Marlin: [BUG] Layer shifting: Reports and solutions

Is anybody else seeing layer shifts on BugFix 2.0.0 ? I'm seeing one or two of them on long prints. I'm seeing them on the X-Axis (and mostly in the negative X direction).

I'm running an IDEX machine. So mostly, I'm asking if anybody is seeing layer shifts on non-IDEX machines.

Anybody???

UPDATE: I think we know this problem affects non-IDEX machines also. If you are seeing Layer Shifts, please update this thread and let us know what you are seeing.

All 497 comments

I'll chime in quickly to confirm multiple idex machines, and rolling back to 1.1.9 problem vanishes. Working on matching settings and trying to reproduce elsewhere now.

If you have S-Curve acceleration, try disabling it and check if you still get layer shifting (see https://github.com/MarlinFirmware/Marlin/issues/12398).

If possible, please narrow down to a specific date where the problem starts to manifest. This can be done in LOG2(n) steps by following this procedure:

- Test October 1 and see if the problem exists.

- Yes? << Test September 1 and see if the problem exists.

- No? >> Test September 15 and see if the problem exists.

- Yes? << Test September 8 and see if the problem exists.

- Yes? << Test September 4 and see if the problem exists.

- No? >> Test September 6 and see if the problem exists.

In this manner the issue can be narrowed down to a specific date.

References: #9487, #9768, #11047, #11479, #11577, #11801, #11885, #12239, #12365

Hello,

I have the same problem on a CoreXY with a MKS SBase motherboard.

I have done several tests in my case the deactivation of the S-curve acceleration does not change anything.

I will test with the code versions as you request tonight.

After having made many attempts to print the same G-code, the shift of the layers is not random. All the parts I have printed that all have the same offset (all the parts are identical).

That is helpful information. I have so far not been able to reproduce the issue, so if it can be narrowed down to some specific change that will be very useful.

To keep some of the discord info here as well, first user reports of shifts came to me on October 20th. I'll have another machine here Friday to give me more opportunity to test, since it only occurs on long prints it'll be a bit slow going to track down.

To keep some of the discord info here as well, first user reports of shifts came to me on October 20th.

My experience is similar. Using a branch from September 21st... I am NOT seeing the failure.

UPDATE: I think I just saw a shift in both the X & Y axis with the September 21st code.... Damn!!!!

Test with the version of October 29th last night same problem. I do a test with the version of October 15th tonight.

I flashed Oct 13th last night and am running things now.

version of October 15th same problem for me.

October 1st version no layer shift for me it's okay.

October 1st version no layer shift for me it's okay.

I'm not sure that is true! Would you mind doing another long print with it please? I'm pretty sure I saw a dual X & Y layer shift with the September 21st code.

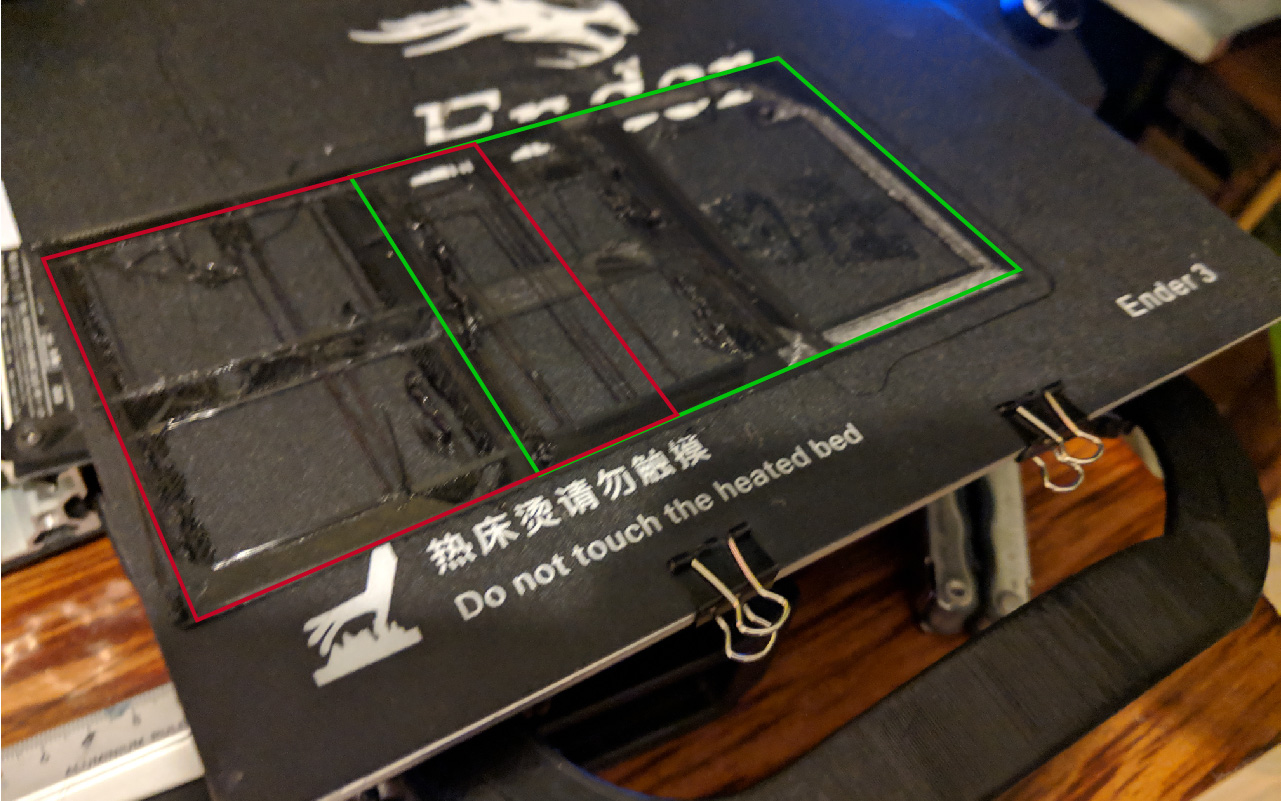

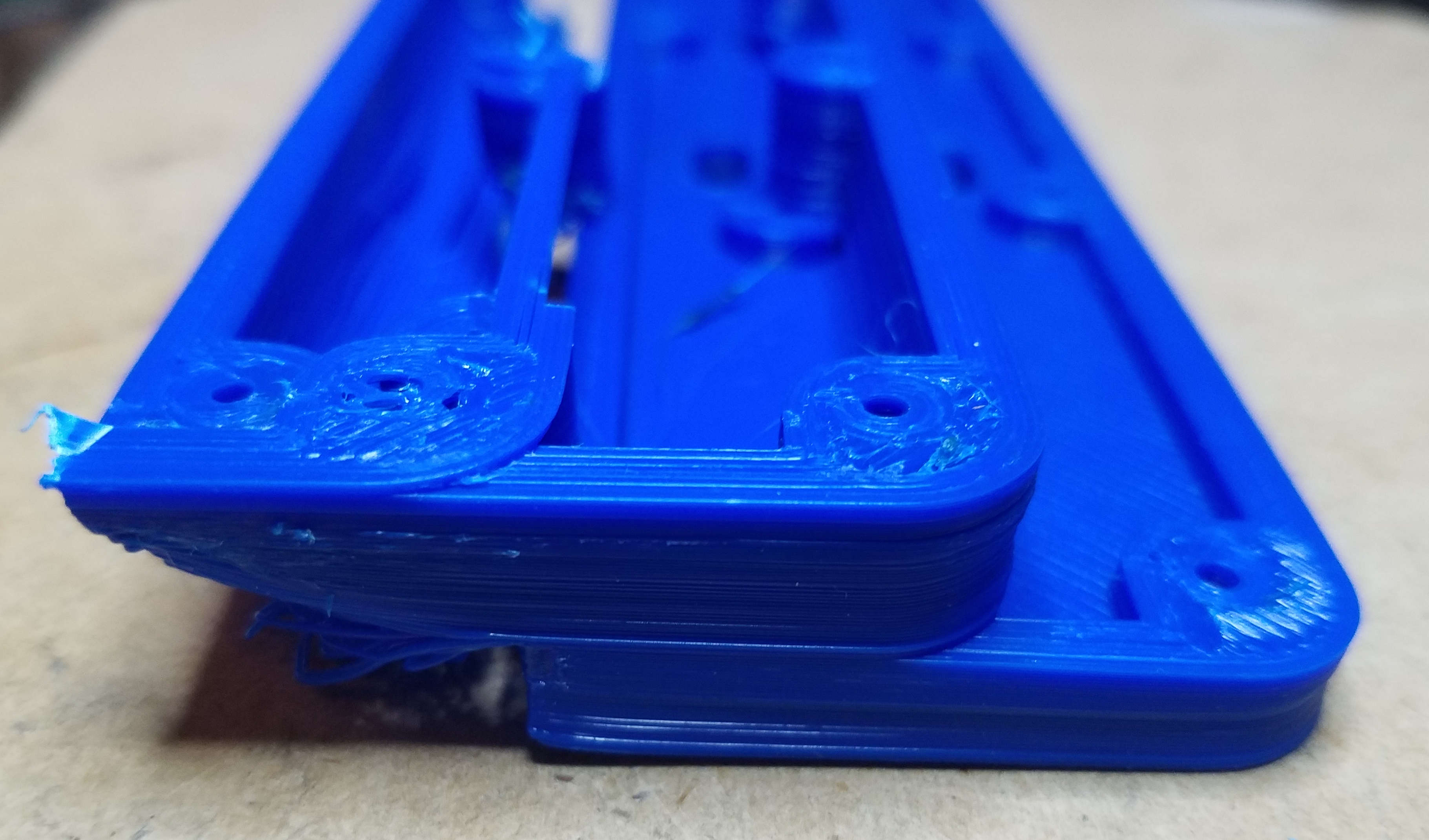

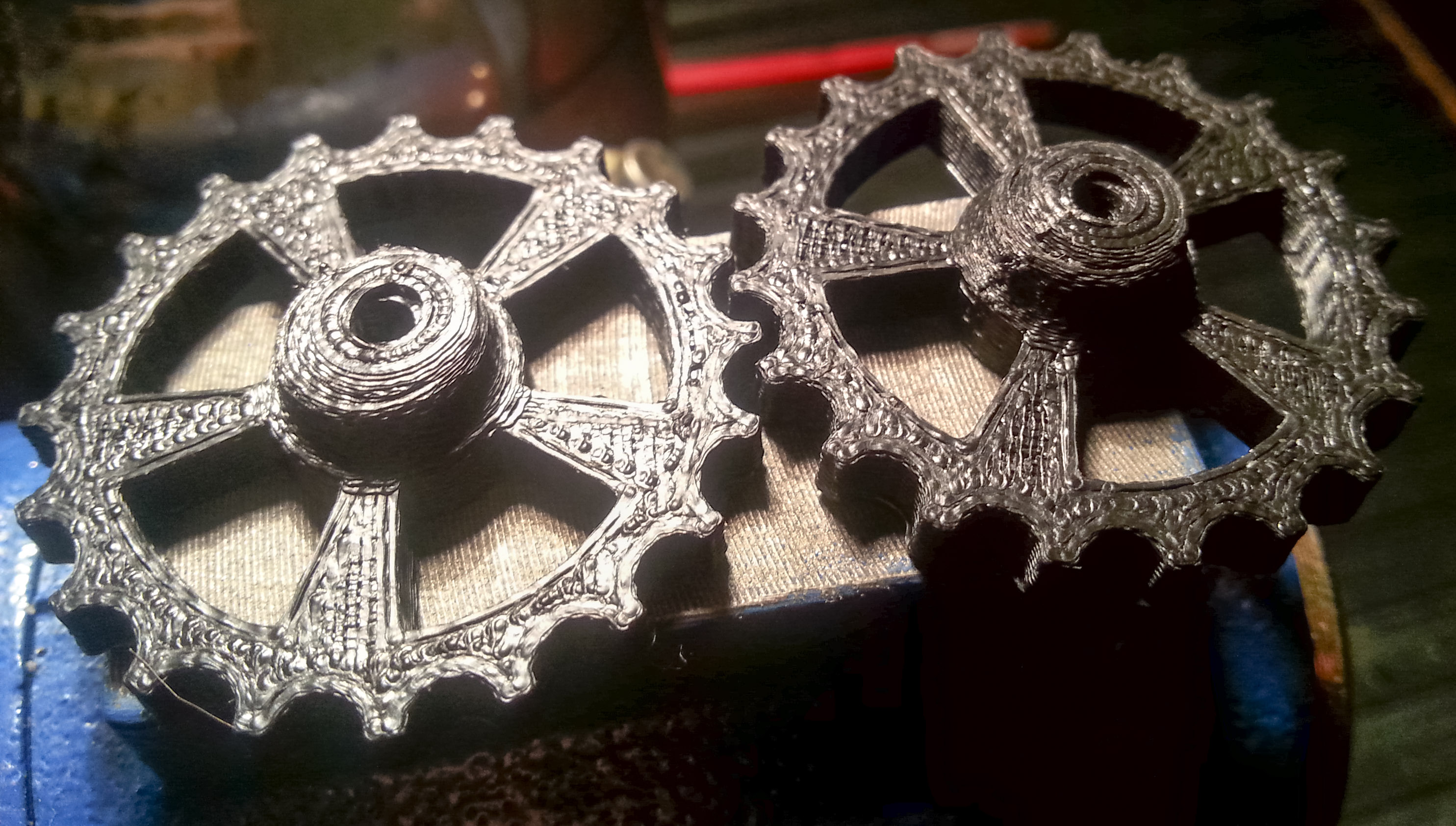

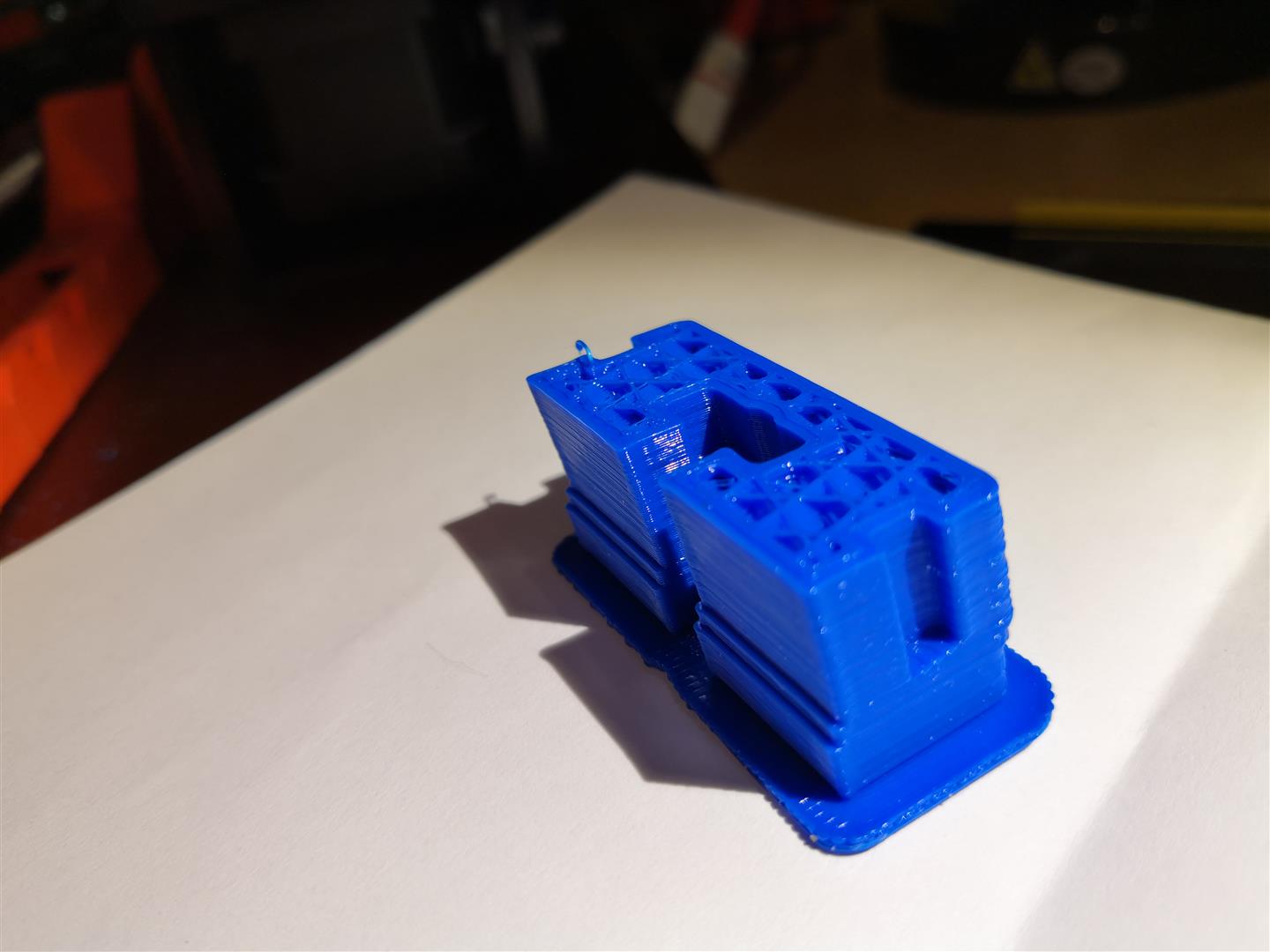

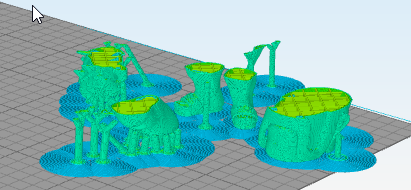

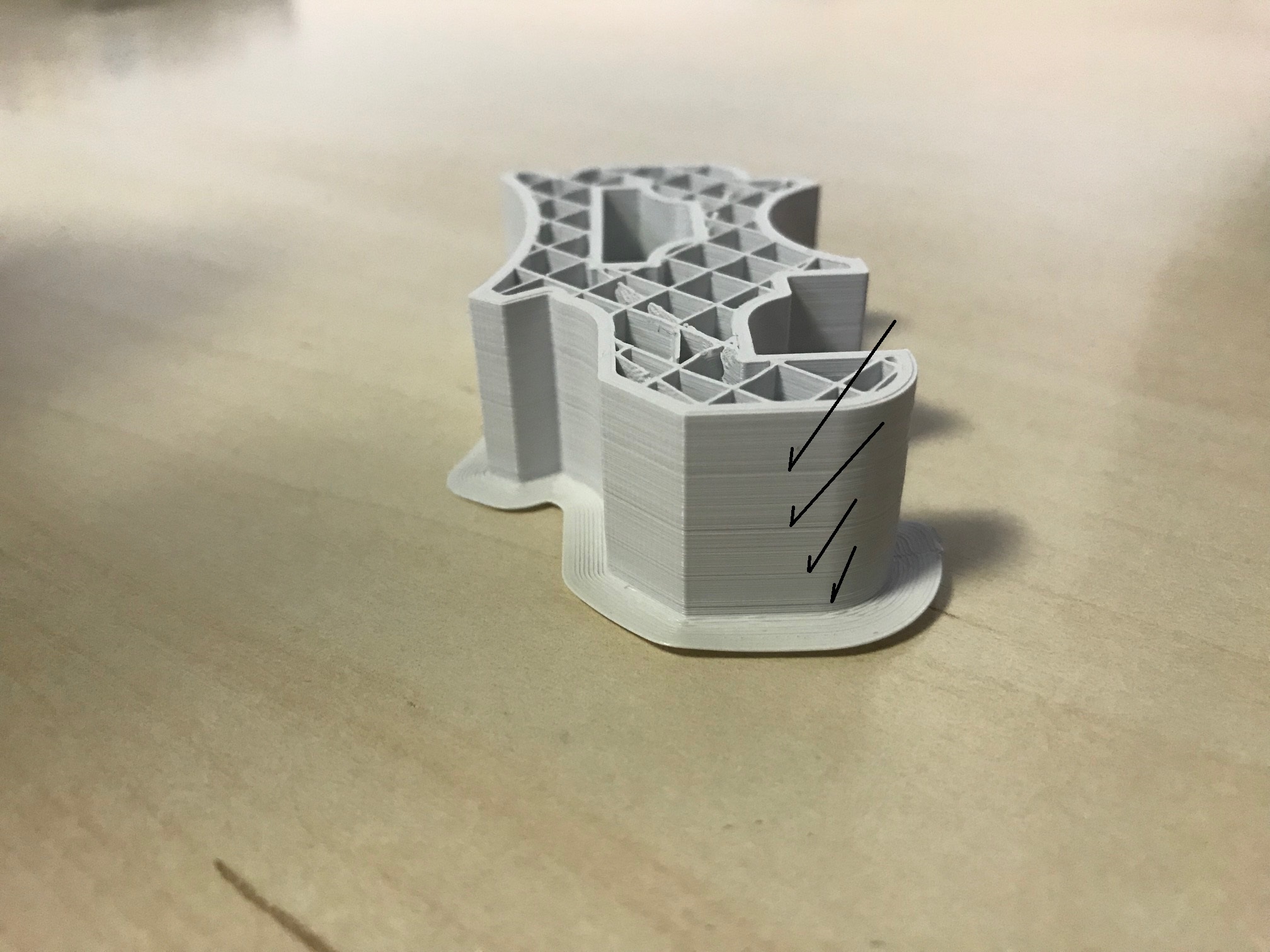

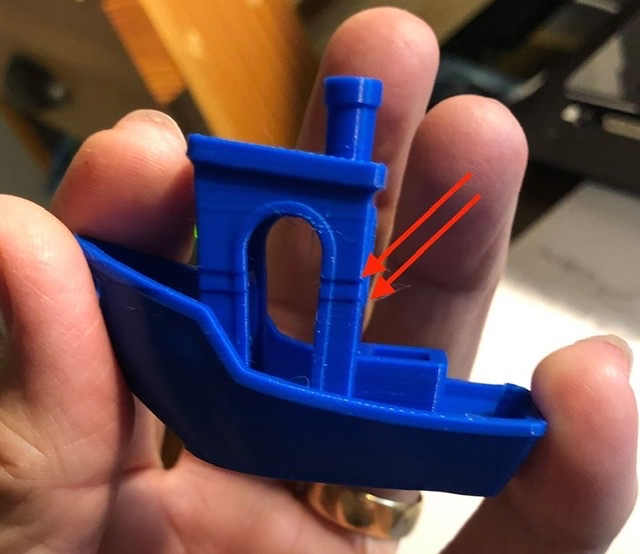

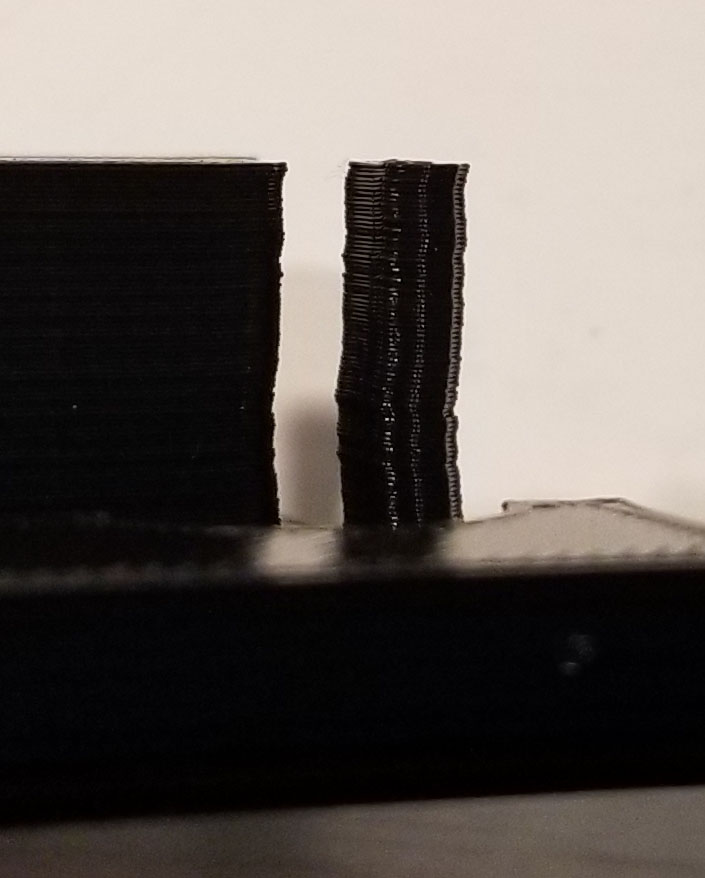

First photo firmware on October 1.

Second photo firmware dated October 15th.

The screws show the offset of the layers well.

Omg so much??? Good to know I have 1.1.9 bugfix for now

So, sounds like some change between Oct 1-15 is affecting some (so next try Oct 8). And maybe something from around Sept 21 is affecting others (so next try Sept 25). I'll look at changes between Oct 1-15 and see if there are any suspect commits.

I did a test at the 7 cotobre (last committee of the day) no problem.

I'm trying again on October 15th I have a doubt about the firmware I flashed for the test on October 15th (sorry).

Do you want my configuration files? If it helps, I use the same ones for each compilation.

Edit : No problem with the code of October 15th (still sorry) so for the moment: October 15th ok / October 29th not ok. Next test with the October 21 version.

Edit 2 : October 21th it's ok

i'm losing steps with the latest 2.0.x too, i'll try to rollback to 1.1.6, which some people are reporting is working fine. I'm using a corexy with tmc2130

What low level things are different between 2.0.0 and 1.1.6 ? It is probably not a stepper driver losing steps because of timing differences. The reason I say that is with IDEX machines in Duplication mode, both extruders are losing position at the same time (and the same amount).

It feels more like a set_directions() call is missing or getting out of phase with other things happening...

I still had issues with Oct 13th here. Just flashed Sept 27th and I'm running again. I'm using the same 30hr gcode for every test. 2nd idex machine got delayed, didn't see it occur on the singlenozzle crx. Still more to go...

I still had issues with Oct 13th here. Just flashed Sept 27th and I'm running again. I'm using the same 30hr gcode for every test.

I'm using the exact same .GCode file. And on that print, I had a small X Axis shift after about 10 hours. And that is with the Sept. 21st code base (bugfix 2.0.0).

If Sept 21 is bad, then try Sept 1 and see if it works. If it does, then try Sept 10, and so on… Too bad we can’t find a short print that consistently causes the issue to occur.

I will look at the set_direction behavior and see if anything obvious stands out.

I'm going all the way to the 1.1.9 release date of 2.0 since we don't see it in 1.1.9 but have yet to find a good 2.0 date. Just built aug3rd (3 days forward but the couple commits are minor and stop idex crashing was pulled from 1.1)

If Sept 21 is bad, then try Sept 1 and see if it works.

Actually.... I've gone a different path. I loaded up the current 1.1.9 and back ported a few things I need into it. I'm 8 hours into a print and so far, no problems... If the print finishes OK, I'll kick off another large print on it to confirm the problem is not on 1.1.9.

I wish that would tell us about 2.0, but who knows where the problem lies? It might be associated with display update, serial communication, G-code parsing, or any number of things. But if you happen to port something into 1.1.9 that causes bad behavior, that would be a great find.

Fyi I'm using SD to eliminate serial errors and monitor from my PC while it's running.

@InsanityAutomation my screen and sd support are disabled, i'm printing trough octoprint. so i dont believe they are causing the problem. i

I wish that would tell us about 2.0, but who knows where the problem lies?

Mostly... I'm looking for a point in time without the problem. (and I do have some large prints I have to get done) But I'm starting to suspect the planner:: changes to merge lines to avoid stutter.

It would be good to have a 2.0.0 version that had planner:: stutter changes taken out of it.... I think there is a 50%-50% chance the problem goes away if we do that.

After a lot of testing since my last message my layer shifts occur if I enable "Z_STEPPER_AUTO_ALIGN" during compilation.

Whether I use G34 or not in my G-code I have layer shifts.

If I compile the firmawre without the "Z_STEPPER_AUTO_ALIGN" my prints are correct without layer shift.

I think this is another problem than the one addressed in this post.

If I compile the firmware without the "Z_STEPPER_AUTO_ALIGN" my prints are correct without layer shift.

Several of us with layer shifts do not (and never have had) Z_STEPPER_AUTO_ALIGN enabled. I don't think this is the cause.

But I have more information. The long 1.1.9 print I did last night came out OK. I'm going to run another long print today and into the night with 1.1.9.

That's why I think my problem is not necessarily the same as the one being sought here.

In all this in my case it has an influence on my layer shift. But the tests I did on different versions of the firmware certainly don't give any indication of your problems.

One thing is certain after having performed a tenth test for me the activation of Z_STEPPER_AUTO_ALIGN causes a layer shift for sure.

I'm not saying that this is not a different problem I'm just giving the results of my tests.

One thing is certain after having performed a tenth test for me the activation of Z_STEPPER_AUTO_ALIGN causes a layer shift for sure.

Thank You for the careful analysis!!!

Thank You for the careful analysis!!!

I'm not here to fight. I thought the purpose of a beta was to debug all the bugs I see that I'm sorry to see that I wanted to make things progress by doing tests.

I didn't take into account the tests I did I must be crazy and the results I got are irrelevant after all. If my problems appear in others they will probably be like me crazy. After all, after counting the total number of prints I made to test the problem, 20 pieces whose result still depends on activating the same parameter or deactivating the parameter represents nothing.

I go back to smoothieware and am really disappointed with the way things are interpreted here so. If some people doesn't find a bug it's probably because it doesn't exist.

Thank You for the careful analysis!!!

I'm not here to fight. I thought the purpose of a beta was to debug all the bugs I see that I'm sorry to see that I wanted to make things progress by doing tests.

That comment was sincere! If somebody is willing to print 10 times to gather evidence, that counts as careful analysis!!!

In your prints.... Do you see the failure at the same place in the print? Or does it fail at random times? In the layer shifting I'm seeing, it happens at random times.

But I'm very sure it is not just a stepper motor that wasn't strong enough be cause some times it has both X & Y shifted. And @InsanityAutomation has seen the layer shift on an IDEX machine in Duplication mode. So it wasn't just one stepper that lost steps. It was two at the same time.

Confirmed that it was the X axis shifting in duplication mode? Of course Y shift in duplication mode would have no special significance.

And @InsanityAutomation has seen the layer shift on an IDEX machine in Duplication mode. So it wasn't just one stepper that lost steps. It was two at the same time.

Confirmed that it was the X axis shifting in duplication mode? Of course Y shift in duplication mode would have no special significance.

That is what I remember. I'm sure he will jump in with confirmation soon. (At the time we were talking about multiple steppers losing position at the same time. That is why I think this is true.)

Yes, it was x that shifted both parts in duplicate mode. I'll dig up the photos from the end user who first reported it later tonight.

@Christophe76350

you could try to increase stepper pulse width manually in Configuration_adv.h :

#define MINIMUM_STEPPER_PULSE 4

I had layer shifts with CoreXY, LPC1768 and DRV8825 that lead to "skewed" prints like in your picture

Issue #11047

In your prints.... Do you see the failure at the same place in the print? Or does it fail at random times? In the layer shifting I'm seeing, it happens at random times.

The layer shifts are all the same with each impression. There is nothing random, I had a moment to question the mechanics but no problem on this side. I have a second mechanically identical one that works with a Rhumba motherboard and the no layer shift on the same Gcode with the firmware compiled with Z_STEPPER_AUTO_ALIGN enabled.

@Christophe76350

you could try to increase stepper pulse width manually in Configuration_adv.h :

#define MINIMUM_STEPPER_PULSE 4I had layer shifts with CoreXY, LPC1768 and DRV8825 that lead to "skewed" prints like in your picture

Issue #11047

I'm currently testing.

Issue #12491 could be related, but would mean this layer shifting is due to skipped steps.

A couple ideas:

- Test with unloaded steppers and see if they maintain position

- Slow down the stepper ISR (to ~1/4th the frequency). Keeping all curve computation the same while slowing down the step rate would reduce the chance for missed steps. But if it's a logic issue, the skew will still be apparent (unless it's a timing issue/interaction with another ISR).

Don't give up trying to narrow down the specific day that the issue appeared. These threads tend to go on forever with speculations, when the best use of time would be to meticulously seek out the specific commit that introduced the problem.

I'm 30hrs in on the Aug 3rd snapshot with no issues. From there we can safely say the issue appeared in 2.0 later, and was not a result of the refactoring. I have another machine now validating Sept21st however if it's anything like the bugs fixed for 1.1.9 some machines never saw it and some couldn't get rid of it.... I honestly don't know how to ensure I hit the worst case scenario here to force a machine to skip steps, so if the machine has never skipped I don't know if it ever will....

Have we checked for a correlation between stepper driver types or motherboard?

Fyi, brand new machine out of the box with factory firmware dated sept21st layer shifts on X using the same gcode I'm running on the other machine. Aug 3rd snapshot now has 38hrs with no shift.

Have we checked for a correlation between stepper driver types or motherboard?

I didnt noticed any issues using the latest firmware with the a4988, only with the tmc2130

Worth noting one machine is all stand-alone tmc2208 spreadcyle, the other is 4988 on both X and tmc standalone spreadcyle on y.

I have another machine now validating Sept21st however if it's anything like the bugs fixed for 1.1.9 some machines never saw it and some couldn't get rid of it....

I have also seen the layer shifts with a September 21st code base. Right now, I think we have two book ends. The problem seems to have been introduced somewhere between August 3rd and September 21st.

I'm also have this nasty issue. D-bot CoreXY 1.7A steppers.

Few days ago changed RAMPS 1.4+mega2560 w marlin 1.1.8 for RURAMPS4D 1.3 + DUE.

TMC2130 SPI on X,Y,E . TMC2208 in standalone on Z. Homing with endstops. TMC2130 lib v 2.5.0. 800ma/16 steps in adv.cfg. Tried to set from 700ma to 1000ma without any result, switcing on/off hybrid mode didb't help as well. What left ? Try to disable stealthchop, S-curve, older TMC 2130 lib ?

Shifs occur at speeds over 50mm/s. Acceleration is set to 1000.

I'm kinda tired, almost every print is ruined. Wanted to increase printspeed, but did increase a hedache.

Could anybody post a link to Pre-August 2.0 build ?

Not sure if my issues are related, but I experience extreme shifting with TMC2208:

Although I'm still dialling in the new configuration, this x-axis shift happened a few times already with the same print. It's a fairly simple bracket printed through octoprint. Est. print time was 1:35 and the . shift started right away but became really noticable around 5%. The x-axis eventually is so far off, the hot-end keeps banging on the x-min stop… This happened with manual mesh bed levelling, tonight I'll try again with turned levelling off. No problems at all with homing or manual movement via Gcode, printing via Cura through USB or Octoprint or setting a higher/lower current.

Machine: Ender-3

Board: Fysetc F6 v1.3

Drivers: TMC2208 drivers (Watterott, configured through software serial)

Power: 24v

X Stepper current: 700mA

Microsteps: 16

Mode: Stealthchop (hybrid mode off)

Marlin: 0946cbcdca99d833d1a4667d00daf112394107c0 (but this happened with older commits too)

I've tryed some print and found that S-Curve acceleration and different TMC2130 libraries doesn't affect the shifting at all. decreasing speed to 50mm\s or switching to spreadcycle (hell, its noisy!!!) helps. And the drivers are really hot. 60 degrees at least, although they are fan-cooled. With RAMPS 1.4. it was OK even at 80mm\s.

Looks like we're getting closer. Let's try Sept 1st next!

I have a print 25hrs in on a sept1st snapshot. No shifts yet.

Question not really related: i reverted back to the 1.1.9 marlin, and i'm setting things up. Which hybrid threshold is a good start value for a 1.7a 4kg stepper? i heard is best to keep spreadcycle for high speeds

I'm kinda tired, almost every print is ruined. Wanted to increase printspeed, but did increase a hedache. Could anybody post a link to Pre-August 2.0 build ?

Question not really related: i reverted back to the 1.1.9 marlin, and i'm setting things up.

I understand the frustration! But the early information points to September 1st being OK. Instead of scampering off to all kinds of different points in the code base, it would be very helpful if the people that need a solid base all re-group at BugFix 2.0.0 as of September 1st. That should give us several things. Most importantly, we will get more confirmation the problem wasn't in the code base prior to that point of time.

Here is a pointer to August 31st. (I don't know what time of day people's September 1st snap shot were taken. So this is one day before everybody's report of OK.)

https://github.com/MarlinFirmware/Marlin/tree/74a04aed552fa7f93ef42fe3e5e4f095dda4aac6

Thanks a lot. Got insulting shift on 3h print with november build at 45mm\s.

But with one you sent me link to all went perfect at 50mm\s ! And drivers, as well as motors are defenitely cooler than with the november build.

I'm also have this nasty issue. D-bot CoreXY 1.7A steppers.

Few days ago changed RAMPS 1.4+mega2560 w marlin 1.1.8 for RURAMPS4D 1.3 + DUE.

TMC2130 SPI on X,Y,E . TMC2208 in standalone on Z. Homing with endstops. TMC2130 lib v 2.5.0. 800ma/16 steps in adv.cfg. Tried to set from 700ma to 1000ma without any result, switcing on/off hybrid mode didb't help as well. What left ? Try to disable stealthchop, S-curve, older TMC 2130 lib ?

Shifs occur at speeds over 50mm/s. Acceleration is set to 1000.

I'm kinda tired, almost every print is ruined. Wanted to increase printspeed, but did increase a hedache.

Could anybody post a link to Pre-August 2.0 build ?

try using the 1.1.9 if possible, after changing to it, i'm not having any shifts, printing now at 80mm/s with mov speed of 100mm/s. using tmc2208 with full stealthchop

Just to update, over 100hrs running the sept1st snapshot here without a shift yet. A few more customer parts to get out and I'll bump up to Sept 15th.

Using a July download of the 2.0 firmware, changed from repetier. Has layer walking in the X and Y when printing with OctoPrint, same Gcode prints fine when printing from SD card. Just downloaded and configured a Nov version, downloaded 11-23. Still have the layer walking with OctoPrint

Hardware:

Due w/ RADDS shield, DRV8825

CoreXY

A possibility??? https://github.com/MarlinFirmware/Marlin/issues/12540#issuecomment-442267831

Given that the torture gcode were using is a massive amount of short jerky moves, it very much sounds like we're dealing with the same issue!

A possibility?

Strangeness in the acceleration handling could certainly be involved. I’ll look at it and review changes made in that region of the code over the past few months.

Fyi, I finally got a machine opened back up and now running the current snapshot but with junction deviation on instead of traditional jerk. If it is good with the torture test here, I'll turn junction deviation back off to confirm it's still present today. If no change, I'll go back to Sept 15th, before the planner overhaul for fwretract.

Fyi, current code base with junction deviation was notably slower than with traditional jerk, after a 47hr print finished (that took 36hrs before) it only had a single shift that was half the size of what they were previously. This was between 40 and 45hrs in. Again same gcode. I should start selling these lithos with a single shift here or there just to get material cost back lol

That's why I think my problem is not necessarily the same as the one being sought here.

In all this in my case it has an influence on my layer shift. But the tests I did on different versions of the firmware certainly don't give any indication of your problems.

One thing is certain after having performed a tenth test for me the activation of Z_STEPPER_AUTO_ALIGN causes a layer shift for sure.

I'm not saying that this is not a different problem I'm just giving the results of my tests.

@Christophe76350 Hey, I hope you keep testing. You have definitely found something and I can absolutely confirm that #11302 is also causing significant layer shifting for me. Been trying everything to pinpoint the cause until I saw your post and decided to comment out Z_STEPPER_AUTO_ALIGN.

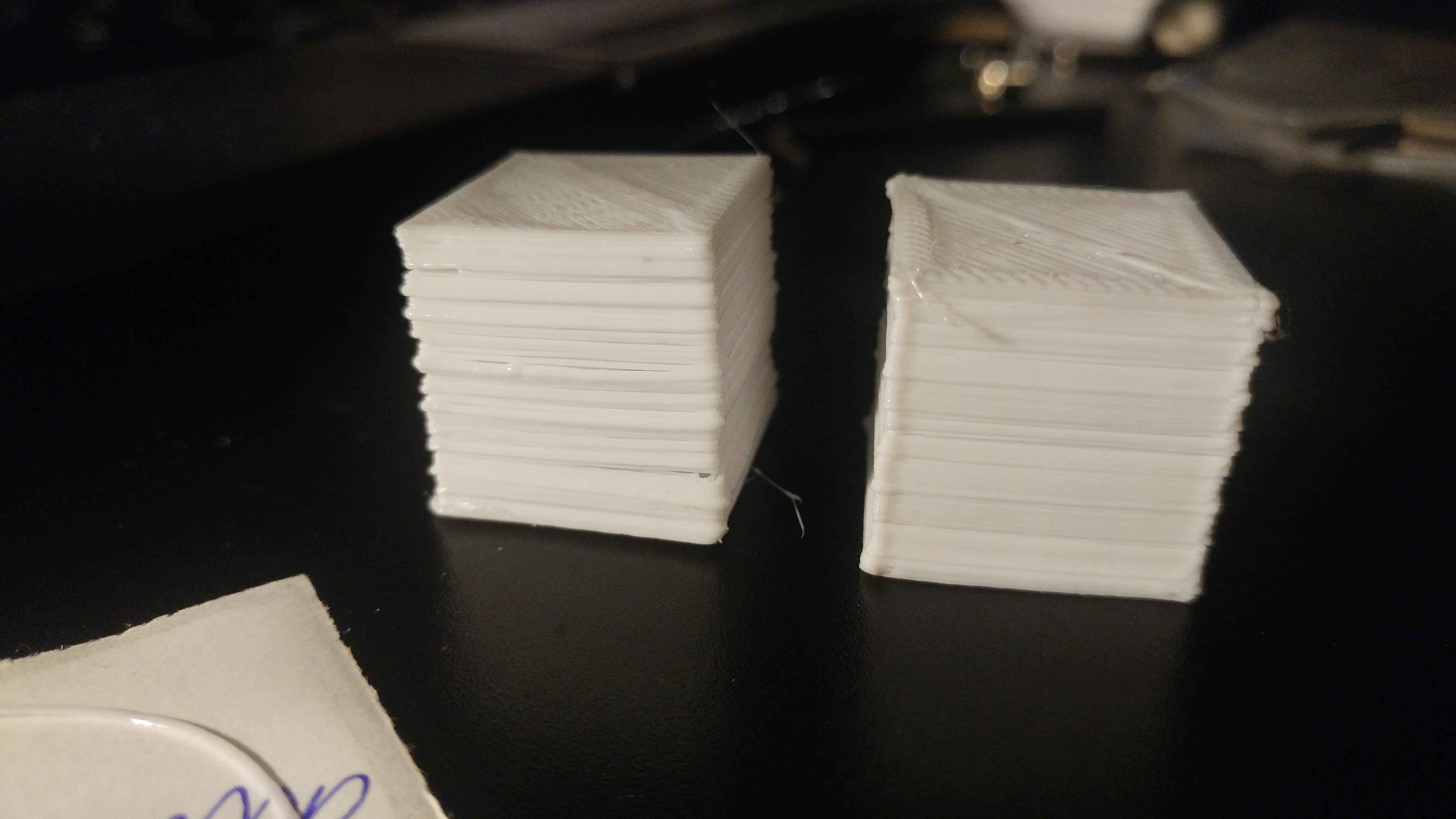

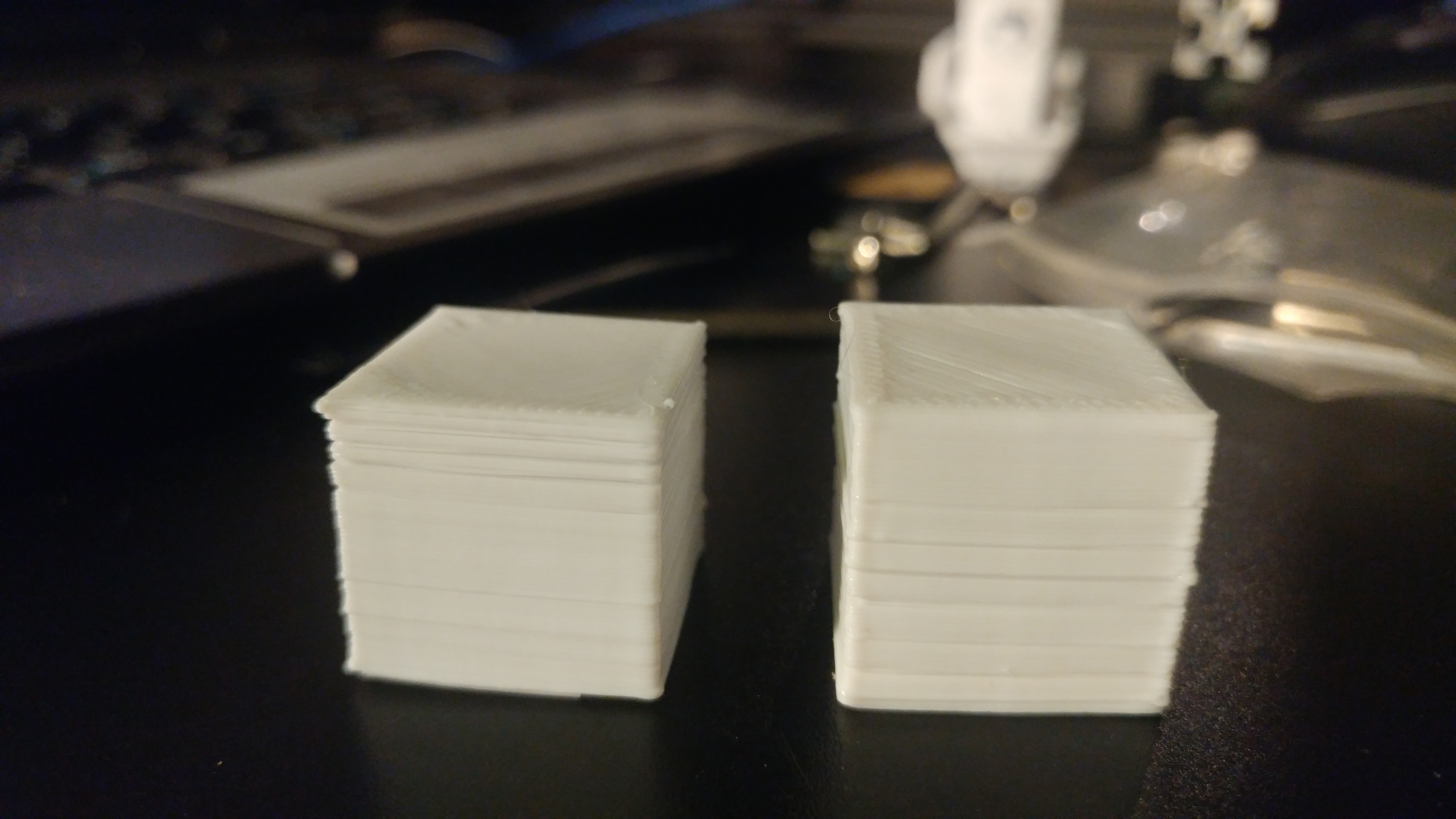

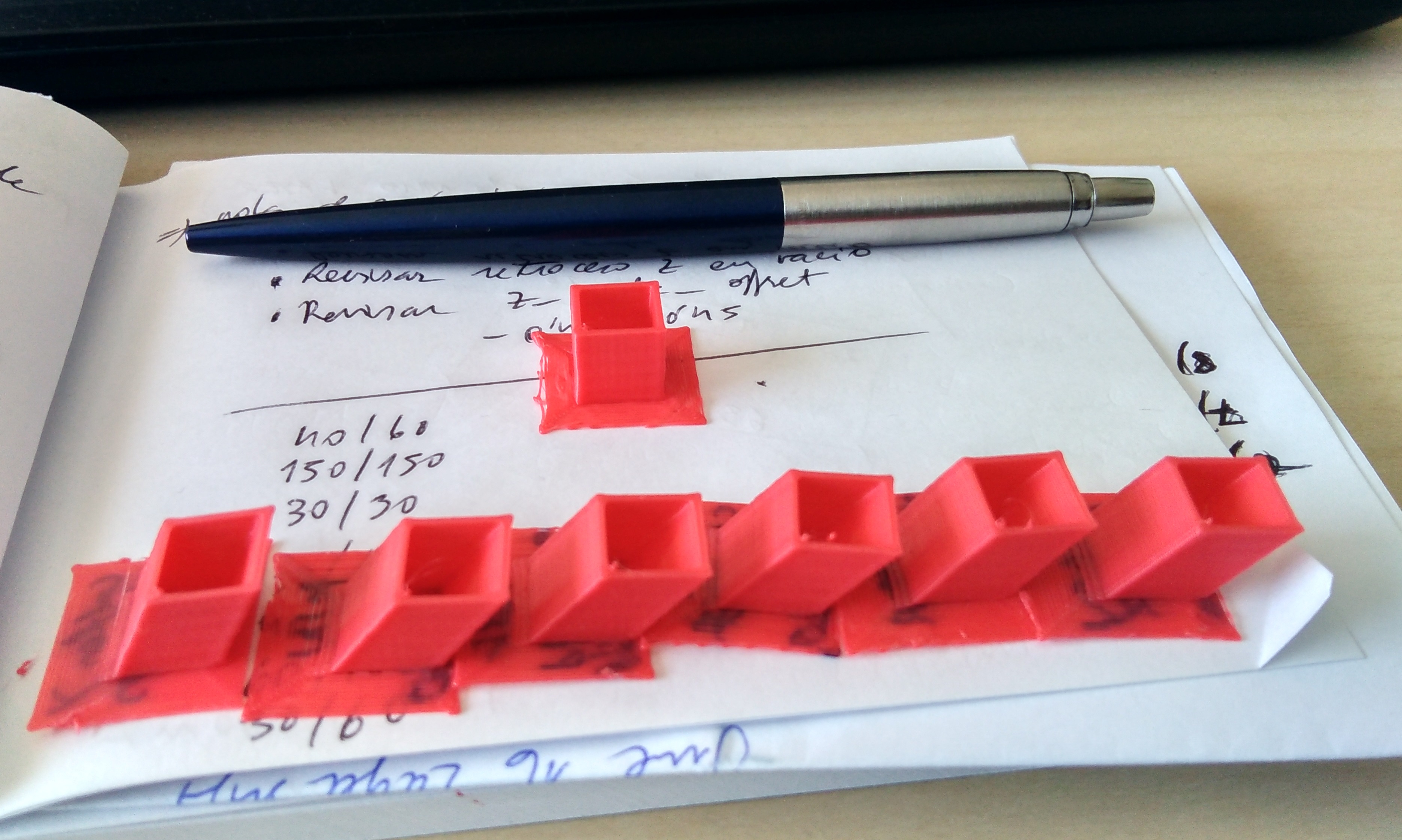

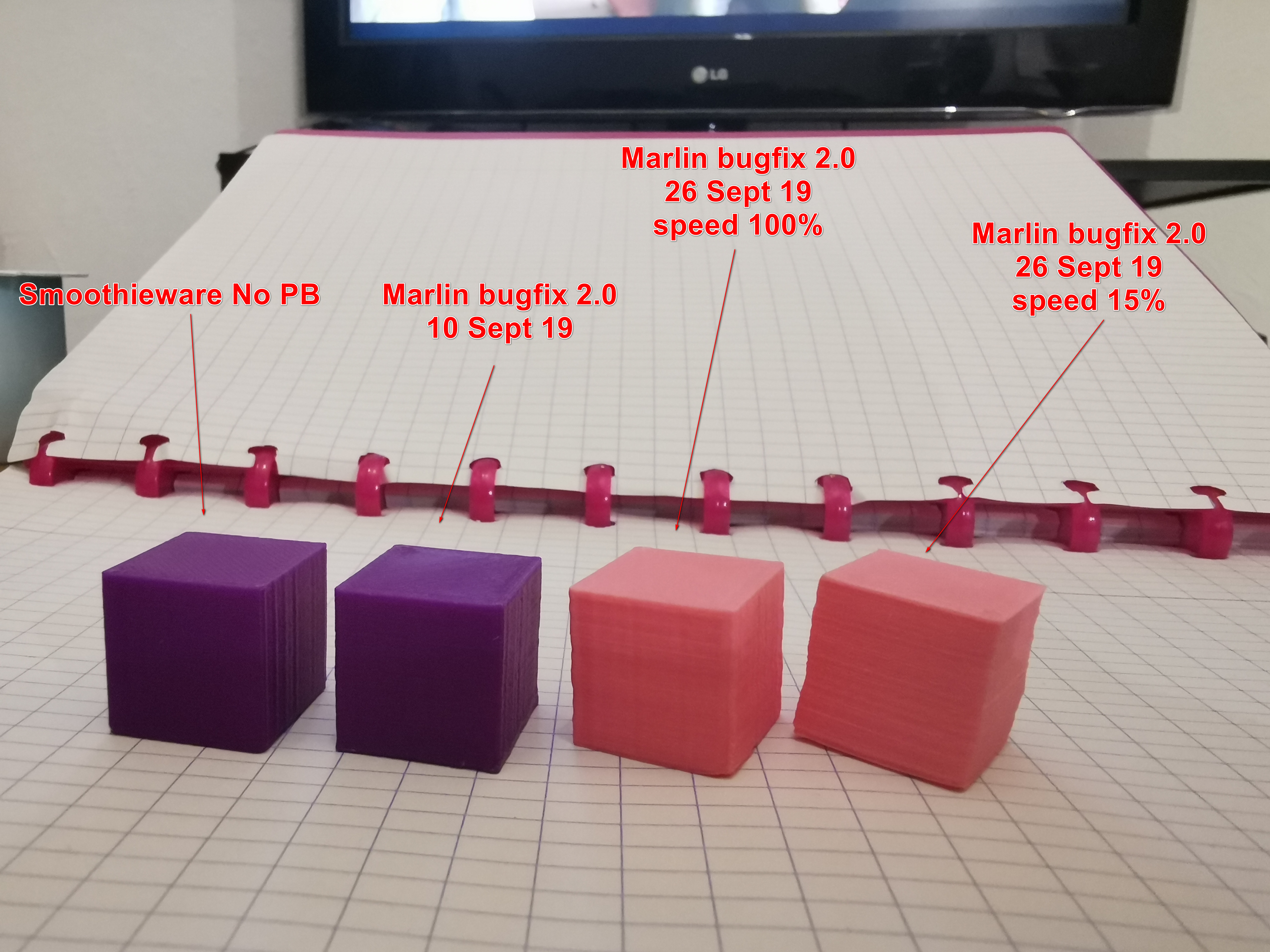

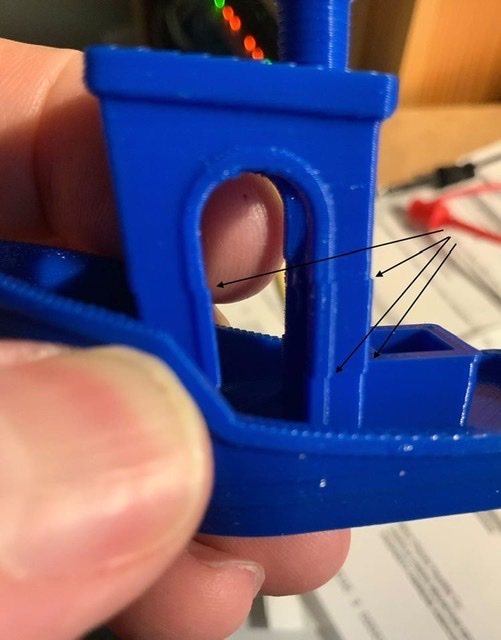

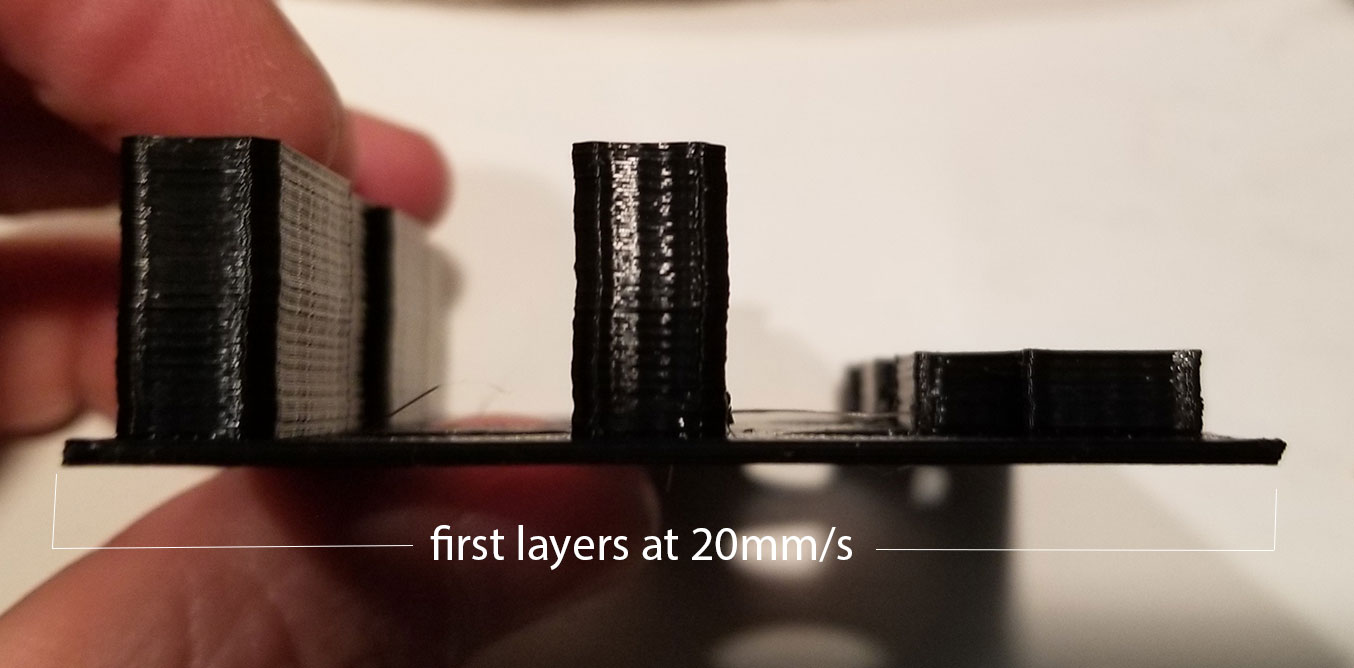

Here are before and after images of some prints of the 20mm hollow calibration cube. The image on the left is w/o s-curve acceleration and adaptive step smoothing enabled, the right image is with those two featured turned on.

With Z_STEPPER_AUTO_ALIGN enabled:

With Z_STEPPER_AUTO_ALIGN commented out:

As you can see, with Z_STEPPER_AUTO_ALIGN commented out, there is a significant reduction in layer shifting (doesnt seem to be completely gone).

This was printed on a CoreXY machine running Nov 30 git of bugfix-2.0.0 on an LPC1768 (mks-sbase).

I'm wondering if we should back out all planner and stepper motor changes going back to Sept. 1st. And then slowly, and carefully start adding things back in. And maybe not in the original merge order.

A strategy like that might help us figure out what is causing the trouble.

There do appear to be quite a few combination of things having an impact here which is what's making it so difficult to pin down...

I believe the G34 issue I posted above is related to #11205

I had a couple of layer shifts yesterday and today. Both were in the Y direction.

That one shifted 2.0 mm.

The next one shifted 19.2mm and later 22.9 mm.

I home to the Y MAX endstop so I deliberately ran the head into the Y MAX endstop to see what position it reported. The endstop message said 477.72. It should have been 436.0 so the Y positioning was off by 41.7 mm. The two shifts totalled 42.1 mm so we have a reasonable agreement in offsets.

After hitting the endstop I immediately did a M114 and it reported a Y of 600 with a Y count of 189666.

Next I did a G28 which gave me a Y of 436 with a count of 173102.

The difference between the two counts divided by my steps-per-mm give a distance of 41.72 mm.

Something definitely messed with the coordinate system.

The only recent changes I've made were to enable JUNCTION_DEVIATION , ADAPTIVE_STEP_SMOOTHING and LIN_ADVANCE. I do NOT have S curve acceleration nor Z_STEPPER_AUTO_ALIGN enabled.

I'll back those three changes out and restart the last print. The first shift happened at the 10-12 hour point so it'll be late Wednesday before I have confidence that the shift has gone away.

The only recent changes I've made were to enable JUNCTION_DEVIATION ADAPTIVE_STEP_SMOOTHING and LIN_ADVANCE. I do NOT have S curve acceleration nor Z_STEPPER_AUTO_ALIGN enabled.

I have never had any of these enabled. And I have seen the layer shift problem on bugfix 2.0.0 in the past month.

I take it the only alternative is to go back to one of the dates that Scott mentions and use that to print the problem object.

I'm going to go straight to 1 Sep. My home built has been driving me nuts & I don't have the time to narrow down the date where the problem started.

Just commenting as an observer: It might be useful to track the git hash + config files for every observation, it might help chasing down other factors that might not immediately be obvious. A lot of testing has been done, it would be good to know on which hash exactly and what features were enabled / disabled? My 2 ct.

I grabbed the 2018-09-01 Bugfix2.0 but still had a layer shift at about 8 hours into the print.

Are the dates in Scott's post 2017 or 2018?

Are these shifts only happening when Z changes or can they happen in the middle of a layer? My latest shift was less than the width of the wall so about 2/3 of the shift was over the plastic on the previous layer. Under a magnifying glass I couldn't find any Z discontinuities in the first layer of the shift.

@Bob-the-Kuhn These are for 2018

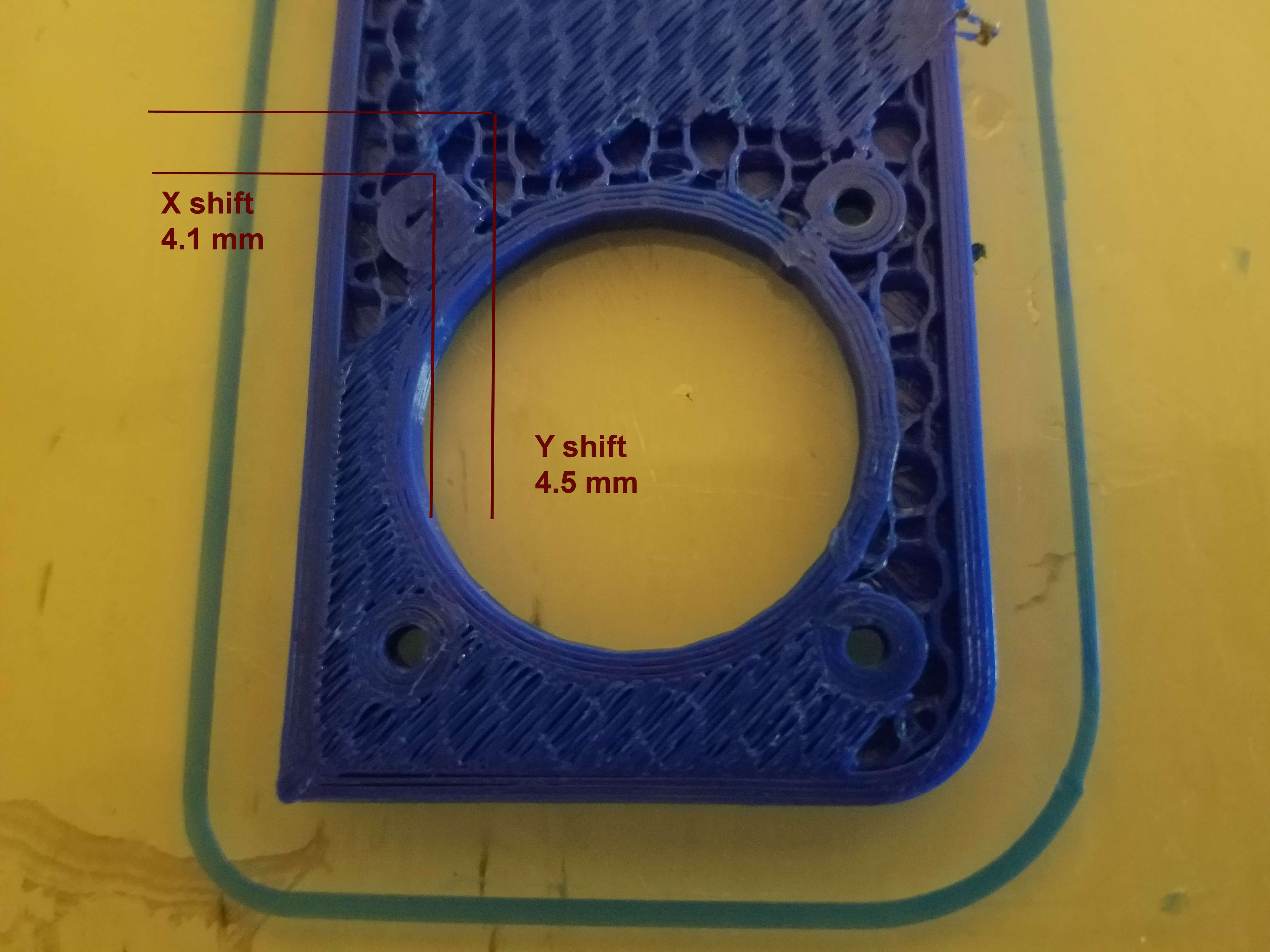

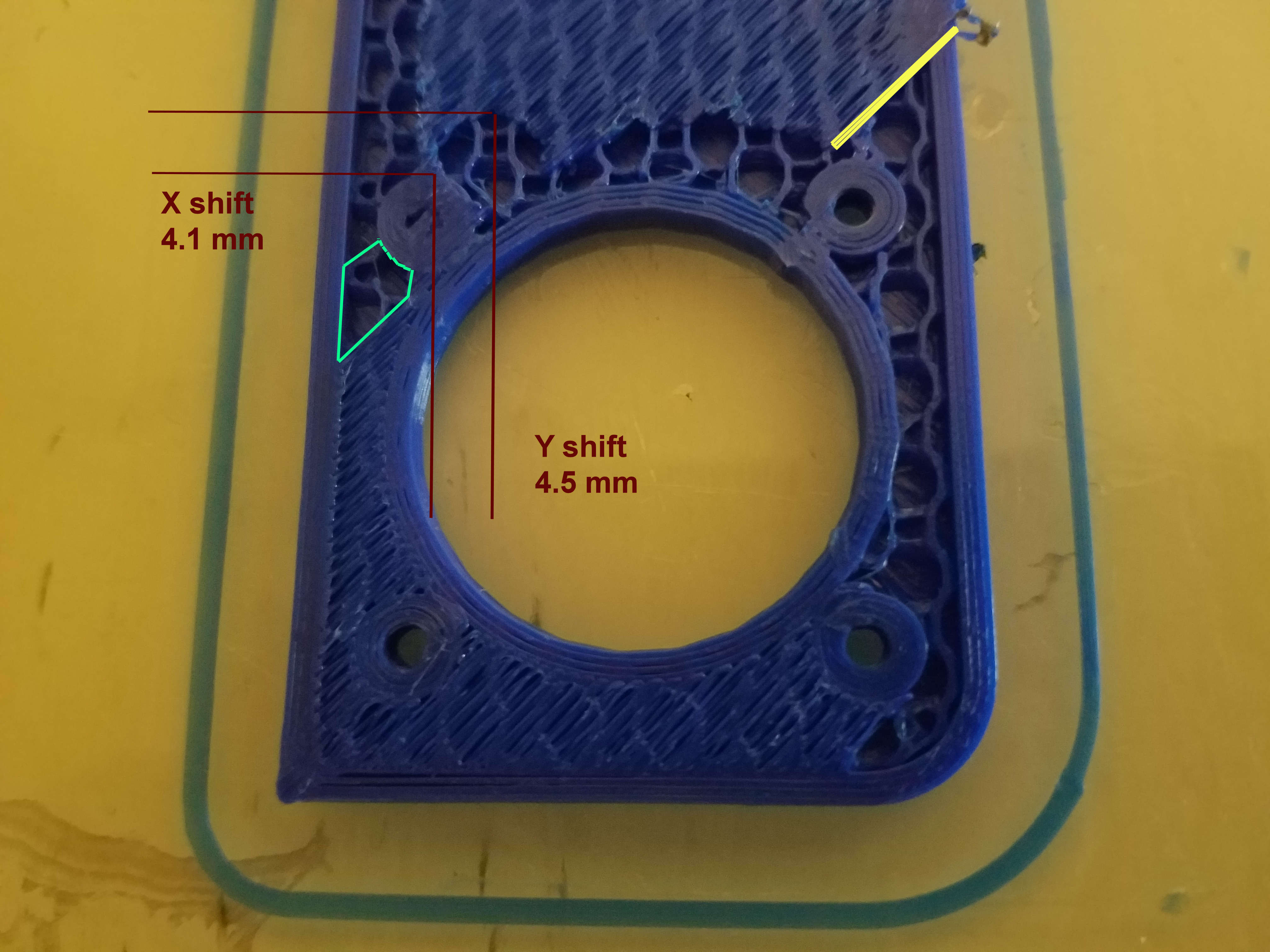

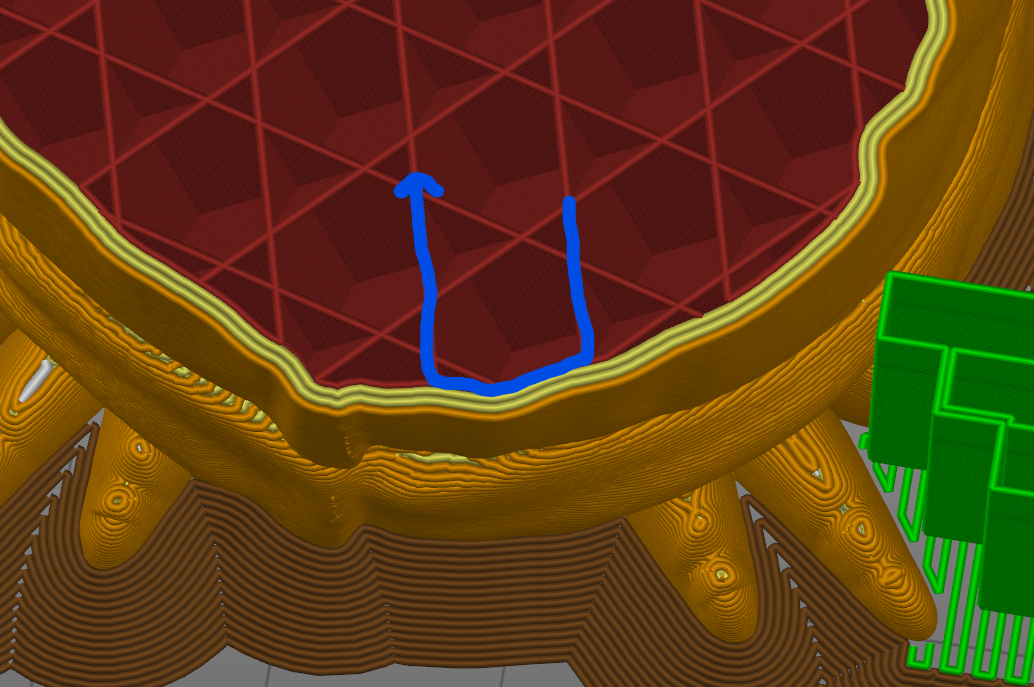

Just caught a layer shift before it went to the next layer.

In the lower left is the normal infill. Across the top is the shifted infill.

I think I'm running the Bugfix 2.0 code from the last commit on 1 SEP 2018. I went to history, scrolled/paged to the last commit on 1 SEP 2018, clicked on the "browse repository at this point" and then downloaded the ZIP. The configuration files are very different than the 3 DEC 2018 ones (the latest one I downloaded).

I reprinted the shifted layer and can pinpoint exactly where the shift happened.

The infill was proceeding normally from lower right to lower left and then up the left side to the second small hole where it would stop and then resume at the yellow highlighted area and then proceed right to left..

The area outlined in green is where the problem started. It should have been printed before the area in yellow but was skipped entirely.

The area in yellow is the first of the shifted printing. It should be touching the large circle and stopping at the first straight line.

It would be great if we can get some gcode that causes the shift... That would make it fairly straight forward to debug and find the flaw.

My initial reaction is that re-running same gcode may or may not reproduce the shift because I've had different shifts on one object and on another object one pass and one shift but … I'm pretty sure I changed bugfix dates/snapshots and probably re-sliced between the two runs.

I've started a (hopefully) 26 hour build using the 31 AUG snapshot. I'd really like to have that succeed before I start doing 6 hour prints trying to reproduce the issue.

Is there a know good date?

Is there a know good date?

I thought Sept. 1st was good. But your test up above is calling that into question.

Here's the gcode from the problem area in the shifted layer:

; missing area starts in next 5-15 lines

G1 X 80.917 Y 146.889 E 30.43964

G1 X 81.627 Y 146.740 E 30.46808

G1 X 78.332 Y 150.035 E 30.65089

G1 X 78.893 Y 150.035 E 30.67290

G1 X 82.336 Y 146.592 E 30.86395

G1 X 83.045 Y 146.443 E 30.89239

G1 X 79.454 Y 150.035 E 31.09167

G1 X 80.015 Y 150.035 E 31.11368

G1 X 83.755 Y 146.295 E 31.32121

G1 X 84.464 Y 146.147 E 31.34965

G1 X 80.576 Y 150.035 E 31.56541

G1 X 81.137 Y 150.035 E 31.58742

G1 X 85.183 Y 145.989 E 31.81192

G1 X 86.317 Y 145.416 E 31.86180

G1 X 81.698 Y 150.035 E 32.11813

G1 X 82.259 Y 150.035 E 32.14014

G1 X 87.451 Y 144.842 E 32.42829

G1 X 88.586 Y 144.269 E 32.47816

G1 X 82.820 Y 150.035 E 32.79813

G1 X 83.381 Y 150.035 E 32.82014

G1 X 89.720 Y 143.695 E 33.17193

G1 X 90.200 Y 143.453 E 33.19303

G1 X 90.233 Y 143.743 E 33.20451

G1 X 83.942 Y 150.035 E 33.55363

G1 X 84.503 Y 150.035 E 33.57564

G1 X 90.290 Y 144.247 E 33.89681

G1 X 90.347 Y 144.751 E 33.91670

G1 X 85.064 Y 150.035 E 34.20991

G1 X 85.625 Y 150.034 E 34.23194

G1 X 90.421 Y 145.238 E 34.49808

G1 X 90.579 Y 145.641 E 34.51506

G1 X 86.186 Y 150.034 E 34.75887

G1 X 86.747 Y 150.034 E 34.78088

G1 X 90.738 Y 146.043 E 35.00235

G1 X 90.971 Y 146.371 E 35.01813

G1 X 87.308 Y 150.034 E 35.22143

G1 X 87.868 Y 150.035 E 35.24342

G1 X 91.210 Y 146.693 E 35.42885

G1 X 91.320 Y 146.842 E 35.43611

G1 X 91.488 Y 146.976 E 35.44455

G1 X 88.429 Y 150.035 E 35.61429

G1 X 88.990 Y 150.035 E 35.63630

G1 X 91.800 Y 147.225 E 35.79224

G1 X 92.123 Y 147.463 E 35.80798

G1 X 89.551 Y 150.035 E 35.95069

G1 X 90.112 Y 150.035 E 35.97270

G1 X 92.513 Y 147.633 E 36.10596

G1 X 92.904 Y 147.804 E 36.12268

G1 X 90.673 Y 150.035 E 36.24651

G1 X 91.234 Y 150.035 E 36.26852

G1 X 93.379 Y 147.889 E 36.38758

G1 X 93.867 Y 147.963 E 36.40694

G1 X 91.795 Y 150.035 E 36.52195

G1 X 92.356 Y 150.035 E 36.54396

G1 X 94.488 Y 147.902 E 36.66230

G1 X 94.863 Y 147.860 E 36.67709

G1 X 95.240 Y 147.712 E 36.69300

G1 X 92.917 Y 150.035 E 36.82193

; start of shifted section

M106 S89.25

G1 E 34.82193 F 2400.00000

G92 E 0

G1 X 93.166 Y 118.933 F 2100.000

G1 E 2.00000 F 2400.00000

M106 S255

G1 F 300

G1 X 92.690 Y 119.409 E 2.02641

G1 X 92.878 Y 119.782 E 2.04280

G1 X 93.724 Y 118.936 E 2.08972

G1 X 94.282 Y 118.939 E 2.11162

G1 X 93.067 Y 120.154 E 2.17906

G1 X 93.255 Y 120.527 E 2.19544

G1 X 94.987 Y 118.795 E 2.29155

G1 X 95.366 Y 118.696 E 2.30690

G1 X 96.021 Y 118.322 E 2.33652

G1 X 93.443 Y 120.900 E 2.47956

G1 X 93.632 Y 121.272 E 2.49

These are lines 1827-1904 in the attached file.

The green area is not missing. It's on top of the circles near by.

What's that structure in about the mid of the green area? Is that debris on top of the previous layers infill? Could the nozzle have been caught by that?

I'll flash the Sept 1st snapshot back tonight and start another 50hr torture test. See if maybe I just didn't run enough there.

I can confirm that I have also have been seeing the layer shifts.

I have not printed in quite a while as I was upgrading my printer to new electronics.

Rearm + TMC2130 drivers. I thought the drivers were at fault and might be something with the re-arm implementation.

It would be good to know what hardware + drivers each person is using (perhaps make a table on the 1st post), and utilize that as a reference. Perhaps we notice a pattern....

@AnHardt is correct - the "missing" is actually over the circular area.

The layer being printed is the first solid layer. The infill is the 3D Honeycomb frm the Slic3r slicer. The main structure in the middle of the green area is a partial honeycomb. In the picture it looks like there may be some residue from the shifted layer on top of it. I don't remember seeing any residue when looking at the actual part. When looking at the actual part I didn't notice any residie. I expect it's just the way the last infill layer is reflecting light. Other areas of uncovered infill have the same color.

I'm running a Due with A4988 drivers. and 23HS41-1804S steppers. My machine is basically a CNC machine with a 3D print head currently mounted to it. Big, strong & SLOWWWWW.

@AnHardt is correct - the "missing" is actually over the circular area.

The layer being printed is the first solid layer. The infill is the 3D Honeycomb frm the Slic3r slicer. The main structure in the middle of the green area is a partial honeycomb.

@Bob-the-Kuhn Does this mean you are no longer convinced the Sept. 1st snap shot is bad? A number of us did long prints with Sept 1st and did not see a problem.

I definitely had a layer shift with the 1 SEP snapshot. It's just that my "missing" assessment was wrong. The plastic is just in a location I didn't notice.

I currently doing a print of 60 copies of the layer that had a shift. I'm at 45 without a big shift. There was a small shift towards +X by 2 mm about layer 20 and then a shift back at about layer 30.

Lots of possibilities as to why I'm seeing shifts, Could be that I'm occasionally loosing steps.

I did complete a 313 layer 34 hour build this morning using the last commit on 31 AUG 2018. There was somw waviness in the walls but nothing big enough to put calipers on.

I've ordered some rotary encoders. If I can figure out how to use them then I'll be able to better judge the reliability of my hardware.

I was getting quite significant layer shift with the latest 2.x, I tried to revert back to 49e107c (the last commit on the 1st of September) but I'm getting the same issue. It solved it by disabled junction deviation (I still need to try to reenable scurve). But this looks to be just a workaround and might just hide the issue, as @Roxy-3D says that problem shows even with this disabled (https://github.com/MarlinFirmware/Marlin/issues/12403#issuecomment-444517607)

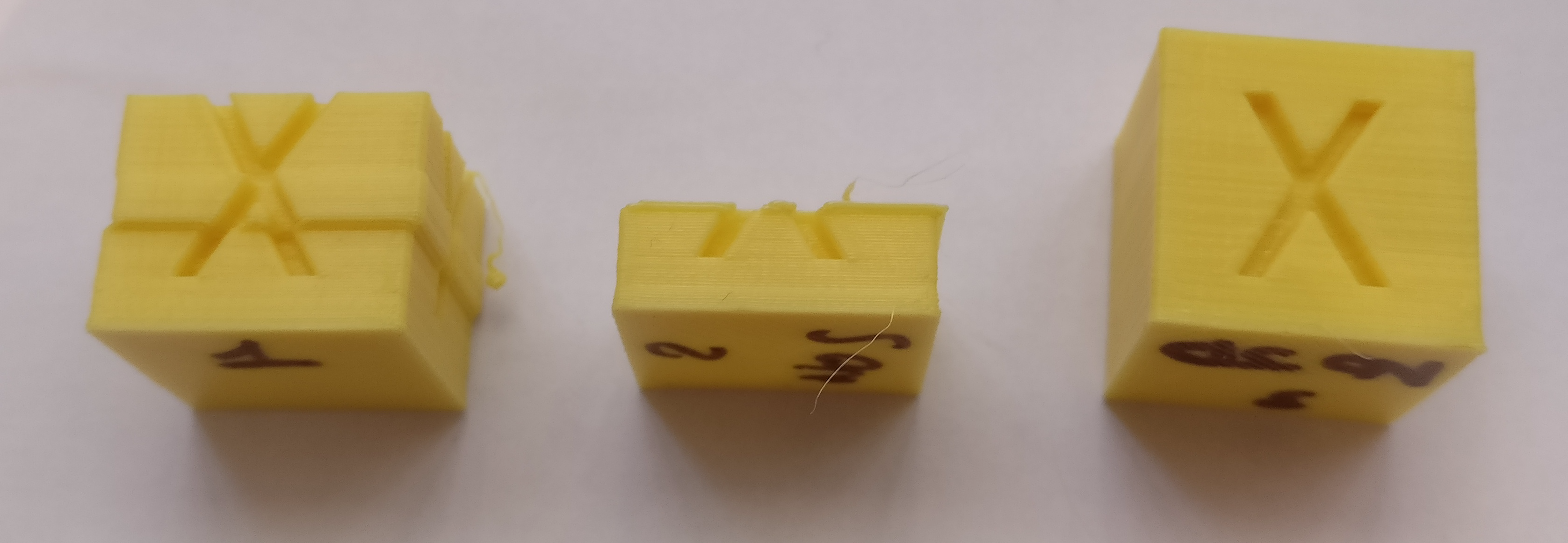

- Print with Junction Deviation and Scurve enabled

- Print with Junction Deviation enabled and scurve disabled

- Print with Junction Deviation and Scurve disabled

What's interesting is that the layer shift at the same layer for the first two cubes (and I think a third one from yesterday but I don't have it around to check)

I'm getting more and more of the opinion we need to back out all Planner and Stepper Motor changes from Sept. 1st to the current time. Verify that is 'clean'. And then very slowly, carefully, and with full testing add the changes back in one at a time.

Does anybody have the skill set and inclination to create a branch like that? If so, we can probably get the community to spread out the work of adding in each subsequent change and help test the different versions.

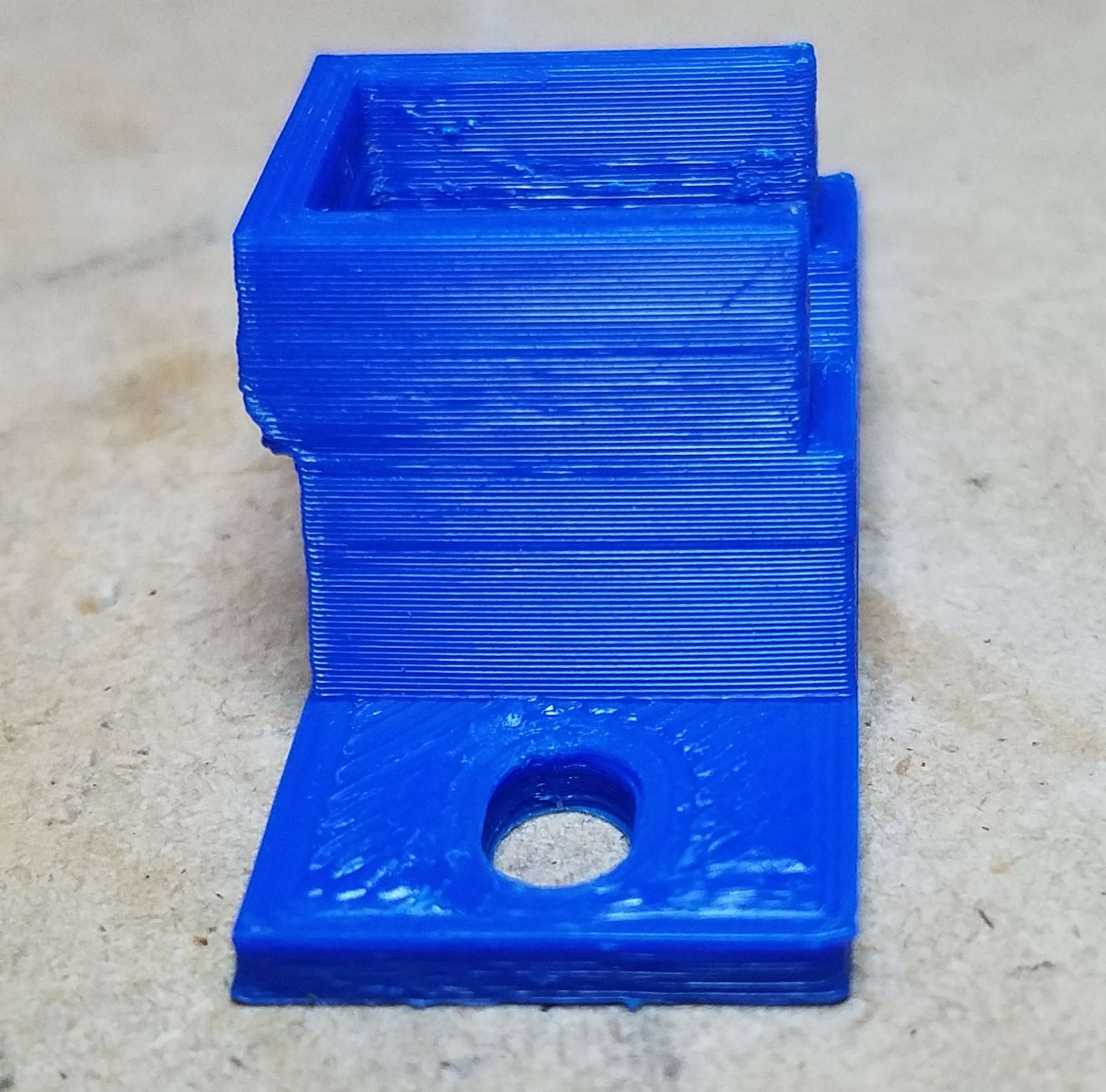

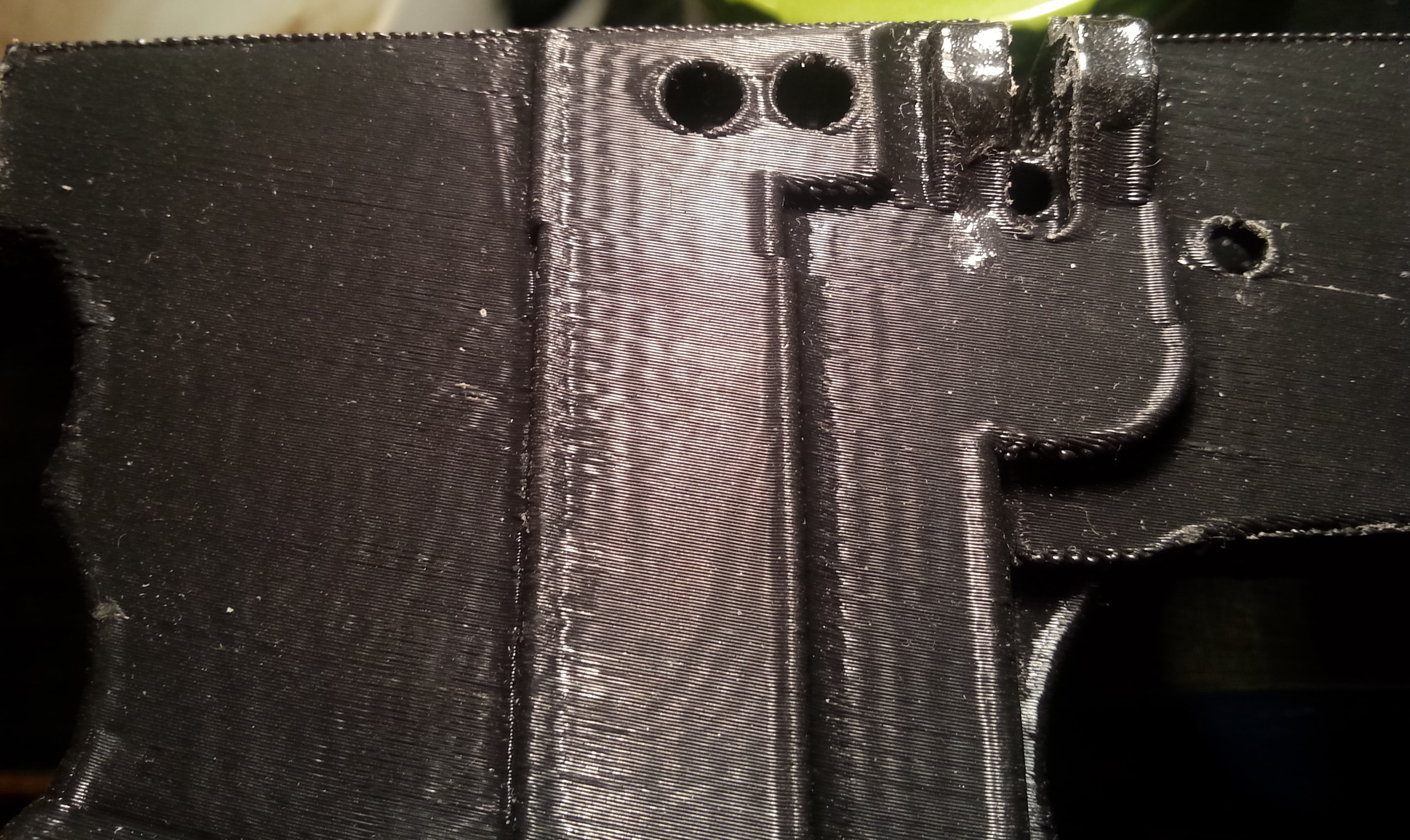

I've been seeing a few shifts lately too. I pritnted these today and all 4 are shifted in the same way. Interestingly in the area where simplify3d slows down from between 5-20mm/s.

The other one I printed at the begining of the month and had tried scaling the object. In the slicer it looked normal but then suddenly a whole section was shifted out. Both of these are long prints (first one is .1), second is large on sBase with DRV8825 drivers. I was running with 3us pulses, maybe now I'll increase to 4. I last pulled commits 25 days ago around "fix skew correction".

I also have witnessed layer shifts with bugfix 2.0 on a Anet A8 with a MKS GEN L board with TMC2130's on all motors. Last print had a layer shift in Y axis of approx 1mm at approx the 22nd layer. Then no other anymore. Params were 600ma current on x,y,z,e with 16 microsteps, 10 jerk for x and y, default acceleration set to 400, max to 2000,2000,... Interpolation was ON and drivers are configured for stealthchop and SPI. I'm now going back to 750ma and see if it improves. In any case, the Y motor does get 80°C hot after an hour of printing while X remains at +- 50°C. Strangely enough, with the Anet A8 board, they never reached 45°C, even not after multiple hours of printing.

After multiple prints without problems, today I suddenly experienced tlayer shifting. As always with 3d printing things can go wrong so I restarted the print. I was suprised to see that the second print had the exact same layer shifting. After looking at the gcode in Cura I could not see strange things and started googling.

Quite quickly I found this topic about the layer shifting bug.

Because nothing much changed about my printer I started thinking what I changed in the slicing software. I rememberd that I turned on acceleration and jerk control (to be honest I think it was only acceleration control) so turned them both off, sliced and restarted the print. This time it printed without any layer shifts.

I use a RAMPS board with a november Marlin 2.0bugfix and Octoprint.

I've used a caliper to measure where the layershift starts and it's around 3mm this should be around layer 15 (0,2mm layer hight)

I also included both files. I hope this is helpful.

Pitan_Body_v1.1.gcode.zip

Pitan_Body_v1.1(no jerk and acc ctrl).gcode.zip

@jvdbrg have you tried this with a current 2.0.x as well? I recall a change was made around november to the planner which affected the printer behavior when using Cura's acceleration / jerk control feature (https://github.com/MarlinFirmware/Marlin/issues/12364)

It would be interesting to see if you still experience the shift with current 2.0.x

I also have witnessed layer shifts with bugfix 2.0 on a Anet A8 with a MKS GEN L board with TMC2130's on all motors. Last print had a layer shift in Y axis of approx 1mm at approx the 22nd layer. Then no other anymore. Params were 600ma current on x,y,z,e with 16 microsteps, 10 jerk for x and y, default acceleration set to 400, max to 2000,2000,... Interpolation was ON and drivers are configured for stealthchop and SPI. I'm now going back to 750ma and see if it improves. In any case, the Y motor does get 80°C hot after an hour of printing while X remains at +- 50°C. Strangely enough, with the Anet A8 board, they never reached 45°C, even not after multiple hours of printing.

Update 17/01/2019

Replaced default steppers to 2.0A ones with low inductance. Increased current to 1000mA on x and y. The TMC2130 drivers are cooled with a lot of airflow over the heatsink. Steppers are now only a bit warm approx 35°C. Cura sliced object shows again layer shifts around the 27th and 35th layer. Then no shifts anymore. So I still believe it's firmware or slicer command related and not a hardware issue.

Fails_12-15hrs_in.rar.zip

Attached fails about 10-12 hours in when printing from OctoPrint. If I turn the X/Y stepper current voltage to 1.8V (from 1.2V as stock on the Trex3) and print from SD, then I can get failures within a few hours. This is IDEX, and X layer shifts affects both extruders. The layer that the shifts occur appears to be random. 7 tries at this print before I decided to just do it at 50% scale, which worked fine. It was approximately 9 hours.

Hi @simon-jouet,

I also had layer shifting problems on my HyperCube Evolution CoreXY printer.

As you are printing on a CoreXY with junction deviation enabled, your problem is probably caused by the bug #12851 that I fixed recently.

Mine now runs very fast and smoothly with travel speeds of 300mm/s and travel acceleration of 4500mm/s² and infill print speed of 200mm/s without layer shifts so far.

I have large shifts, too on my CoreXY. I think it was fine after you fixed that bug, but after I compiled and flashed today, every print fails. The printer makes a loud "whump" noise and shifts 1-2 cm. This happens at random layers. Might be completely unrelated to the issue you found.

I lowered the acceleration from 4000 to 1000 and the speed to 100 without any difference. Drivers are TMC2130 running at 900mA 30V. I disabled StealthChop through the new menu item on the lcd and lowered the hybrid threshold to 1. No difference, only a bit louder.

I think it mostly shifts to the lower right.

@hamster65

Yes, that loud "whump" noise is why I investigated the movement behavior of my printer. When the tool head takes a sharp corner, we expect it to slow down and then accelerate again. Therefor I tested the motion with several zig-zag travel moves at high speeds. It turned out that the tool head did not decelerate in some cases (i.e. certain angles) and caused too much load on the steppers which resulted in lost steps.

Here are my tests for my print bed of 30x30cm² that all run fine and smooth now. You will see that the angle between segments gets wider with every script. Maybe you will want to increase travel acceleration, junction deviation and speed in several test runs and see if and when your printer fails.

M204 T4500 ; Travel acceleration

M205 J0.07 ; Junction deviation

G1 Z20 F300

G1 X150 Y20 F24000

G1 X140 Y30

G1 X160 Y40

G1 X140 Y50

G1 X160 Y60

G1 X140 Y70

G1 X160 Y80

G1 X140 Y90

G1 X160 Y100

G1 X140 Y110

G1 X160 Y120

G1 X140 Y130

G1 X160 Y140

G1 X140 Y150

G1 X160 Y160

G1 X140 Y170

G1 X160 Y180

G1 X140 Y190

G1 X160 Y200

G1 X140 Y210

G1 X160 Y220

G1 X140 Y230

G1 X160 Y240

M204 T4500 ; Travel acceleration

M205 J0.07 ; Junction deviation

G1 Z20 F300

G1 X150 Y20 F24000

G1 X140 Y40

G1 X160 Y60

G1 X140 Y80

G1 X160 Y100

G1 X140 Y120

G1 X160 Y140

G1 X140 Y160

G1 X160 Y180

G1 X140 Y200

G1 X160 Y220

G1 X140 Y240

G1 X160 Y260

M204 T4500 ; Travel acceleration

M205 J0.07 ; Junction deviation

G1 Z20 F300

G1 X150 Y20 F24000

G1 X140 Y50

G1 X160 Y80

G1 X140 Y110

G1 X160 Y140

G1 X140 Y170

G1 X160 Y200

G1 X140 Y230

G1 X160 Y260

G1 X140 Y280

M204 T4500 ; Travel acceleration

M205 J0.07 ; Junction deviation

G1 Z20 F300

G1 X150 Y20 F24000

G1 X140 Y40

G1 X160 Y80

G1 X140 Y120

G1 X160 Y160

G1 X140 Y200

G1 X160 Y240

G1 X140 Y280

M204 T4500 ; Travel acceleration

M205 J0.07 ; Junction deviation

G1 Z20 F300

G1 X150 Y20 F24000

G1 X140 Y140

G1 X160 Y280

My TMC2130s are running at 950mA at 24V. However, after some month without issues, I had to increase the step pulse width to 1µs as the extruder motor suddenly stopped turning. (I'm using a 32 bit board (MKS SBASE 1.3) that may be too fast and hence generates too small pulses) .

Stealth chop is no option for me too as it fails miserably at fast travel moves.

S-curve acceleration and adaptive step smoothing are enabled.

My layer shifts mostly happend at the same layer of a print and there were several "whumps" during prints.

@swilkens I'm currently in the proces of setting up the new firmware. When it is installes, I will try to print the item and get back on this item.

Todays tests was the right 46mm spaced x-carriage holder that can be found on: https://www.thingiverse.com/thing:1428253

6 out of 6 samples had layer shift on every print. No bigger shifts than 2mm. 4 of them have x axis shift, 1 of them has both and 1 of them has shifts on Y axis.

Layer shifts occured very early in the print and seem to be repeatable. I rotated the print object 90° to make the y-axis work harder on some of the samples, still the X is favored for layer changes. Since I use the stock Anet A8 extruder, weight will be the major concern.

I then installed the latest Bugfix 2.0 with the latest TMC library (0.3 I think). Now I have an option in the menu that allows me to turn stealthchop off for x and y. They run in spreadcycle now.

Result, no layer shifts so far (layer 162, 2Hrs of print)...

I have given op on stealthchop, it just doesn't work with my printer. Maybe it does work better with a higher voltage !

I have large shifts, too on my CoreXY. I think it was fine after you fixed that bug, but after I compiled and flashed today, every print fails. The printer makes a loud "whump" noise and shifts 1-2 cm. This happens at random layers. Might be completely unrelated to the issue you found.

I lowered the acceleration from 4000 to 1000 and the speed to 100 without any difference. Drivers are TMC2130 running at 900mA 30V. I disabled StealthChop through the new menu item on the lcd and lowered the hybrid threshold to 1. No difference, only a bit louder.

I think it mostly shifts to the lower right.

I did some testing today with CoreXY/MKS Sbase setup, I've build my unit so that X-stepper has longer cable. Seems that balancing the longer cable would need higher current setting

define DIGIPOT_I2C_MOTOR_CURRENTS { 1.8, 1.6, 1.6, 1.4, 1.4 }

I haven't tested with the big model but small one gives promising result. Equal currents 1.6+1.6 and 1.8+1.8 gave layer shift but 1.8+1.6 seem to work.

I made some progress on this issue tonight. I'm not convinced this is really a Marlin issue. I think it might be a cheap heatsink and cheap thermal adhesive problem.

Edit: I did turn up the current from 1.3A (stock) to 1.8A to force the temperature to rise a little faster. I had noticed that the higher current settings tended to have more layer shifts. These drivers, if properly designed and properly cooled, should be able to handle 1.8A with no problem. Obviously here there is a serious design problem, but these are identical to the drivers that I purchased on Amazon a while back as well.

See these two videos

https://youtu.be/SP_xGC-Hjo4

The CoreXY layer accuracy with SBase board is far from reasonable :-( With the Smoothware I had no better luck. 8-bit board with Marlin 1.1.9 is just great.

I started to wonder if 32uSteps has something to do. I switch the jumper next to heat-sink to 16uS and reduced the Marlin FW steps 160->80. For some reason the steppers move 2x distance ??? How to set MKS Sbase to the 16 microstep mode?

@J-PN did you remember to reload the default settings and store them in eeprom using M502 and M500?

I re-flashed the FW with the new values.

That is not enough, the values are stored in eeprom and will override the default settings. You need to reload the (new) firmware defaults and store them in eeprom.

Also could you explain what you mean by "The CoreXY layer accuracy with SBase board is far from reasonable"? What is wrong with it? It would also probably help if you provide details of your 8 bit and 32bit systems in particular what drivers are you using, what voltage, what microstepping etc.

@J-PN There is still a known issue with CoreXY and 32Bit Hardware #11047

Find this line in Configuration_adv.h

//#define MINIMUM_STEPPER_PULSE 2

and change to

#define MINIMUM_STEPPER_PULSE 4

I must say, I didn't do the 'Initiate Eeprom' after the reflashing the FW.

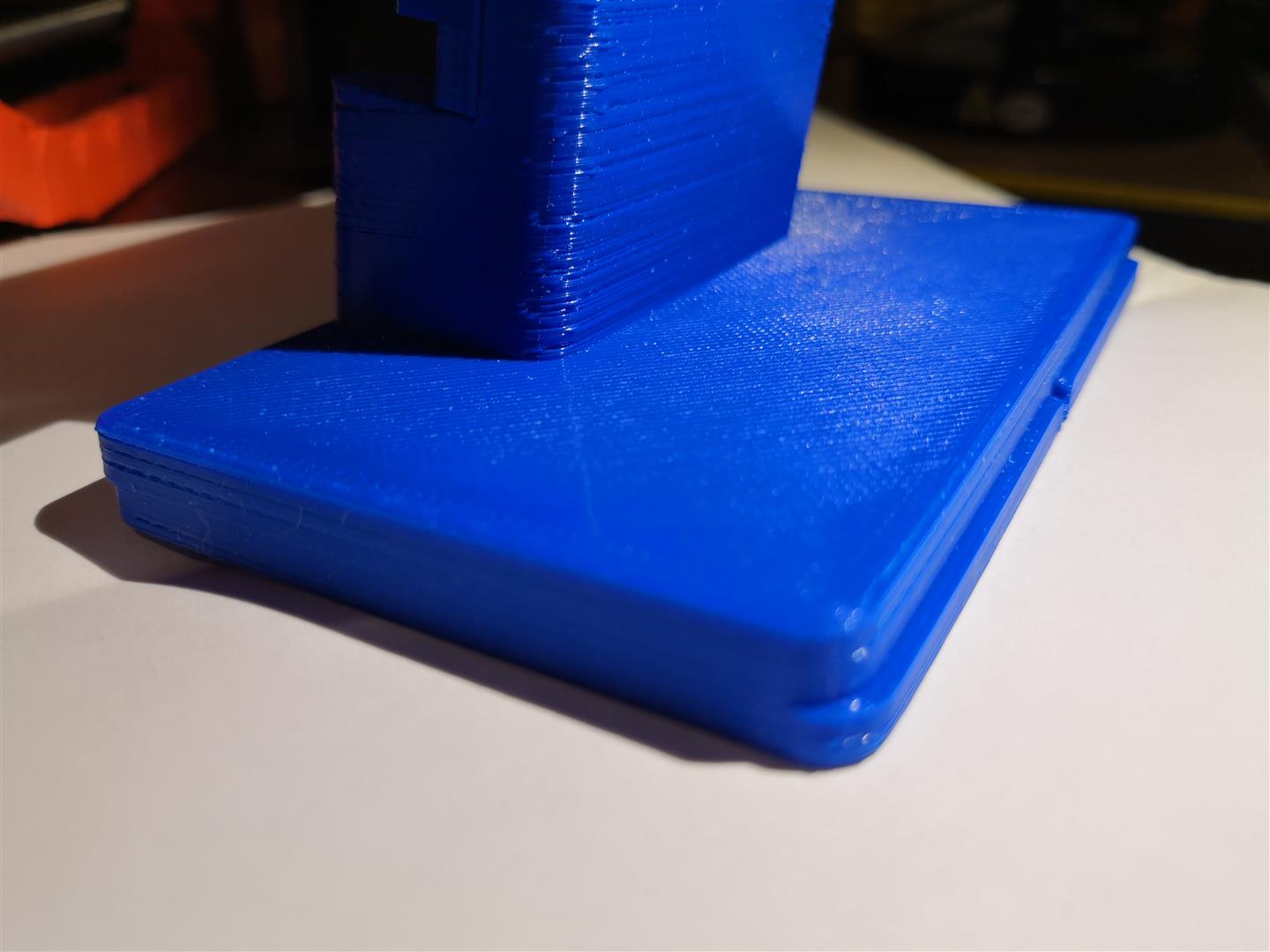

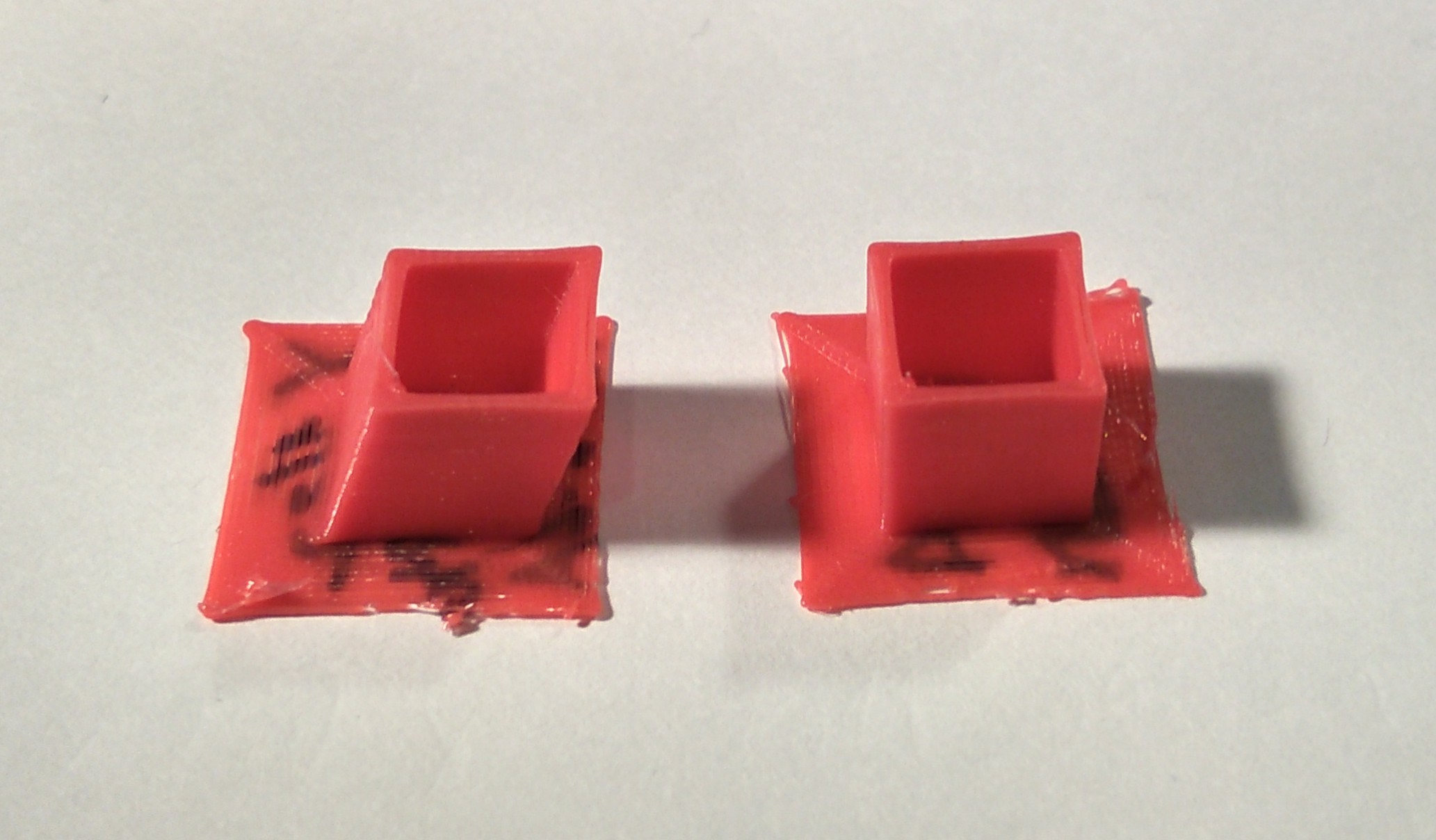

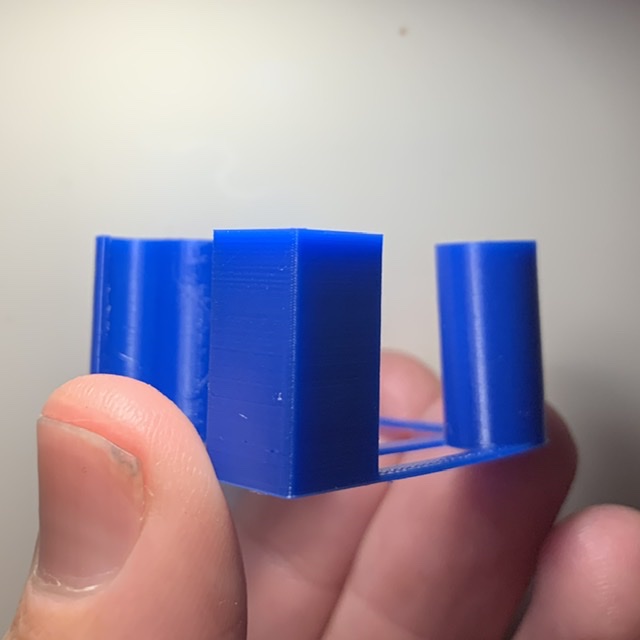

With the example currents 1.2 the print drift very heavy towards back right corner (Tronxy X5S)

In the picture top result: original Metzi board (A4899)

The next ones with MKS SBase with onboard drivers DRV8825 (heat sinks are cool, X&Y motors slightly warm, extruder bit more warmer)

In the picture middle result: DIGIPOT_I2C_MOTOR_CURRENTS { 1.8, 1.6, 1.6, 1.4, 1.4 }

In the picture bottom result: DIGIPOT_I2C_MOTOR_CURRENTS { 1.6, 1.4, 1.4, 1.4, 1.4 }

I've noticed that the X motor needs higher current setting (longer cable).

You can see that even before the actual layer-shift the layers are uneven, micro-stepping holding issue?

You will almost certainly need the change to MINIMUM_STEPPER_PULSE mentioned above (I certainly do on my SBase). I would try that before going any further. You will also need to do the M502 M500 after making pretty much any config change.

The reason for using current driven motors instead of voltage driven is so

that the cable length doesn't matter. The reason the x stepper needs more

current is definitely not due to the longer cable. There's something else

going on there.

On Mon, Feb 11, 2019, 12:26 PM J-PN <[email protected] wrote:

I must say, I didn't do the 'Initiate Eeprom' after the reflashing the FW.

With the example currents 1.2 the print drift very heavy towards back

right corner (Tronxy X5S)In the picture top result: original Metzi board (A4899)

The next ones with MKS SBase with onboard drivers DRV8825 (heat sinks are

cool, X&Y motors slightly warm, extruder bit more warmer)X5S190127.zip

https://github.com/MarlinFirmware/Marlin/files/2852909/X5S190127.zip

[image: _20190211_220933]

https://user-images.githubusercontent.com/46862137/52590967-59786c80-2e4b-11e9-8188-07100b536d0a.JPGIn the picture middle result: DIGIPOT_I2C_MOTOR_CURRENTS { 1.8, 1.6, 1.6,

1.4, 1.4 }

In the picture bottom result: DIGIPOT_I2C_MOTOR_CURRENTS { 1.6, 1.4, 1.4,

1.4, 1.4 }I've noticed that the X motor needs higher current setting (longer cable).

—

You are receiving this because you commented.

Reply to this email directly, view it on GitHub

https://github.com/MarlinFirmware/Marlin/issues/12403#issuecomment-462481222,

or mute the thread

https://github.com/notifications/unsubscribe-auth/AbmHXrmkf9pUMEUhuPkRmXtLCDK7mC0Aks5vMdIFgaJpZM4YY1Jm

.

current driven motors instead of voltage driven is so that the cable length doesn't matter

Yes, I agree the current driven system should compensate the cable+motor inductance.

need the change to MINIMUM_STEPPER_PULSE

I've tested with 'MINIMUM_STEPPER_PULSE 2' and without and haven't noticed any difference.

The same with MAXIMUM_STEPPER_RATE 250000 & MINIMUM_STEPPER_DIR_DELAY 650

MINIMUM_STEPPER_PULSE 2 is the default setting for DRV8825 drivers, so there is no difference

Try MINIMUM_STEPPER_PULSE 4 or at least 3

Hi, yes I put the MINIMUM_STEPPER_PULSE 4 and MINIMUM_STEPPER_DIR_DELAY 1000 just in case. With those the quality is OK.

I wonder if the SBASE example Configuration_adv.h should be update on the build

X5S_19Feb19.zip

Just as an update... Enabling spreadcycle instead of stealthchop for x & y solved my issues. No layer shifts anymore in the last 1.5 kg of filament printed ; and most prints are parts for the AM8 BLV mod, so a good variation of curves, straight lines, short accelerations, bridges etc...

I also enabled linear_advance but not s-curves as my 8bit 2560 might not be able to calculate all of that.

the error of the layers shift is present in 1.1.x and 2.0bugfix in 1.1.7 there are no layer shift errors.

The error appears during large displacements. 2 test cubes diagonally into the edges of the print field. 1 cube anywhere in the field runs without shifts.

The error appears during large displacements. 2 test cubes diagonally into the edges of the print field. 1 cube anywhere in the field runs without shifts.

Wow! This is very helpful information if it can be duplicated! I do not have a printer available. But I would be very appreciative if some people can do this type of print and see if they can duplicate @demson 's results!

Yes, the result was repeated on different files. The error does not depend on the MINIMUM_STEPPER_DIR_DELAY MINIMUM_STEPPER_PULSE options, tried more than necessary, turned off the multistep but this does not help. The executable file with the cubes attached. https://yadi.sk/d/YWIW-rJScjTgSg

The size of the print field is large, but I think that if you just put 2 cubes on the diagonal of the field, the result will be the same.

The error appears during large displacements. 2 test cubes diagonally into the edges of the print field. 1 cube anywhere in the field runs without shifts.

Wow! This is very helpful information if it can be duplicated! I do not have a printer available. But I would be very appreciative if some people can do this type of print and see if they can duplicate @demson 's results!

In the opposite. Without the configs this statement is worthless.

If the acceleration is low and the max-speed of the skipping axle is that high, it gets to top speed only on long moves (or never) - it's a simple configuration error - with too high top speed.

the configuration file did not change from firmware 1.1.7 to firmware 1.1.x and 2.0.x and 7 was not missed by steps with the same values of speed, acceleration, jog

Junction deviation for example is not configurable in 1.1.7. This could result in a higher cornering/stat/stop - speed of a long move - what will increase the reachable top speed of the move by the same amount.

the error of the layers shift is present in 1.1.x and 2.0bugfix in 1.1.7 there are no layer shift errors.

The error appears during large displacements. 2 test cubes diagonally into the edges of the print field. 1 cube anywhere in the field runs without shifts.

I had issues with missing steps, too. 1) on my 3 printers and 2) on my openpnp driven by marlin on radds.

The problem for 1) was that Slic3r since some version added gcode to control the acceleration, speed, etc and I didn't know about that change. The defaults were too high and I had missing steps on the y-axis with the heavy prusa style bed. I changed the values in slic3r and the problem went away.

But for 2) I still saw some missing steps on X and Y - PnP machines have to run fast, so I needed to go into the limits. I observed missing steps if I had the DEFAULT_RETRACT_ACCELERATION, DEFAULT_ACCELERATION and DEFAULT_TRAVEL_ACCELERATION set to something very high because I wanted to limit the acceleration per axis with DEFAULT_MAX_ACCELERATION.

this does not work, but would be preferred as it allows for fast movements on E which is rotating the pick and place machine's nozzle:

#DEFAULT_RETRACT_ACCELERATION 20000

#DEFAULT_ACCELERATION 20000

#DEFAULT_TRAVEL_ACCELERATION 20000

#define DEFAULT_MAX_ACCELERATION { 2500, 2500, 5000, 20000 }

this does work but is slow due to the very limited acceleration on Z and E:

#DEFAULT_RETRACT_ACCELERATION 2500

#DEFAULT_ACCELERATION 2500

#DEFAULT_TRAVEL_ACCELERATION 2500

#define DEFAULT_MAX_ACCELERATION { 2500, 2500, 5000, 20000 }

With the settings below I have no step loss in X and Y but a slow machine. With the upper settings I have missing steps in acceleration phase in X and Y direction although the acceleration should be the same... Maybe there is a glitch/bug in the acceleration limitation?

@Roxy-3D i have done 4 prints of the same 36 hour print and have not seen any issue

no blobs, etc and no layer shift

are there any stl i could have a go at that will provoke this?

@boelle do you have any 400mm base machines?

i'm building one, at very slow speed as i do not have a bottom less pit full of cash

it will be 500x500x500 or damm close to that, Z is verified to be a little over 500, but i still have to buy extruder and the build plate itself

I have a gcode file sliced explicitly to torture the planner that has been very reliable in triggering layer shifts, but most of my machines are 400x400 so it's centered there. It will fit on a 300x300 barely in the back right edge. I can send a link for it if you'd like, just adjust fan and hotend temp as needed, and set a bed temp before starting.

I think it will be enough just to count the pulses, if at the point 0 0 after printing there will be a number of pulses other than zero, this will mean a shift.

@InsanityAutomation Can we twist your arm to locate the part at about (100mm,100mm) and slice it there? That might enable people with smaller machines to give it a try and help us understand the problem.

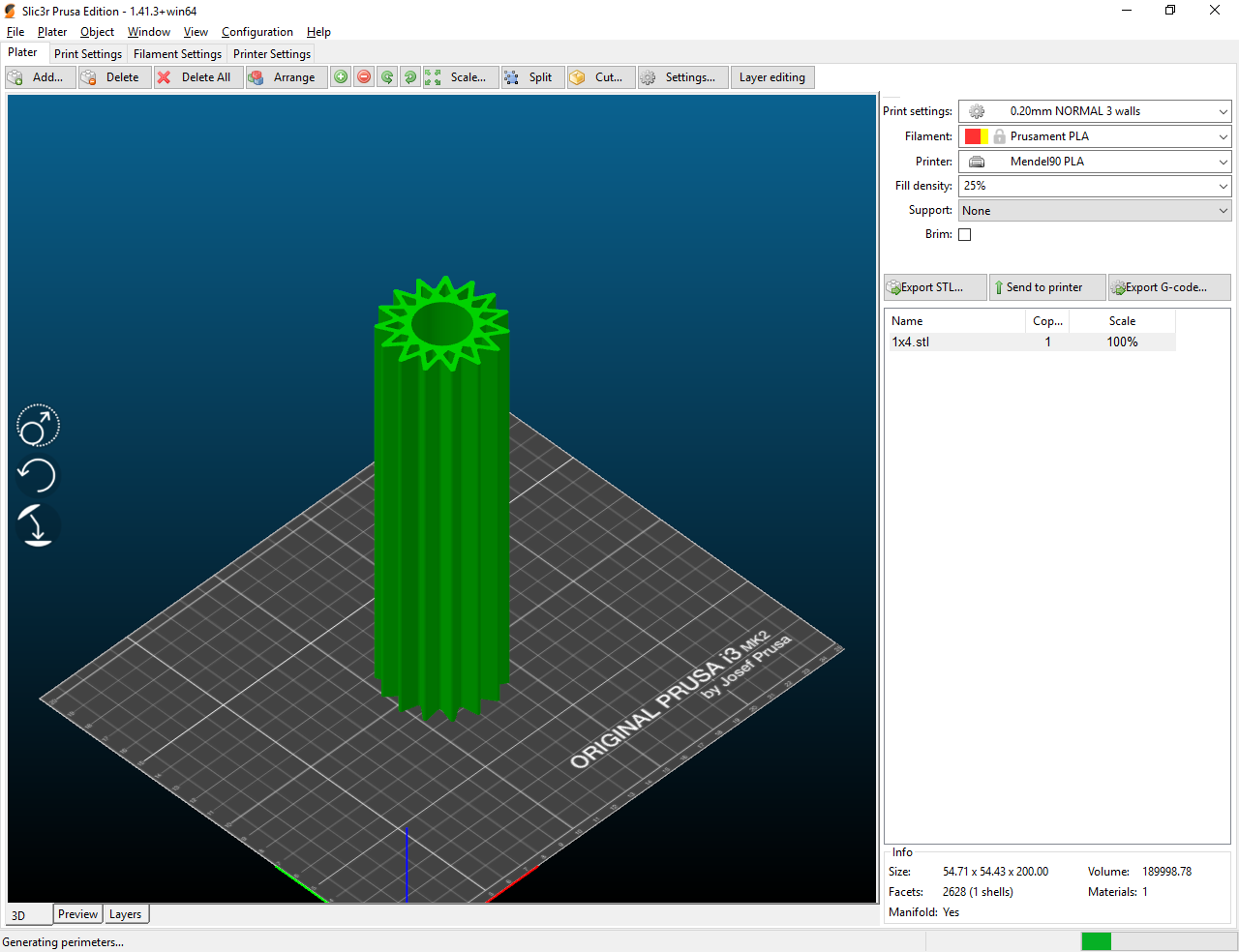

i have printed a 200mm tall gear shaped object, takes 36 hours sliced with slic3rpe as if the printer was a mk2.5

gcode is 84MB :-/

@InsanityAutomation Can we twist your arm to locate the part at about (100mm,100mm) and slice it there? That might enable people with smaller machines to give it a try and help us understand the problem.

Ill go over the parameters I used again and see what I can put together probably Sat. Should be able to make something a bit smaller.

thinking of it...

since you most likely will reslice this would it make more sense to place it in the 0,0 corner?

then no matter how big or small a bed people have they can just use G92 to get it to print in the center

just my simple thought, might not work

since you most likely will reslice this would it make more sense to place it in the 0,0 corner?

Also... Do we have people with Delta's seeing the issue? If so, slicing close to the (0,0) corner might let them use the file....

Has anyone tried uncommenting the

//#define TMC_DEBUG

in configuration_adv.h?

Right now I don't believe we know if the layer shift is coming from the

software, or if the stepper driver itself is messing up.

However, the M122 command may generate TOO much info.

We probably also need to uncomment //#define MONITOR_DRIVER_STATUS

The MONITOR_DRIVER_STATUS would also stop the print on overheat. I found

that with my stock TMC2208 boards, the chip itself was running at very high

temperatures (over 100C) while the heat sink was still around 30C. I

scraped off the enamel on the board under the heat sinks and then adhered

them with arctic silver thermal adhesive. With this mod, I had layer shifts

reduced significantly and the highest recorded temperature on the chip was

about 50C. (Still had layer shifts, though, on at least one design that

included long straight moves).

-Steve

the configuration file did not change from firmware 1.1.7 to firmware 1.1.x and 2.0.x and 7 was not missed by steps with the same values of speed, acceleration, jog

Yes, but the way the Planner schedules the acceleration ramps and max speed has been affected. It would be very helpful for you to reduce the max feed rate and accelerations (by maybe 15% or 20%) and see if your scenario still causes the problem... Knowing what happens would be helpful!!!

i got the torture test ready, but it will take arround 50 hours and take about 180g of filament

and since i'm adding to my core xy build i need the working printer free to print parts. So not sure when but it will prob happen either at end of weekend or during the week.

i would not mind sharing the gcode if @InsanityAutomation can give his blessings, i just wonder what is the best way to share since its 139MB, google drive maybe?

all i did with his code is adding my own start code and then i used G92 to "trick the printer to print in center of my mk42 bed where the model org. was centered on a 300x300 bed

also retracts are changed from 3mm to 0.8mm since i have a direct drive

i would not mind sharing the gcode if @InsanityAutomation can give his blessings, i just wonder what is the best way to share since its 139MB, google drive maybe?

You should be able .ZIP it up and attach it to a post here....

bummer 10mb limit and its ~47MB zipped

will upload to google drive and post a share link instead :-/

I'll do a smaller one to post here. That one is fine, but setup for a big machine. My web server won't have an issue hosting it directly either.

oki doke :-D

speed limits were due to the feed rate, visually did not pull out at maximum speed. when I commented out multistep it seems to me the speed dropped even lower. For this reason, I think it is unlikely that hardware will skip steps. Accelerations and runs were lowered. At a decrease of jog (jog=5 >> jog=1), displacements occurred a little slower. In my test file, the shifted axis was X, Y axis shifted much less.

hello,

In my selfmade machine (cartesian + ramps 1.4 + 1 motor X a4988+ 1 motor Y TB6600 + 2 motors Z 2 a4988, Z_DUAL_STEPPER_DRIVERS + bugfix-1.1.x_20180731) i have a almost "constant" layer shift in Y-axis.

I see that the movements within a layer are ok but there is a the problem with changing layer movement:

G0 Fxx Xxx Yxx

G0 Xxx Yxx Zxx

do you know if in Marlin i can set something for having this G0 X Y Z as G0 X Y + G0 Z (avoid losing steps)? or it would be rather in the slicer configuration?

jerk Y 0.0mm/seg accel Y 300mm/seg*seg feddrate Y 20mm/seg, gcode ok in gcode viewer.

heavy bed, and no printing without shift in layers. YZ_skew_factor smooths but don't fix.

without S_CURVE_ACCELERATION

without JUNCTION_DEVIATION

first two layers and last two layers with more shift.

hello,

after a lot of 10mm cube tests in bugfix-1.1.x, changing 1 parameter each time, the problem of constant shift layer has disappeared flashing Marlin 1.1.8 in ramps 1.4. Without any change in hardware configuration.

I've copied/pasted parameters form Marlin bugfix-1.1.x in M 1.1.8.

It's not a enclosed solution, but it works.

I just want to add my 2 cents... I had the same issues with layer shifting with s-curve acceleration and jerk enabled as seen in #12398. Even though my jerk settings were very very conservative. I think the issue may actually be cpu bottleneck even on 32 bit. Moving to junction deviation (which I still don't understand how to tune correctly...) seems to have solved the problem. Will report back once more testing is completed. A good test part is a stl file with circles, like this one.

I'm actually still suffering layer shifts with junction deviation as well... still investigating.

hello,

after some tries, i've found that my problem of constant layer shift was in the TB660 driver on Y axis. It wasn't working properly.

I have changed it and then i got good printings.

Using Marlin bugfix-2.0.x 2019 03 26 "e3ab547"

without junction deviation, without s-curve, jerking X and Y 0.1

Can you enable all of them and see if layer shifts come back? This would help narrow down the issue to a specific feature

I will try.

One thing that i don't understand is that, with the broken TB6600 on Y axis, in marlin 1.1.8 the problem of constant shift layer looked almost solved ( some noise between layers) but with bugfix-1.1.x and bugfix-2.0.x there was a uniform shift layer. Photo above left.

Do you consider the attached print to be due to this issue ? I'm starting to get this bad print after moving from Marlin 1.1.8 to Marlin 2. It doesn't happen every time, but I'm totally able to replice the shown issue with Slic3r Prusa Edition and the benchy. Simplify 3D doesn't exibit this issue.

Hello....

Anybody have .gcode files to test this problem ?

Anybody???

@robbycandra Just start a printer going on something that is going to take 12 hours to print. I think there is a fair chance you will see a small layer shift some where in the print.

@Roxy-3D , because it takes hours to print. It is better if someone can share the GCODE files. Hopefully it can be tested using 20x20x20 cm workarea.

Here's the problematic section of a file that would shift every time for me in different places.

short shift test.gcode.zip

Mirror: Download shift test

@pinchies , i will try your gcode.

I use my printer almost everyday but never found any layer shift problem.

@pinchies , I have print it and found no layer shifting.

But if the printer frame is not rigid, its difficult to print your gcode.

That's good to hear, thanks for testing, but I still have some questions:

- did you you have S_CURVE_ACCELERATION enabled?

- did you have JUNCTION_DEVIATION enabled? What value?

I'm also facing the loosing steps problem, my guess is that my drivers(TMC2130) overheat.

I found the if you have more than 4 warnings the current will be decreased by 50mA(default value), but for this to happen you must have active TMC_DEBUG and MONITOR_DRIVER_STATUS

#if ENABLED(MONITOR_DRIVER_STATUS)

#define CURRENT_STEP_DOWN 50 // [mA]

#define REPORT_CURRENT_CHANGE

#define STOP_ON_ERROR

#endif

I checked with the M122 command and seems to be OTPW true on Y axis(the one skipping steps).

I'm also on the latest 1.1.9 bugfix.

The problem appeared when trying to print a model that has rectilinear infill instead of honeycomb. I think that all the straigth lines are causing a problem.

UPDATE: Layer shift while writing this, doesn't seem that the OTPW is the problem, I set the current to 900(just to see if OTPW is the culprit). Below are my driver status, I just had a layer shift on Y axis, and Y doesnt have a warning.

Recv: X Y Z E0

Recv: Enabled true true true true

Recv: Set current 900 900 850 900

Recv: RMS current 887 887 826 887

Recv: MAX current 1251 1251 1165 1251

Recv: Run current 28/31 28/31 26/31 28/31

Recv: Hold current 14/31 14/31 13/31 14/31

Recv: CS actual 28/31 28/31 26/31 28/31

Recv: PWM scale 78 99 39 79

Recv: vsense 1=.18 1=.18 1=.18 1=.18

Recv: stealthChop true true true true

Recv: msteps 16 16 16 16

Recv: tstep 447 175 65535 5107

Recv: pwm

Recv: threshold 10 10 1 8

Recv: [mm/s] 993.25 993.25 1976.56 1022.87

Recv: OT prewarn false false false false

Recv: OT prewarn has

Recv: been triggered false false true false

Recv: off time 5 5 5 5

Recv: blank time 24 24 24 24

Recv: hysteresis

Recv: -end 2 2 2 2

Recv: -start 3 3 3 3

Recv: Stallguard thrs 8 8 0 0

Recv: DRVSTATUS X Y Z E0

Recv: stallguard

Recv: sg_result 0 0 0 0

Recv: fsactive

Recv: stst

Recv: olb

Recv: ola

Recv: s2gb

Recv: s2ga

Recv: otpw

Recv: ot

Recv: Driver registers: X = 0x00:1C:00:00

Recv: Y = 0x00:1C:00:00

Recv: Z = 0x00:1A:00:00

Recv: E0 = 0x00:1C:00:00

@pinchies , When testing your gcode.... Yes and Yes... using default value.

Hi same thing here with A4988.

The problem is manifested on big accelerations. (As for bridges)

The problem is present since all the versions> = 1.1.9

No S_CURVE_ACCELERATION.

No JUNCTION_DEVIATION.

I had layer shifting with TMC2130 as well, version used was like 3 weeks ago - sorry can't remember the exact date. Downloaded version today, and all seems to work fine. tmc2130 library downgraded to 2.0.1 (no idea if this really did help)

Hey there! I had layer shifts pretty early in April of 2018 and reported them here: https://github.com/MarlinFirmware/Marlin/issues/10446#issuecomment-467527351 It was never solved, but several people had those issues. - I just used an older Marlin version since then.

I think I finally nailed it down now and fixed it.

Set K Factor of Lin_Adv to 0 in the firmware, since I have it in my GCode. - Before I had the factory setting of 0.22 (I think so) in my Firmware AND a K factor in my GCode.

I tried fashing the release, the bugfix and always had the layershifts when using both K factors. Now the bugfix runs fine without shifts.

So maybe you want to try that out

@viperchannel, do you have the gcode files? I you still have.. please share it here.

@robbycandra

Sure. I had the shifts at around 10mm height in the Y axis. 3 times in a row in the same spot. About 1mm above the deck. I checked the file with the octoprint Gcode viewer and it looks fine in there.

After setting the K factor to 0 in the config, the same Gcode printed without issues.

(Using TMC2208 drivers, RAMPS Board, octoprint newest release version, Marlin latest bugfix with Lin_adv)

Been printing for a year now with that config with a older (I think dec 2017) build of marlin with no issues and not a single shift. So it is 100% not a hardware issue.

@viperchannel do you have a pic about the layer shift on benchy? I've posted above my benchy where i get something similiar to a shift (i think it's related to a slow down, when slicer slow down speed, i Always get these strange layers similiar to a shift. Happens with all slicers)

@viperchannel , thanks... will try tommorrow

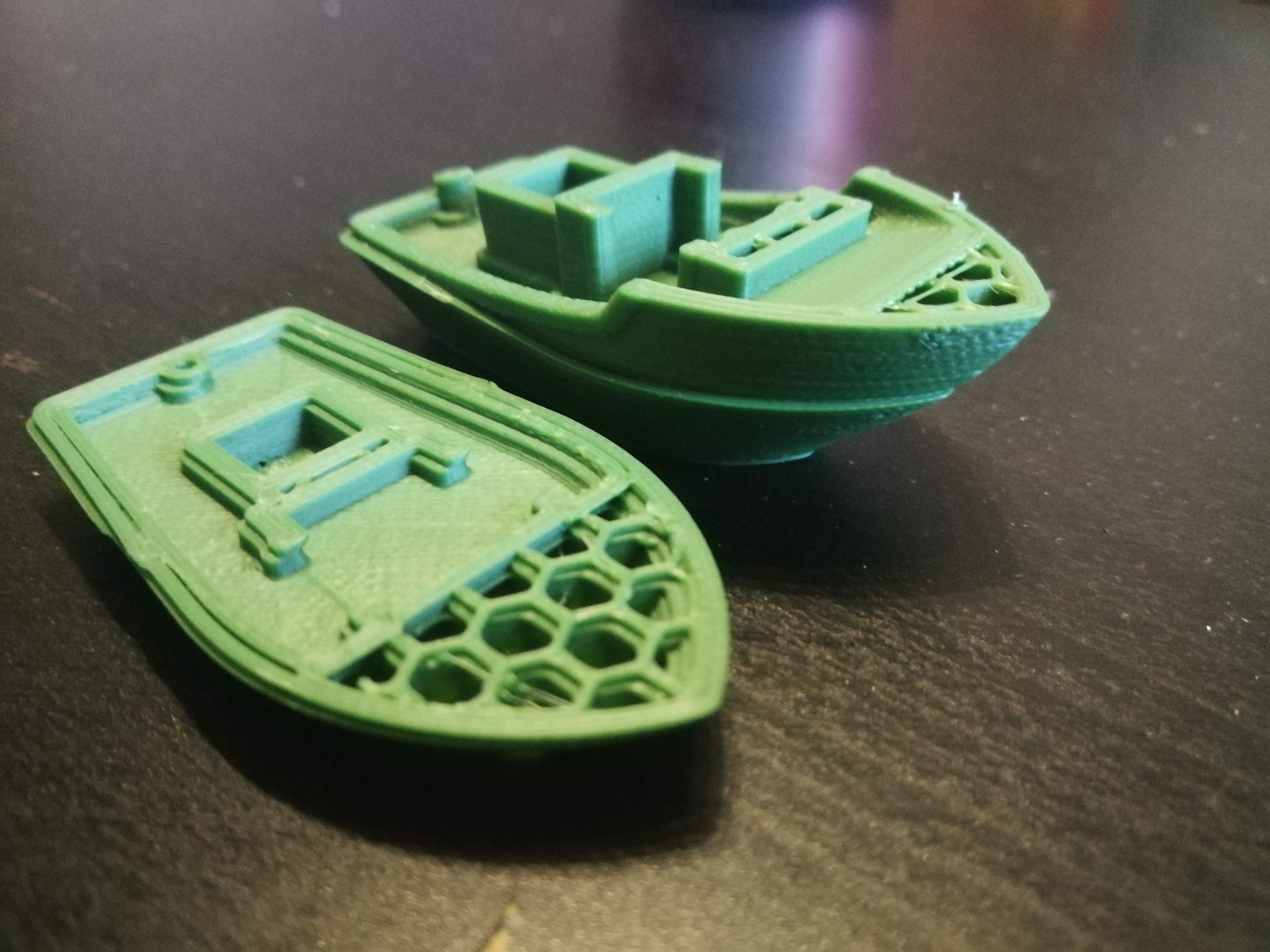

@guestisp Sure. One is printed with 1.19 and one with 1.19 bugfix. Both a fresh config, manually edited and just adjusted the basic stuff like bedsize, boardtype, endstop settings etc. Nothing fancy. I ripped one of the boats apart on the pic to check the layer adhesion, thats why it is lower than the other. That has nothing to do with the shift itself. But if you look closely, you can see that the shift is at or almost at the same position. But the shift distance itself differs. I have another one that has an eaven bigger shift as the ones from the pic at the same spot.

@robbycandra thanks, be aware, it is pretty high temp (ASA filament) so don't try printing it with PLA without adjusting the temp

Print looks bad, but this was my first time using that filament, so I still need to find the right settings. But the shift is pretty obvious.

@viperchannel looks quite different from mine...

hello,

after a lot of 10mm cube tests in bugfix-1.1.x, changing 1 parameter each time, the problem of constant shift layer has disappeared flashing Marlin 1.1.8 in ramps 1.4. Without any change in hardware configuration.

I've copied/pasted parameters form Marlin bugfix-1.1.x in M 1.1.8.

It's not a enclosed solution, but it works.

I had this problem too.

It was solved reducing acceleration.

The high speed was causing vibration and step loss.

Actually I'm using this values:

#define DEFAULT_ACCELERATION 1000 // X, Y, Z and E acceleration for printing moves

#define DEFAULT_RETRACT_ACCELERATION 2000 // E acceleration for retracts

#define DEFAULT_TRAVEL_ACCELERATION 1000 // X, Y, Z acceleration for travel (non printing) moves

@viperchannel , I have print your g code and found no layer shift

Using latest bugfix2.0 . LIN_ADV, S_CURVE, JD all enabled.

Thabks for testing it. I also sucessfully printed the file without shifts after setting K value to 0and only use the k value from the gcode. I am 99%sure that my shifts were caused by using a k factor both in the gcode and the firmware and maybe that caused some buffer overload or something after a certain printing time. I had about 30h of printing since i changed tgat without a single shift

Hi @viperchannel , I test your GCode using default K value (0.22),

I dont think its because the K value.

By reducing the jerk by 50% the fault disappears.

However an impression of 1:15 take 5 minutes more ...

That is so strange. The K factor is the only thing I changed. I had that shift in all prints, no matter if release or bugfix version. Once i printed lla the stuff i need, i will chnage the k factor back in the FW and try it again to see if the shift returns

I test your GCode using default K value (0.22)

Very little OT: is there any test to see if K value is correct, othe than the calibration pattern made automatically by the firmware ? I don't see differences in printed lines, so i'm looking at something better

There is a difference in the lines, but be sure to set the correct pattern for your firmware in the pattern generator, and have lin adv activated in the formware of course. otherwhise you wont see a difference. There is version 1.0 for 1.18 firmware and 1.5 for 1.19 firmware. I personally think it is way easier to see the difference with the new 1.5 version.

I'm using the 1.5 version but lines are too thin and numbers printed on the right most of the time doesn't stick to the bed, that's why i'm asking for a different test.

Note:

I use default value for acceleration, JD, E-Jerk.

But i use this

#define MIN_STEPS_PER_SEGMENT 6

#define MINIMUM_STEPPER_PULSE 5

I change this because i think the default value is too low.

The quality of driver in the market is not as good as original polulu driver.

@guestisp , try to reduce speed to 50% at first layer manually.

This gcode is not easy to print.

@guestisp , try to reduce speed to 50% at first layer manually.

I was talking about the Linear advance calibration, not about this gcode. End OT.

@robbycandra I printed with default setting and got the shifts and with acceleration set to 1500- The same. But after reflashing without the K I also tried both and had no more shifts. What board are you using and what drivers? I have a ramps with dual Z setup and 2208 drivers on all axis and a A4988 on the extruder.

@guestisp you have to fix bed leveling first and bed adhesion before playing around with LinAdv. Otherwhise you will have a very hard time to see the difference of the lines. I will print one for you and show you how it should look and how easy you can see the difference in the lines

@viperchannel I can see "differences" in lines but they are very small. I don't know which line choose as they are very similiar. What I don't see properly are the numbers printed on the right. Bed level is OK, as i'm able to print "standard" prints properly and I'm using the original bltouch + UBL

This can happen if you are a tiny bit too low. I am just heating up and will show you the result. We can also mail if this gets too OT for here. ping me at viperchannel @ hotmail . com

@viperchannel , I use MKS GEN L 1.0. Using 5 pcs A4988. Dual Z setup.

Default Max Acceleration 3000, 3000, 100, 10000 at first print. and 3000 3000 100 4000 at second print.

Default Accell all set at 1500

Your gcode use too much retraction i think.

Have you try this ?

#define MIN_STEPS_PER_SEGMENT 6

#define MINIMUM_STEPPER_PULSE 5

BTW, if we look at this issue #12365, we can see that @anycubic also have layer shift at same location with @viperchannel .

@robbycandra no, I haven't yet tried it, but I will later.

I have a ton of retraction, I know that. But thats just for that kind of filament while using a bowden extruder. My ABS and PLA settings are way lower.

Maybe it has something to do beacuse of the driver combination. I read that alot of users that had shifts in my initial thread were also using TMC drivers. Good find with issue #12365 !

Regarding my #12365 switching to Re-arm seemed to solve the issue (maybe be-linear is to heavy for a Delta and 8 bit? Don't know). Also TMC2130 + 24v to VMOT sorted little "random" shifts, hope it helps

@viperchannel, check this out #13819.

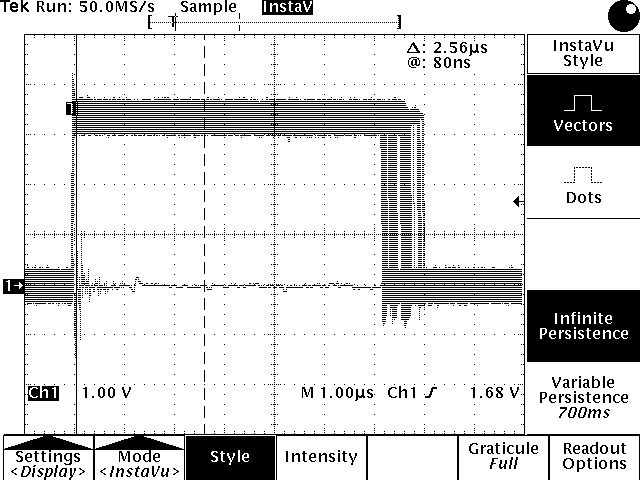

@Roxy-3D , maybe the problem is in the min stepper pulse combined with Lin Adv + TMC

Hi ,

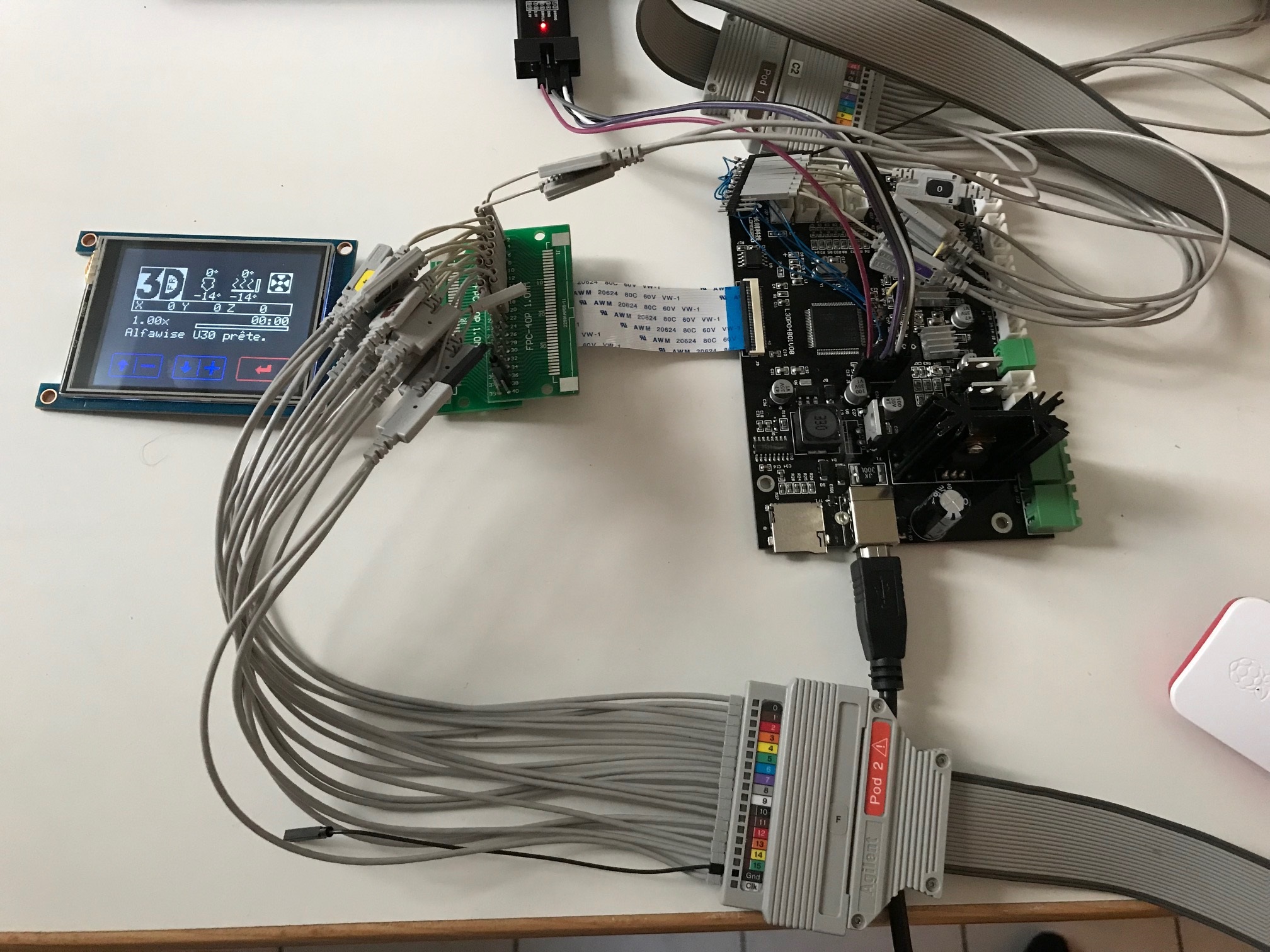

Just to add to the list of people having the issue on 32 bits cpu. Alfawise boards with bugfix 2.0.x from 14/04/19. As of today we have about 10 testers that trie many things. Those printers do use a4988 basic stepper drivers.

U30 has a smaller bed than u20 and this helps.

On u20 increasing current in the steppers seems to reduce the occurrence of the issue.

The faster the print the more we have layer shifts.

Increasing again vref allows to go faster.

It looks like to avoid loosing steps we have to increase current while we are not at the limits of the machine

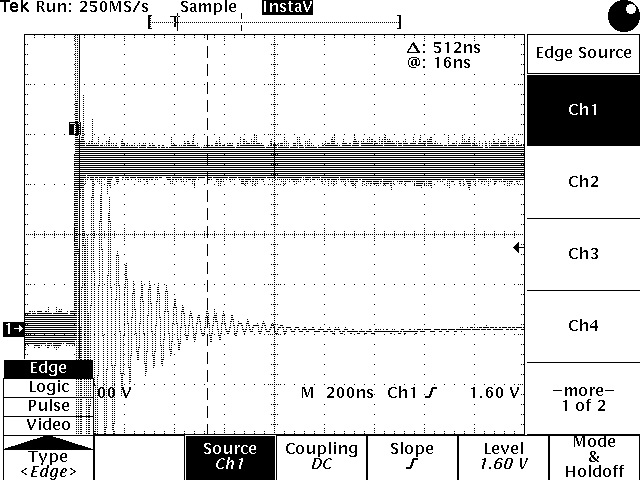

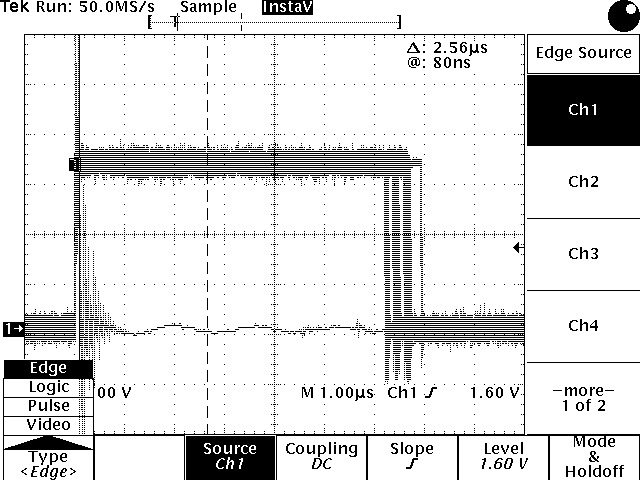

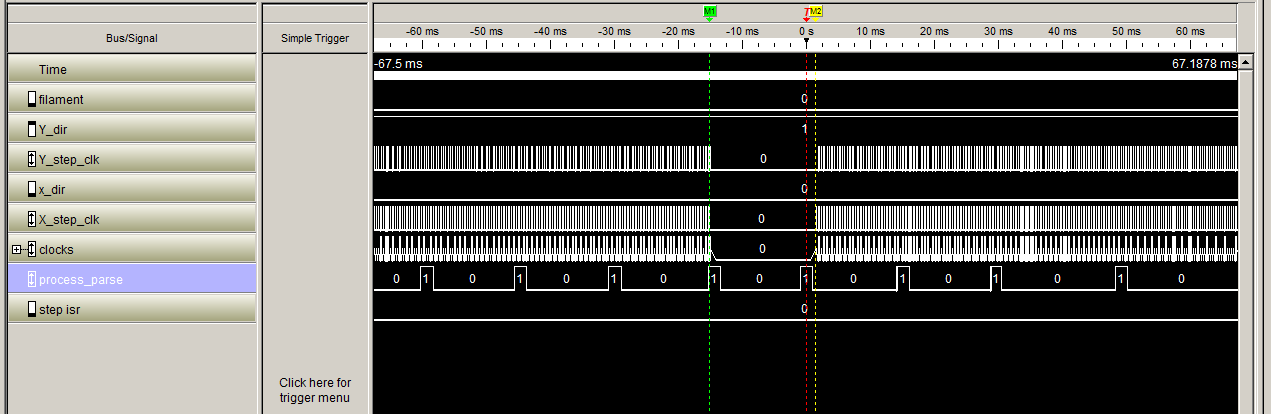

I will place a digital oscilloscope on step cell pin with infinite rémanence as a logical explanation could be that the Steps are getting too quick for the stepper to move ahead, and only by increasing current we somehow overcome this. I will post the findings here in 12 hours with a screen capture.

@Roxy-3D I opened https://github.com/MarlinFirmware/Marlin/pull/13819

I have the exact same problem!

@hobiseven If necessary I also have a scope as well as a logic analyzer. If necessary I can take the time to hook up both an measure as well.

@chrisqwertz , @hobiseven, i think you can solve this problem.

@chrisqwertz

What I would look for is a bad timing management for pulses / clocks, possibly at direction switch time. At least this is what I am thinking of. As I explained above, increasing the intensity in the steppers, boosting VREFs, pushes the bug to higher speeds. And increasing the Vref simply allows the steppers to react faster.

This is why, what I think is going on, is that at some point in time, pulses are too fast, beyond the machine setup defined in Config.h. and then, of course, the stepper misses steps, and take a bit of time to recover.

As a first measure, I would trigger on step clk rising edge, and place the digital oscilloscope on infinite remanence so we will see all clock cycles on the screen, specifically the ones shorter than what they are supposed to be.... Then we will check after that, what we discover... Stay tuned for screen captures tonight...

@robbycandra I think that :

define MIN_STEPS_PER_SEGMENT 6

define MINIMUM_STEPPER_PULSE 5

is just a band aid helping to overcome the issue, but not really addressing it. If I am correct, and that the clock pulses are sometimes miss calculated, then it would help to get a decent width pulse...

Let's see tonight on the hardware.

I will start with a 50mm/sec Gcode, in which I will also set all travels to 50mm/s MAX.

My configuration files for Marlin are attached.

With such config, we have 80 steps per mm in X and Y, with 16 microsteps per steps > we should not have more than 64K step clocks per second , and anything faster then that should not happen. We should not see any clock cycle below 15.6µS...

Please let me know if my reasonning is OK. I am assuming step cycles are evenly spread, and that I really wonder wether Marlin can do that... Let's see

50mm/sec * 80step/mm = 4.000step/sec. Its 250usec

Max Print Speed using A4988 is around 35.000 step/sec.

Yes, but what about the microsteps... They are seen as regular steps from the microcontroler, don't they?

Hence my 4K * 16 = 64K

4K is already micro step

200 step / rotation * 16 microstep / step

-------------------------------------------- = 80 microstep / mm

20 teeth / rotation * 2mm / teeth

Ok!

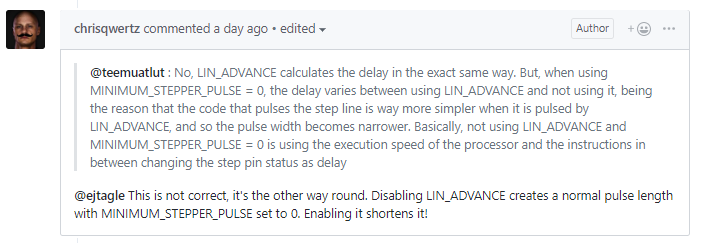

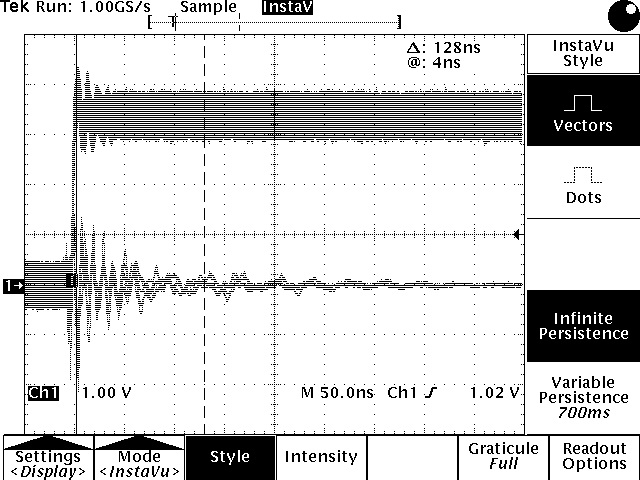

@chrisqwertz : I did connect my stepper clock to a tektronix oscilloscope, with instavue feature : You trigger a trace, and it remains on the screen , as long as you want, and you accumulate traces. I did set infinite time. I trigger on the rising edge of the stepper clock. I did set the clock to 6µs in Marlin . This works well, but it seems that I do not only have clean clock signals. I also have nasty super short pulses, like 2 clock cycles at 72Mhz, which is my STM32 clock. This is then ringing like hell in the stepper clock wire. Please note I had to solder tiny wires on the board to connect my scope, so the huge ringing may come from that, but this is really looking strange, as this happens maybe once every minute or two. I am attaching the gcode I used to generate this. This is a ducati bike m48 nut, printed at 150mm/s, with transits @ 170. I also attach the pictures of the very strange super fast glitch I have on the clock line. Again on,y once every minute or so.

Can you, or any other hardware guy using Marlin, hook a digital scope, and check if you have that sort of short pulse? I do not know if this is the root cause of layer shift, but this looks super bad on a clock line.

CFFFP_ecrou_ducati_75011395A.zip

@thinkyhead , this is an easy thing to check...

@hobiseven , is there any connection between your finding above with @chrisqwertz finding below...

Don't give up trying to narrow down the specific day that the issue appeared. These threads tend to go on forever with speculations, when the best use of time would be to meticulously seek out the specific commit that introduced the problem.

I agree, but I had no layer shifts anymore since I switched from stealthchop to spreadcycle mode ; but it is well possible that when I drive up the speed, layer shifts are coming back but at a higher speed. So I can't rule this out yet.

@DavidThijs