Marlin: [FR] Prusa MMU 2.0 support

I will try to add support for the Prusa MMU 2.0 to Marlin as soon as I have a unit at hand. So just to avoid reinventing the wheel: is anybody already working on MMU 2.0 integration?

All 370 comments

I guess Prusa will publish their sources, so we probably we should wait for that?

Prusa already released source code of their firmware with MMU support.

https://github.com/prusa3d/Prusa-Firmware/blob/MK3/Firmware/mmu.cpp

I walked through the Prusa sources already. Nothing too complex, but we'll have to generalize, implement the serial communication based on the HAL, etc. to make the MMU usable with as many printers as possible.

So I didn't buy an MMU from Prusa I made one myself. My trouble right now os just the communication. Like I try to explain below.

The system is simple and just need messages system by Serial to work independently. Just an add-in system.

Objective:

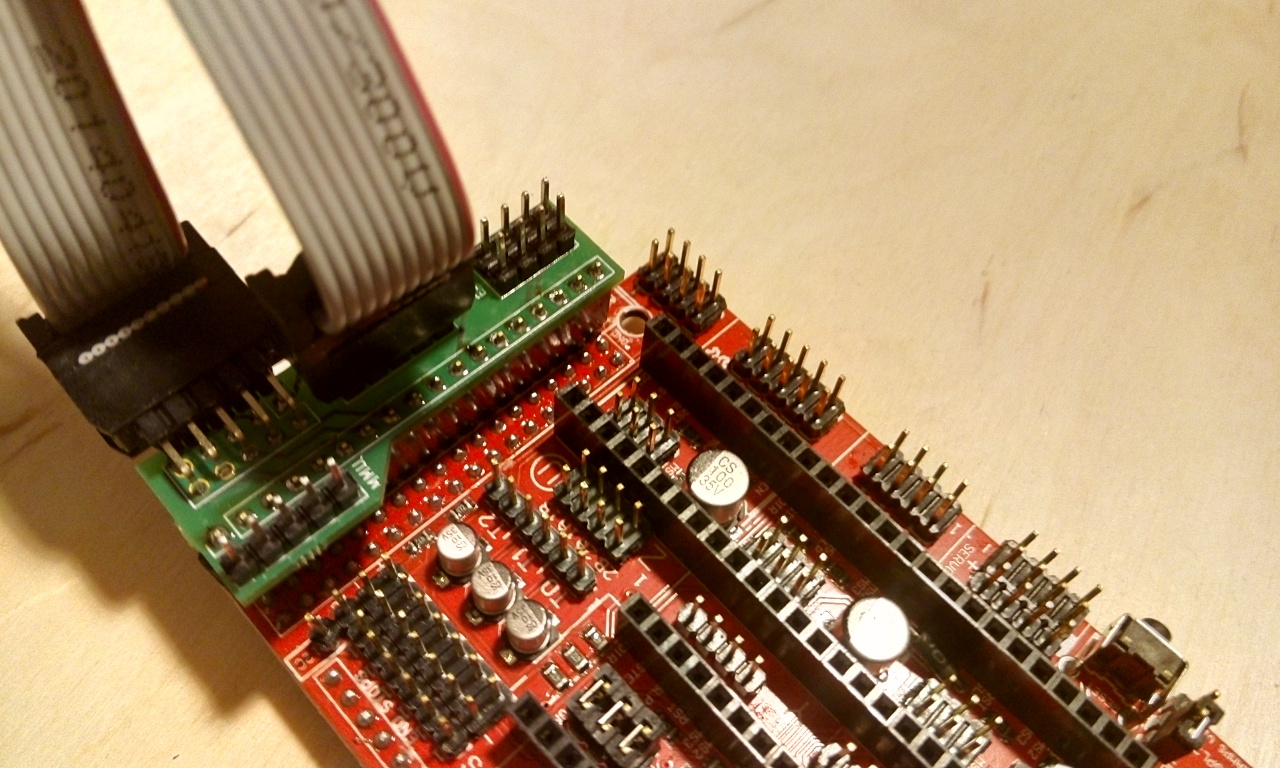

Connect One Multi-Material unit to a printer with communication by Serial on pins Rx2Tx2 (MEGA + RAMPS 1.4 configuration)

What's needed:

Make a Clone of all movements of extruder E0 to other motor (E1) same way that we can make with the Axis like Z and Z2.

Instead of Make some tool change, pick the T number and send it by Serial on format "T1." or "T2." or "T3." , Etc. To change the tool on multi material unit.

just continue the print after receive "OK." for example.

I know, this isn't a trouble is an improve to new generations of printers with a lot of material with just one extruder noozle and with direct drive extruding with just one motor on head.

Can you help me?

If you are available to help me I'll post here all the hardware and the code of Multi Material Unit after test and check that os works well.

This was what I posted on #11879

It shouldn't be too tricky to implement, except that right now we don't support a second serial connection in the AVR version of Marlin. So that would need to be added in.

Does it really need multiple extruders to be defined in Marlin and multiple sets of stepper signal pins? It was my understanding that a single E0 extruder is all that's needed from the Marlin side, and the steppers on the MMU are controlled by its onboard MCU.

@FNeo31 is your MMU based on the PCB and firmware published by Prusa? I'm building one myself, waiting for the PCB at the moment.

From my understanding there is no replication of extruder movements to the MMU. The MMU loads the filament into the extruder and then moves out of the way. The extruder will then pull the filament just through the MMU box. Otherwise you would have to take care for some slack in the filament path should extruder and MMU get out of sync (like the Mosaic Palette+ does).

Just peeked at the MALYAN_LCD which uses Serial1, and evidently we can do that on AVR very easily. So strike my previous comment about serial.

It shouldn't be too tricky to implement, except that right now we don't support a second serial connection in the AVR version of Marlin. So that would need to be added in.

Does it really need multiple extruders to be defined in Marlin and multiple sets of stepper signal pins? It was my understanding that a single E0 extruder is all that's needed from the Marlin side, and the steppers on the MMU are controlled by its onboard MCU.

That's also my understanding, yes.

Just peeked at the

MALYAN_LCDwhich usesSerial1, and evidently we can do that on AVR very easily. So strike my previous comment about serial.

I already created PR #11880 to enable additional uarts. But I'll have a look at the MALYAN_LCD.

Just peeked at the

MALYAN_LCDwhich usesSerial1, and evidently we can do that on AVR very easily. So strike my previous comment about serial.I already created PR #11880 to enable additional uarts. But I'll have a look at the MALYAN_LCD.

Ok, MALYAN_LCD uses Arduino Serial1 directly. But to provide MMU support also for boards other than AVR some abstraction in the HAL will be required, I guess.

The HALs all provide some kind of emulation of the Arduino Serial# ports, so things like MALYAN_LCD ought to work with any MCU.

Hello, how are you ?, I'm trying to develop the adaptation for marlin I believe that the most complex part will be interpreting the gcode sent by the serial to select the filament and its respective size

@radsonpatrick My MMU build is still missing the control board, so for the moment I'm using one Arduino Mega2560 + RAMPS for Marlin and another Mega2560 emulating the MMU 2 unit. This way I can implement the serial communication without an actual MMU. I have the initial setup routine (requesting version, buildnr and FINDA status from the MMU) working with my emulator. Next step will be to implement the filament load/unload commands. If you are interested I can push the current state to my github repository.

There is no gcode send to or from the MMU by the way. The printer firmware sends simple commands like "Unload filament", "Switch to filament x", "Load filament" to the MMU which answers "ok" when the command has been executed.

Do you already have som documentation how you build everything? Or is it just a RAMPS +

spare Mega2560 for now?

It would be nice if you can push everything to a repository that we can have a look. I am more then willing to support 👍

I want to understand, so he does not cut filaments in size? than a cutting blade would be serious for that, but that's more sense, would not it just interpret the M600 code?

The spare Mega2560 is emulating the MMU until I have a working MMU2 unit. Connecting the real MMU2 to the printer board is quite straightforward.

But first a short disclaimer: the following info is without guarantee, it's based on the assembly guide and the schematics for the control board published on Prusa's github repository. So if you kill your MMU2 by connecting it to any printer other than the Prusa Mk3, don't blame me for that.

Ok, so to hook up the MMU to a RAMPS board you can follow https://manual.prusa3d.com/Guide/3.+Electronics+and+MMU2+unit+assembly/757?lang=en down to Step 40.

The power cable (green) will go to your power supply. Prusa uses 24V on the Mk3, but 12V should be fine for the MMU steppers, too.

The signal cable (pink) has the following connections

- +5V - blue wire

- RX - white wire

- TX - green wire

- RESET - brown wire

So on the RAMPS board you will connect

- the blue wire to a free 5V pin,

- RESET to a free digital pin,

- RX (white) to pin 16 (TX2)

- TX (green) to pin 17 (RX2)

If you have an LCD connected to AUX-4, pins 16 and 17 could be an issue, depending on the display at use. But UART0 is USB, and the pins of UART1 and UART3 are used for endstops, so UART2 is the only remaining serial to communicate with the MMU2.

SoftwareSerial might be an option in case pins 16 and 17 are used for the display, or for printer boards which have no serial connection at all.

I'm not using the prusa, I'm using marlin 1.1.9, so it will not be useful to me, I watched some videos and I understood the operation, so your already in what stage? charging the filament? communication with the main arduino?,I want to be a DIY

I'm working in a MMU system made by me to the tool seletor on MMU and positioning I'm using a 28YBJ-48 stepper with a ULN 2003 drivers to be more compact. For the MMU board I'm using one Arduino nano with ATmega 328.

I'll Change the pin -Y to the position of X+ top put the end stop of Y and conect the serial2 of mega+ramps1.4 to the nano.

The extruder motor I will clone to feed motor on MMU. Direct controlled by main board. Instead of blade I Will put a gate stop.

PS I don't have a PRUSA too

If you need help with something I am at your disposal. Do you have photos of the project? will you use the same desing as mmu2.0?

@FNeo31 @radsonpatrick I'm building a Prusa MMU2 myself based on the sources published on Prusa's github repository. If everything works out - missing part is the controller board - I'll have an exact clone of the original Prusa MMU2.

Therefore what I'm implementing in Marlin is based on the firmware and communication protocol for Prusa's MMU2. If your self-designed MMU units behave in exactly the same manner they should work, too.

Is your documentation of the development of your project in github?

@revilor If you need help I'm giving my whatsaap to exchange ideas about this upgrade.

OT @revilor don't know if you need it or not but on aliexpress there is a mmu2 board clone available.

A question about your project, there are some parts in mmu2 that are not easily on the market (brass tubes on carriage and brass nut for ptfe come in my mind) where did you found them?

OT @GMagician Brass tubes were no problem here in Germany, 6mm outer and 5mm inner diameter like this https://ebay.us/xATVqt Cutting to 25mm length is no problem as Brass is easy to work with. The selector is not moving too fast, so I guess reducing the openings in the printed part to 5.1mm or so and go without the brass tubes should work fine, too.

For the PTFE mount I modified the printed part using the published OpenSCAD file. I reduced the center hole to a diameter of 5mm, tapped an M6x1 thread and directly screwed in the pneumatic connector. On Twitter I have a photo https://twitter.com/revilor3d/status/1043900826257960961.

The most challenging part for me was the stepper with a 130mm shaft for the pulleys. I could not find one on the market so I modified a stepper I had laying around and replaced the shaft with a 150mm long 5mm smooth rod, photo also on twitter.

Thanks for the tip regarding the controller board. I have all the soldering equipment so doing it myself should be fine. But good to know there is a fallback should I screw up.

My latest sources are now in my repository: https://github.com/revilor/Marlin/tree/MMU2

Check Configuration_adv.h and feature/Prusa_MMU2.

Hello, is fully compatible MMU2 with Marlin? I'm finishing my MMU2 clone (Arduino+ramps+drv8825) , it will work with Marlin?

Good question. Please try it and let us know!

SoftwareSerial might be an option in case pins 16 and 17 are used for the display, or for printer boards which have no serial connection at all.

Is it really possible to use two pins in software serial mode and the TMC2130 with SPI?

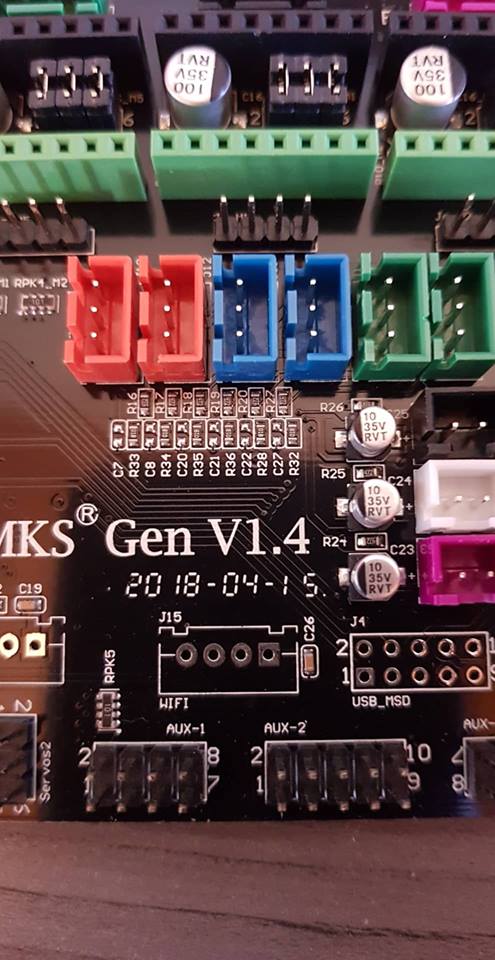

Connected five TMC2130 and an Full Graphics disply to my MKS Gen 1.4 so SoftwareSerial is the only option right?

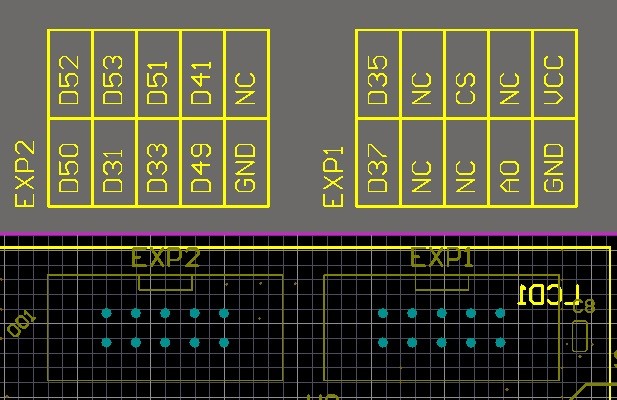

@Lyr3x There should be ways to avoid SoftwareSerial. I assume you are not using pins 16 or 17 as CS for your TMC2130s. So the question is: what is the exact display you are using? Because most of the displays I checked do not use pins 16 and 17. In that case it would just be a question of how to get to the pins of the EXP1 connector. You could cut the wires to the display or create some kind of adapter for that purpose.

If D16 and D17 are used by the display or you can't find a way to use them, moving the Y or Z endstops to other pins could be an alternative. This would free the uart1 or uart3 pins to communicate with the MMU.

If you can't get a hardware serial to use, SoftwareSerial might be an option. But with all the timing-critical stuff that's going on inside Marlin I'm not sure it really is. The main board is asking the MMU for the FINDA status every 300ms, so there is a lot of communication. You would have to test and see if SoftwareSerial works, I guess.

@makerbitter We are not there yet, but the plan is to make Marlin fully compatible with MMU2. So if your clone uses Prusa's MMU2 firmware or at least implements the MMU's serial communication protocol, it should work.

@revilor I'm using this type of Display right now: https://reprap.org/wiki/MKS_MINI_12864

Correct me if i'm wrong but it seems this type of display does not use 16/17:

#elif ENABLED(MKS_MINI_12864) // Added in Marlin 1.1.6

#define DOGLCD_A0 27

#define DOGLCD_CS 25

// GLCD features

//#define LCD_CONTRAST 190

// Uncomment screen orientation

//#define LCD_SCREEN_ROT_90

//#define LCD_SCREEN_ROT_180

//#define LCD_SCREEN_ROT_270

#define BEEPER_PIN 37

// not connected to a pin

#define LCD_BACKLIGHT_PIN 65 // backlight LED on A11/D65

#define BTN_EN1 31

#define BTN_EN2 33

#define BTN_ENC 35

#define SD_DETECT_PIN 49

#define KILL_PIN 64

@Lyr3x From all the information I found regarding your display I would say you are good to go using pins 16 and 17 for serial. They are not used by the display.

Important notice: I missread the schematics regarding the serial connection, you have to swap the green and white wire on your printer board. White is RX on the MMU side, green is TX.

So on the RAMPS board you will connect

- the blue wire to a free 5V pin,

- RESET to a free digital pin,

- RX (white) to pin 16 (TX2)

- TX (green) to pin 17 (RX2)

I corrected my comment above accordingly.

Alright, everything I need is ordered. I bought the control board from AliExpress. We'll see if this is working out.

@revilor Do you can give an status update?

I plan to build my own version of MMU2 with stm32f1 board (actualy based on blue pill).

Status update: handling filament change for the T0..4 gcode is implemented in my repository. The MMU unit seems to do what it is supposed to do for a material change. But still a lot of testing is required. My next step is to print and mount the Mk3 extruder upgrade parts and then try a real multi-material print.

Btw is it possible to have 2 mmu2 units?

@alexxy To control 2 MMU units you require two free serial ports on your printer board. And support for two MMUs in Marlin, of course.

@revilor

Which board do you use currently? Did you build your own MMU2?

Hi there, If you are interested I ported MMU2 firmware for Ramps... It could help in Marlin part.

It is still the first implementation, I have to tweak motor movement to do not grind too much during homing (no feedback from tmc's drivers). In the following days, I should fix those issues.

My fork: https://github.com/bula87/MM-control-01

I did an mmu2 implementation using Ramps board + Arduino mega 2560. It has been fully operational since October 20th, 2018. I print every day with it and added a 2nd sensor at the top of the mk3 extruder to make it extremely reliable. Code was developed from scratch. https://github.com/cskozlowski/mmu2

Is there any progress in Marlin implementation? Is only compatible with Mk2.5/MK3 firmware?

Check the repository from revilor. He's implementing it in a way that we can use the official Hardware. I can test it soon

I do not understand, why it should be so complicated.

As I understand by now, the MMU2 controller get only comandos like "retract filament into mmu2" "select tool" and "load filament into extruder". Also the MMU2 sends Back an OK. By the way - which are the exact commands transfered between both controllers?

So "communication" should be very simple without changing anything in Marlin (or any other controller firmware).

Simply use an small extra arduino (3-4$ for a Clone). Connect dir/step signals from printer stepper driver for the extruder. The Arduino simply count steps if dir is in retract direction, resetting counter if a forward step is done. If the counter exeeds a certain number, obviously the printer has not only done a retract but fully unloaded filament.

So an "unload" can be detected by the extra Arduino. If you didn't have access to dir/step, you may simply add an optical rotary encoder to your extruder motor.

So in gcode its a simple long backward movement of the extruder (Not m600 !). I think slic3r does that anyway on colour change (with an special accelleration profile to reduce blops in filament).

As the extra Arduino detects the unload, it can send the propper comand to mmu2 controller by serial connection. So filament will be retract into mmu2.

Next step: choose material number.

In gcode move extruder 1...5 mm forward. As the extruder is empty (mmu2), nothing happens - but by dir/step or optical rotary encoder the Arduino now knows that you want material 1...5 next. Arduino waits muu2 completed filament been retracted (getting "O.K.") and sends command to choose material 1...5.

Next gcode command is m600. You need to add the lenght for loading new filament, as normaly the filament would be squezed out of the nozzle to clear it, but we only have to put it to the nozzle, squezing and clearing will be done in wipe tower (or infill or extra object).

M600 will mostly wait to "O.K.-button" to be pressed. So connect an relais in parallel to the O.K.-Button. So Arduino now can "Push" O.K. when it gets the o.k. for new filament loaded from mmu2 by serial. This May not needed, if printer has filament-sensor and filament-autoload.

The difference between changing marlin and / or mmu2 firmware and using an "Interface-Arduino" is, that an Interface-Arduino would work with nearly any firmware - not only Marlin.

@blackus3r I used the printed parts and PCB from Prusa's github repository to build a MMU2 clone.

The electronics of my MMU 2.0 clone is working nearly fine, but i have some issues with filament loading (filament is slipping) and homing of the mmu. The stallguard threshold is not working fine for me.

@revilor your Marlin is fully functional with the MMU 2 clone board? Did you make prints successful?

Has anyone got a functioning marlin fw for a genuine MMU 2.0 with ramps 1.4

I've enabled all the options, 5 extruders, the multiplexer, nozzle park and advanced pause feature but still need to find the pins so I can change them as I have a full graphics display and anything else I'm missing for the proper communication between the two

I am also a little confused. As I see there is cskozlowski´s code to implement the MMU2 with an MEGA2560/RAMPS but this only works with the einsy board and the prusa firmware.

But is there a current way to interface it to marlin fw?

the latest versions of marlin have all the options for it

Where can I download?

It's all within the latest release of marlin, but again I'm not sure if what I've by will work or if there are more options that need to be tweaked as I haven't got my mmu2 yet. Was hoping someone here could help me eventually

I the Marlin 1.1.9 is no included. Could you send me the download link?

Check the config file it's next to the signal nozzle and Cyclops options. It'll then make you enable nozzle park, advanced pause feature and 5 extruders. Plus which ever pins you want to set as the outputs but I used the default ones so far

That's as much as I've done so far, knowing my luck it's more complicated than that and I'll have to modify the mmu 2 fw and potentially add more to marlin. I heard people talking about hal files and such which I don't know what they are

@0lympu5 It for sure is more complicated than just enabling 5 extruders. The serial communication between MMU2 and the printer has to be implemented in Marlin. I'm working on that and if you are interested check my repository which also has a description of how to wire the MMU2 to a RAMPS board.

Unfortunately I'm very busy at work these days so at the moment the project is stalled on my side. The code as is should work but is not tested yet. Therefore I would not recommend using it but if you want to be the first alpha tester please let me know.

@revilor the repository link don't work. I have a MMU2 board, I would like test the MMU2 with your Marlin.

Looks like I lost a 2 in copying the URL, the repository link is fixed now.

The configuration options for MMU2 are located at the and of Configuration_adv.h

obviously im just spit balling here as i ordered my mmu2 late so wont be shipped for a while. What is it like editing firmware for prusa printers, just an idea if i bought the Einsy board that is used on the mk3 and just change relevant settings like bed size, etc

Olympu5, sorry but I have the feeling that you are mixing things up here.

MMU2 support is not built into marlin at this time. What is built in is "MK2 Single Nozzle Multi-Material Multiplexer" which is the old MMU for the MK2 printer version.

Based on your recommendation I bought the MMU2.0 and am now standing here without marlin support. Next time when you make claims, please make sure they are true.

But I should also have checked myself.

Ok, so what is left is revilor´s (UNTESTED!) code which is based on an old (3months) marlin 2.0 which I also can´t use since at this time there were problems with my LPC1768 board.

So, now I will try to move the changes to a current marlin.

Sorry for an inconvenience but i was asking a question and not stating any working prototype. I already have the hardware to potentially run a mmu, with a ramps board and cnc expansion board just the adapter is plagued with issues of switching filaments.

@revilor Obviously the most complicated part is getting the two boards to talk to one another, I have a cnc expansion board giving me 6 extruder outputs so far. Is it possible to use this instead of the multiplexer, im presuming id need to add endstops for homing and connect the finda probe straight to the main board if a tool selector code was available.

If not im struggling with the wiring of the ramps as i have a full graphics display taking up pins 16 an 17, i only have 3 endstops so there is space there if it useful also aux 2 is empty

@yellobello I just merged the latest 2.0 branch into my MMU2 branch. So it's no longer based on a 3 months old Marlin 2.0 - but still untested.

@yellobello I just merged the latest 2.0 branch into my MMU2 branch. So it's no longer based on a 3 months old Marlin 2.0 - but still untested.

Ohnnnooooo! I just did the exact same thing last night... we should have told each other so one of us would have had less work ;-(

But, while doing this it came to my attention that the LPC1768 code uses different designations for the serial ports.. for the AVR version its "internalSerial", for LPC1768 it is "SERIAL_PORT_X" where X is one of 4 serial ports to choose from. OK, this can be easily fixed. Going further, the LPC1768 serial port code is much much simpler than the AVR code, where loads of functions like SERIAL_ERRORPGM() are not implemented... I currently I loads of compile errors with this. Let´s see where it will take me .. probably not too far since my C++ is a bit rusty

@revilor when will you be able to test it. I would love to help you out and test it but my unit wont be shipped till march

@revilor would you mind to make a pull request to have it merged into the marlin bugfix-2.0.x branch?

So, maybe Roxy3d or someone else with experience with the HAL could take it on and actually make it work, because I tried and got stuck.

As far as i tested yet, the implementation of @revilor should work. Initializing and position change of the selector worked like charm. Because of a mechanical issue with my MMU clone i couldnt print yet.

@Lyr3x what setup did you use?

@yellobello I changed all my uses of SERIAL_ERRORPGM() to SERIAL_ECHOPGM() or SERIAL_ECHOLNPGM(). And I just made another change so now my branch at least compiles for LPC1768.

Regarding a pull request: I have no plans to create a PR until at least one successful multi-material print was made using a MMU2 and a printer running Marlin. And there is still some stuff missing in the implementation like a menu to manually load one of the five materials on the MMU2 for a single-color print.

For LPC1768 you will have to change

#define ENABLE_INTERNAL_SERIAL 2

#define PRUSA_MMU2_SERIAL internalSerial

in Configuration_adv.h to

// #define ENABLE_INTERNAL_SERIAL 2

#define PRUSA_MMU2_SERIAL Serial2 // or whatever serial you are using for the MMU

And the hardware reset pin of course.

@0lympu5 I am using a MMU 2.0 board clone with an MKS Gen 1.4 but switching this weekend to an Einsy board and hopefully i can finally make a test print

@Lyr3x I'd love to bear about it, I'm running ramps atm did look at einsy but no customisation really, do like tmc 2130 tho

@0lympu5 I am just switching to the einsy because i build another printer and needed another board. So i dont need to build an adapter for the display 👍

@Lyr3x yeah I will need help down the line finding a replacement for pins 16 and 17 on my ramps board as I have a full graphics display

Saw a post on Facebook about a firmware update for the mmu 2

Can the einsy board be connected to a full graphic lcd?

@revilor Thank you for the changes to your firmware! I really really appreciate it !

I let you know when I have it printing... need to build my MMU2 first, though ;-)

@revilor is my hero right now, cant wait for mine to turn up

A little bit offtopic, but I thought maybe you guys know.

It´s about the extruder needed for the MMU2, I figured that no extruder besides the prusa extruder will work with the multi material upgrade.

First I thought extruder type would not really matter and I could use it with my bowden extruder, then It came to my attention that the MMU2 would not account for the huge amount of filament that sits in the bowden tube between extruder and hotend and therefore can´t be used. And even if it would, the prime tower would get enormous pretty fast.

And then finally I also figured that any extruder that needs manual handling to insert the filament would also not work. I think that about every direct drive extruder that there is, uses some kind of lever mechanism to manually expand the spring that pushes the idler bracket to the drive gear.

OK, even the prusa MK3 type extruder has this spring loaded idler bracket, but it does not rely on someone pushing a lever that will open up the space to insert a filament into the drive mechanism. The simple fact that filament is pressed into the extruder drive wheel by the MMU seems to suffice to load the filament, and finally opening up the idler when the extruder is pulling the filament in towards itself.

I can´t imagine any extruder which is currently being used that does not require someone pushing the idler when loading some filament.

Do you?

And a question that is kind of related:

Why does the MMU2 itself not serve as the extruder? It can be some kind of bowden extruder and actually has everything needed to perform this task. Or am I wrong?

regards!

You may be able to tune the bowden tube length to account for the total length

I'm making a custom mk3 extruder but you could use a bondtech one, same principle as the mk3

I don't think that is correct. My printers are using a Titan and a bondtech extruder setup. Both are capable to load the Filament without pushing the lever to release the spring. The bondtech is working even better because of the two side grip. I tested the Filament load with my mmu and when it pushed the Filament correctly the extruder was not the problem.

The only mechanical issue I have at the moment is the idler body which sometimes is not in the correct position

The MMU2 only cares about the distance between the extruder and itself (which is configured in the MMU). The distance from the extruder to the hotend is handled in your gcode. So the sequence for a tool change goes like this:

- move the filament up beyond the extruder gears

- MMU2 retracts the filament the remaining distance

- MMU2 moves selector to next material

- MMU2 transports the new filament down to the extruder gears

- extruder grabs the filament and transports it all the way down to the nozzle

- purge block/infill/object

- continue print

Steps 2 to 4 are handled by the MMU when a T* gcode is sent. Let's say in your bowden setup you have a distance of 500mm from the extruder gears to the tip of the nozzle. Then the simplified gcode for a tool change to material 4 would look like

G92 E0.0

; unload 505mm to make sure filament is beyond extruder gears

G1 E-505 F1000

T3

G1 E500 F1000

G92 E0.0

; purge

The real unload gcode is more complex than that because the filament has to be moved up and down some small distances several times with the right speeds to create a filament tip which does not cause a jam when the material is loaded the next time.

That's the reason why I think Prusa went back to direct drive extruder with MMU2 because this way you have better and more direct control over the filament movement. MMU2 with a bowden setup would be kind of another MMU1, which is also why the MMU2 is not working as the printer's extruder.

So back to the question of using an MMU2 in combination with a bowden extruder. I think it is possible and if tuned correctly should be at least as reliable as the MMU1, probably better because at least the problems caused by the Y-splitter are gone this way.

But finding the perfect unload gcode sequence will be some work. This also applies to any other non-Prusa printer even with direct drive extruder, by the way. You will have to find the perfect unload gcode sequence for your extruder/hotend combination. The sequence Prusa uses for the MK3 can be a starting point but you will have to tune it for your very setup. I'm sorry guys, but there is no plug and play in this.

Is there any special code required for the extruder in marlin or is It all done with gcode

Communication with the MMU is handled by the T* commands, so in the end it's all just regular gcode. You can check the examples from the MMU2 drivers package or slice a multi-material object in Slic3r Prusa Edition to see how the gcode for MMU2 prints looks like.

Even though I had some misconceptions in my thoughts above, It will be clear to anyone that using a bowden extruder with the mmu2 would be quite wasteful since one would need to get rid of a lot of filament in the prime tower.

Or can you change the filament already to another color but still continue to print with the color in the bowden tube at the actual object until it is let´s say 90% empty and then go for the prime object/tower/infill ? This would need some further optimization of the gcode though.

Either way, I was afraid that only the MK3 B7 extruder would grab the filament without manual intervention so I am going to build the MK3 extruder together with my MMU2 and have the problems of matching the right combination of factors out of the way. I wanted a direct extruder back anyways, so this is my chance now.

I already designed a holder plate for the CR10, if anyone is interested.

I'm doing the same, full mk3 extruder, want to try out the laser filament sensor too. The only difference with mine is I'm running volcano but already got a modified fan blower from thingiverse.

I think the best option for purging is into another object, as about half of my printed parts are either functional or painted I get lists of 'free' models. Closely followed by wiping into infill.

Even though I had some misconceptions in my thoughts above, It will be clear to anyone that using a bowden extruder with the mmu2 would be quite wasteful since one would need to get rid of a lot of filament in the prime tower.

Sorry to interfere here, but you still have some misconceptions: the prime tower is only necessary for the molten filament inside the hotend; the wipe amount is not influenced whether it's a bowden or direct extruder.

Only difference is that you move more filament back and forth during the swaps, but you waste not more.

From my understanding your only waste filament would be what ever is left between the extruder and the hot end, however I'm not sure how the mmu would handle this and depending on if or where you used a filament run out sensor, the unit could theoretically push more filament down but you would loose retraction capabilities for a little bit

What you need to run the MMU2 with any extruder:

- an extruder where you can connect a bowden coupling to the inlet for the feeder tube

- an extruder which can reliably grab the fed filament (bondtech for example)

- a lot of experimenting and playing aroudn with values to get the removed end of the filament with the perfect conical form (no thick blob that will clog inside the PTFE feeder tube or the extruder gears

- and finally a way to serially connect and talk to the unit from the main controller board

Even though I had some misconceptions in my thoughts above, It will be clear to anyone that using a bowden extruder with the mmu2 would be quite wasteful since one would need to get rid of a lot of filament in the prime tower.

Sorry to interfere here, but you still have some misconceptions: the prime tower is only necessary for the molten filament inside the hotend; the wipe amount is not influenced whether it's a bowden or direct extruder.

Only difference is that you move more filament back and forth during the swaps, but you waste not more.

Now I got it.. off course, the whole filament is being pulled back.

I had the knife blade in mind and thought the whole filament would be cut off and left in the tube or something like that. It´s just the tip that is being cut off when the whole filament is pulled back.

Thank you!

Is the tip always being cut off by the MMU?

If so, why then the above mentioned procedure to shape the tip when pulling it out of the hotend.

I have a feeling that I am still somewhat wrong :-)

I don´t have the device yet and I have never seen one in action ...

No, the tip is not always cut.

I think it's currently never cut. At least for me, the MMU2 unit mostly panics (i.e. print pauses and asks for user help to remove the jam/clog) whenever something is wrong.

Yesterday one of the colors did not feed properly and caused a print failure. But that was on the 1.0.2 MMU firmware, today I updated to 1.0.3....

Currently it's very stupid and lacks some of the advertised features (like: detecting that the extruder is not feeding properly, retracting and cutting to remove the clogged tip...)

Any news? I am still waiting for my parts to arrive... they are now starting to come in.. almost part by part!

I just read a thread in the german reprap forum by someone who already built his own MMU2.

He made some very important points, mainly that the 8mm steel ball is actually 7,98mm and so a 8mm ball will get stuck, that only 6,2mm pulleys do work, that one should use FESTO pushfits right from the beginning, that one should print some revised STL files that he posted and when printing the MMU2 one should use 30-50% infill (Honeycomb 3D), use at least 4-5 perimeters and use no supports.

Just to let you guys know.

Revised parts:

-> https://www.thingiverse.com/thing:3237579

-> https://www.thingiverse.com/thing:3232438

-> https://www.thingiverse.com/thing:3237770

Merry Chistmas!

From my experience so far I would say the two most crucial parts in the build are the stepper motors for idlers and pulleys and the springs. I started with 17HS16-2004S (45Ncm) motors from stepperonline but could not get consistent results. Sometimes feeding filament would work, and the next time it would not. So today I replaced them with 17HS19-2004S1 (59Ncm) ones and now everything works perfect with 12V supply voltage and using the 12V/MK2 mode of the latest MMU2 firmware (1.0.3).

Regarding the springs I can't give you more than the dimensions of the ones I'm using: 5.5x17mm. It was a lot of try and error with different kinds of springs until I ended up with the ones at use now. It's like for a regular extruder but a little bit more difficult because of the idler drum mechanics: if the force of the springs is too high the stepper won't be able to bring the idler bearing into position, if it's too small the pulley will loose steps and you don't get consistent results.

So the current status on my side is as follows: I have a working MMU2 clone and have Marlin consistently feed filament to/retract filament from the extruder on tool changes. Next I will have to calibrate the MMU for the length of the PFTE tube, and then finally run a test print.

Sounds like you are almost finished, i had a couple of vouchers so bought a genuine mmu2, cant wait to get it working, have you tested with 24v?

At the moment im running ramps 1.4 with tmc2208 so was looking at a possible upgrade, my main concern is as my set up stands the two systems would be running off of different supply voltages, im already using two psu as i have a large print bed but dont want any voltage jumping between boards as it were.

I did not test it in detail with 24V, but considering the MMU2 runs with 24V on the MK3 I guess you will have no problem doing the same. Just take care you power the MMU steppers and the printer board from the same PSU. It won't work otherwise as there is no separate GND for the 5V circuit (which is powered from the printer board).

Ah okay so I'd need to run everything off one power supply or connect the grounds in some way

@0lympu5 not sure but with "switching" power units you can't connect gnd in common

Ah okay, currently I have a separate 24v psu for my heated bed and 12v for everything else, I believe they are switching power supply

Ok guys, looks like we are getting somewhere :-)

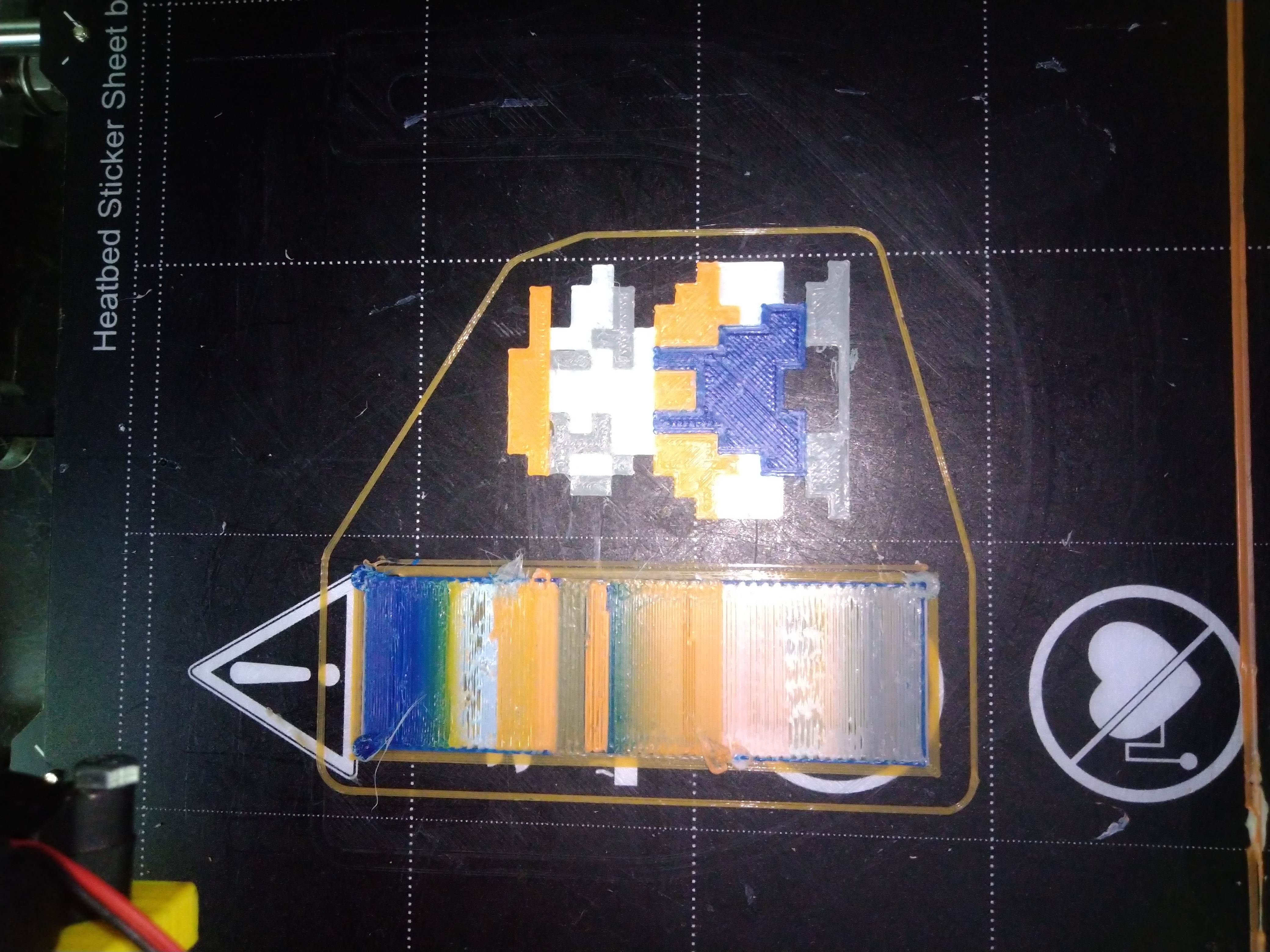

I used the sample lizzard gcode from Prusa's MMU2 examples with the change of just one gcode to enable ABL. I had a jam and that's where the print ended because after fixing that reheating the nozzle triggered a thermal runaway. So there is still some work to do.

@0lympu5 So far the MMU works really really well with a supply voltage of 12V. Therefore no need to go for 24V from my point of view. If your printer runs from 12V and everything is fine just keep it that way.

Hapoy to see someone has made good progress. I did see on another forum a little mod to help with slight inconsistencies in the tip length and shape. They removed the two screws at the end of the mmu 2 holding the ptfe tube connector and replaced them with longer one plus a spring each side to take up the tolerance

@revilor I've just cloned your repository and will attempt to replicate what you have done.

I have genuine MMU2, a custom built corexy printer, MKS gen L v1 (Ramps 1.4) board at 24V.

I am a very happy user of MK2S+MMU1 but don't want to mess a working machine by upgrading to MMU2.

@revilor do you have any advice on setting a mmu2 up with ramps, im mainly worried about the 16 and 17 pins as mine are currently being used?

@0lympu5 What display do you use? Maybe you don't have to worry about 16/17 at all.

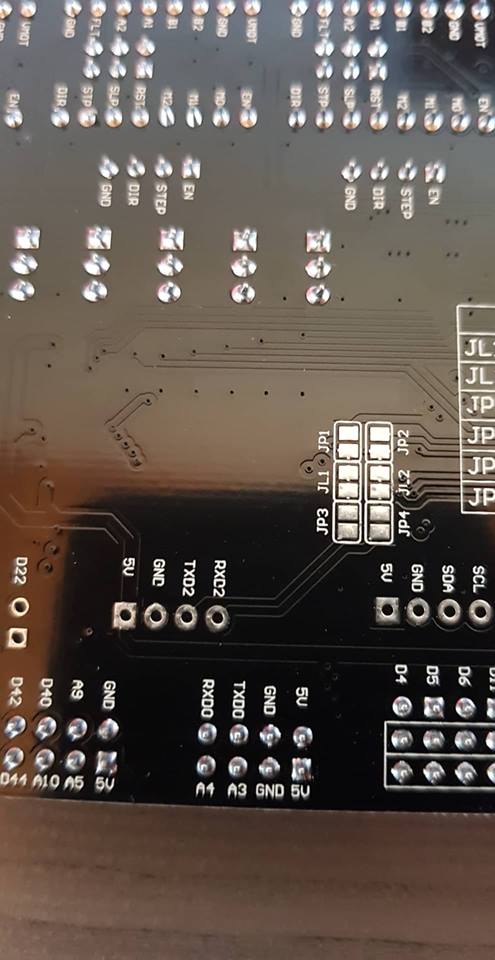

I have an Anet 12864 LCD on my printer which uses the 16/17 pins. So I designed a small adapter for AUX4 on the RAMPS to connect the LCD and the MMU2 and moved the LCD pins from 16/17 to 25/27.

Depending on the endstops on your printer there might be an easier option then to mess with the AUX4 connector though. The ATMega2560 has two more serial ports. On the RAMPS the pins of those are used for Y and Z endstops. So if you have no more then 4 endstops you can just redefine the endstop pins and free pins 14/15 (Y endstops) or 18/19 (Z) to use with the MMU2.

So let's say you have the very common setup with X-/Y-/Z- endstops. Then you use X- and Y- as intended on the RAMPS and connect the Z- to the Y+ connector. In pins_RAMPS.h you define

define Z_MIN_PIN 15

and now have Serial1 on pins 18 (Z-) and 19 (Z+) free to use for the MMU connection.

It seems so easy when it's put like that, thank you

hello. i am also in the process of making a MMU2 clone and i was happy to find about this thread and the good work of the community. in the process of purchasing parts i found out two things you may find interesing..

1- the MKS MINI12864LCD from makerbase has the pins that were on 16/17 moved somewhere else so they are easier to use in conjunction with the UART.

2- the board from makerbase MKS gen 1.4 has an undocumented "WIFI" connector that's ideal to connect to the MMU, i discovered this by accident after i bought it. it has a couple of solder jumpers on the back to redirect the TXD2/RXD2 to that connector

Has anyone tried using the prusa laser filament sensor that sits just above the bondtech system along with the mmu or does the filament sensor in the filament selector of the mmu2 override this

@revilor what's the messages that you sent from motherboard to MMU2?

I'm developing a different system for Multi-Material feeder, with just 2 steppers and with one Arduino nano (clone for the board).

The target is a very low cost Multi-Material feeder. The idea is be modular for future expansion, and make it easy for all to have a Multi-Material printer at home.

To don't make another brunch, just want to know the kind of messages that your brunch send from motherboard to serial1 and what's you need to reply back.

Are Serial 1 (pins 18 and 19) the preset?

I'll put all on thingiverse after test model's for print and the source code and electronics needed to build it. (Sorry for my English)

Has anyone tried using the prusa laser filament sensor that sits just above the bondtech system along with the mmu

Unfortunately the sensor seems to be disabled in the current official firmware. I don’t know why because I imagine a lot of nice features like auto Bowden length calibration etc. Probably work in progress at Prusa research at the moment. I hope so at least

@FNeo31 I added a short document to my repository: serial-protocol.md. For more details you can also check the MMU2 Firmware sources on Prusa's github.

Regarding the Mk3 filament sensor: I have one from the MK2.5 upgrade kit and it would be nice to make some use of it. Especially in combination with the MMU2 it would add a lot of reliability if there were feedback wether the filament reached the extruder or not.

Prusa added a Filament sensor 2.0 engine to the 3.4 release of their Mk3 firmware and they claim that some of the problems of the first iteration were ironed out. Maybe when I've finished MMU2 support it could be my next project to port this stuff over to Marlin. But it has to be reliable, otherwise it's not worth the effort. I haven't checked so far how the experiences from Mk3 users are with the new sensor engine.

Yeah it seemed like a good idea, I have a rather large printer to which I added a interchangeable x carriage head, so I designed a mount for the latest prusa mk3 r3 extruder as I liked the bondtech system and looked solid for constant filament changes.

As people have said with a system such as this every way we can get the printer to check itself after tool changes is better

@FNeo31 which stepper did you remove compared to the prusa design, I have seen a couple of prototypes that have the selector and bearings in one to remove the idler stepper. Although the tests haven't been great for the bearing is applying constant pressure, even on tool changes.

@Olympu5 it's the CAM stepper,

place the bearing with a lever system for idler and direct connection between feeder motor and the extruder.

Anyone looked at using the 're arm board for ramps instead of the arduino mega ?

@FNeo31 @radsonpatrick I'm building a Prusa MMU2 myself based on the sources published on Prusa's github repository. If everything works out - missing part is the controller board - I'll have an exact clone of the original Prusa MMU2.

Therefore what I'm implementing in Marlin is based on the firmware and communication protocol for Prusa's MMU2. If your self-designed MMU units behave in exactly the same manner they should work, too.

So if I have an MMU clone or if I just bought the whole kit and connected it to my makerbase board it should work?

I'm trying to get it to work on a MKS base, for the moment the communication is impossible !

I used part of the @revilor code on marlin 1.1.x, But I can't use the serial3 or serial4 ports

I did a test with the function "SoftwareSerial mmuSerial(15,14);"

I can transmit frames (TX) to a USB UART, the MMU do not move

Marlin is waiting for a "start", but i never get into the function "mmuSerial.available()"

Someone can look at my code ? (https://github.com/AlfiQue/MakerFr_I3-RS/tree/master/Marlin)

I hate fw, no good at it, port rev configs into marlin 1.1x and it wont compile for my board and then try bugfix 1.1 and get stupid binary errors

Short status update: I'm in the middle of cleaning up my stuff and make everything PR-ready. So don't mess with 1.1.x! Go for Marlin 2.0 and get ready to have the same fun with missing layers and stuff all the other MMU2-users with their Prusa printers are having already :-)

I'm trying to get it to work on a MKS base, for the moment the communication is impossible !

I used part of the @revilor code on marlin 1.1.x, But I can't use the serial3 or serial4 ports

@AlfiQue I also have MKS base v 1.5 (but still waiting for my MMU2 board)! What is the problem of using pins 14+15 (serial3) to communicate? Moving x/y max/min plugs to another pins looks possible.

FYI, I incorporated the MMU2 into my HyperCube CoreXY using a Einsy board a few days ago and I am willing to test firmware developed. I discovered this post yesterday so I will be looking to download @revilor code for testing. (Revised-- Noticed this code is for ARM processors. My board does not support this level of code.)

Two issues I have are the MMU2 unit communicating fully to allow for multi-material printing and successful activation and performance of the filament sensor.

The Prusa sensor used VCC, GND, SCL, and SDA. I have everything pinned out correctly on P3 of the Einsy board but the SDA is not in the present Marlin code and frankly I'm unclear how to embedded it or how this sensor truly works. Appreciate if someone could provide clarity and whether this has been rolled up into the Marlin 1.1.9 code for testing.

@dcwalmsley Don't be misstaken. Yes, the main goal of Marlin 2.0 is support for 32bit boards but the 8bit AVR code is still there. In fact I use an Arduino Mega2560 + RAMPS 1.6 + TMC2130s in SPI mode for my printer, so I kind of have an Einsy board too :-) MMU2 works fine with Marlin in my setup so it should also be fine with the real EInsy.

Regarding the filament sensor: we don't have support for it in Marlin at the moment. It would be of great use in combination with the MMU, though. Therefore I have plans to check if the relevant code can be ported over from Prusa's firmware as soon as I'm done with the MMU2.

I'm trying to get it to work on a MKS base, for the moment the communication is impossible !

I used part of the @revilor code on marlin 1.1.x, But I can't use the serial3 or serial4 ports@AlfiQue I also have MKS base v 1.5 (but still waiting for my MMU2 board)! What is the problem of using pins 14+15 (serial3) to communicate? Moving x/y max/min plugs to another pins looks possible.

I did the test will all ports, marlin does not allow the connection

Hi All,

Qucik status update on my integration, working towards running code.

I've pulled tthe @revilor 's fork last weekend on top of marlin2 and

started to run it on Mks Gen L V1 board on a CoreXY printer V-King.

I've assembled the original MMU2 unit.

Marlin resets the MMU2 and wait for "start" from MMU2 but i never receives it.

I've verified that Marlin can actually send and receive the data via Serial3 to an Arduino

that simulates MMU2.

I am hoping that I am close to getting it at least to control MMU2.

I still need to do a lot of work to convert the current extruder on the printer

to be something like Prusa.

@revilor I tried it with your code (in marlin 2.0), and the MMU has come to life :smiley:

Now the next step is to calibrate the MMU :stuck_out_tongue_winking_eye:

At least already a big thank to you @revilor for the work performed :wink:

Hi All,

Qucik status update on my integration, working towards running code.

I've pulled tthe @revilor 's fork last weekend on top of marlin2 and

started to run it on Mks Gen L V1 board on a CoreXY printer V-King.

I've assembled the original MMU2 unit.

Marlin resets the MMU2 and wait for "start" from MMU2 but i never receives it.

I've verified that Marlin can actually send and receive the data via Serial3 to an Arduino

that simulates MMU2.

I am hoping that I am close to getting it at least to control MMU2.

I still need to do a lot of work to convert the current extruder on the printer

to be something like Prusa.

The MMU turn ON ? I had a problem with my chinese board, the ground pin on the connector was not connected (I soldered it beyond that)

Do you have check that you have the TX from printer on the RX from the MMU ?

@AlfiQue I downloaded files for Prusa's new mk3 R3 extruder and found a version opf one of the parts on everything that was prusa sensor for a bltouch, printed everything and bought the bondtech gears from ali express

I did the test will all ports, marlin does not allow the connection

@AlfiQue I just compiled Marlin 1.1.9 with Y_MIN pin remapped to X_MAX pin. So, I got pins 14 and 15 (previously used for Y_MIN and Y_MAX) unused. I can now use Serial3.

I've added Serial3.begin(9600) to setup() in Marlin_main.cpp and, just for check thing working fine, added sending "+" or "-" to Serial3 when encoder is rotated.

After that, I can connect to this serial with USB TTL adapter and see + and - appearing in terminal while I rotate the encoder.

I did the test will all ports, marlin does not allow the connection

@AlfiQue I just compiled Marlin 1.1.9 with Y_MIN pin remapped to X_MAX pin. So, I got pins 14 and 15 (previously used for Y_MIN and Y_MAX) unused. I can now use Serial3.

I've added

Serial3.begin(9600)tosetup()in Marlin_main.cpp and, just for check thing working fine, added sending "+" or "-" toSerial3when encoder is rotated.After that, I can connect to this serial with USB TTL adapter and see + and - appearing in terminal while I rotate the encoder.

I've already done this test, i have a compilation error : '_Serial3' was not declared in this scope_

What is your board ?

@AlfiQue I've got the same issue. I dig a little bit to the Marlin sources and have found what Marlin is preventing including of Arduino HardwareSerial.h, but for Maylan LCD support Marlin needs to use serial port and in malyanlcd.cpp I've found this:

#if USE_MARLINSERIAL

// Make an exception to use HardwareSerial too

#undef HardwareSerial_h

#include <HardwareSerial.h>

#define USB_STATUS true

#else

#define USB_STATUS Serial

#endif

So, I've just put this undef-and-include stuff to the places where I need to use Serial3.

@AlfiQue I've got the same issue. I dig a little bit to the Marlin sources and have found what Marlin is preventing including of Arduino

HardwareSerial.h, but for Maylan LCD support Marlin needs to use serial port and inmalyanlcd.cppI've found this:#if USE_MARLINSERIAL // Make an exception to use HardwareSerial too #undef HardwareSerial_h #include <HardwareSerial.h> #define USB_STATUS true #else #define USB_STATUS Serial #endifSo, I've just put this undef-and-include stuff to the places where I need to use Serial3.

Thanks you for the explanation, I'll do the test

@AlfiQue I downloaded files for Prusa's new mk3 R3 extruder and found a version opf one of the parts on everything that was prusa sensor for a bltouch, printed everything and bought the bondtech gears from ali express

I created a piece to fit on my current head, but I will certainly do the same step as you

@AlfiQue thanks, it was some connection problem. The board and MMU2 communicates now but the

I see start , S1, S2 etc appearing on the pronterface console, using the latest code on the fork.

But none of the steppers rotate,they don't do the homing. The board has power. I've checked it using a multimeter at the fuse by looking at the board schema. It is a genuine Prusa MMU2 powered by 24V.

All powered by the same PSU.

Any ideas?

Thanks

@revilor,

Glad to know that the Marlin 2.0 could work on my Einsy board. Since the version 2.0 is laid out differently than the latest Marlin 1.1.9 files and folders, Would I need to copy all of Marlin 2.0 bugfix then rearrange them the same as Marlin 1.1.9 files are structured before compiling?

As for the filament sensor, I'm in no hurry for it to be implemented although I think we need a working version the supports SCL and SDA connections.

@kursatu The MMU does not home on power up. That behavior changed with the latest firmware versions.

The idler drum should move on power up and also after reset, though. The selector will home when the first tool change happens. When you press the middle button on the MMU to load the first filament homing should happen.

@dcwalmsley You take a copy of Marlin 2.0 in the folder structure it is, edit Configuration.h and Configuration_adv.h, and build it just like the 1.1.* branch. Just make sure you have Ardiuno IDE 1.8.* installed.

So I modified three files to fit my printer design, Configuration.h, Configuration_Adv.h, and pins_EINSY_RAMBO.h.

Compile was successful up and to the end point where I received this message, "fork/exec C:\Users\dcwal\AppData\Local\Arduino15\packages\arduinotools\avr-gcc\5.4.0-atmel3.6.1-arduino2/bin/avr-gcc.exe: The filename or extension is too long.

Error compiling for board Arduino/Genuino Mega or Mega 2560."

Any suggestions on how to get around this problem?

Problem resolved. Uninstalled Arduino and installed 1.8.8 into root drive of C. Then I moved any libraries and other data file to Arduino except for Sketchbook. Left that in C:temp folder. So these changes worked and I was able to compile and upload the firmware to my Einsy board.

On a side note. As of this writing, I'm not either understanding the MMU menu commands as "Loading to Extruder" doesn't seem to work, or the code is in early stage and it isn't incorporated yet. None-the-less, I'm liking the progress thus far. What can I do on the end-user side to help?

My latest MMU2 codebase has now fully implemented LCD menus for filament load/unload, filament runout check using the FINDA probe, T?/Tx/Tc/M403 gcodes, and MMU support in M600. The end of my todo list is getting close.

Bravo my friend @revilor

@revilor is there any additional hardware you used to adapt the mmu 2 with the ramps board? Just got a shipping notification from prusa so wanted to get a head start.

I know I would have to split the connector from the mmu2 so I can attach it to the end stops for serial and separate place for power

@0lympu5 No aditional hardware required. As you said: you just have to find a way to connect the MMU2 serial cable.

@revilor , thanks I've started to use your code , it works well. I was delayed a bit because I apparently burned the steppers somehow, had to wait for a new board.

My setup is a genuine MMU2, MKS gen-l v1 board, CoreXY printer (V-King design).

The printer & mmu2 can load filament, load to nozzle, print.

I've just got it to work did not yet try multi material prints yet, there might be still some mechanical stuff I need to do.

I've noticed M702 C gcode, unload filament. I think it is the only way to unload a filament via gcode.

The current PR does not seem to include that, not that it should. It might be nice to have that if it makes sense.

a few quick Q's:

1) will a filament sensor be required (at the extruder)? or can it work with a titan extruder? i assume the requirement would be that the titan extruder can grab the filament on its own

2) can it work on a re-arm too?

.....

?) for the clone builders like i might be would a 2nd Ramps setup be supported? maybe the 2nd board could run as an SPI slave if there are limited serial ports like the re-arm have

@boelle i cannot help with the second question but from memory of previous discussions over cloned prusa extruders the mmu2 firmware overrides the filament sensor above the extruder and relays only on the FINDA sensor. Rev has mentioned possibly adding or investigating support for the laser sensor as a filament loading fail safe.

If you need serial ports for the mmu2 communication, Rev has discussed a potential fix for people using full graphic displays, using pins 16 and 17. The idea was to move the Z min end stop to Y max, leaving Z min and Z max open for tx and rx

i was told that the re-arm has only 1 serial port left (if any)

i found out that when i wanted to use 5 tmc2208 that all requires interupt able pins to make the softserial for each driver work

Ah i see, that solution was based on a ramps and arduino mega

yep.... Ramps and Re-arm is a bit different :-) but i'm not going back to mega.... way to slow :-P

It would seem odd that they would remove features like uart and serial pins, as they are used for more advanced control which is what re arm is all about

but if all the endstop pins are able to work as serial pins even on the re-arm then i should be good as i only use 4 of them (dual z endstops and dual z drivers)

the thing would be that i will do a clone build as i'm limited in fonds

they have not removed it on the re-arm board, i just think its more limited than an mega

and the 2 are made with different chips and from different companies

re-arm is 32 bit and the mega is only 8 bit... and one runs at 100mhz and the other at 16 mhz

If you dont mind you stepper motor skipping maybe one or two steppers

when you first turn your printer on, you can use two end stops in series for z, i have done it on my build for a dual y axis, but will depend on your printer type and frame design

Mendel90 frame, but with Mk42 clone from spain and the prusa X axis system (rotated 180 degree on y axis to have x motor on right side). and titan extruder on x carraige

i use slic3r PE and i slice as if my printer was an mk2.5, so not sure if it would work with marlin2.0

but lets see what happens, a clone build of the mmu2 with a cheap ramps board would most likely be my choice to keep the price down.... also i have to think if it would make sense and i would make use of it in the long run, if not i would just add something to the printer that is a waste of money that could be used for better things

@kursatu In difference to the Prusa firmware Marlin has no C argument for M702, but you can use plain M702 without any arguments to unload the filament. In the context of the MMU2 there is no other than the current extruder to unload filament from, anyway. You can use M702 C if you like, though. The C will just be ignored.

@boelle I do not recommend software serial for 8-bit boards, but for a 32-bit board it might be ok. The MMU2 requires 115200 baud, for other values you would have to modify the MMU firmware.

For the Titan: Here is how loading the filament to the extruder works: the extruder stepper is disabled when filament is loaded and the MMU2 will first move the filament the calibrated distance down to the extruder (for the MK3 extruder you calibrate the filament to just reach the Bondtech gears). The MMU2 will then feed a few more mm of filament to push the filament between the two Bondtech gears. This can also work with the Titan but it's also possible that because of the geared drive the resistance is too high and the MMU2 is not able to push the filament to where the extruder can grab it. I guess you'll have to test it out and maybe play with the distance calibration a little bit.

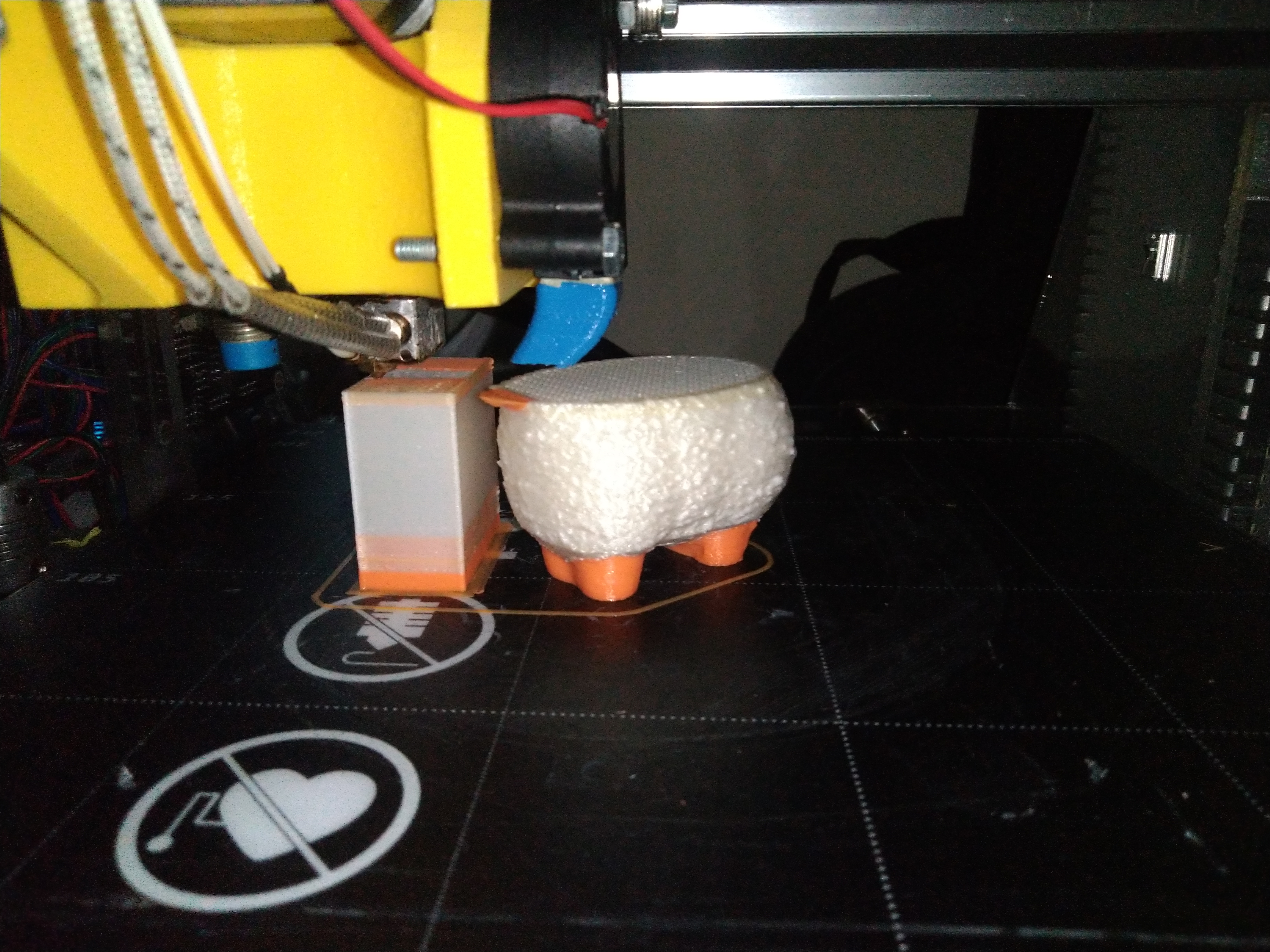

And finally regarding the filament sensor: it is not required but some kind of motion sensor would be very useful to make the operation of the MMU2 more reliable. From my experience and the experience of other MMU2 users it is not uncommon for one material change or the other to not work out 100% perfect which causes missing layers like in one of the photos I posted in this thread above. With a motion sensor somewhere in the filament path this can be detected and avoided by pausing the print/alarming the user. That's why my current project is to synchronize MMU2 operations with any kind of encoder-style filament sensor. Or the PAT9125 laser sensor from the Prusa MK3 which is kind of an encoder, too.

@revilor the reason why i asked about filament sensor is that i dont have one at the extruder

but yes will have to make some tests to see if the extruder can grab the filament with just a light push, normal i push the leaver on the titan extruder to push the filament past the gear

but yes... something that could detect if the extruder in fact did get a hold of the filament would be nice

of course the mk3 has the laser sensor, but us poor people dont have it. maybe add one of these things where an old mouse with ball is converted to detect if filament moves

but yes... something that could detect if the extruder in fact did get a hold of the filament would be nice

of course the mk3 has the laser sensor, but us poor people dont have it. maybe add one of these things where an old mouse with ball is converted to detect if filament moves

You can buy a chinese clone of MK3 filament sensor on aliexpress and it's not so expensive...

does not fit very well on a titan extruder

one option is to build this: https://www.dropbox.com/sh/g4031hbsyz99rme/AAAVz5FlsT3rlf2-YxLdtuxZa?dl=0&preview=sparklab+FTS+Bedienungsanleitung.pdf

hope you are good at german, but basicly its 2 axels rubber coated and one of them have a magnet at the end, and the board has a halleffect sensor

of course the last one needs some "thinking" so it can be direct attached to the ramps or whatever electronics

Q... the mmu has a probe to detect if filament goes in correct in the selector

some call it FINDA other says its just a Pinda with a steel ball... but how does it actually work?

Q... the mmu has a probe to detect if filament goes in correct in the selector

some call it FINDA other says its just a Pinda with a steel ball... but how does it actually work?

This is how FINDA works:

https://josefprusa.cz/wp-content/uploads/2018/08/Finda-1024x667-1024x667.jpg

So, when you insert filament, filament will push metal ball closer to induction sensors, that will detect it presence.

ahh :-)

and i guess people that have problems are beause they calibrate the distance to the extruder wrong so it does not grab the filament

marlin could do a bit better if there is an filament movement sensor somewhere

so that when the mmu has pushed the filament down marlin should check if there is movement when the extruder starts to pull filament

and you could even tell the mmu2 to push a bit while pulling

but just an idea that came to mind, not sure if it would be smart or work

Can anyone who managed to successfully wire the unit to an MKS Gen L share a picture of how they did so? I can't seem to find the correct way to do it...

Thank you!

@Ungreon I don't own a MKS Gen board but as it's just another Ramps variant all that was said in this thread regarding Ramps also applies to this board.

You probably have an LCD connected so the options for the required serial connection would be pins 14/15 or 18/19. Those are by default dedicated to the Y and Z endstops. Check this comment for how to repurpose those for use with the MMU. In case you don't use an LCD pins 16/17 on EXP1 would be your best option.

A general info how to connect the MMU is here. Replace 16/17 by 14/15 or 18/19 if necessary. Choose any free 5V pin for supply voltage, and for the (optional) reset connection you can use any free digital pin, for example D1 or D2 on AUX-1 or D40, D42, D44 on AUX-2.

In the configuration set one of the following depending on which pins you are using:

define INTERNAL_SERIAL_PORT 3 // pins 14/15

define INTERNAL_SERIAL_PORT 2 // pins 16/17

define INTERNAL_SERIAL_PORT 1 // pins 18/19

And in case you want to use hardware reset set MMU2_RST_PIN to the pin you chose for that purpose.

That clears it up a ton. Thank you very much!

@Revilor do you know what is the best 32bits board for your brunch, that use discount full graphics display?

I'm running Marlin with Mega 2560 and discount 20x4 LCD and everything is fine and when I put the full graphics on my board when I start printing the temperature becomes unstable because the Arduino supposed to be overloaded and the PID didn't work well. On SD menu append the same. Too slow, so I want to upgrade the machine.

Thanks in advance

For ATMEGA 2560 the pins for Serial 1 are 18/19. I have a full replica of the MMU 2.0 board and I assembled everything. Unfortunately, I am still unable to make marlin talk to the MMU. I even tried swapping the TX/RX just in case. The board powers up and if I hold the right button the MMU goes into some strange sequence where it rotates the "extruder" then the fifth green led flashes for bit, later oh the fourth and then all 5 leds start blinking orange. Any idea what that means?

PS. During this sequence the pulley and the selector are not moving. I tried swapping motors just to verify they work and they do, but the sequence only tries to me the "extruder".

@DimitarKrastev Thank you for pointing out that I mixed up serial 1 and serial 3, I changed my comment above accordingly.

Your MMU seems to behave as it is supposed to. All 5 red LEDs blinking means that there is filament in the selector, therefore the selector will not move/home until you remove the filament. Once the filament is removed all green LEDs will blink and you continue homing by pressing the right button.

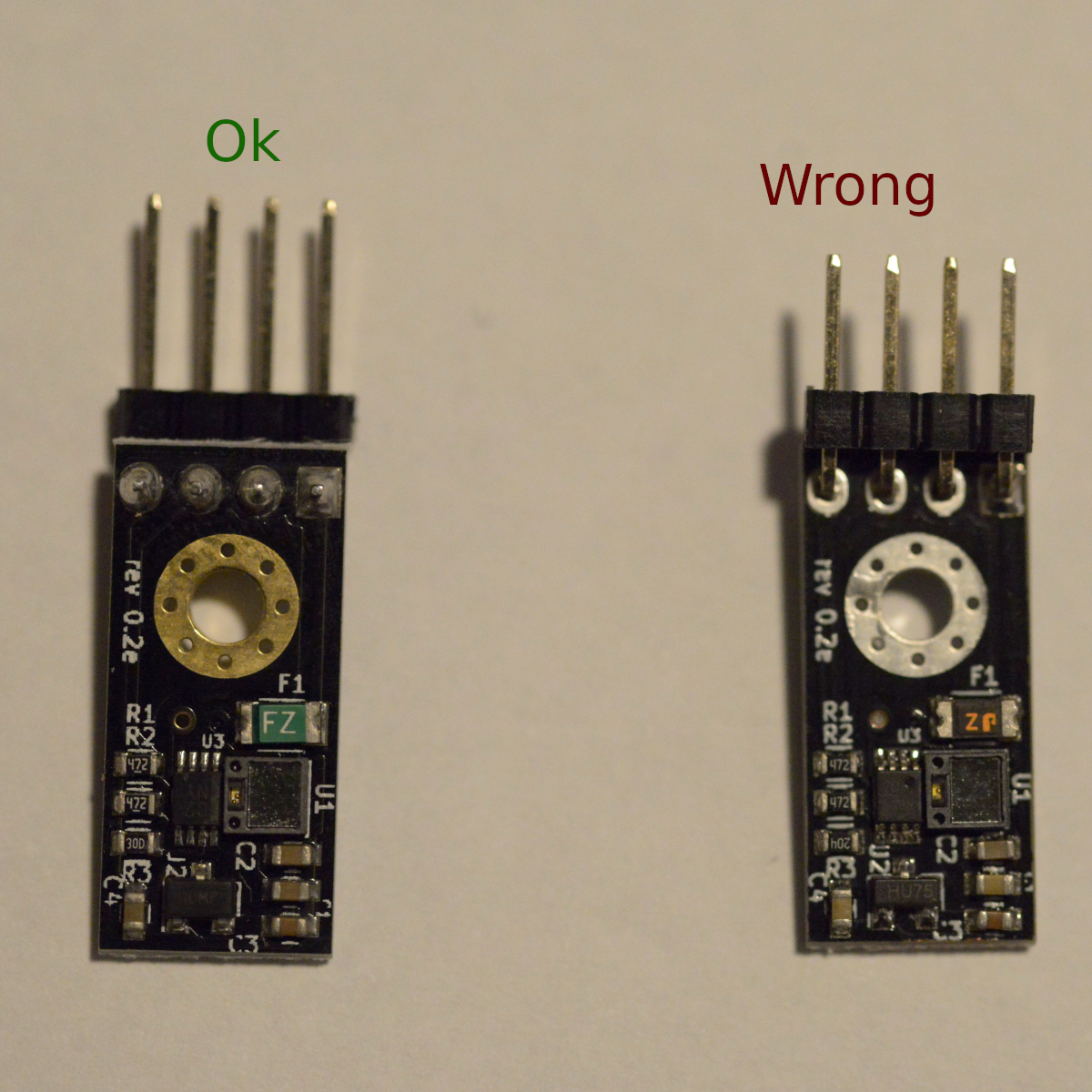

If in your case there is no filament loaded then probably the FINDA is to close to the steel ball and triggers even without filament. Or - as it's not a stock MMU - you use the wrong sensor type which triggers when there is no filament.

On startup only the idler drum homes, the selector will home when the first tool change occurs or when you first select a filament slot using the MMU buttons (as in your case).

@revilor Actually I don't have a FINDA connected ATM (maybe that's causing the issue). As for homing - when it powers on nothing is homing, I don't know how to make it home actually.

@FNeo31 I don't have any experience with 32bit boards. What's important regarding the MMU2 is that there is a serial port available. That's all I can contribute to your search for a 32bit board.

@revilor how have your latest tests gone?

@FNeo31 The FINDA sensor is an NC (normally closed) type so not having a sensor at all is for sure causing the behavior you see from your MMU. You could jumper the sensor signal pin to ground to see if homing and initial communication with Marlin works.

If you want to do so: when you look at the control board like on this picture you have to shorten the two left-most pins of the sensor connector (blue and black wire on the photo) using a jumper or jumper wire. But be careful and don't mess this up otherwise you could shorten the 5V circuit which will probably destroy the board. You have been warned. You could also attach a switch to those pins and manually emulate the FINDA sensor.

@0lympu5 I'm quite happy with how things are going. The Marlin part is working reliably and so does the MMU2 unit. I still have issues with about 5 to 8 out of 100 material changes. But that's fine for me at the moment because I now also have the PAT9125 laser sensor in the extruder working and so far 100% of material change issues have been detected either by the MMU itself or by the laser sensor. So with looks at the end result I'm getting perfect multi-material prints, but from time to time some manual intervention is required during the print.

I think most of the issues I have are due to the fact that I'm using a V6 knock-off hotend at the moment. I will soon replace it with a genuine E3D V6 and hopefully will have less issues afterwards.

How was the laser module implemented and does it function as a type of check point after each change only or continuously throughout print

Please have a look at #12962. The sensor is on all the time and should detect any kind of filament motion issue. The most important part for me at the moment is when material change happens and issues there have been detected reliably so far. But further tests will be required to fine-tune the code.

@revilor Thanks man. What is the correct diameter for the steel ball beneath the FINDA sensor? I didn't get one in the clone kits and I couldn't find information online. Thanks!

@revilor I've been reading into your work for the laser sensor and as I am still waiting for my mmu2 to arrive, I wanted to know how you included the sensor in your set up, such as wiring and whether it is included in your marlin branch for the mmu2

@DimitarKrastev I use a 7.5mm steel ball. 7mm should also be fine but 8mm will usually not fit into the slot.

@0lympu5 No, the laser sensor stuff is not in the MMU branch. It's an independent PR. I have a MK3 clone so it is the exact same setup as on the Prusa printers where the sensor sits in the slot on top of the extruder casing. On the printer board side it is wired to the I2C connector on the RAMPS. If you use the cable that usually comes with the sensor you have to swap white and blue wires on the 5 pin connector to make it fit.

@revilor I found my finda sensor and now the load/unload is working great on the MMU side. Unfortunately I am still not able to get the serial connection to work. I haven't connected the reset wire, is it possible that is causing the issue? Also isn't there supposed to be a GND wire? Right now there is 5V, RX and TX, or maybe it is getting the GND from the main power cord from the PSU? Do you mind to have a chat in some IM. I think I am getting pretty close and I am missing something really small.

Thanks.

PS. Does this serial config look OK to you? I am trying to use Serial 1 on pins 18 and 19. Also what the difference between the two defines? Why are they two?

#define INTERNAL_SERIAL_PORT 1

#define MMU2_SERIAL internalSerial

@revilor How did you flash your MMU board? Arduino IDE or Slic3r PE ? Also should I burn bootloader> Sorry for the dumb questions, but I am not experienced with embedded.

I got it working. The homing is acting a bit strange. The barrel and the selector try to go their extreme positions and they produce very nasty sound every time. The printer says the MMU needs attention, but at the end it ends up OK. Is your homing sequence so unsmooth as well?

@revilor How do you slice the models for MMU?

@DimitarKrastev

On AVR boards by default only serial 0 for USB connection is active. Therefore you have to activate the serial port you want to use for the MMU2 with the first define

define INTERNAL_SERIAL_PORT 1

This creates a new serial named internalSerial, and that's what you set with

define MMU2_SERIAL internalSerial

to be used for the MMU2 connection. On 32 bit boards which usually have all the available serials enabled by default you would only set

define MMU2_SERIAL Serial1

Regarding the homing sequence of the MMU2: homing of the idler barrel is not too loud with my unit, but the selector is another story. Sometimes it will home to the right which is a nice and smooth operation. But most of the time it homes to the left - well, I would not call it homing, it just slams the selector against the wall on the left - and then it is very noisy. So far I was not able to figure out how the homing direction is chosen but homing to the left - at least in the way it is done at the moment - I consider a bug in the MMU firmware.

By the way: if you operate the MMU at 12V and have not done yet, also try

define MMU2_MODE_12V

which should make the MMU less noisy.

For slicing from my point of view there is only one option at the moment and that is Slic3r Prusa Edition. I use 1.42 alpha1. I have the MMU2 sitting on a MK3 clone, so this is a perfect fit. If you don't have a Prusa printer or clone my recommendation would be to get your extruder as close to Prusa's as possible (meaning direct drive and E3D V6 hotend). Then the ramming sequences generated by Slic3r PE should also work for your setup. You for sure do not want to figure out those ramming sequence gcodes on your own.

@revilor i have a slightly modified prusa r3 extruder but i have a very large printer for which i use a volcano instead of a normal e3d v6, i wont get my mmu2 unit until march. Do you think it will be an issue?

@0lympu5 I definitely would love to use a Volcano in combination with the MMU2. But I have not tried and from my experience so far I think it will be very time-consuming to get it work, and I consider the probability very high it will not work at all. A Volcano with that long melt zone will be very tricky to deal with when it comes to finding a reliable and repeatable unload sequence that will allow the MMU to load the filament again the next time it is used without jams or any other issues.

So if you ask for my opinion or recommendation I would say: go for a regular heater block and a 0.6 or 0.8 nozzle. You might not be able to print as fast as with the volcano but you will have less issues when it comes to the MMU. With regard to the Volcano and multi-material the Palette+/2 is probably the better fit.

Also check out this thread in the Prusa forum.

@revilor My experience with the selector is the same and I am running on 24V. I am using a Titan Aero extruder and I am trying to make it work with Simplify 3D and I think I am getting closer.

Can you post an example gcode with mmu that you successfully printed. I want to see how the filament is being changed. From that I believe I might be able to produce an universal set of scripts for Simplify 3D.

@DimitarKrastev Here you go: MMU-test.gcode.zip This is a test print of five 15x15x15mm cubes, each tool uses different ramming settings for rammed volume: 9mm^3 for T0, 13mm^3 for T1, 18mm^3 for T2, 24mm^3 for T3, 32mm^3 for T4.

The ramming sequence is part of the purge tower gcode, so it might be a little bit diffucult to extract. Instead you could use the ramming sequence used in Prusa's firmware (and now also in Marlin) to unload filament from the LCD menu as a starting point for your scripts:

#define MMU2_RAMMING_SEQUENCE \

{ 1.0, 1000 }, \

{ 1.0, 1500 }, \

{ 2.0, 2000 }, \

{ 1.5, 3000 }, \

{ 2.5, 4000 }, \

{ -15.0, 5000 }, \

{ -14.0, 1200 }, \

{ -6.0, 600 }, \

{ 10.0, 700 }, \

{ -10.0, 400 }, \

{ -50.0, 2000 }

Those are extrude distances in mm and feed rates in mm/minute and would translate to a toolchange script like

; move to purge position

...

; ramming sequence

M83 ; E relative

G1 E1.0 F1000

G1 E1.0 F1500

...

G1 E-10.0 F400

G1 E-50.0 F2000

G4 ; wait for E moves to finish

; ramming and unload from hotend done

T<n> ; tool change

; feed filament from the extruder gears to the nozzle, do purge sequence, etc.

@revilor Thanks for the info. I used it as a base and I am tweaking the ramming sequence. I am also having trouble with the restart distance once the filament has reached the extruder. It seems it is pretty inconsistent. There is either not enough filament to complete half of the purge tower layer or there is too much which causes a blob so big that knocked my BLtouch and broke its mount. How are you handling the purge towers?

@DimitarKrastev For me the purge towers are handled by Slic3rPE and it works just as expected.

When you have inconsistencies with the purge I would point to the calibration of the MMU2. I'm quite sure you did this, but just to have it mentioned here and also for future reference: the procedure is laid out in chapter 6 of Prusa's 3D Printing Handbook. You need a consistent calibrated distance for all five MMU2 filament channels.

For the direct drive extruder of the Prusa printers you calibrate for the filament to just reach the Bondtech gears. When filament is loaded the MMU2 will transport the material the calibrated distance down to the gears. In a second step it will push the filament a few millimeters into and beyond the gears. The extruder stepper is disabled for this purpose to reduce the resistance of the drive gear.

In your case with the Titan Aero I wonder if maybe the MMU2 is not able to push the filament in because of the higher resistance the geared drive has. Or maybe it works some time and some time it does not an that's the cause of the inconsistencies you get. You could try to calibrate the MMU2 to stop the filament transport slightly above the extruder gears so that in the second step it will move the material just far enough for the Titan Aero to grab it but does not try to push the filament all the way in between the drive gears.

Another possibility could be that the MMU pulleys are grinding into the filament because of issues in the filament path or - again - in the calibration. This could cause problems the next time the filament is loaded because the pulley will have less or no grip at the grind mark and will therefore transport less material than required.

@revilor The mmu2.cpp at Marlin bugfix-2.0.x line seems to be broken.

I've just got the code, it stopped working. The earlier code in your fork worked fine.

It is due to the wrong timeout , MMU_P0_TIMEOUT (3 secs_, being used to unconditionally.

It is supposed to be used only for P0 command, so everything times out.

I've worked my way around it but did not trace how it got to the Marlin bugfix-2.0.x line,

@revilor I have calibrated the MMU bowden length. My problem was that I overtightened the MMU and it was grinding sometimes. Anyways, filament loads are 100% consistent now.