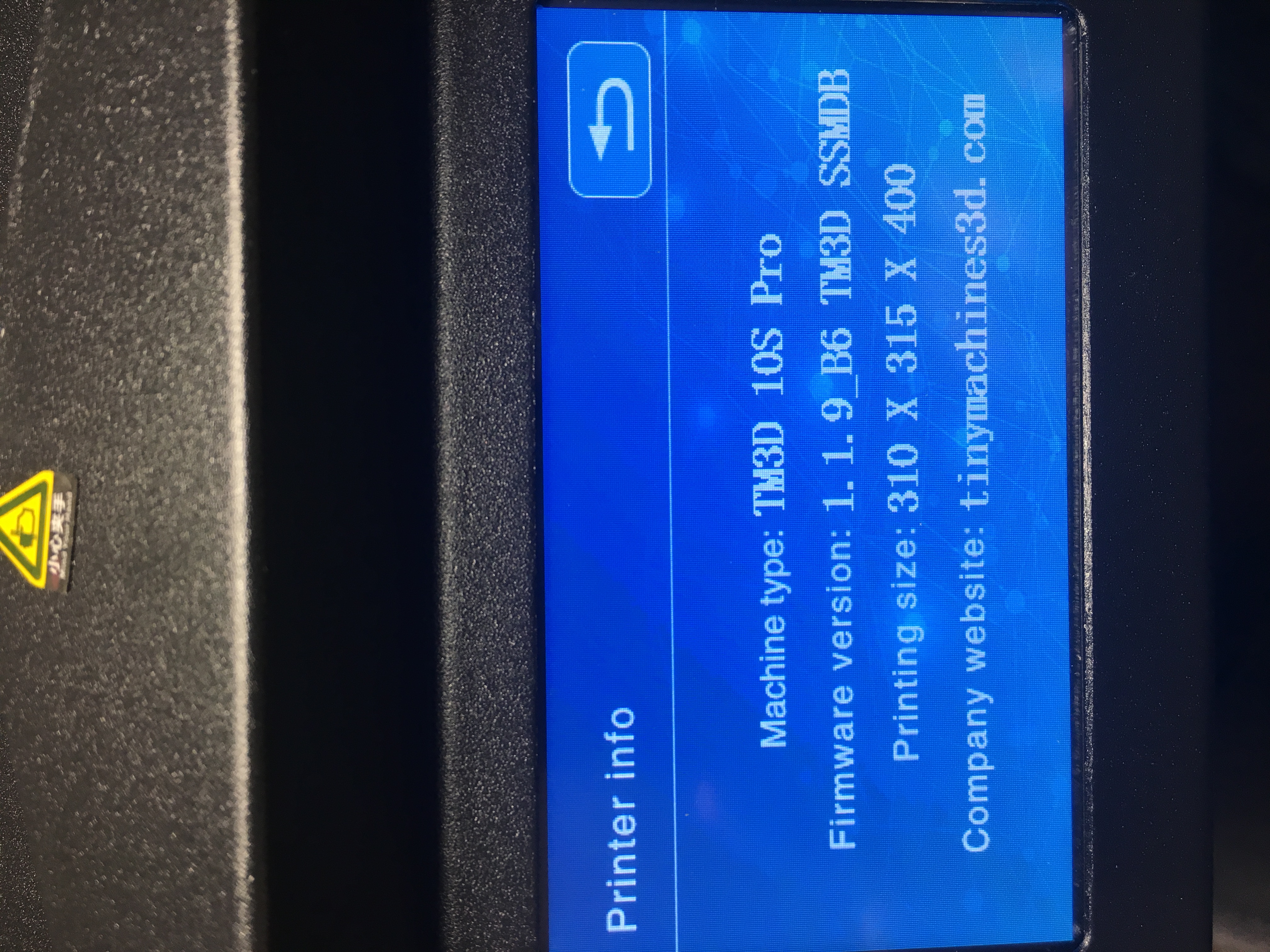

I've received BLTouch 3.0 yesterday, but I was expecting actually 2.2 (it wasn't published on the Antclabs site). However I saw that latest firmware 1.60.7 (Creality CR10S-Pro) is not stable - and it was mentioned on their official video as counterpart to their BLTouch kit for Creality printers.

Today, I've checked and they don't show 1.60.7 as downloadable version, but 1.60.71 instead. It is interesting to know whether they fixed the same issue or whether their stability issue was something else.

@InsanityAutomation Could you please confirm that this new commit should be enough to fix the issue with homing?

@paulpenney @FanDjango Can you give me your shipping addresses? Antclabs would like to send the people in this thread a Bl-Touch v3.0 to help insure their probe is well supported. @Bob-the-Kuhn (I already have your address!)

There are two easy ways to get me your address without posting it publicly here. You can join www.3dprintboard.com and send me a private message with it. Or... You can bring up Discord, join the Marlin server, and send me a private message there.

@Roxy-3D: I sent you a discord as requested

@Roxy-3D I sent you a PM on the 3d Printing Forum.. your name there is simply "Roxy"? Thanks again,

Paul

Thank You. I've sent everybody's address to Antclabs. I'm guessing it will take several weeks for the v3.0 Probes to arrive.

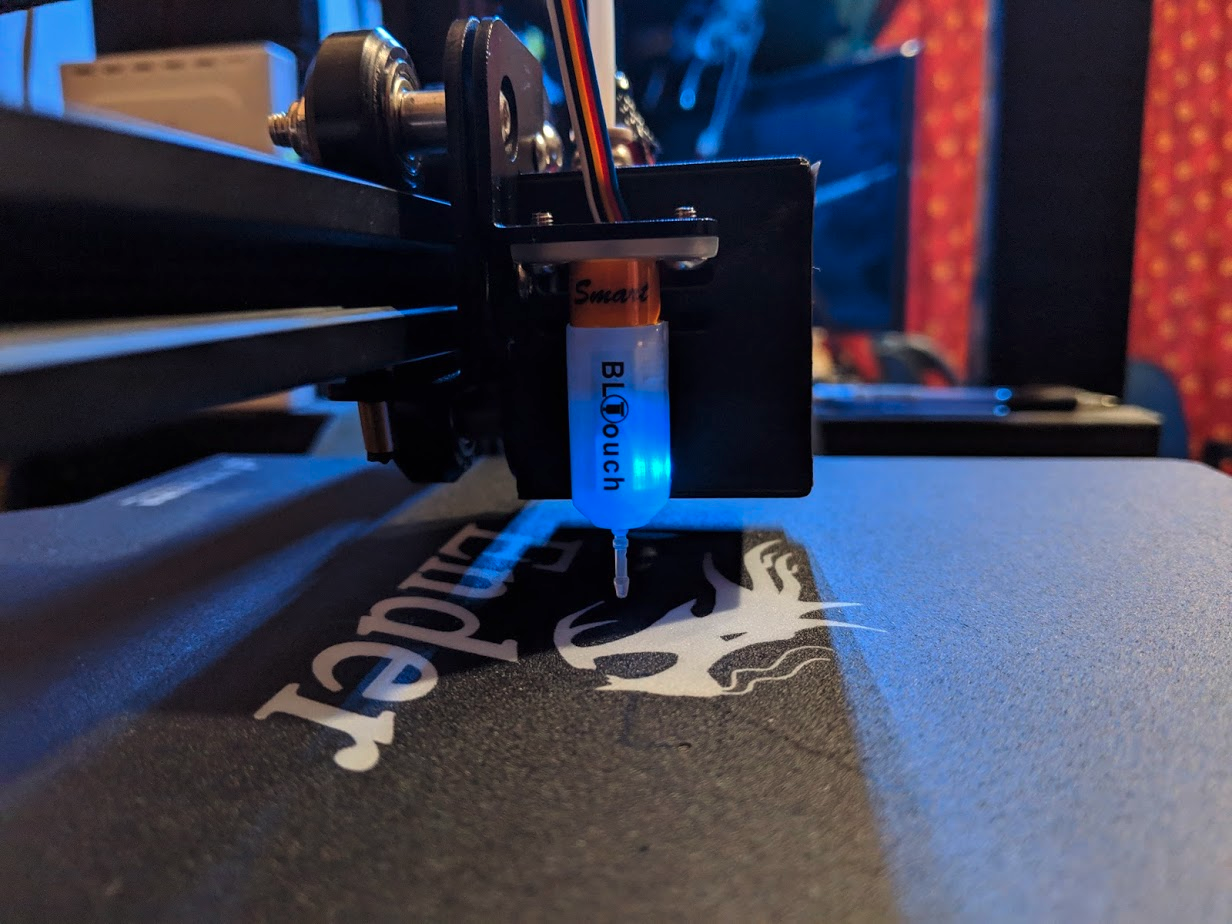

Dang... looks like I might be another "victim" of issues with BLTouch v3.0. As seen in the pic, that means I've got 3.0, yeah?

I bought it off Amazon: https://www.amazon.com/gp/product/B076PQG1FF

I am pretty sure my issues are the same as @paulpenney, but my observation was slightly different:

He wrote,

Probe deploys properly and Z lowers to meet bed. The probe touches the bed and sucks up into the unit as expected and glows red, but the Z axis continues to move downward as if it didn't recognize the action.

I would say that mine continues gets stowed (sucked up), but then redeploys ~half a second later and then stows again when it hits the surface. It's at _this_ point that it registers the Z endstop or whatever and stops going down. So it won't drill into the bed indefinitely. I can hold down the plunger as its testing and it will definitely stop. but it's like it takes half a second of it being unable to fully deploy for it to register.

This thread is a bit technical for me... is there a (temporary?) fix to get the v3.0 sensors to work correctly that someone could sum up?

@CWSpear: Official fix according to the vendor for now seems to be to remove a capacitor (see above). Not recommended, can damage the hardware and difficult to undo.

Next recommended possible fix: Use the newest bugfix-2.0 download to get the V3.0 support (add the needed config statements). This means downloading, modifying the configuration files accordingly and uploading to your printer. @InsanityAutomation has got this working and it wouldn't be committed if it weren't worth trying 🥇

Consider the new parms for the V3, as they stand currently:

/**

* The BLTouch probe uses a Hall effect sensor and emulates a servo.

*/

//#define BLTOUCH

#if ENABLED(BLTOUCH)

//#define BLTOUCH_DELAY 375 // (ms) Enable and increase if needed

// BLTouch V3.0 and newer smart series

//#define BLTOUCH_V3

#if ENABLED(BLTOUCH_V3)

//#define BLTOUCH_FORCE_5V_MODE

//#define BLTOUCH_FORCE_OPEN_DRAIN_MODE

#endif

#endif

You would want to activate the define for BLTOUCH_V3 and then for your case probably choose the BLTOUCH_FORCE_5V_MODE (or choose nothing, it should default to that in Marlin).

I am still trying to get a V3.0 here somewhere through normal channels (out of curiousity) but no chance. I still find it difficult to believe that the normal pre-BLTouch V3.0 Marlin does not work with the probe when pin-pull-ups are enabled. If it needs the new BLTouch V3.0 commit (which sets 5V mode instead of open-drain-mode), then as a next step I would like to see a schematic of the output stage (is it more than just the output pin of the ATTINY13A, what resistors and capacitors are on that output pin?). Can be measured but I can't find a V3.0 here, as I said.

It's sort of time to stop experimenting and to get down to some hard facts from ANTClabs. I know they need some secrecy because of the blatant cloning that they are experiencing but maybe just a small part of the details might help.

I myself am equipped with both 5V and 3.3V boards and V2.x BLTouches, they work fine with Marlin. Got some on order but who knows what version will arrive.

I have a CR-10 for what it's worth.

I installed the latest from the bugfix-2.0.x branch, and set up the BLTouch, uncommenting out BLTOUCH_FORCE_5V_MODE and BLTOUCH_V3.

It didn't seem to make a difference.

Also, as a side note, when I hit the different options in the new menu, I see stuff like,

echo:enqueueing "M280 P0 SBLTOUCH_5V_MODE"

in the serial monitor log, when I would expect

echo:enqueueing "M280 P0 S140"

Maybe something isn't getting converted correctly in the code? This is true for all the commands, like self-test, stow and deploy. I can execute the commands directly and they work as expected.

But I'm still seeing the delayed response, even if I send M280 P0 S140 to ensure it's in 5V mode.

Ok, scratch that. It does seem to be working when I do a G28 Z 🎉

Does still seem to be some kinks, such as the issues I listed above and it doesn't seem to want to take my Z offset into consideration, but maybe I'm doing something wrong (first time with 2.x firmware) (is G28 Z supposed to take into consideration Z offset? This is actually the first time I've really gotten this far).

@CWSpear I just opened a pull request to fix the menus.

For a Creality machine, can try my pre-configured branch here - its caught up the the current changes and open PR's

https://github.com/InsanityAutomation/Marlin/tree/Creality_2.0_Devel

@paulpenney @FanDjango

I apologize! It turns out I also need to give Antclabs your phone numbers so they can fill out the Custom's forms.

@InsanityAutomation My printer is CR-10S Pro what is the easiest way to back port BLTouch 3.0 commits?

Currently Creatily offers only source code of V1.60.3 (Marlin1.1.6) : https://www.creality3d.cn/download/source-code_c0001

Any suggestions?

@juliandroid Ill have a patch in the Tinymachines builds in the next couple days or so, and when its proven will be published as B6. Testing is in progress now :)

@InsanityAutomation

looking forward to the tinymachines fix for my CR-10S Pro. I ordered my BLtouch on Amazon. I just installed it and spent a few hours tracing the wiring and troubleshooting. Finally found this thread not knowing there was a new version of the BLtouch. Sure enough I have V3.0. I feel like Antclabs did a terrible job on this rollout of new hardware. I'm down one machine on productivity.

So I think this must be the same problem Im getting. Video here https://youtu.be/eAfLy4Y4R9M

So I think this must be the same problem Im getting. Video here https://youtu.be/eAfLy4Y4R9M

yep. the sensor will say V3.0 on the side with the connector.

Yep sure does. It's a version 3.0. Ordered off Amazon. Just for clarification the fix is listed above, correct?

@Kaisertron grab the code from the open pull request. Should have a v3 running nicely.

@InsanityAutomation ok sorry if I sound like an idiot I just need to flash the firmware in the current state on the page you listed or change setting for my Ender 3. Besides the obvious x and y probe offset.

I did some playing with a couple of the V3 units. As best I can tell the main differences between the V3 and V2 are:

- Open drain is the new default rather than a totem pole output (this was reported earlier by others)

- The output driver on V3 (after issuing S60 then S140 commands) is very weak compared to the V2.

I measured the following output voltages with a resistor to ground on two V3 units and a V2. The V3 was given S60 then S140 commands before taking the measurements.

R V3 V2

open 4.47V 3.95V

10K 0.96V 3.90V

1.2K 0.15V 3.59V

These numbers translate into an output impedance of about 30K on the V3 and 0.1K on the V2.

Wow! That concerns me. 30k ohms on a signal wire that is going be run next to stepper motor wires and heater wires makes me think it will be picking up electrical noise.

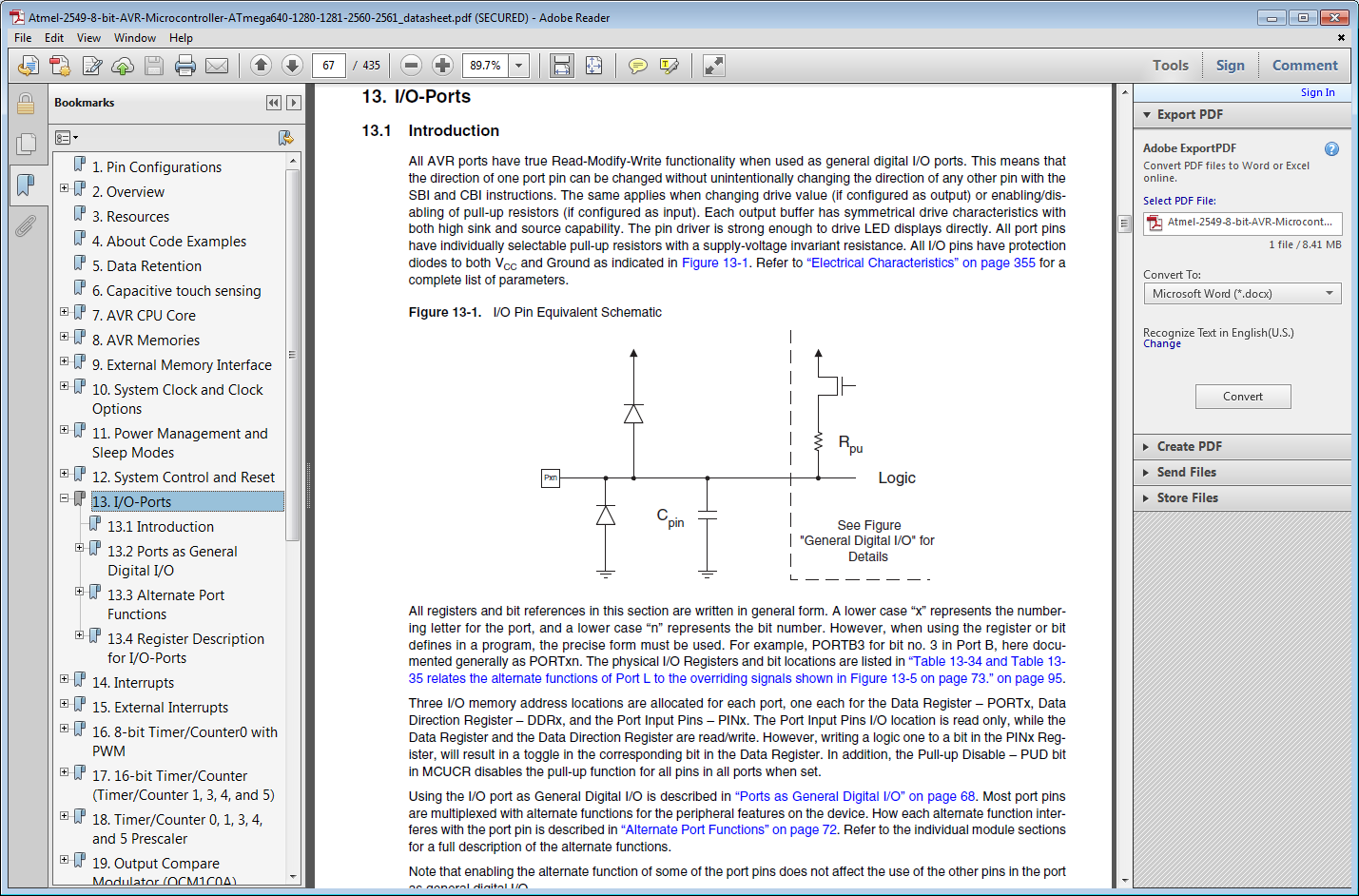

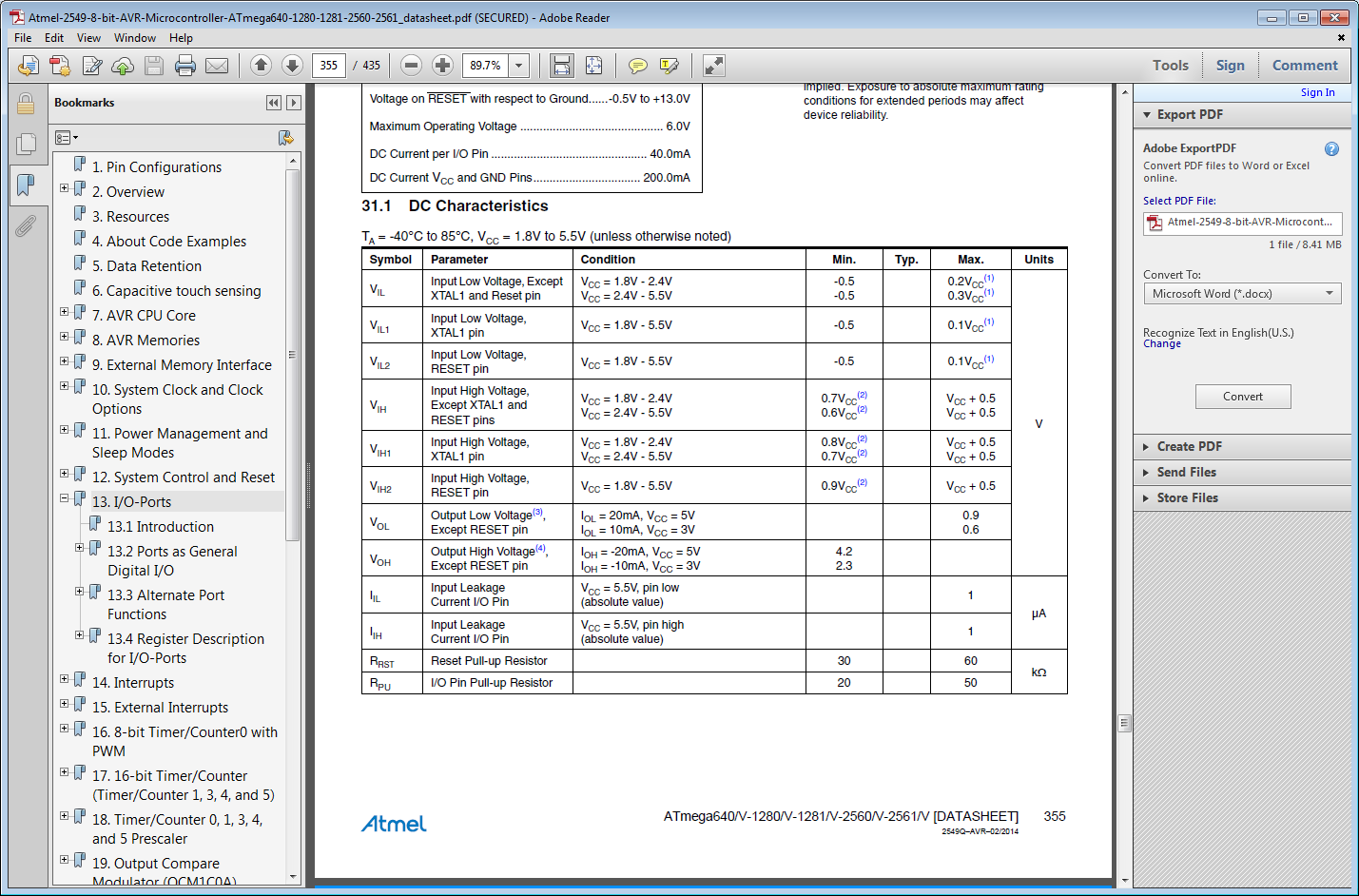

Bob, can you give us some 'typical' numbers? Do you know off the top of your head what TTL (7400) chips have as an output impedance? Looking at the AVR data sheet... It appears the AVR's are going to have between 20k and 50k ohms of output impedance (Rpu value):

So, maybe 30k ohms is OK?

30K is OK if there are no capacitors on the line.

Noise pickup on long lines is also a concern.

On the other hand it would be similar to a mega2560 & RAMPS with mechanical switches and no external pullup resistors. In that case the only pullup would be the Rpu. I don't know if that is a common system or if it has a reputation for false/missing triggers.

On the other hand it would be similar to a mega2560 & RAMPS with mechanical switches and no external pullup resistors. In that case the only pullup would be the Rpu. I don't know if that is a common system or if it has a reputation for false/missing triggers.

It used to be more common. But many RAMPS boards just had a switch from the signal pin to ground. And the pull up resistor inside the GPIO macro cell (or the processor) was used to provide power. It would be good for some of the old school types to jump in here and correct me if I'm wrong. But I think we used to see noise and had debounce logic in use for that case.

I see the following main categories of V3 uses:

- Inputs that have a 10K or stronger discrete pullup and no capacitors. RAMPS_FD_V1 is an example. V3 can be used right out of the box in this case.

- Inputs without external pullup or capacitors - Mitigations: Use V3 option in Marlin to enable the 30K pullup, enable the contoller chip's pullup via the Marlin option and/or add an external pullup resistor.

- Inputs with capacitors - rule of thumb calculations indicate that 0.1uF is the area where problems can start. Mitgations are the same as previous with leaning heavily toward external pullup resistor.

My recommendation for responding to people that are having problems with V3:

- Enable the endstop pullup for the BLTouch's pin. This enables both the controller's and the BLTouch's weak pull up resistors.

- If the above doesn't work then add an external pullup resistor. A 1K external pullup should be strong enough without imposing a large burden on the BLTouch or the power supply.

@Bob-the-Kuhn

Bob... The 30k ohm output impedance is only for the driving +5 volt side, right? The probe can sink a lot of current easily, right? Otherwise, adding a 1K ohm external pull up resistor would over power the probe, right?

Yes, the probe can sink a lot of current. The data sheet says max IO is 300mA. In my testing the output low voltage rose less than 10mV between no load and a 1K load (5mA) which means it hardly knew the 1K was present. I wouldn't worry even if someone used a 0.1K pullup.

There are no concerns with the low voltage portion of the BLTouch's output.

The problem is being able to provide enough current to charge the capacitance on the line up to about 2V in less than 5mS (10mS BLTouch pulse width minus 5mS Marlin guaranteed sense time). I'd be surprised if there were a system out there where just the cabling had enough stray capacitance to have problems when the Marlin endstop pullup option is enabled.

@InsanityAutomation do I just need the new configuration.h file from your example configurations fo rmy CR-10S Pro. Sorry, I'm still pretty green with this stuff.

@Bob-the-Kuhn Thank you for the explanation!

So changing the direction of the discussion a little bit: If we turn on the pull up resistor on the signal pin for the BL-Touch probes..... Are we OK? I think that is what I'm hearing you say.

We will have to use the new version from the pull and put the examples from the Creality file and apply our own settings. I just bought the older version BLtouch. This is a little outside our knowledge level and they dont have time to explain how to install for the dozens of different printers. This is more for development purposes than application to end user.

I found a schematic for the Ender 3 that was created by a user. It shows a 10K pullup to 5V with a 4.7uF capacitor. The time constant for that is 47mS which means it should get to 63% of 5V in 47mS.

All I could find on the Ender 3 CPU is that it's a 5V Atmel 8 bit CPU. Being very conservative, assume that the logic 1 transition is at 1.5V, it'll take 0.35 time constants or 16.5mS to go from zero volts to a logic one as seen by the CPU. If we assume the transition is at 2.5V then it'll take about 33mS. Add 1% for the pullup resistor tolerance and 20% for the capacitor tolerance and worst case might be in the 40mS range.

I'm thinking an external 1K pullup is the only thing that will guarantee Ender 3 and BLTouch V3 compatibility.

If I get the older version in which I think I will I'm willing to ship my V3.0 out to one of you guys for development help

If I get the older version in which I think I will I'm willing to ship my V3.0 out to one of you guys for development help

@Kaisertron I can exchange your v3.0 for a new, never used v2.0 BL-Touch if you would like to do that.

(And if you would prefer an even older v1.x, new, never used BL-Touch, that can be done too...)

Are you on Discord? If so, we can exchange shipping addresses right now.

(It doesn't look like you are using Discord. You can create an account at www.3dprintboard.com and send me a message there with your address. And I'll reply and send you my address.)

@Kaisertron That name (jvkaiser) isn't showing up as available for messages at 3dprintboard ???

Hmmmm.... I can find the post you just made with the 'jvkaiser' name.... But I can't find a user with that name.

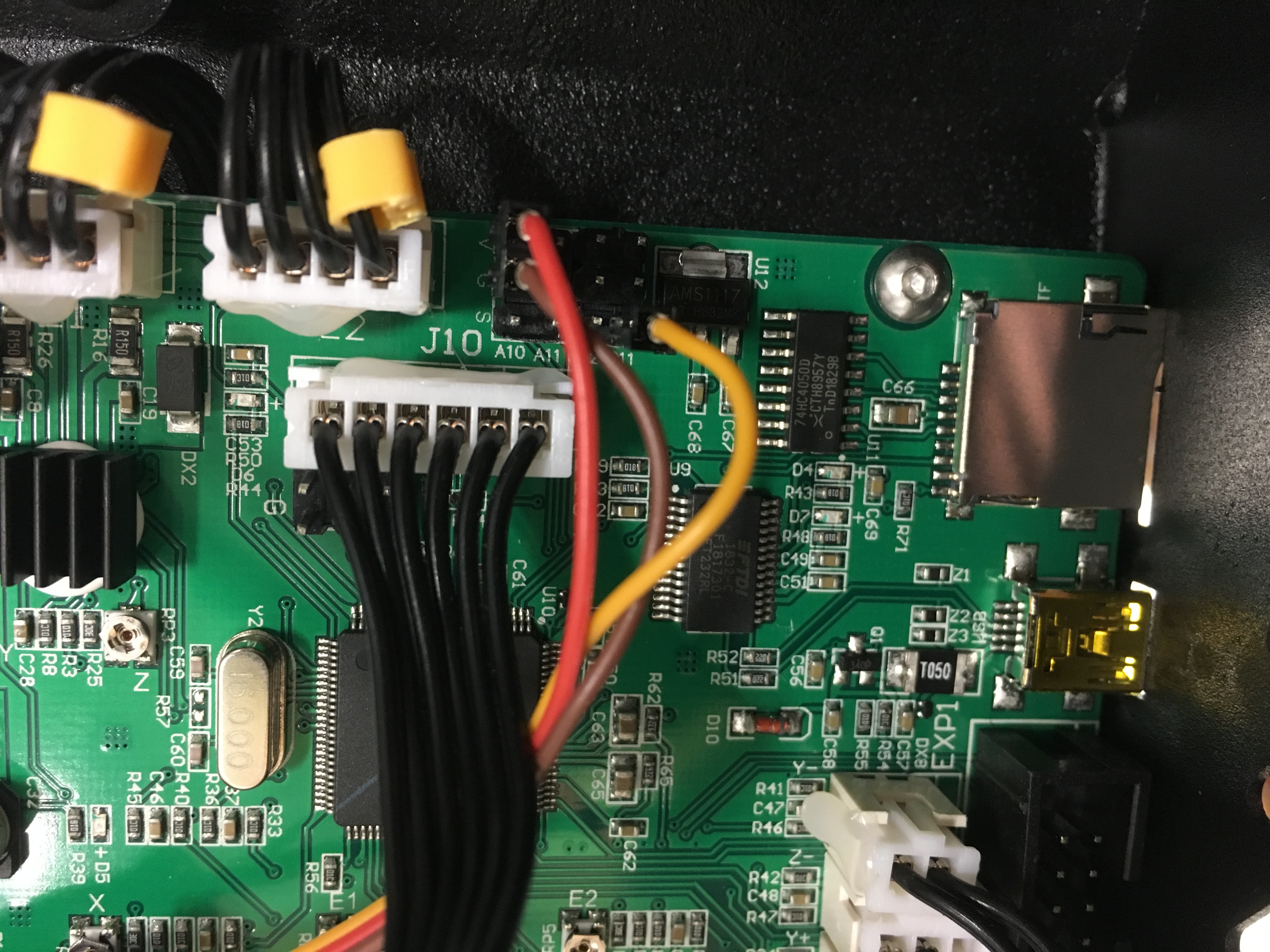

Here's one idea to add the external pullup.

Steps:

- Keep the wire cable installed. It helps keep the pins from moving if the connector gets hot.

- Pre-form the 1/8W 1K resistor

- Pre-tin the resistor and the connector

- Using a tweezers to hold the resistor, tack the resistor lead to the white wire contact.

- Use the tweezer to bend the othe lead into the final position.

- Solder the resistor to the red wire's contact.

- Re-solder the white wire contact.

- Clip the excess resistor wire.

- Apply thick super glue to the resistor. Do not put the glue on the connector or you may end up glueing the two mating parts together.

Yes, I know the picture has a 10K in it but I couldn't find my 1K 1/8W resistors.

@InsanityAutomation - Thanks for all your help so far. I am having some issues with customers and the CR10S pro with the 3.0. Can you confirm or deny that your firmware is updated to resolve these issues as of now? Is there anything else the user has to do besides uncomment the machine and ALB Bl touch?

@Bob-the-Kuhn : On my GT2560, it is as you say:

On the other hand it would be similar to a mega2560 & RAMPS with mechanical switches and no external pullup resistors. In that case the only pullup would be the Rpu.

Just the Rpu. And yes, there is a danger of noise on a bunched up cable to the extruder, I can confirm.

On my MKS SBASE, things are more complicated (3.3V):

I need to find out the values of the components on the GPIO input and will post them here. But: These are part of an effort to make the input pin 5V tolerant, which is really not needed, this MPU already has got internally 5V tolerant input pins on this specific port. I will test the BLTouch V3.0 on this board when it arrives.

It would seem consensus is nearly reached:

ANTClabs statement is that removing that one single capactor should solve the problem (see far far above). Not really desirable, I know, but that capacitor probably should be added in to your rise-time estimates.

If (as confirmed) in the default open-drain mode with just the Rpu active, the V3.0 won't work, and ANTCLABS speak of removing the capacitor, the problem this addresses is the rise-time. Then the ONLY good solution would be to add a pull-up (as you suggested. Easier to add something (a pullup) than to remove something (the capacitor) especially as a lower pull-up impedance and a capacitor will subdue noise more effectively, which is definetly a problem (one such issue was actually mentioned further up).

@paulpenny I added the code to the source section, but one user reported it still wasn't working. Made a bracket earlier today and I plan to hook it up and see what's going on with that board either today or tomorrow.

@InsanityAutomation Thanks so much! We're big fans of your firmware and any issues our customers have with the 10SP seem to be solved with it. Until now of course ;)

@paulpenny - thank tinymachines for donating a development machine! As soon as they saw how bad it was stock he got one to me so I could figure it out! The Marlin 2.0 port is progressing. It's not done, but far enough to at least show at mrrf.

Ended up here after having issues installing new Bltouch and discovered I got the V3.0 from the same amazon link above that CWspear posted. I have an ender 3 would it be possible if someone posted the new marlin 2.0 profile set up for that?

Here's another idea on adding an external 1K pull up resistor. Definitely easier to do.

@Bob-the-Kuhn would just adding this resistor solve the V3.0 issues without needing to update the firmware(besides uncommenting it)?

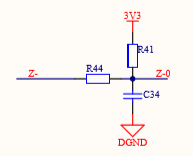

Folks just some more data points for you. The MKS Sbase and Bigtreetech SKR V1.1 (and probably V1.3) both have similar input circuits (see the schematic posted above by @FanDjango). On the SKR schematic the values are:

R41: 10K (pullup to 3.3V)

R44: 1K (inline with input)

C34: 0.1uF (between ground and the pullup)

On the Sbase schematic these seem to be:

R41: 1K (pullup to 3.3V)

R44: 5.6K (inline with input)

C34: 0.1uF (btween ground and the pullup)

Will the external pullup work for both of these?

If Antclabs is saying the problem can be fixed by removing that capacitor on the BL-Touch probe... Does this mean they will start shipping without that capacitor?

@Roxy-3D that would be an easy fix but has anyone confirmed it? I don't want to clip mine and find out I trashed my bltouch.

@Roxy-3D

Afaik, antclabs was referring to the C7 capacitor on the Ender 3 mainboard not a capacitor on the BLTouch

That's what I heard as well.

Thank You for the clarification!!!

I believe that adding the 1K external pullup will make the V3.0 act the same as previous BLTouch versions.

@gloomyandy - I'm pretty sure that neither of these need the 1K external pullup. The V3.0 should work with or without the software mods.

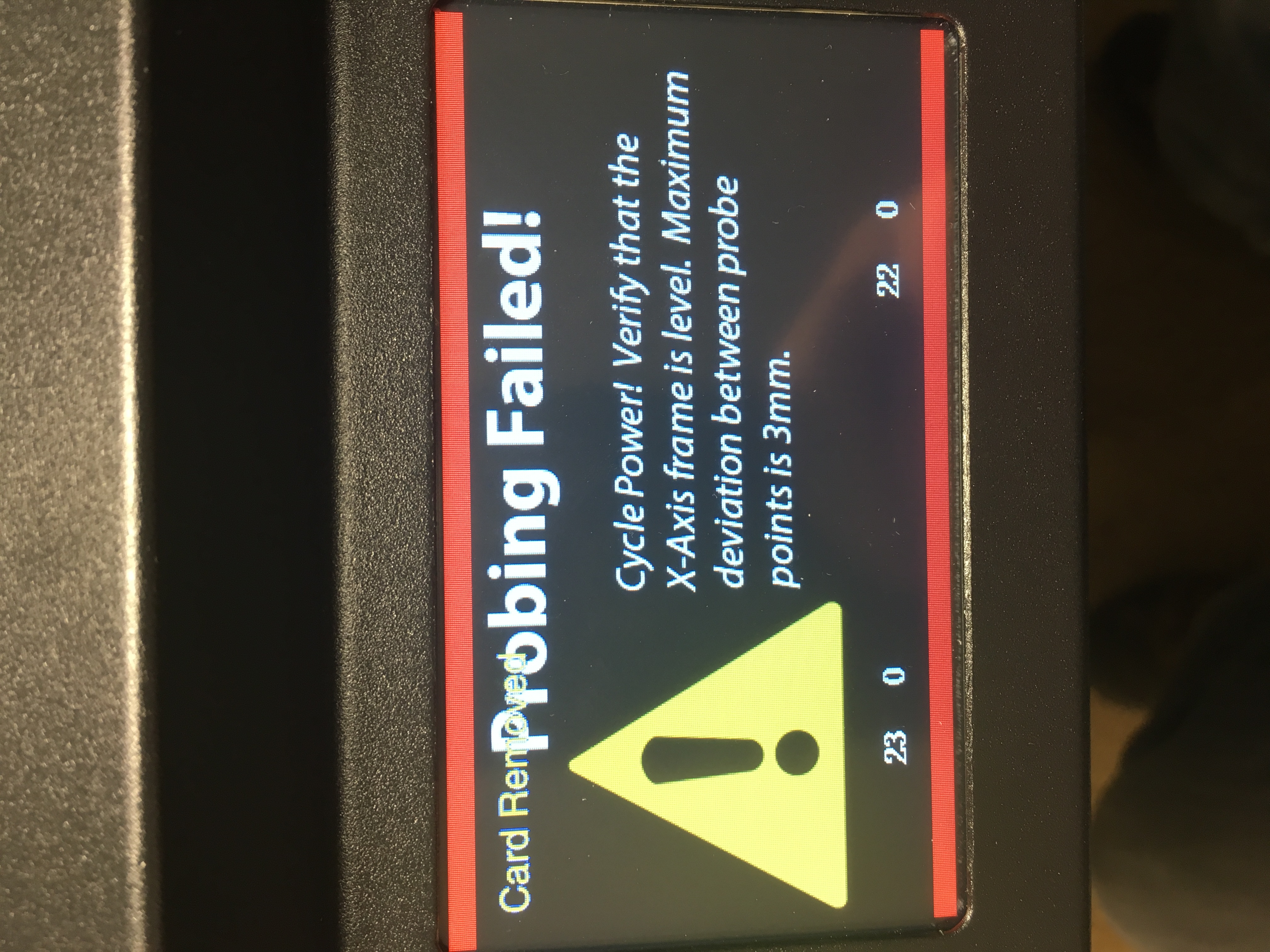

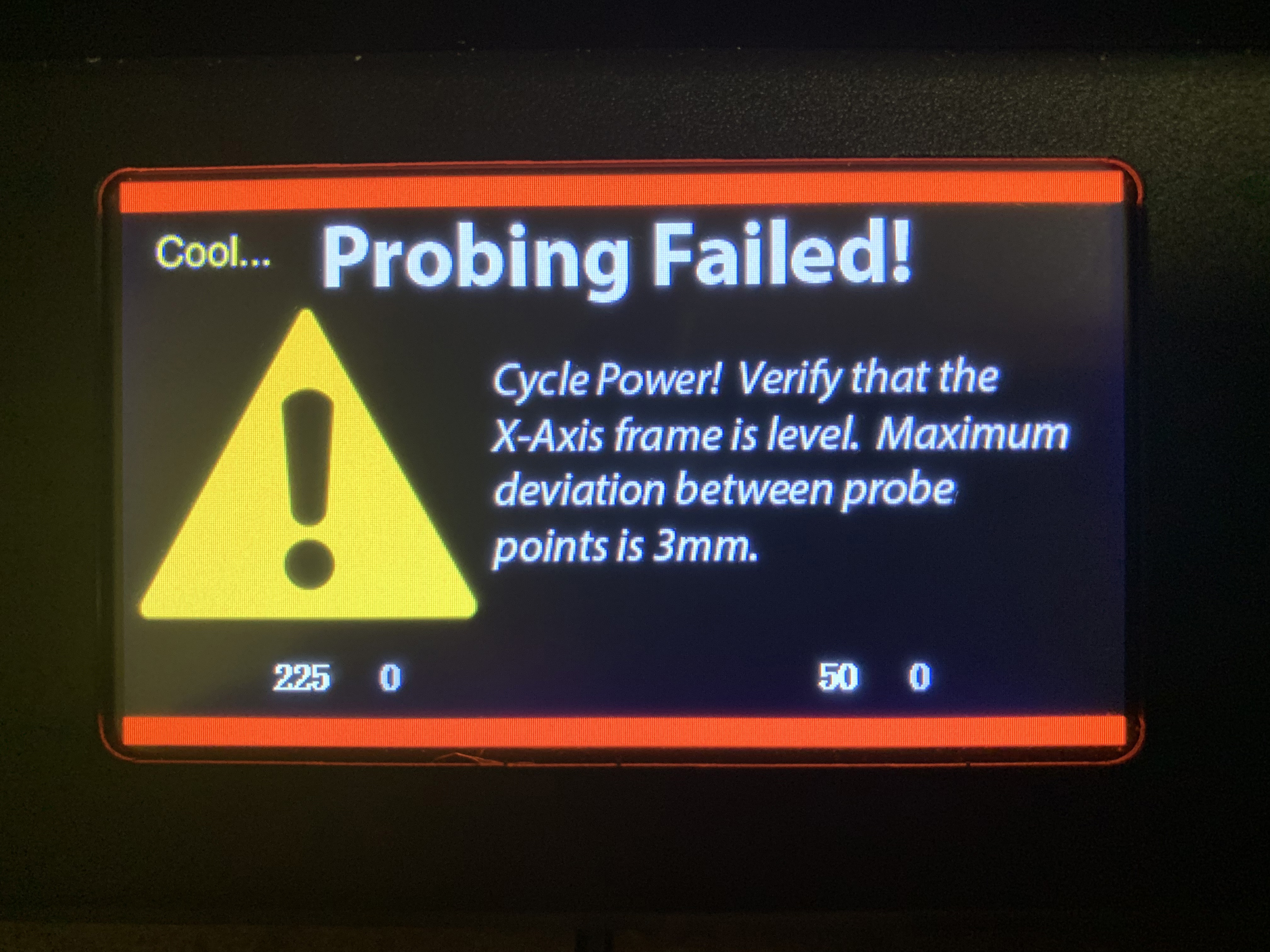

I'd just like to mention that I ran into the same issue with the new BLTouch v3.0. G28 would crash into the bed, G29 would skip points or not finish the leveling.

Switching to the new Marlin 2.0.x bugfix version solved my issue. Thanks!

Upgrading my CR-10S Pro with the BLTouch v3.0 and the InsanityAutomation Creality_DWINTest firmware drove me a little crazy on weekend. After several crashes with creepy sounds of the motors, I found this Bug-Report. The workaround with the 1k resistor doesn’t work for me.

I also found this CR10SP mod https://www.reddit.com/r/CR10/comments/aq6fi9/finally_cr10spro_with_bltouch_without_that_stupid/ by 33cl. He uses different PINs than in the the 3D Printing Canada Video do. For initial tests I used 33cl’s firmware and the BLTouch works without any problems. On G28 the probe deploys and the motors stop on contact.

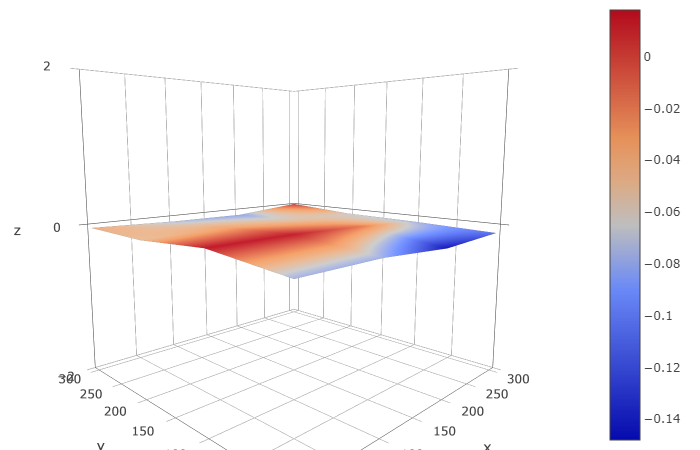

After comparing the BLTouch related parts in the two firmwares I modifyed the Creality_DWINTest firmware with code from 33cl's and it seems to work. I'm not happy with the actual levelling results but thats a whole different problem.

I second @Ragaroah comment. Installed Marlin 2.0.x bugfix and now the BLTouch v3.0 is working great on my Ender 3-S.

Thanks for all the efforts!

@gtorige - just to confirm - the V3 works on the Ender 3 with Marlin 2.0.x bugfix and no other changes?

If yes then that's VERY good news for the community. That means the addition of an external resistor is not needed by anyone!

I don't understand but I'm glad to be wrong in this case.

Indeed @Bob-the-Kuhn, no issues now. I'm able to run G29 and G28 without any problems on my Ender 3 Pro.

@Bob-the-Kuhn correct. Ender 3 with Marlin 2.0.x bugfix and BLTouch V3.0. No resistor added

I just did the standard changes on Configuration.h and Configuration_adv.h to enable BLTouch like uncommenting the #defines for BLTouch, adding the #define SERVO0_PIN 27, adjust offsets and disable speaker, SD Card, slim LCD, etc... In Configuration_adv I've enabled babysteps and disabled ARC.

Just basic changes. If there's something I should try to help the community feel free to ask

Edit: my board is the Melzi by Creality v1.1.4

@Bob-the Kuhn Would it be okay to use a 1/4W 1K resistor. That’s all they have at Altex...

Has anyone solved this bug for the CR-10S PRO?

@kuksinsky I have the code that should work in the DwinTest branch in my fork, however reports indicate its still having issues. I planned to hook it up on that machine this weekend but ran out of time. I may get to it tonight.

@jacobwtyler - the wattage isn't important. The 1/8W was thinner leads which is easier to use.

Have you tried the latest Marlin 2.0.x code? Reports are coming back that the new code is all that was needed for the Creality Ender 3 which we think is the worst case.

It's looking like an external pullup is not needed.

Upgrading my CR-10S Pro with the BLTouch v3.0 and the InsanityAutomation Creality_DWINTest firmware drove me a little crazy on weekend. After several crashes with creepy sounds of the motors, I found this Bug-Report. The workaround with the 1k resistor doesn’t work for me.

I also found this CR10SP mod https://www.reddit.com/r/CR10/comments/aq6fi9/finally_cr10spro_with_bltouch_without_that_stupid/ by 33cl. He uses different PINs than in the the 3D Printing Canada Video do. For initial tests I used 33cl’s firmware and the BLTouch works without any problems. On G28 the probe deploys and the motors stop on contact.

After comparing the BLTouch related parts in the two firmwares I modifyed the Creality_DWINTest firmware with code from 33cl's and it seems to work. I'm not happy with the actual levelling results but thats a whole different problem.

Marlin.zip

@RmnX1 I tried your firmware on my cr-10s pro and it didn't seem to work. when i go to the levelling menu, the x and y home and the bltouch sensor comes out and goes back in and stops.

@ RmnX1 I tried your firmware on my cr-10s pro and it didn't seem to work. when i go to the levelling menu, the x and y home and the bltouch sensor comes out and goes back in and stops

@Bl0wnp0ny Have you wired the BLTouch as described in 33cls howto?

Brown -> A10G

Red -> A10V

White -> D12S

Yellow -> D11S

Black -> nc

Homeing and leveling work for me, but the leveling results vary greatly. Also, the adhesion is very bad despite correcting Z offset during print. :/

good call. i forgot to move my white wire. So black doesn't get connected?

is your leveling results related or something different?

Are you still on the original build surface? I found wiping the bed at temp with a damp towel works very well.

@RmnX1 just rewired and no go. going to try uploading your firmware again.

@Bl0wnp0ny Right. The black doesn't get connected

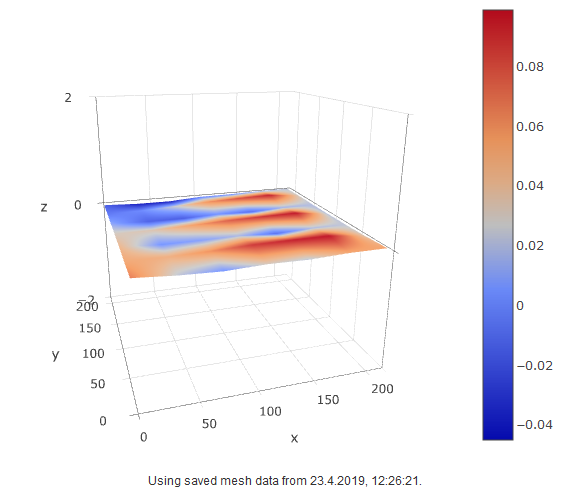

I did three levelings in a row after a print. The last two are very close together

https://nxc.oliver-assmus.de/index.php/s/SzZ3Xd8WEc3ECy9

I'm using the original surface and clean it with isopropanol before printing. The printer is just one week old and it's my first one, so it's all really new to me. Till now it's also more try and error for learning. But I think that the stock 1.60.3 firmware with the capacitive probe got better printing results instantly after unboxing.

I can check my cabeling and flash my firmware again. Maybe I forgot something to mention...

Okay...here's my cabling https://nxc.oliver-assmus.de/index.php/s/SzZ3Xd8WEc3ECy9#//IMG_3202.JPG

Don't be surprised about the cable colours. I used a network cable to expand the BLTouch cable. On the picture

green (BL red) --> A10V

brown (BL brown) --> A10G

white/blue (BL white) --> D12S

orange (BL yellow) --> D11S

blue (BL black) --> not connected

I also flashed my firmware mod again and did a "offline test" only USB connected with manually moves of x and y to the stop.

G28 x

SENDING:G28 X

[...]

ok P15 B3

G28 y

SENDING:G28 Y

[...]

ok P15 B3

G28 z

SENDING:G28

[...]

ok P15 B3

A few seconds after G28 Z the probe deployed, I touched it. A few seconds later it deployed again, I touched it again and got the ok.

Maybe you can flash the firmware from 33cl and do some tests with Printrun.

interesting that the last 2 are very close together. Was the bed cooling off while leveling?

let me know if you find anything. i have the red, brown, and orange wires wired up like the original bltouch, the black wire is clipped with no connection and the white wire is connected next to the orange jumper.

No. The bed temperature was permanently set to 70°C (because it's the temperature inside of the heating and the delta to the surface is 10°C at my setup). The first measuring was after moving all axes. The second directly after the first, and the third directly after the second. I'll keep testing and learning.

@Bob-the-Kuhn I got the printer (actually a CR10) working with the 1/4W pull-up but I haven’t tried the v2.0 firmware fix yet. Seems to be some inconsistency in the mesh bed leveling so I think I’m going to try the software fix and clip off the pull up. Would it make any sense to do this? Seems like there is still a slight delay between when the probe touches the bed and when it retracts.

Yes, removing the resistor makes sense. So far everyone has said the new marlin code is all that was needed.

The pulling up of the probe is solely under control of the BLTouch. It'll come back down unless Marlin issues a stow command.

@kuksinsky I have 10S Pro, but I'm still hesitant to disassemble current capacitive sensor and replace it with BLTouch V3.0 since I don't have a base that is working and I wouldn't know what is the problem if something goes wrong.

Once @InsanityAutomation gives a green light with particular pair of Mainboard+LCD firmware to flash I can try upgrading that.

Some people reported poor sensing, but there is another difference between BLTouch 2.2 and 3.0 - the recommended distance between the sensor and the bed is now 4mm +/- 0.3mm, so old mount adapters are no longer optimal.

tempted to go back to the stock sensor until this is figured out. i already cut the capacive sensor's connector off to wire up the bltouch so i'll have to solder it back on. At least it was decently usable. My printer has been idle for almost 2 weeks now.

@RmnX1 do I need to uncomment #define BLTOUCH_FORCE_5V_MODE in your modified firmware?

nvm that didn't seem to work either.

My BL Touch has been a paper weight since I got it. Lucky I saw this bug before I started installing it!

Hope @InsanityAutomation can come up with an awesome solution since Antclabs has been no help!

@StreckerCM

My BL Touch has been a paper weight since I got it. Lucky I saw this bug before I started installing it!

Hope @InsanityAutomation can come up with an awesome solution since Antclabs has been no help!

Current bugfix-2.0.x contains pull-commits by @InsanityAutomation to support the BLTouch V3.0.

Note that there are printer types out there that

a. will work unchanged

b. will work if a 1K pullup is connected to the signal line and +5V

c. will work if the newest Marlin bugfix-2.0.x is flashed, configuration is modified, no 1K pullup needed

and maybe some more - like "doesn't work yet".

So what is your printer?

@FanDjango it is a CR10S Pro

@Bob-the-Kuhn

Something I would like to run by you:

In open-drain mode (the default), the V3.0 BLTouch should be acting like a normal-closed microswitch SIGNAL to GND.

Take any printer that can handle such a microswitch as a probe, for example the ones mounted on a servo. If that printer is configured to work with that switch, it should work with the BLTouch in open-drain mode as well, were it not for the output only being a pulse - a real switch closes "a long time". Sadly, due to capacitances and pull-ups being widely different on various printers, the effective length of the pulse varies greatly.

Shouldn't we try configuring the input pin in the same way as if we had connected a normal micro-switch and because of the pulse nature of the signal, make sure this pin is interrupt-capable and turn on the interrupt?

I suppose that since not all scenarios have got interrupt capable probe pins, one must alternatively resort to sampling the pin - but then the sample rate must be made significantly higher than it is now.

The current solution to use 5V mode or a 1K pullup just make the pulse width at the MCU longer, which kind of proves that point.

So in my mind the best solution would be to use the BLTouch in the default mode and make sure we don't miss the short pulse.

It is also interesting to note that ANTClabs actually comment on not needing or wanting the capacitors so prevalent on many printers boards, (rightly) claiming that it lowers accuracy (although it might be needed in noisy environments):

(this is from their website)

Hello Everyone,

I've been following this thread closely and I would like to add that I purchased 2 BLTOUCH V3's recently and installed them on a FLSUN C Plus machine with a MKS Gen L v1.0 board running 1.1.9 with no issue, started working right away with no modifications to the software (with the exception of enabling BLTOUCH) or hardware. I also installed it on a Zonestar P802NR2 running a ZRIB V2.1 board (2560 chip) (I know that this printer was never meant to have a BLTOUCH but I like to print on glass and the inductive sensor wasn't cutting it), wouldn't work under 1.1.8 or 1.1.9. But after a long reconfiguring and pin remapping (using X+ for the servo pin) and using Marlin 2.0 with the BLTOUCH_FORCE_5V_MODE and OPEN DRAIN MODE, it is working great now, the only major thing is to use the new 4.3mm distance instead of the 3.3mm offset. Works like a charm now, thanks to everyone involved in providing the fix.

Jeff

@FanDjango - the input pin configuration for a BLTouch IS the same as for a NC mechanical switch.

The difference used to be in how fast it was sampled. Currently all types of endstops are sampled at the same rate - no more than 2mS apart. Two consecutive active samples are needed to declare an endstop active.

What the interrupt mode does is start the sampling sooner. After that it's every 2mS max.

Marlin is designed to catch the 5mS pulse of the original BLTouch. It takes quite a big capacitor to shorten the V2's and V3's 10mS pulse to under 5mS.

I'm doubious of the accuracy claim. It's repeatability that matters most. As long as the homing speed doesn't change then the home position of the head will stay the same.

After some tests with the @InsanityAutomation firmware and the 33cl's firmware and cabeling for the CR-10S Pro, my BLTouch v3.0 works in general with Z_MIN_PROBE_ENDSTOP instead of Z_MIN_PROBE_USES_Z_MIN_ENDSTOP_PIN. The probe works how expected (deployment, stowing and triggering), also the homing. Despite many times in manual leveling and preparation, the auto-leveling results are very unsatisfying. My prints will start with a default Z-Offset of -0.9 up to -1.0 but the adhesion is always very bad and differs much on different bed positions. With 33cl's firmware it's a little better than with InsanityAutomation

@Bl0wnp0ny I took 33cl's firmware as reference and there is no #define BLTOUCH_FORCE_5V_MODE. So I commented it and also modified other references. For me it works. After new changes, I always test them with an unpowered printer, only the board connected via USB and send G-Codes on serial monitor. Only if I'm sure that the printer won't destroy itself, I do tests with power on. Thats are my lessons learned from the first tries ;-)

I'm not very familiar with 3D printing and Marlin yet and unfortunately I do not have much time to test currently. But the configuration gives incredible many options for optimization. It makes a lot of fun to me!

Hi Jeff,

I saw your email earlier and have a couple of questions. I too just purchased a BLTouch v3 (timing is everything). I'm planning to install it in a Tevo Tornado which has the MKS Gen L v1.0 board. Based on your experiance it looks like I should not have any issues. The one question I have is, you mention the change in the offset from 3.3mm to 4.3mm. Is this within the software or physically with the mount?

Sincerely,Brian [email protected](737) 529-6751

On Wednesday, March 27, 2019, 10:22:07 AM CDT, estrelaj <[email protected]> wrote:

Hello Everyone,

I've been following this thread closely and I would like to add that I purchased 2 BLTOUCH V3's recently and installed them on a FLSUN C Plus machine with a MKS Gen L v1.0 board running 1.1.9 with no issue, started working right away with no modifications to the software (with the exception of enabling BLTOUCH) or hardware. I also installed it on a Zonestar P802NR2 running a ZRIB V2.1 board (2560 chip) (I know that this printer was never meant to have a BLTOUCH but I like to print on glass and the inductive sensor wasn't cutting it), wouldn't work under 1.1.8 or 1.1.9. But after a long reconfiguring and pin remapping (using X+ for the servo pin) and using Marlin 2.0 with the BLTOUCH_FORCE_5V_MODE and OPEN DRAIN MODE, it is working great now, the only major thing is to use the new 4.3mm distance instead of the 3.3mm offset. Works like a charm now, thanks to everyone involved in providing the fix.

Jeff

—

You are receiving this because you are subscribed to this thread.

Reply to this email directly, view it on GitHub, or mute the thread.

Hey Brian,

I was referring to the mounting position, the offset from the nozzle to the tip of the BL. You also need to set the Z Probe offset in the software too.

Jeff

Jeff,

Thanks for the quick reply. I have enough variability in the mount that I can account for the extra 1mm of offset. The springs should be able to soak that up. Was there anything else that you had to do differently with the Gen L board? If not I'm going to start the upgrade!

Sincerely,Brian [email protected](737) 529-6751

On Thursday, March 28, 2019, 12:12:23 AM CDT, estrelaj <[email protected]> wrote:

Hey Brian,

I was referring to the mounting position, the offset from the nozzle to the tip of the BL. You also need to set the Z Probe offset in the software too.

Jeff

—

You are receiving this because you are subscribed to this thread.

Reply to this email directly, view it on GitHub, or mute the thread.

Not really, just make sure you're on 1.1.9 or higher of Marlin

Hello everyone

I got the BLTouch V 3.0 working on my Ender-5 !! I updated to Marlin 2.0.x bugfix and defined bltouch AND IMPORTANT: define BLTOUCH_V3 ! With these two settings done and of course all the other settings you would do on Marlin 1.1.x, my BLTouch worked perfectly !

Thanks to everyone :)

Paul with my CR 10S pro if I upload the bug fix for BLTouch 3 will it fix the problem........... I also changed Z_MIN_PROBE_ENDSTOP instead of Z_MIN_PROBE_USES_Z_MIN_ENDSTOP_PIN but no luck still does not work...... very frustrating having a new probe and cannot use it.

Paul with my CR 10S pro if I upload the bug fix for BLTouch 3 will it fix the problem........... I also changed Z_MIN_PROBE_ENDSTOP instead of Z_MIN_PROBE_USES_Z_MIN_ENDSTOP_PIN but no luck still does not work...... very frustrating having a new probe and cannot use it.

What pins did you connect it to? It is possible that the bltouch v2 connection scheme is not suitable for the third version.

Been doing some testing here with BLTouch V3.0

On my MKS SBASE V1.3 it is a drop-in replacement for the previous BLTouch probe, no problems. Needed to change the Z-Offset though, so on the mechanical side it is maybe not a drop in replacement after all, but this is documented in their datasheet.

I would like to sum up some of the previous posts:

Thanks to the efforts of @InsanityAutomation and @Bob-the-Kuhn there are hardware and software solutions to the BLTouch V3 problems:

YOU ARE LUCKY; YOU DONT NEED TO FLASH NEW FIRMWARE and DONT NEED TO SOLDER A 1K PULLUP, if...

...your printers controller board has given the designated input pin enough pull-up (either because the processor involved has got "good enough" pull-ups internally and you have set the pull-ups to be active, or because they have added external pull-ups on the board), the BLTouch V3.0 will work just like the previous ones. NO NEED TO FLASH a the new Marlin firmware with the BLTouch V3.0 support in this case, and even if you do, no real need to #DEFINE the BLTOUCH as V3, but I would recommend it. If you are in doubt, why not post your printer/controller board here and let's check the schematics to see what's all connected on that pin and what the chances are.

Otherwise, if you...

DONT WANT TO FLASH A NEW FIRMWARE...

...chances are close to 100% that soldering a 1K resistor between the white (PROBE SIGNAL) and the red (5V) wires of the probe will get it working. The wattage and the physical size of the 1K resistor is secondary, but the smaller the better for fitting it in somewhere (see above - posts by @Bob-the-Kuhn and further down by @StreckerCM).

Otherwise, if you...

DONT WANT TO SOLDER ANYTHING

...chances are close to 100% that using the new Marlin firmware or if you need special versions (a special fork) for your printer, using a newly updated version of that fork which contain the recently made changes for the BLTouch V3.0 will get it working. In this case, you need to then use the correct definitions in the BLTouch section of configuration.h and then flash the new firmware (see above, but also check the github commit history).

Otherwise ...

TOUGH LUCK?

(meaning the BLTouch V3.0 does not work for you as is, you don't wan't to add a 1K pullup and you don't wan't to flash a new firmware) ... all is not lost. If this is an idividual case, you could offer to swap with someone that is willing to give you his previous version of the BLTouch in exchange. Maybe you could ask in here?

Paul with my CR 10S pro if I upload the bug fix for BLTouch 3 will it fix the problem........... I also changed Z_MIN_PROBE_ENDSTOP instead of Z_MIN_PROBE_USES_Z_MIN_ENDSTOP_PIN but no luck still does not work...... very frustrating having a new probe and cannot use it.

What pins did you connect it to? It is possible that the bltouch v2 connection scheme is not suitable for the third version.

Hello Kuksinsky

Ive connected the pins exactly like Jason at 3D Printing Canada shows on there Youtube channel https://www.youtube.com/watch?v=PLKEhdznVMY

so

(bottom left (S)ignal) rowD11 (Orange wire), then (top middle (G)round) row A10 (Brown wire) and finally top right (V)olt row A10 (Red wire)

Paul with my CR 10S pro if I upload the bug fix for BLTouch 3 will it fix the problem........... I also changed Z_MIN_PROBE_ENDSTOP instead of Z_MIN_PROBE_USES_Z_MIN_ENDSTOP_PIN but no luck still does not work...... very frustrating having a new probe and cannot use it.

What pins did you connect it to? It is possible that the bltouch v2 connection scheme is not suitable for the third version.

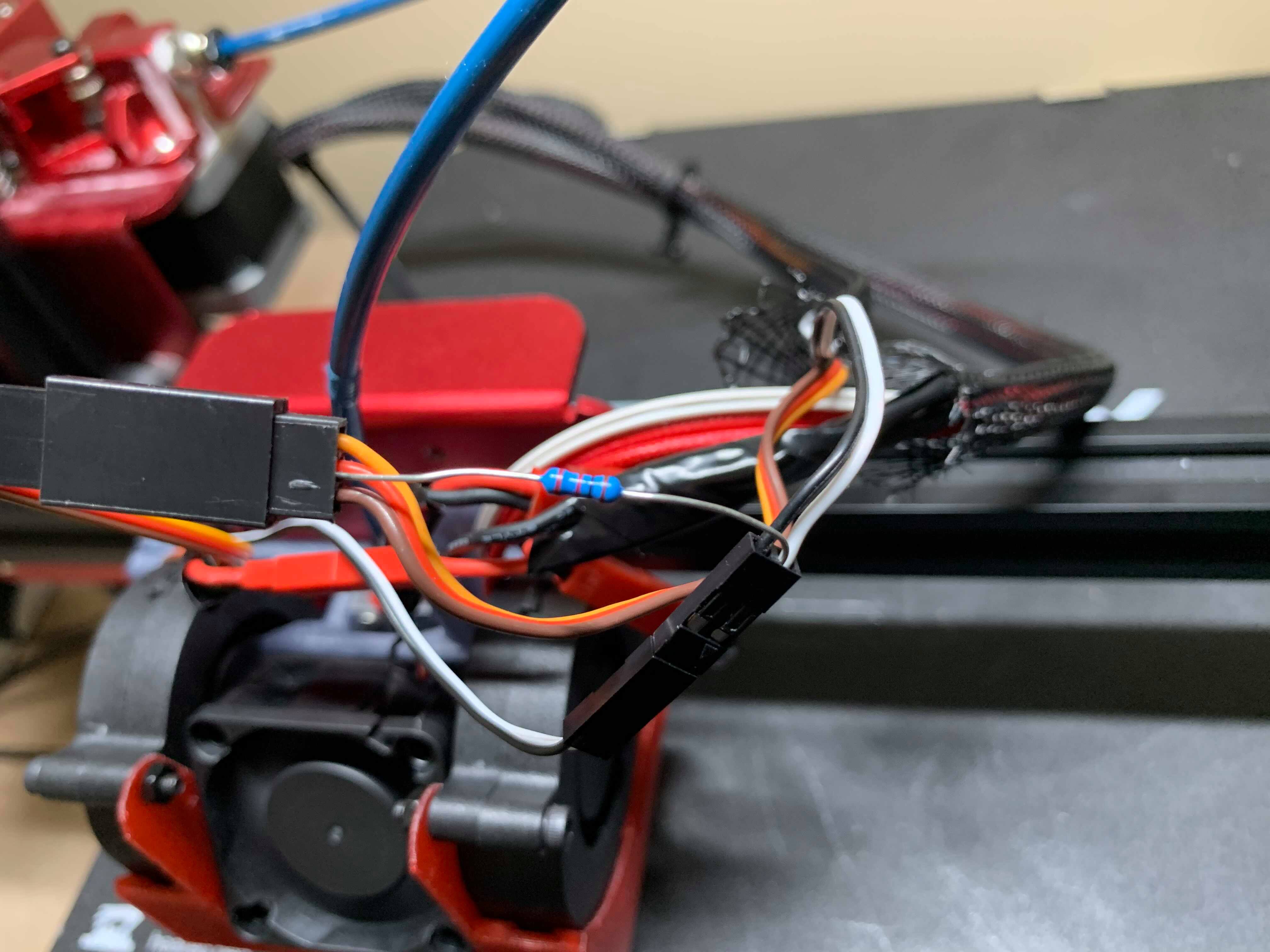

Here are some pictures of the pins I use on my Cr10S pro

Ive connected the pins exactly like Jason at Canada 3D printing shows on there Youtube channel https://www.youtube.com/watch?v=PLKEhdznVMY

so

(bottom left (S)ignal) rowD11 (Orange wire), the (top middle (G)round) row A10 (Brown wire) and finally top right (V)olt row A10 (Red wire)

Can we back port this fix to the 1.1-Bugfix branch? It would be nice to have this in a production-worthy release sooner rather than later. I would draft the PR myself but I don’t feel comfortable enough with the marlin codebase and development processes to know if this is more than just a straight up cherry-pick or what.

anybody can help me solve this problem with my Cr10S pro....... and BLTouch 3.0

please let me know if you have the same printer and got it to work......

sincerely GilLarose

I have an anycubic i3 mega with trigorilla board and the same problem with the bltouch v3. I can control it but when i start g29 the bltouch doesnt trigger and the nozzle hits the bed.

I just finished working through this issue on an Ender 3. I resolved it by

pulling down the latest 2.0-Bugfix build from the website and then enabling

BLTOUCH_V3 and all of the associated options.

On Fri, Mar 29, 2019 at 2:35 PM mister2212 notifications@github.com wrote:

I have an anycubic i3 mega with trigorilla board and the same problem with

the bltouch v3. I can control it but when i start g29 the bltouch doesnt

trigger and the nozzle hits the bed.—

You are receiving this because you commented.

Reply to this email directly, view it on GitHub

https://github.com/MarlinFirmware/Marlin/issues/13345#issuecomment-478105357,

or mute the thread

https://github.com/notifications/unsubscribe-auth/ABg6FkvTzfHTJFEkzLMnR8XkhqBvnMT-ks5vblzagaJpZM4bmrEd

.

@caseyjmorton do you mind sending me a copy of your configuration.h file and back end advanced

Not at all. I’ll send it a little later tonight once I get home. Keep in

mind that you will need to customize the probe offsets. I am using the Hero

Me gen 2 hotend duct/mount, which I highly recommend. I’ll post a like to

the files for it on thingiverse if you are interested.

On Fri, Mar 29, 2019 at 8:40 PM Kaisertron notifications@github.com wrote:

@caseyjmorton https://github.com/caseyjmorton do you mind sending me a

copy of your configuration.h file and backend file—

You are receiving this because you were mentioned.Reply to this email directly, view it on GitHub

https://github.com/MarlinFirmware/Marlin/issues/13345#issuecomment-478189024,

or mute the thread

https://github.com/notifications/unsubscribe-auth/ABg6FnQmDEt0AVe9XLoZXxTYSGVpr8ikks5vbrKGgaJpZM4bmrEd

.

@caseyjmorton that sounds great a lot of users use the Creality Ender 3 and CR 10 so I think it would be very beneficial for them to have an easy drop file and over right ability. This would help clear up most of the clutter on users finding this thread.

Yeah you are right. It may be best to host the configuration files on a

thingiverse thing on their own. I’ll post a link in a bit.

C

On Fri, Mar 29, 2019 at 9:09 PM Kaisertron notifications@github.com wrote:

@caseyjmorton https://github.com/caseyjmorton that sounds great a lot

of users use the Creality Ender 3 and CR 10 so I think it would be very

beneficial for them to have an easy drop file and over right ability. This

would help clear up most of the clutter on users finding this thread.—

You are receiving this because you were mentioned.

Reply to this email directly, view it on GitHub

https://github.com/MarlinFirmware/Marlin/issues/13345#issuecomment-478192118,

or mute the thread

https://github.com/notifications/unsubscribe-auth/ABg6FgvxaHmB5_2TYxI5pRBmze31ZvRqks5vbrk5gaJpZM4bmrEd

.

Paul with my CR 10S pro if I upload the bug fix for BLTouch 3 will it fix the problem........... I also changed Z_MIN_PROBE_ENDSTOP instead of Z_MIN_PROBE_USES_Z_MIN_ENDSTOP_PIN but no luck still does not work...... very frustrating having a new probe and cannot use it.

What pins did you connect it to? It is possible that the bltouch v2 connection scheme is not suitable for the third version.

Here are some pictures of the pins I use on my Cr10S pro

Ive connected the pins exactly like Jason at Canada 3D printing shows on there Youtube channel https://www.youtube.com/watch?v=PLKEhdznVMY

so

(bottom left (S)ignal) rowD11 (Orange wire), the (top middle (G)round) row A10 (Brown wire) and finally top right (V)olt row A10 (Red wire)

I also did as in this video. This works for the second version. But for some reason does not work in the v3.

I can confirm that @FanDjango 's workaround works on the CR10S Pro. I didn't even need to solder to test it just put the 1K resistor into the back of the dupont connector.

Just going to tape it up to protect it and use it like this until a more permanent solution is found.

@StreckerCM I don't think anything more permanent will be found. The choice is adding the 1K pullup or updating the firmware, which tells the BLTouch to "do a sort of pull-up". I usually glue the two dupont receptacles together with a tiny bit of superglue, thus there is not such a long distance to overcome. But you still risk a crash of the nozzle if the connection ever becomes flaky, thus I prefer the firmware update.

@FanDjango

even if you update the new firmware on the Cr10s Pro IT DOES NOT WORK believe me i have tried you still have to install the pull up 1k resistor to work...... thank you FanDjango i did this today to my Cr10s Pro and boom the BLTouch is now doing its thing.......

Are you enabling ENDSTOPPULLUP_ZMIN_PROBE? Theoretically if you do that in

conjunction with the new BLTouch 3.0 settings it SHOULD work without the

resistor. I don't have a CR10 to validate but I think the CR 10 has the

same board as the Ender 3.

Casey

On Sat, Mar 30, 2019 at 5:28 PM FanDjango notifications@github.com wrote:

@StreckerCM https://github.com/StreckerCM I don't think anything more

permanent will be found. The choice is adding the 1K pullup or updating the

firmware, which tells the BLTouch to "do a sort of pull-up". I usually glue

the two dupont receptacles together with a tiny bit of superglue, thus

there is not such a long distance to overcome. But you still risk a crash

of the nozzle if the connection ever becomes flaky, thus I prefer the

firmware update.—

You are receiving this because you were mentioned.

Reply to this email directly, view it on GitHub

https://github.com/MarlinFirmware/Marlin/issues/13345#issuecomment-478290803,

or mute the thread

https://github.com/notifications/unsubscribe-auth/ABg6FibSG-avkAjfBOx0ZV9U_Fq0Gk6uks5vb9cOgaJpZM4bmrEd

.

Casey,

The problem board seems to be the CR10SP - It has a different board than the CR10.

On Mar 30, 2019, at 7:04 PM, Casey Morton notifications@github.com wrote:

Are you enabling ENDSTOPPULLUP_ZMIN_PROBE? Theoretically if you do that in

conjunction with the new BLTouch 3.0 settings it SHOULD work without the

resistor. I don't have a CR10 to validate but I think the CR 10 has the

same board as the Ender 3.Casey

On Sat, Mar 30, 2019 at 5:28 PM FanDjango notifications@github.com wrote:

@StreckerCM https://github.com/StreckerCM I don't think anything more

permanent will be found. The choice is adding the 1K pullup or updating the

firmware, which tells the BLTouch to "do a sort of pull-up". I usually glue

the two dupont receptacles together with a tiny bit of superglue, thus

there is not such a long distance to overcome. But you still risk a crash

of the nozzle if the connection ever becomes flaky, thus I prefer the

firmware update.—

You are receiving this because you were mentioned.

Reply to this email directly, view it on GitHub

https://github.com/MarlinFirmware/Marlin/issues/13345#issuecomment-478290803,

or mute the thread

https://github.com/notifications/unsubscribe-auth/ABg6FibSG-avkAjfBOx0ZV9U_Fq0Gk6uks5vb9cOgaJpZM4bmrEd

.—

You are receiving this because you were mentioned.

Reply to this email directly, view it on GitHub https://github.com/MarlinFirmware/Marlin/issues/13345#issuecomment-478297016, or mute the thread https://github.com/notifications/unsubscribe-auth/AU_y2VWfcjSOfl9ITYUU77V_bwqd9bodks5vb-2DgaJpZM4bmrEd.

Aaahhh, gotcha. Does that one use the Melzi board?

C

On Sat, Mar 30, 2019 at 7:31 PM paulpenney notifications@github.com wrote:

>

Casey,

The problem board seems to be the CR10SP - It has a different board than

the CR10.On Mar 30, 2019, at 7:04 PM, Casey Morton notifications@github.com

wrote:Are you enabling ENDSTOPPULLUP_ZMIN_PROBE? Theoretically if you do that

in

conjunction with the new BLTouch 3.0 settings it SHOULD work without the

resistor. I don't have a CR10 to validate but I think the CR 10 has the

same board as the Ender 3.Casey

On Sat, Mar 30, 2019 at 5:28 PM FanDjango notifications@github.com

wrote:@StreckerCM https://github.com/StreckerCM I don't think anything

more

permanent will be found. The choice is adding the 1K pullup or

updating the

firmware, which tells the BLTouch to "do a sort of pull-up". I usually

glue

the two dupont receptacles together with a tiny bit of superglue, thus

there is not such a long distance to overcome. But you still risk a

crash

of the nozzle if the connection ever becomes flaky, thus I prefer the

firmware update.—

You are receiving this because you were mentioned.

Reply to this email directly, view it on GitHub

<

https://github.com/MarlinFirmware/Marlin/issues/13345#issuecomment-478290803

,

or mute the thread

<

https://github.com/notifications/unsubscribe-auth/ABg6FibSG-avkAjfBOx0ZV9U_Fq0Gk6uks5vb9cOgaJpZM4bmrEd.

—

You are receiving this because you were mentioned.

Reply to this email directly, view it on GitHub <

https://github.com/MarlinFirmware/Marlin/issues/13345#issuecomment-478297016>,

or mute the thread <

https://github.com/notifications/unsubscribe-auth/AU_y2VWfcjSOfl9ITYUU77V_bwqd9bodks5vb-2DgaJpZM4bmrEd

.—

You are receiving this because you were mentioned.

Reply to this email directly, view it on GitHub

https://github.com/MarlinFirmware/Marlin/issues/13345#issuecomment-478298365,

or mute the thread

https://github.com/notifications/unsubscribe-auth/ABg6FsIvc1PW7Eo6wcf09TNssEGlw1icks5vb_PFgaJpZM4bmrEd

.

The boards are different - the CR10 board is the same as the ender 3 and only has four outputs and is Sanguino based. The CR10S Pro uses an ATmega 2560 base and is considerably different in functionality and layout.

On Mar 30, 2019, at 7:33 PM, Bob Kuhn notifications@github.com wrote:

Same controllers, same software and V3s but one needs the 1K pullup and one doesn't.

I'm starting to think there are two V3 variants:

One where you get a strong pullup and never needs the 1K pullup.

One with a weak pullup that needs the 1K only in a few cases. That's what I have in hand.

—

You are receiving this because you were mentioned.

Reply to this email directly, view it on GitHub https://github.com/MarlinFirmware/Marlin/issues/13345#issuecomment-478298469, or mute the thread https://github.com/notifications/unsubscribe-auth/AU_y2eRtImwEpTux7VXhZQBc9m9bnTeQks5vb_RbgaJpZM4bmrEd.

Nevr mind - just deleted it

Thanks for the clarification.

On Sat, Mar 30, 2019 at 7:36 PM paulpenney notifications@github.com wrote:

The boards are different - the CR10 board is the same as the ender 3 and

only has four outputs and is Sanguino based. The CR10S Pro uses an ATmega

2560 base and is considerably different in functionality and layout.On Mar 30, 2019, at 7:33 PM, Bob Kuhn notifications@github.com wrote:

Same controllers, same software and V3s but one needs the 1K pullup and

one doesn't.I'm starting to think there are two V3 variants:

One where you get a strong pullup and never needs the 1K pullup.

One with a weak pullup that needs the 1K only in a few cases. That's

what I have in hand.

—

You are receiving this because you were mentioned.

Reply to this email directly, view it on GitHub <

https://github.com/MarlinFirmware/Marlin/issues/13345#issuecomment-478298469>,

or mute the thread <

https://github.com/notifications/unsubscribe-auth/AU_y2eRtImwEpTux7VXhZQBc9m9bnTeQks5vb_RbgaJpZM4bmrEd

.—

You are receiving this because you were mentioned.

Reply to this email directly, view it on GitHub

https://github.com/MarlinFirmware/Marlin/issues/13345#issuecomment-478298585,

or mute the thread

https://github.com/notifications/unsubscribe-auth/ABg6FmxXoMTqKceQYPlYPnmljcTQE0jJks5vb_T1gaJpZM4bmrEd

.

IMHO, this is smelling more and more like an issue that Paris needs to

address in hardware.

On Sat, Mar 30, 2019 at 7:37 PM Casey Morton caseyjmorton@gmail.com wrote:

Thanks for the clarification.

On Sat, Mar 30, 2019 at 7:36 PM paulpenney notifications@github.com

wrote:The boards are different - the CR10 board is the same as the ender 3 and

only has four outputs and is Sanguino based. The CR10S Pro uses an ATmega

2560 base and is considerably different in functionality and layout.On Mar 30, 2019, at 7:33 PM, Bob Kuhn notifications@github.com wrote:

Same controllers, same software and V3s but one needs the 1K pullup and

one doesn't.I'm starting to think there are two V3 variants:

One where you get a strong pullup and never needs the 1K pullup.

One with a weak pullup that needs the 1K only in a few cases. That's

what I have in hand.

—

You are receiving this because you were mentioned.

Reply to this email directly, view it on GitHub <

https://github.com/MarlinFirmware/Marlin/issues/13345#issuecomment-478298469>,

or mute the thread <

https://github.com/notifications/unsubscribe-auth/AU_y2eRtImwEpTux7VXhZQBc9m9bnTeQks5vb_RbgaJpZM4bmrEd

.—

You are receiving this because you were mentioned.

Reply to this email directly, view it on GitHub

https://github.com/MarlinFirmware/Marlin/issues/13345#issuecomment-478298585,

or mute the thread

https://github.com/notifications/unsubscribe-auth/ABg6FmxXoMTqKceQYPlYPnmljcTQE0jJks5vb_T1gaJpZM4bmrEd

.

Casey yes i have tried both end stop version and still did not work

Like i wrote on previous thread my printer is the Cr10s Pro and the new firmware will not fix the problem so after uploading the new DWINSET on github/insanityautomation/marlin/creality

and flash the board still did not work so after all that the 1 k resistor did the the trick

Gilbert Larose jr.

Stunt Coordinator

3-2-1 Action inc.

(514) 231-9540

e-mail: [email protected]

web: www.321action.ca

On Mar 30, 2019, at 7:04 PM, Casey Morton notifications@github.com wrote:

Are you enabling ENDSTOPPULLUP_ZMIN_PROBE? Theoretically if you do that in

conjunction with the new BLTouch 3.0 settings it SHOULD work without the

resistor. I don't have a CR10 to validate but I think the CR 10 has the

same board as the Ender 3.Casey

On Sat, Mar 30, 2019 at 5:28 PM FanDjango notifications@github.com wrote:

@StreckerCM https://github.com/StreckerCM I don't think anything more

permanent will be found. The choice is adding the 1K pullup or updating the

firmware, which tells the BLTouch to "do a sort of pull-up". I usually glue

the two dupont receptacles together with a tiny bit of superglue, thus

there is not such a long distance to overcome. But you still risk a crash

of the nozzle if the connection ever becomes flaky, thus I prefer the

firmware update.—

You are receiving this because you were mentioned.

Reply to this email directly, view it on GitHub

https://github.com/MarlinFirmware/Marlin/issues/13345#issuecomment-478290803,

or mute the thread

https://github.com/notifications/unsubscribe-auth/ABg6FibSG-avkAjfBOx0ZV9U_Fq0Gk6uks5vb9cOgaJpZM4bmrEd

.—

You are receiving this because you commented.

Reply to this email directly, view it on GitHub, or mute the thread.

@FanDjango @InsanityAutomation

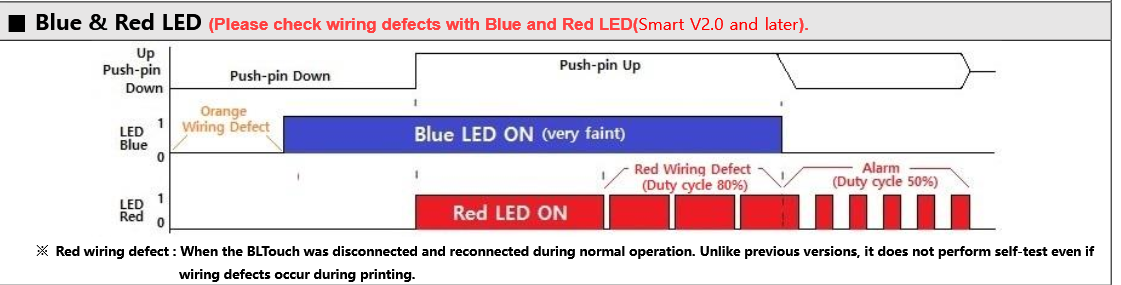

Installed a BLTouch v3 on my Ender3 Pro and i can confirm the Creality_2.0_Devel firmware looks to have the BLTouch working correctly, no c7 snip needed. Though there is the problem with it where it starts off blinking red/blue. On the previous v2 i had installed, on power-up it would do a self test then stay red. with this fw and the V3 it will turn on be red for a moment then blink red-blue 50/50 duty cycle until a auto home is started.

Is this a new/known behavior or is there a bug?

@Stephenm64 To me it looks like the new BLTouch V3 only does a self test when it is commanded to do so. In very cryptic terms on the bottom of the datasheet they mention that the self-test behaviour has been changed. Probably a change for the better, a power-on self test could hit the printed object if it was done for (say) a power glitch on the 5V line. I suppose this is for safeties sake.

@GilLarose So we have found a printer, the CR10s Pro, which needs both the new firmware and the 1K resistor to make the BLTouch V3 work?

It would be nice to know the following, just to totally sure:

- Would the 1K resistor alone, without the new firmware, have done it?

- Before using the 1K resistor, in the new firmware, ENDSTOPPULLUP_ZMIN_PROBE was correctly set?

But if it is working for you now, that's fine. Other's using this printer will come across this here and will go on from this point - @InsanityAutomation who so quickly made the changes to the firmware would probably really like to know why his modifications don't appear to work on one (up to now) special case.

@Stephenm64 Probably a change for the better, a power-on self test could hit the printed object if it was done for (say) a power glitch on the 5V line. I suppose this is for safeties sake.

I guess that also includes "Print resume" after power failure?

I guess that also includes "Print resume" after power failure?

I have been asking myself what prompted ANTClabs to modify the V3 in such a fashion as to cause the problems we have been seeing.

- some new commands (at new servo angles)

- a new output configuration (open drain)

My personal take on this is:

- the old output stage, 5V logic level had two disadvantages: a). Need to cut a trace to change to 3.3V logic (even older probes: you absolutely needed some resistors) b). Can potentially destroy an input pin on a non-5V tolerant processor/controller board

- the power on self test could occur at, let's say, inopportune times

So, what a nice idea, let's make it configurable by software and choose a safe default mode (open drain) which cannot harm anyone. Might not work for everyone - but I think that they surely did some testing of their own and who knows how many probes are being installed and work out of the box somewhere - we only see the fails here, right?