Marlin: [bug] Layer Shifts on bugfix-1.1.x and 2.0.x

Description

Random layer shifts on different heights on both x and y axis, sometimes on both, sometimes just on one axis, reducing speed, acc and jerk, raising vref does not show any improvement. (tried reducing it to half)

Sometimes it happens on the second layer, sometimes after 2h. I checked all the mechanical parts; they are fine, and if I go back to a bugfix version from january it works fine without any shifts.

Steps to Reproduce

The only differences between my working jan bugfix (as far as I can remember) and the current 1.1.x bugfix and 2.0 bugfix that I made are:

Activating Babystepping

Activating Fade Z

Both config files are attached, the working Jan version and the 2.0 Version

Configs.zip

Additional Information

This is my first Bug report, this is not my native language. I tried my best, let me know what additional information you need.

All 415 comments

Layer shifts are usually a mechanical issue. As far as we know there's no randomness in Marlin. If an issue occurs at _some point_ in a G-code file, it will _always_ occur at the same point in the file. Can you provide a G-code file that demonstrates this issue consistently?

I dont think its a gcode issue. The objects in the slicer dont show that behavior in the preview. Also the heigth of the shift is always different. If I print the same file multiple times, sometimes it happens in the second layer, sometimes it works fine untill 2h midprint. I printed an object at least 5 times, everytime it was different, sometimes on X, sometimes on Y. Thats wh I don`t think it is a mechanical issue, since the axis change.

Then I flashed from 2.0 to the latest 1.1.x bugfix with the same issue. In both cases I reduced Acc from 1600 to 800. raised an lowered Vref, decreased feedrate to 70%. Then I switched back to my january build, printed the same object (had to slice it again, the only setting I changed was the K value in the startcode to a v1.0 value) and it printed absolutely fine.

Could it be, that I somehow reached the cpu capacity of the adruino? I have no idea what else it could be.

What I also did:

More cooling on the steppers, but they stay cold anyhow.

Powered my ramps with and deactivated the diode, so it does not use the arduino VR. (thought it might be caused by dropping 5v because of power consumption)

Loosend and tightened the belts

removed the belts and made sure all axis move extremely smooth

checked the aligment of all axis mit a micrometer

Sliced the file multiple times

printed with different materials, that require higher and lower bed temperature

I really have no idea what to do else. And since it works with the older marlin version, I think it has something to do with the fw

Oh and btw, the shifts aren`t huge shifts. They range from around 0.5-2mm, but I never measured them.

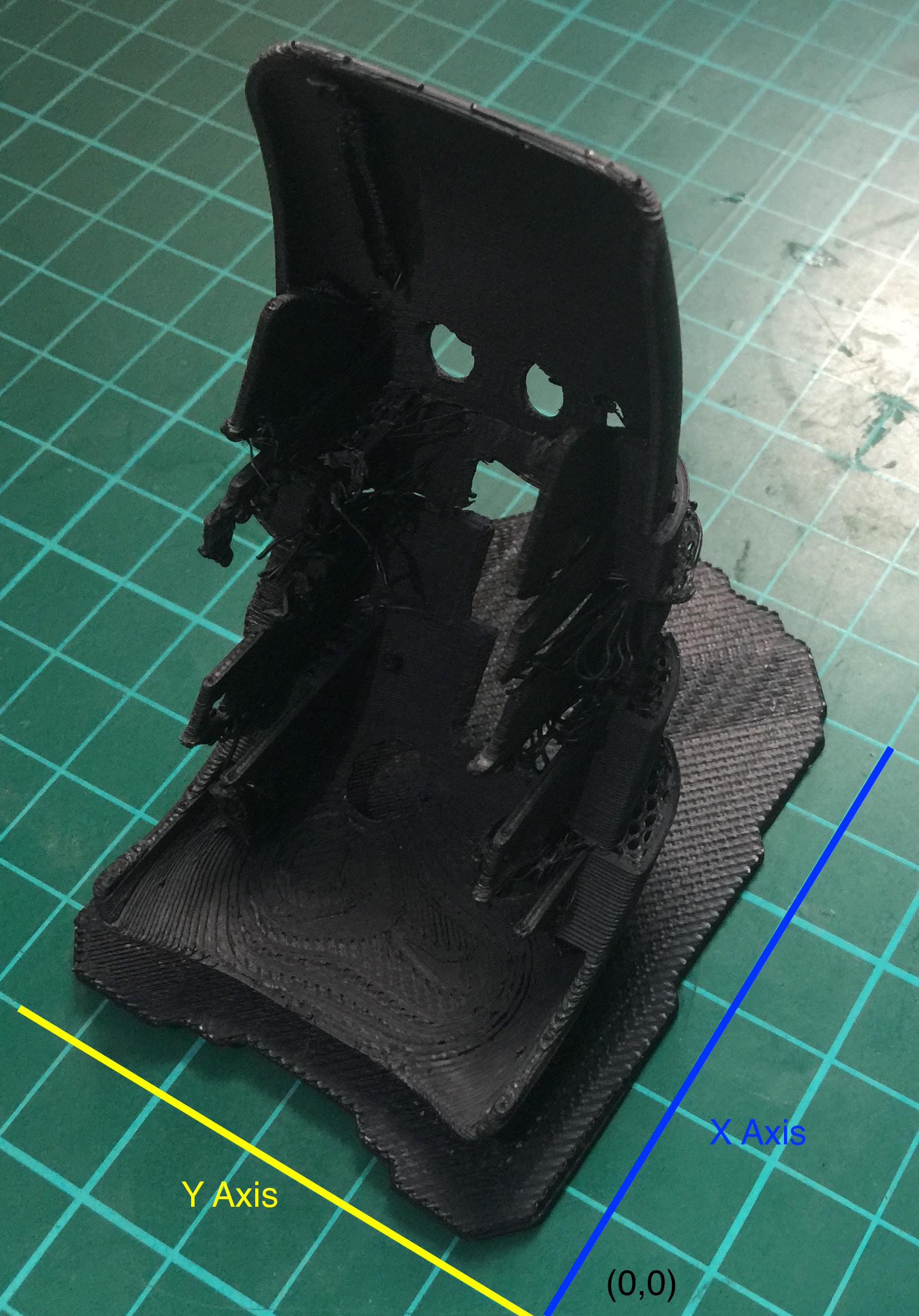

Here is one of the gcodes I have used. The object had a shift in X direction at around 2.1mm heigth, than another one in the opposite direction 1.63mm later, and after another approx 3.3mm it had a shift in Y direction.

Before that I printed 2.5kg of the same filament, same kind of objetcs, same slicer settings (exept K value because of V1.0 and 1.5) on my january build with no problems at all.

failed object.zip

Could be your drivers overheating. You say you increased cooling for steppers but not to drivers. You also increased Vref that increases heat output. Lowering it to half would likely lead to insufficient torque and to skipped steps.

Sorry, I ment the drivers, not the steppers. I have increased cooling on them, but that was not the reason, eaven with the smaller fan, they did not get noticably warm. I just didn`t know what else to do and wanted to eliminate as many reasons that could cause the problem as possible. Adjusting Vref was just a try, it did not help at all. Motors never got above 45°C btw.

If you have Z fade with a small number and you have a very uneven bed your nozzle will rub on layers and then cause shifting. you could try increasing the M420 to make it fade over a longer distance.

I have also aready though of that. But some shifts happened before reching the fade height and some 20mm after. With a 0.2 layer heigth, thats a lot of layers. I have also tried to move the axis while printing by hand. Thats nearly impossible it has so much torque, i would rip my extruder off the mount bore skip a step.

My thought are, that all the calulations like fade height, bed leveling, linear advanced, babysteps somhow max out memory or buffer during a print. Or it has something to do with linAdv 1.5. I have no idea if that is realistic at all.

I’m currently investigating a similar issue, trying to determine if firmware related or something else.

Had two 5 hour+ prints which have suffered layer shifts in the Y direction.

Initial print was with ABS and had some warping, so i thought might have been with the nozzle hitting the print. 2nd attempt, resliced and used PLA, same result. layer shifts at different heights, always in the Y direction

I'm trying to replicate with simpler, quicker prints that i can observe. All ok so far.

Printer has been fine previously.

Keep experimenting. Disable various features. Test various settings for acceleration and jerk. Etc. The most important thing will be to narrow it down to a single causative factor.

I can already tell, that is is 100% caused by the firmware or one of its functions.

I did not have a single print without shifts on the newer firmwares and as soon as I switched back to the old one, I didn`t have single shift.

Had it printing for 16h yesterday on various prints, including identical gcodes that had shifts with the newer versions with the exact same mechanical, acc, jerk, vref etc settings and not getting a single shift while using the old version.

I can confirm this with the 2.0.x bugfix -branch. After updating from 1.1.5 there is sometimes "loud thunk" and erratic moves in the middle of print (my printer if very silent normally and these "thunks" didn't happen with 1.1.5) and I'm also experiencing layer shifts, even with prints speeds of 50mm/s (1.1.5 goes fine with 80mm/s). I'm sure there is no mechanical failure or problem with stepper controller reference voltages, I've played around with different accel & jerk speeds. I even tried the BEZIER jerk and while it makes the overall printing smoother, the erratic moves are there.

I try to experiment more during weekend and if possible, make some comparisons with different values.

Finally an issue regarding the TMC2130 layer shifts which occur with the bugfix-branches!

I'm experiencing the very same behavior as you guys are describing.

It's _possible_ that I'm seeing the same behavior.

I'll need to start eliminating commits and see which change introduced this. If any.

If you guys want to try something, turn off MONITOR_DRIVER_STATUS. That way there will be no communication to the driver after the initial setup.

I am kind of happy, I am not the only one that has those issues. I am currently running the TMC2208 on my printer btw. so I do not use SPI.

Also judging by the initial report, this is not isolated to TMC drivers.

OK, may be, just saying I never had any of these problems with the A4988 drivers.

This could be because of the less torque of stealthchop though...

I even changed to much oversized stepper motors (400mA to 1700mA, H-Bot) but still I get these layer shifts.

This could be because of the less torque of stealthchop though...

It is not, I'm running TMC2100 on my printer and it has been condigured to use spreadCycle mode

Also judging by the initial report, this is not isolated to TMC drivers.

Correct, my other printer (Tevo Black widow) has drv8825 and the same issue seems to bother there too, erratic looking moves that are louder than normal printing, although no layer shifts (yet) as I'm driving steppers with more force.

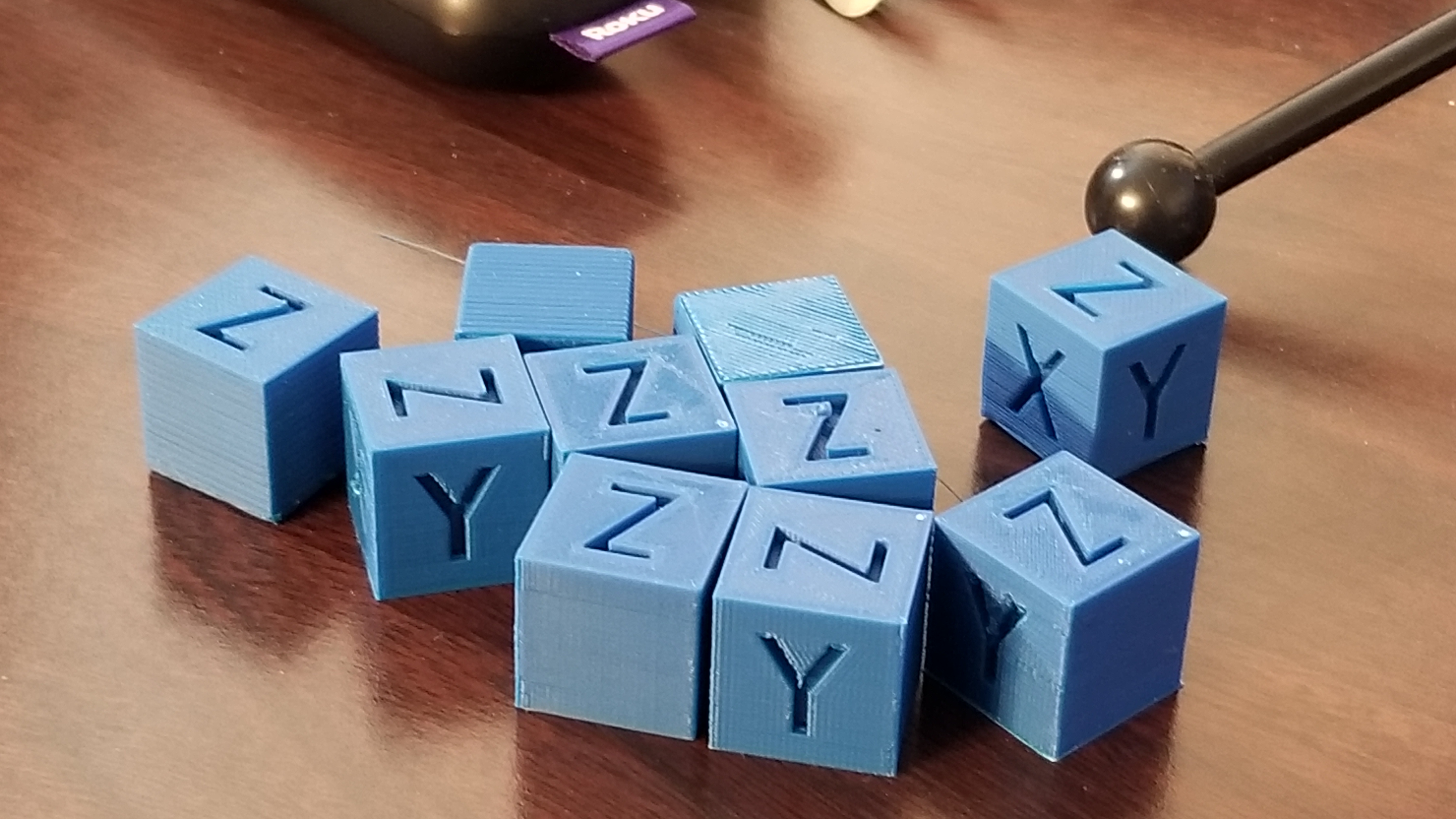

Same gcode-file with 1.1.5 (except modified lin_advance value):

@Jartza: Could you post your

DEFAULT_AXIS_STEPS_PER_UNIT and your

DEFAULT_MAX_FEEDRATE ?

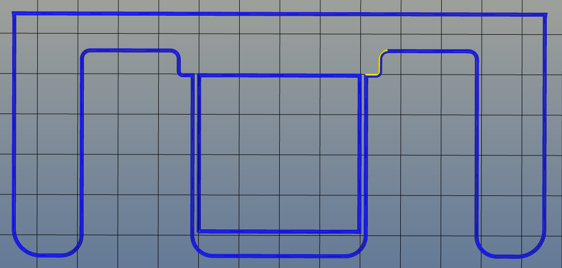

A long time ago, when i switched to the bugfix2.0.0 branch, for my printer, i need for the Z axis

STEPS_PER_UNIT = 4000, and if i set MAX_FEEDRATE to 3 or more, the Z axis does not move, but it does a horrible noise (brrrr, but with some discontinuities). I am pretty sure there is some overflow in computations somewhere, never investigated them. Maybe that is being triggered somehow in some strange case also

The way to reproduce always reproduce it is:

define DEFAULT_AXIS_STEPS_PER_UNIT { 80, 80, 4000, 97 }

define DEFAULT_MAX_FEEDRATE { 300, 300, 4, 30 }

And try to move the Z axis with the LCD menu...

#define DEFAULT_AXIS_STEPS_PER_UNIT { 80, 80, 400, 96 }

#define DEFAULT_MAX_FEEDRATE { 150, 150, 8, 50 }

There is limit how much 8-bit cards can output steps.

I also have #define MINIMUM_STEPPER_PULSE 2

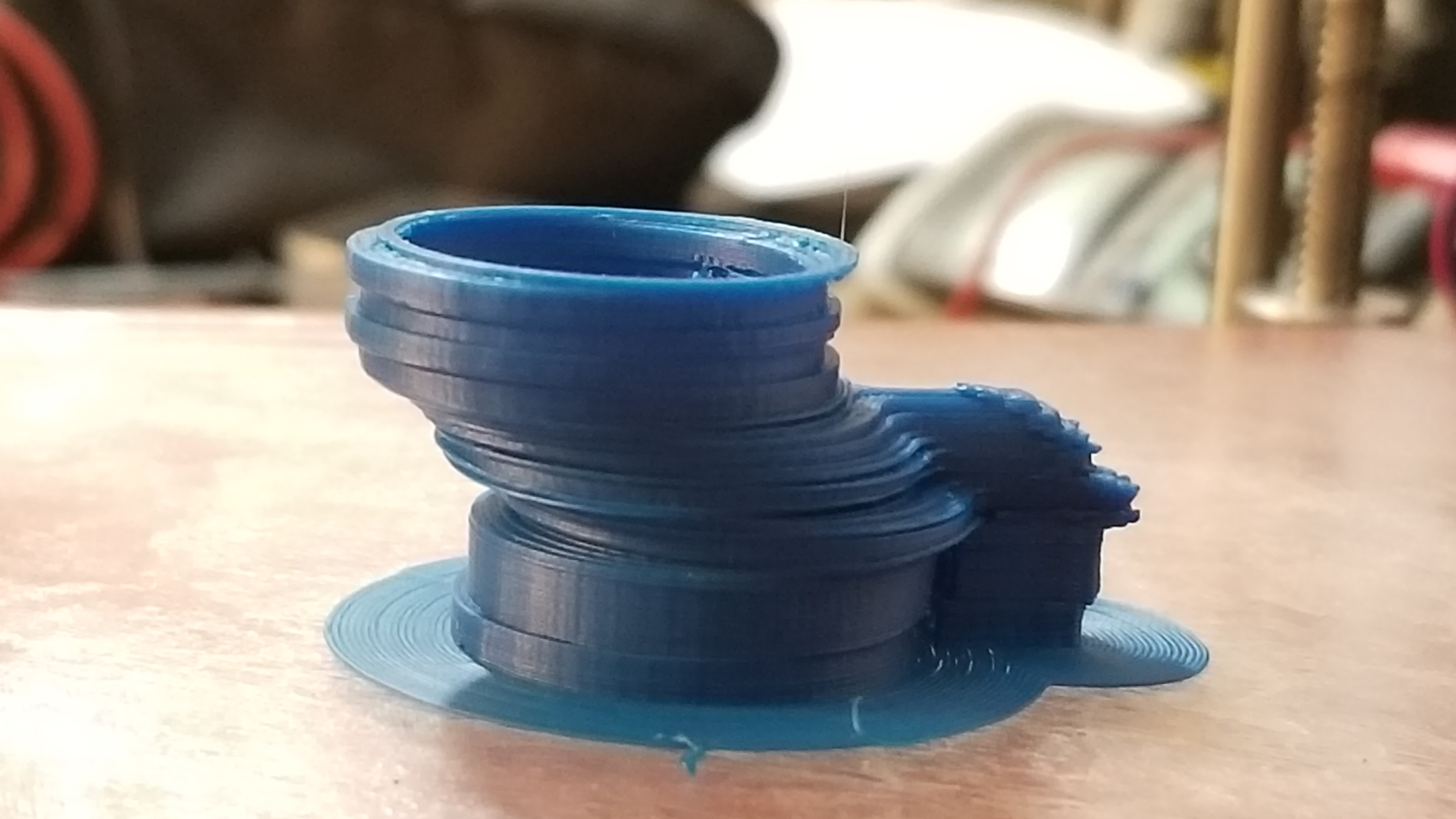

Printing regular 20x20x20 calibration cube, there's almost always now loud "thunk" also when the the perimeter has been printed (there is just very short move command). I tried to record it on video, but the "thunk" is so low frequency that cellphone mic didn't catch it but it's very audible by ear :)

I have my current printer on an old build of 2.0 and its running fine, so ill upgrade it to the latest and let you know if there is any clunking/shifting or whatnot. Ill look, but i might be able to figure out the date i downloaded it and ill know what commit its on.

My 2.0.x is less than week old, but I will update later today to latest bugfix-2.0.x to see if it helps any.

Ill look, but i might be able to figure out the date i downloaded it and ill know what commit its on.

Try git log -n1 to see the last commit :)

My 2.0 was april 11th, the 1.1.x bugfix was april 17th.

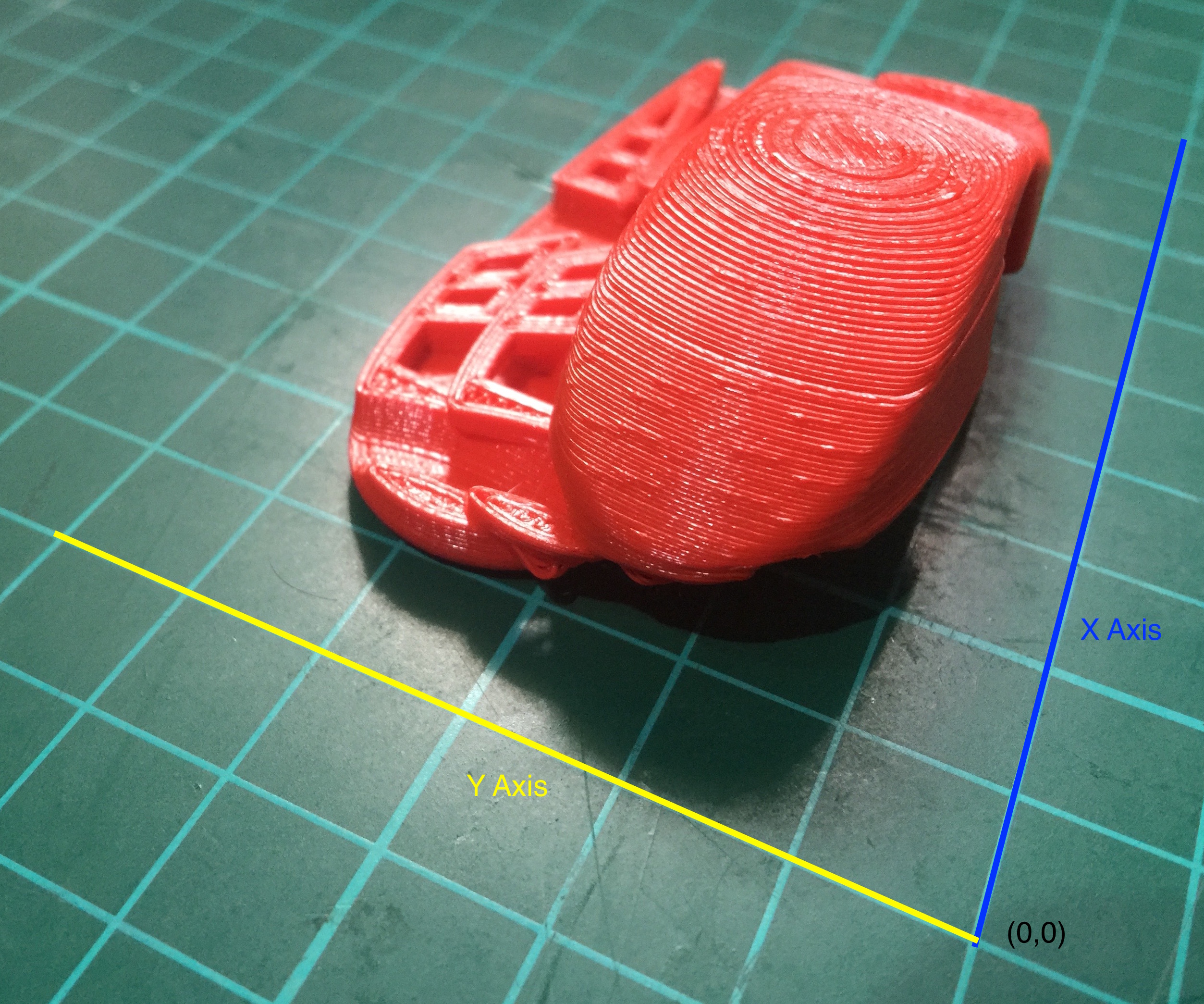

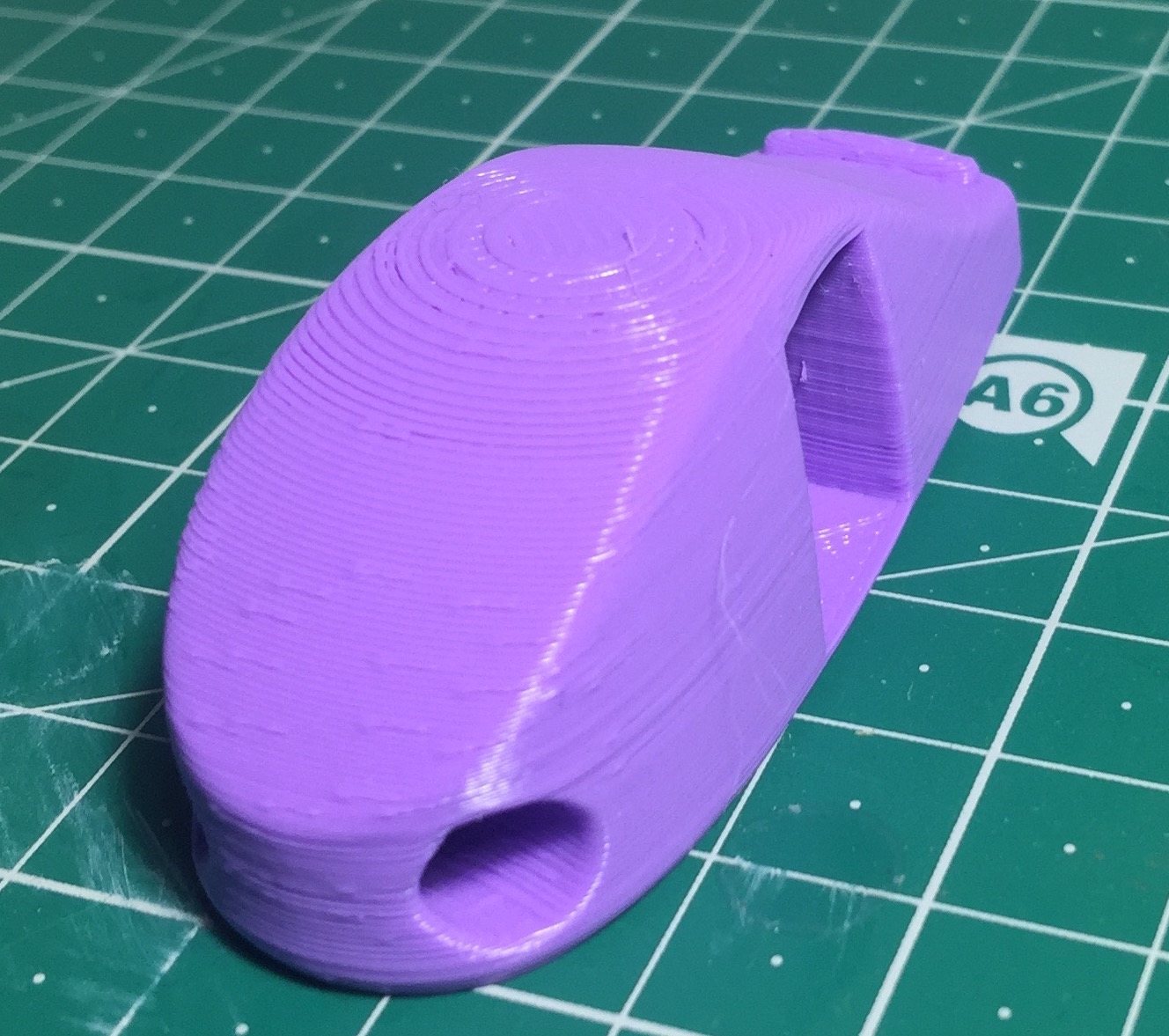

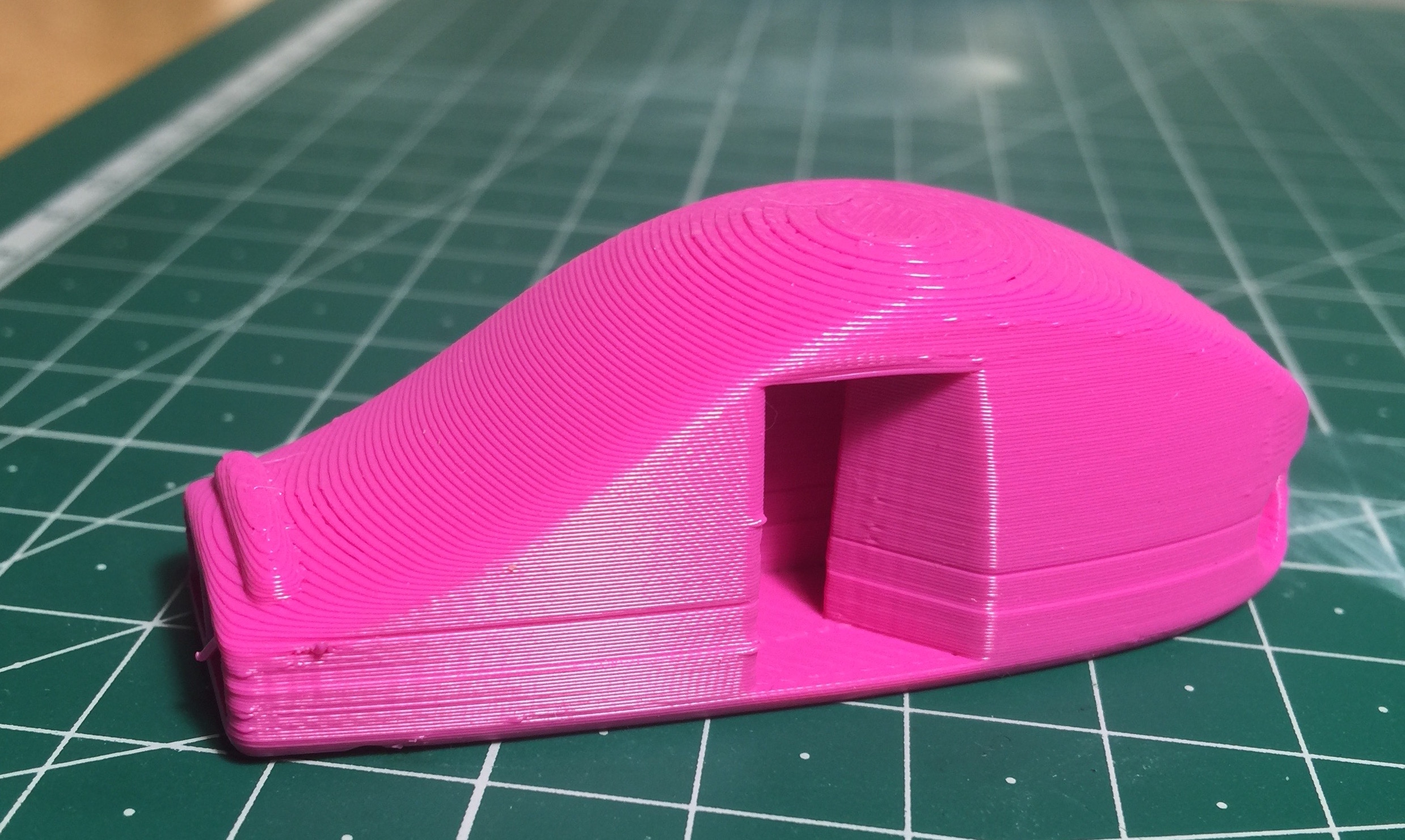

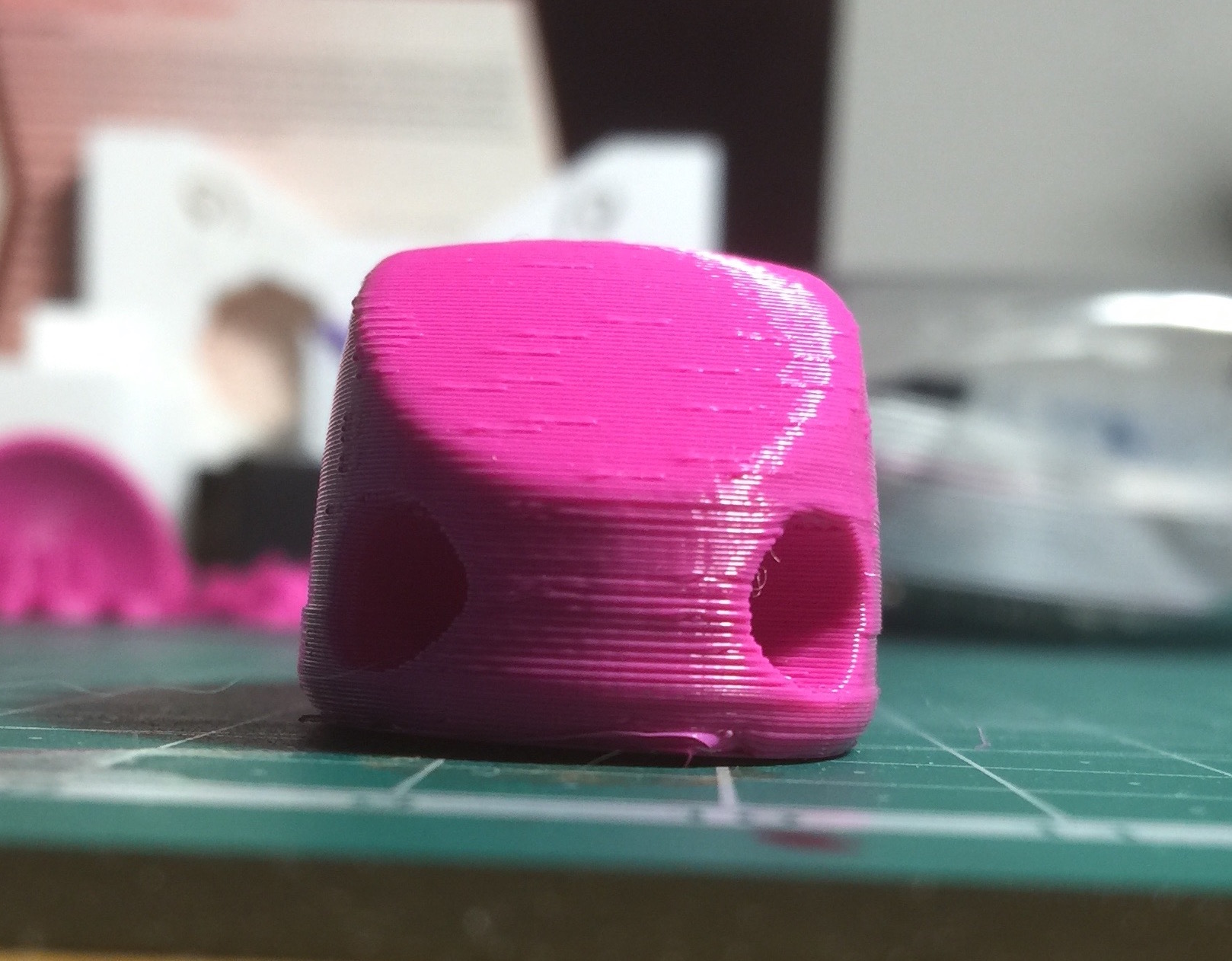

By looking at Jartzas pic, i noticed that my shift is different. It looks like his print shifter over several layers. It looks like the little house started to continously move to the left. My shifts are just one layer. For example, it starts the print, after several perfect layers, it shifts in one direction and stays there for a while, untill the next shifts happens. I dont have shifts that stack up on several layers like on the pic

@viperchannel that's the most rad example. I searched for mechanical failure and tested belts, wheels, bearings etc. from my printer because I had sudden layer shifts in 1-2 layers in some prints and first thought was of course mechanical/electrical issue. After checking everything, I reflashed 1.1.5 and redid the prints with same gcode without any issues (or clunking)

Are you all using UBL? If so you might want to try the very latest (as of a couple of hours ago) bugfix version. There has just been a fix made to the way that UBL handles moves that may have some impact on this (but may not).

I was using #define AUTO_BED_LEVELING_BILINEAR on all versions.

@Jartza I would agree with you, but i am using an Arduino Due (32bits) and the problem is exactly the same. If i get some free time, i´ll start debugging...

I can already tell, that is is 100% caused by the firmware or one of its functions.

My 2.0 was april 11th, the 1.1.x bugfix was april 17th.

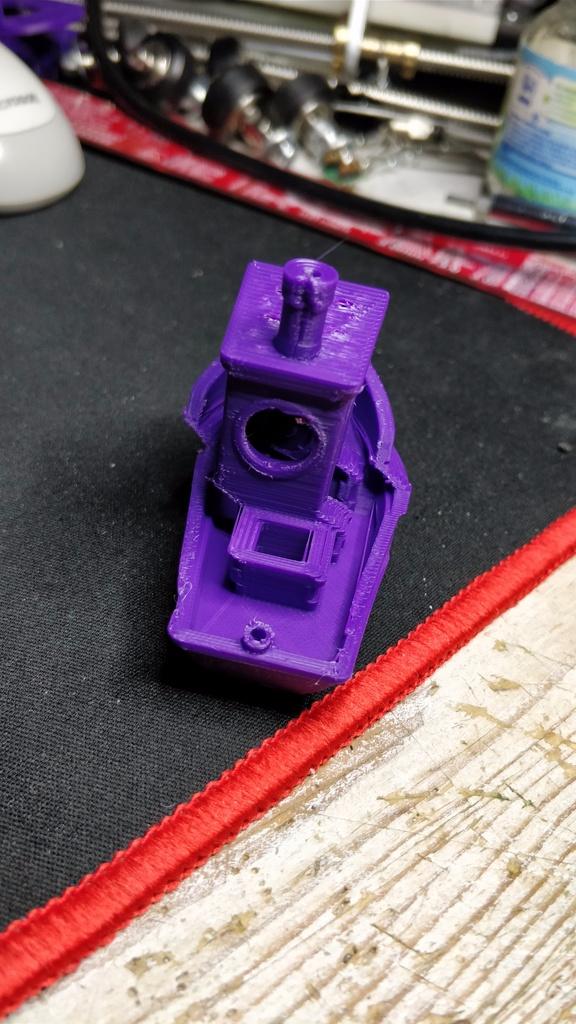

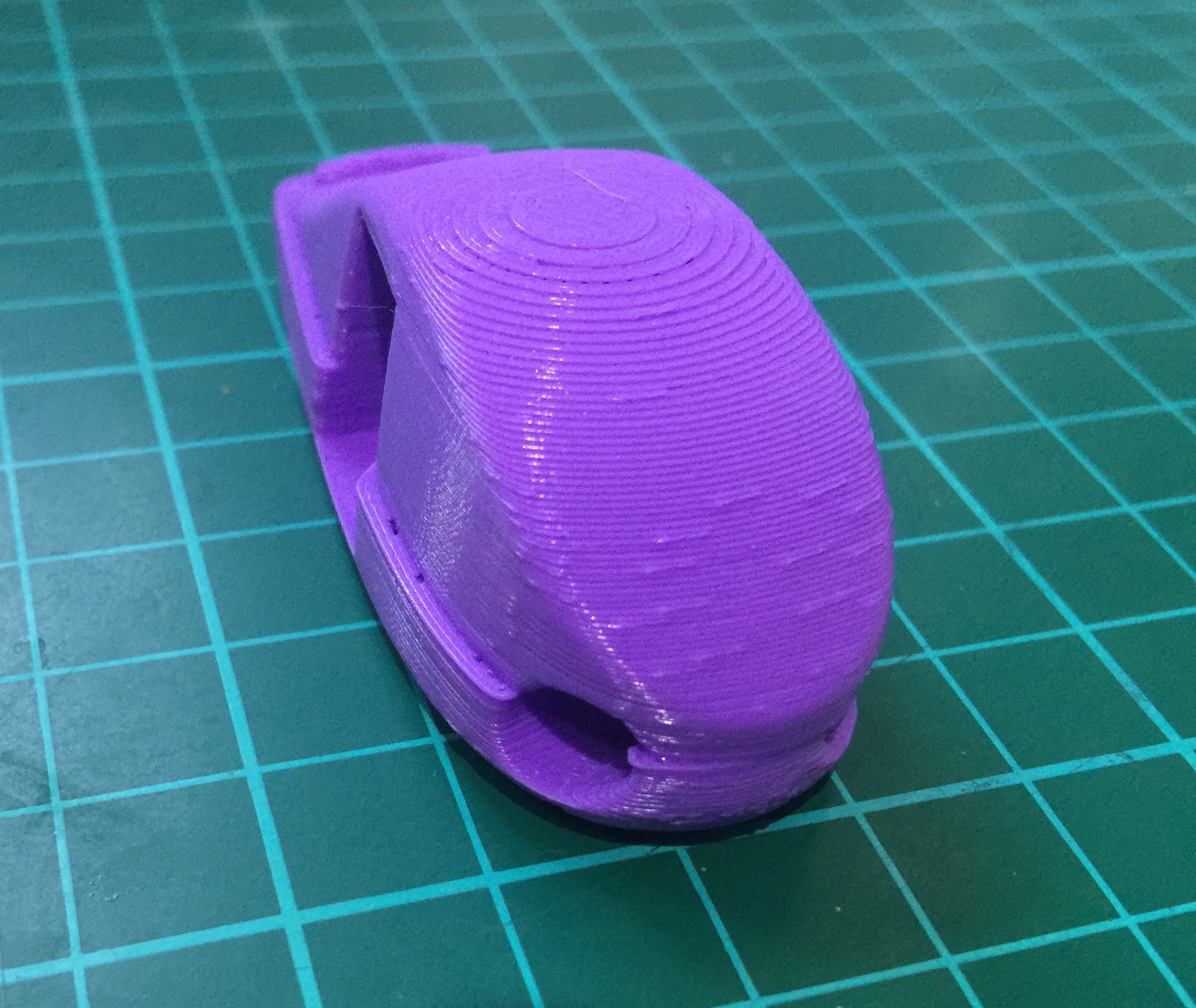

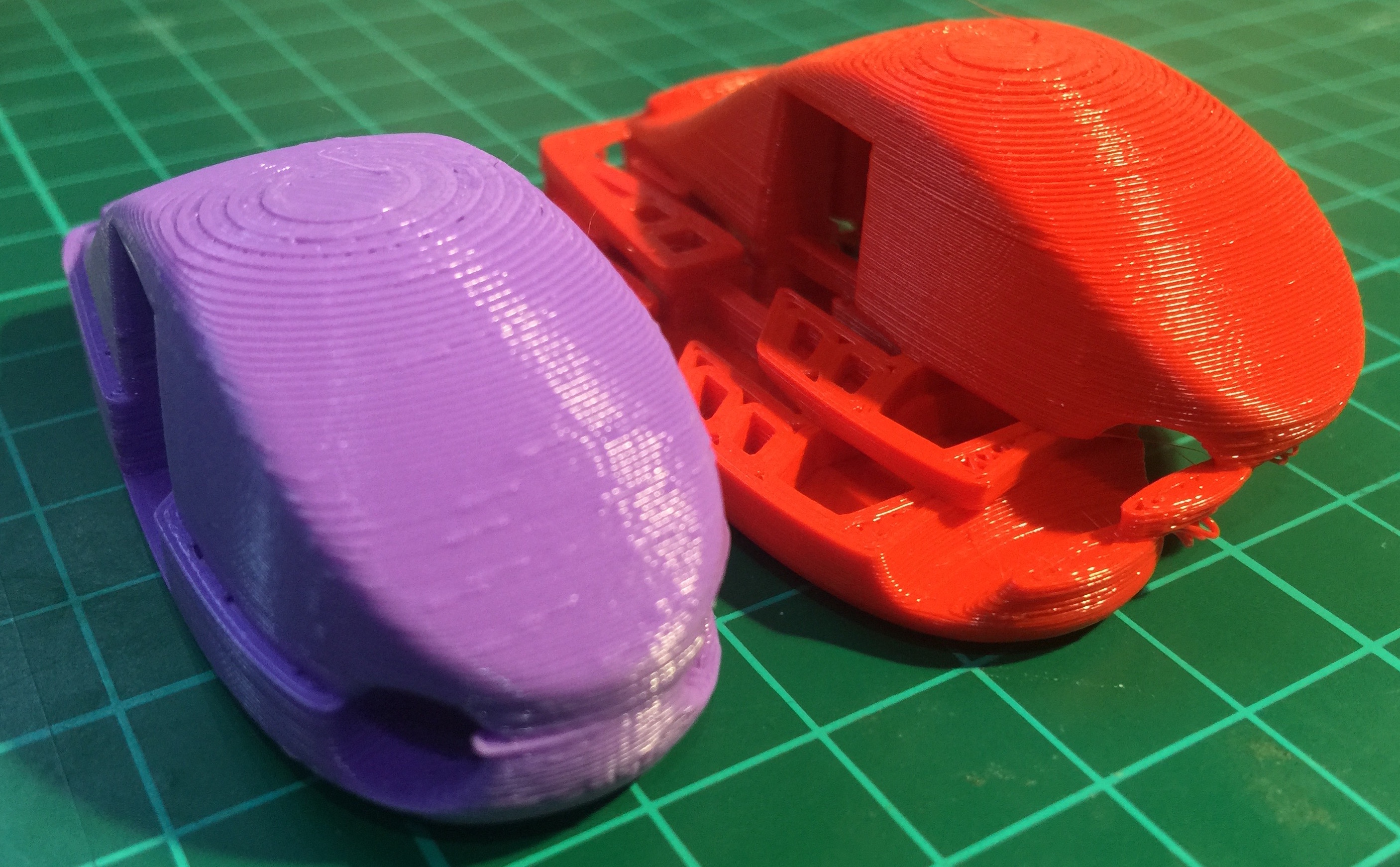

I'm unable to reproduce the issue, unfortunately. I now have a small pile of perfect Benchy boats. I'll see if adding enabled features from your configs causes the issue to appear and if I'm able to get the issue to manifest then I'll be able to start narrowing it down to some point in time, and maybe a specific commit.

bugfix version from january it works fine

I reflashed 1.1.5

Many changes since January (and since 1.1.5), but I'll do a comparison and see if anything stands out. If you can determine the most recent version or commit where the problem is not present, that will be super helpful.

@viperchannel — Have you tested with LIN_ADVANCE disabled to see if that feature is contributing?

@autonumous — Please zip and attach your configurations.

Not yet tested without Lin adv. I will give it a try over the weekend if I find some time.

@thinkyhead by disabling LIN_ADVANCE do you mean completely removing the define, or just setting the value to 0?

Try both, as time allows.

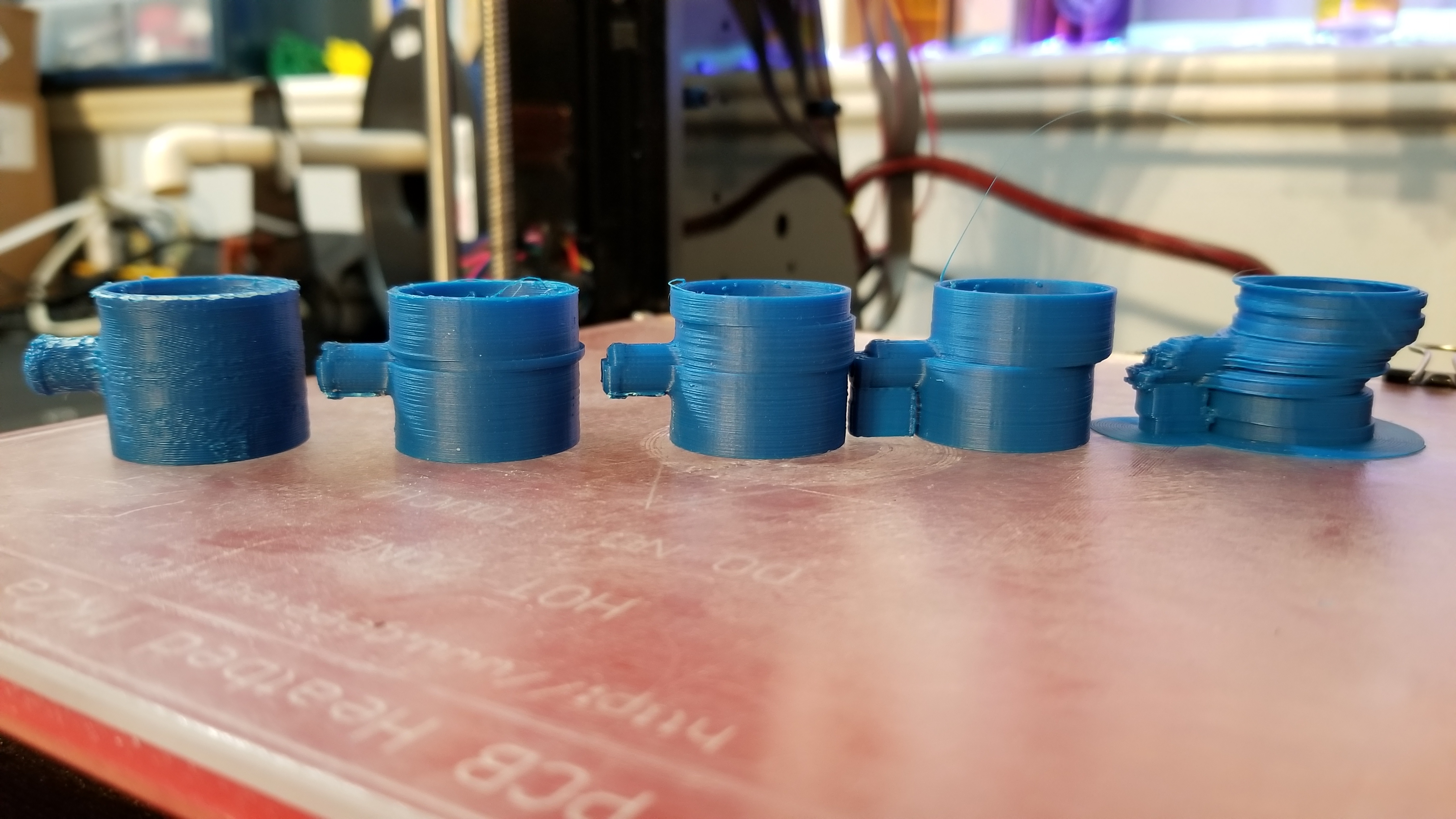

This is definitely a firmware issue, the machine is randomly going full speed ignoring jerk in tight spaces. It just goes to full speed in the Y direction only. I can tell that it happened from the loud "thunk" that penetrates my walls and vibrates the floor. This started happening when testing non linear prints. It wont do it on prints that simply move in straight lines. If the print has a curve, like a pipe or tunnel whos diameter is on the horizontal plane it will do it. I can visually see that the machine it self is moving faster in certain palces than I set it too.

I can send you the file i am trying to print or gCode and my configuration files if you need. There is something about this firmware that it's not obeying speed and jerk limits and it's torque ripping the Y axis out of step.

let me know what you need, I think I can say this is 100% repeatable at this point for me. Even switched out stepper drivers, got tons of them laying around since it's cheaper to buy them in lots of 4. Standard A4988.

I am really going to hate downgrading firmware for now, all these new features are nifty to have.

that explains why I’m not able to reproduce with simple models. Simple cubes came out fine. Just tried a benchy had had a very slight layer shift, whereas the “curvy” model i was previously printing had many many layer shift.

Yep simple cubes come out 100% fine, add curves in tight spaces with walls it goes bonkers.

All this prints just fine on 1.1.8:

I can send you the file i am trying to print or gCode

@Grimshadows — Please do! I would like to test with the G-code that gives you the most trouble — that cylinder, for example.

Some reported they are using the 2130 tmc. Wouldn't they stop the print when overheating and report a driver error?

I have also already done the cooling experiment and switched from a 40mm fan to a 120mm fan and still had the shifts.

(comment deleted after reviewing the thread)

@thinkyhead

Skimmer Intake Venturi.txt

One thing that I did forget to mention earlier because i hadn't noticed yet. Is that this is also making my extruder overshoot too. To the point that it feed enough filament to snap it inside the extruder just after the gear, My extruder is setup to have a ton of torque when needed enough to break the line if it cant pass through (I have only ever seen that with a clogged head, this head is not clogged). The Y axis torque rip and the extruder over shooting filament seem to happen at the same time.

I am going to try printing using another engine, giving Simplify a swing to see if the behavior is Cura related.

Thanks! I will test it later today and see if I can reproduce the issue. I hope that I can, really, because then we'll all be on the same page!

@Grimshadows I "dry printed" the gcode (without filament and temps to 0) and I think that's very good model to find out the problem as the printer really shakes violently with that gcode. Maybe I should test print with filament too 😆

@thinkyhead looks like disabling LIN_ADVANCE either by setting it to 0.00 or undefining LIN_ADVANCE has no effect on this...

@Jartza Those speed settings are really really toned down from the speeds this thing normally runs at. I toned them down thinking it was a speed issue. Doing a run with simplify now at my normal speeds, lets see if it's the slicing engine. i'll give an update in about 35 min. violently shaking is ok as long as im not hitting the chassis harmonic frequency.

I am pretty sure, my motors were much warmer on the bugfix versions than they normally are. If you are switching between versions, take a look at that. I cannon play around this weekend, I have some prints I need to get finished first.

Ok, ran the print in Simplify.... So... it may not be the Firmware after all not one skip. I don't even have S3D setup for fine tuning and calibrated for this level of detail. i mainly have it set up for speed. So there must be something that Cura is doing different with the slicer than S3D. I think I am going to calibrate S3D at this point and run with it. I don't want to give up the features gained in 1.1.8. Still doesn't explain why linear shapes print fine on Cura but not curved objects.

Video Link if your curious,:

https://youtu.be/FyQbR1NfjtM

yes... my tripod is a 3.5 inch VISE.

I did all my files in simply and had the skips. So it's not Cura that causes it

I did notice the big difference is that cura is using G0 commands every few lines. S3D is all G1 commands. I remember that in firmware G0 was being treated like a G1 for sometime did that change? I see why cura is trying to do it, to conserve momentum in a direction it has to go next instead of coming to a full stop; and hit accel and decel constraints. I am wondering if that could be part of the problem. (Sometimes its faster to follow a curve than a stright line)

All my simple test prints seem to be fine. The kids have more benchys, and cubes than they know what to do with! :-)

Just tried to print a whistle from thingiverse, and suffered several shifts.

As always, slicer was S3D. only other big difference is that i’ve just printer at 0.2 layer height, my tests have been 0.3. So will continue to use this same profile/process for other tests and try to reliably reproduce the issue.

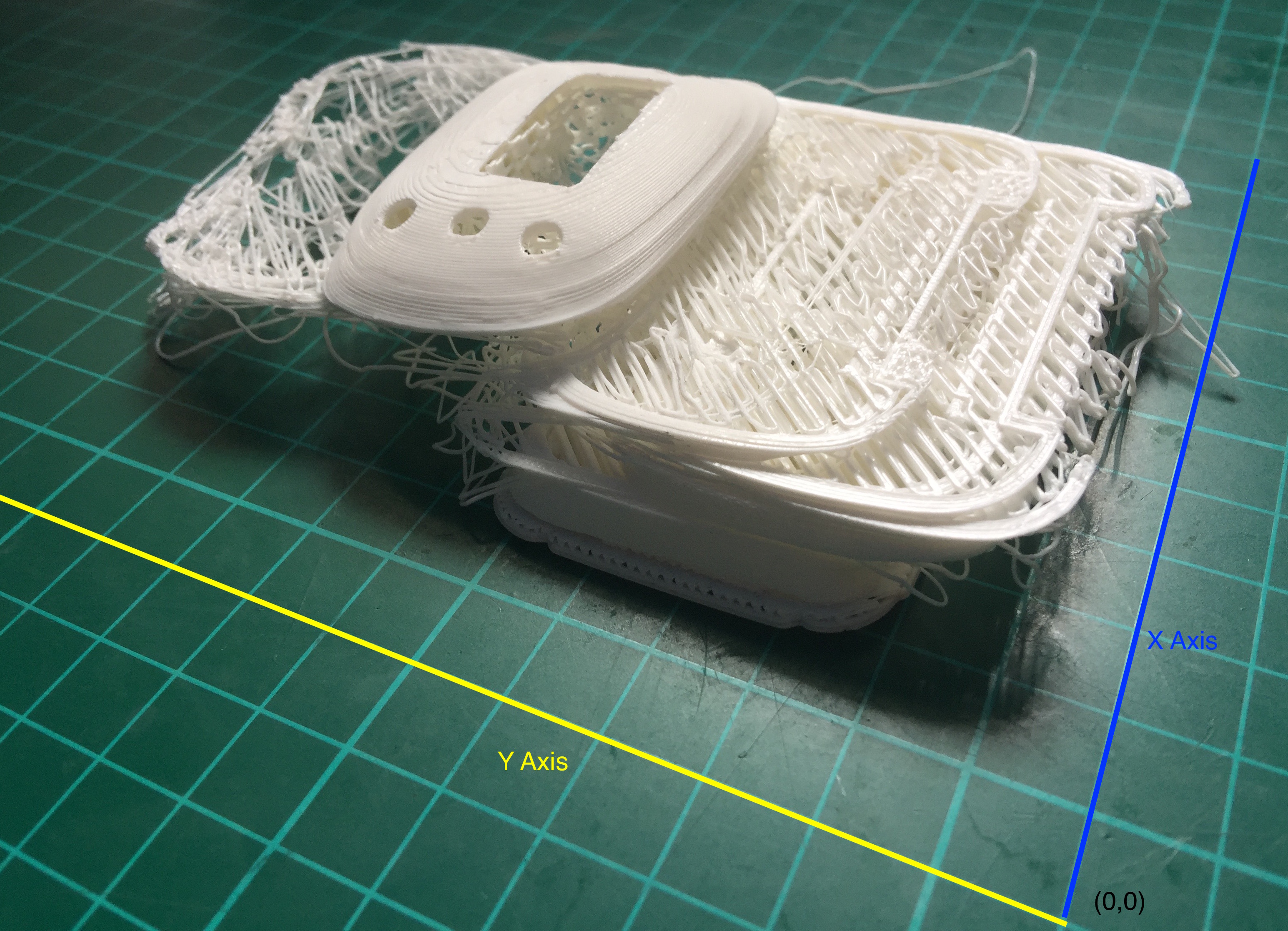

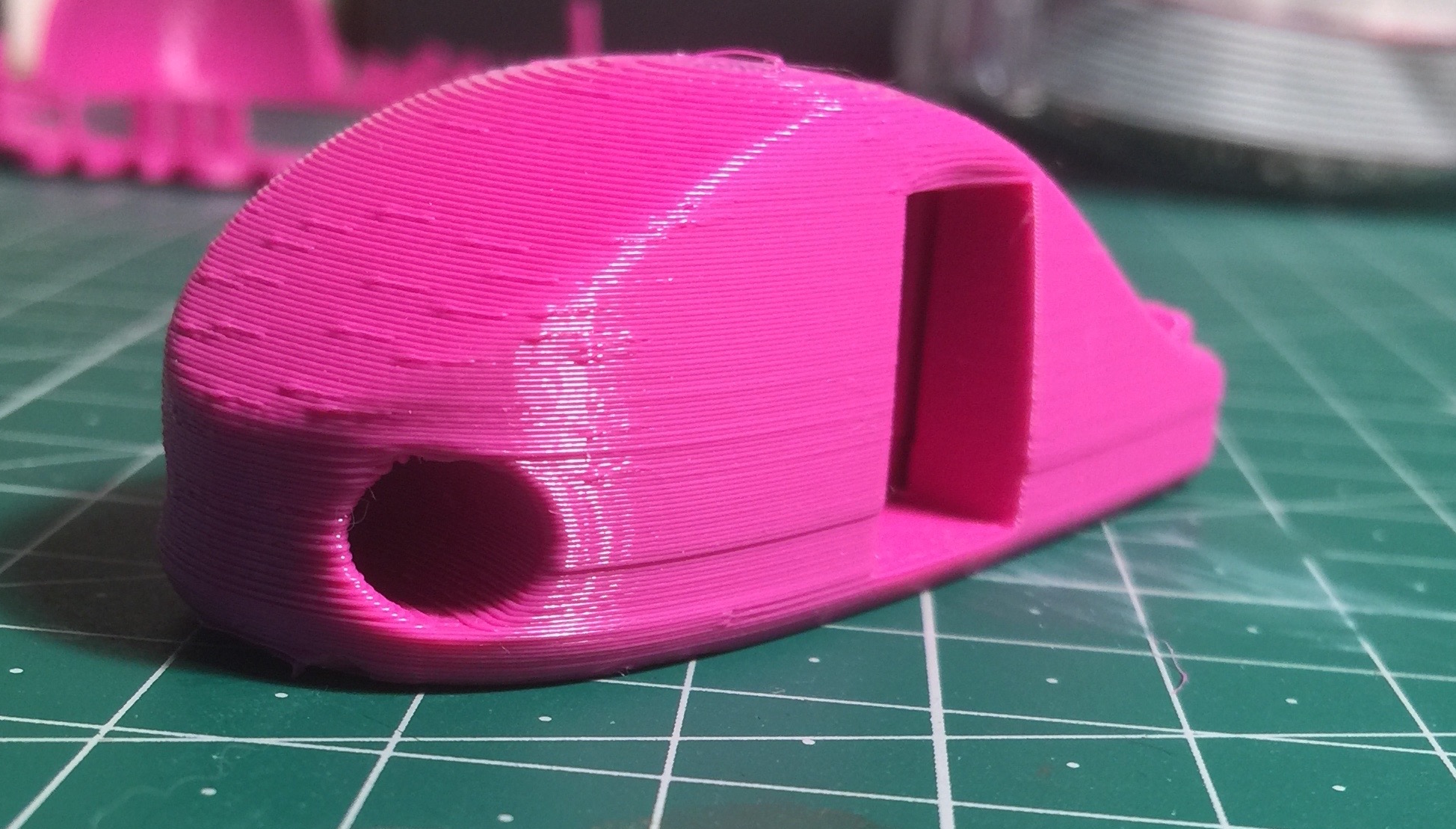

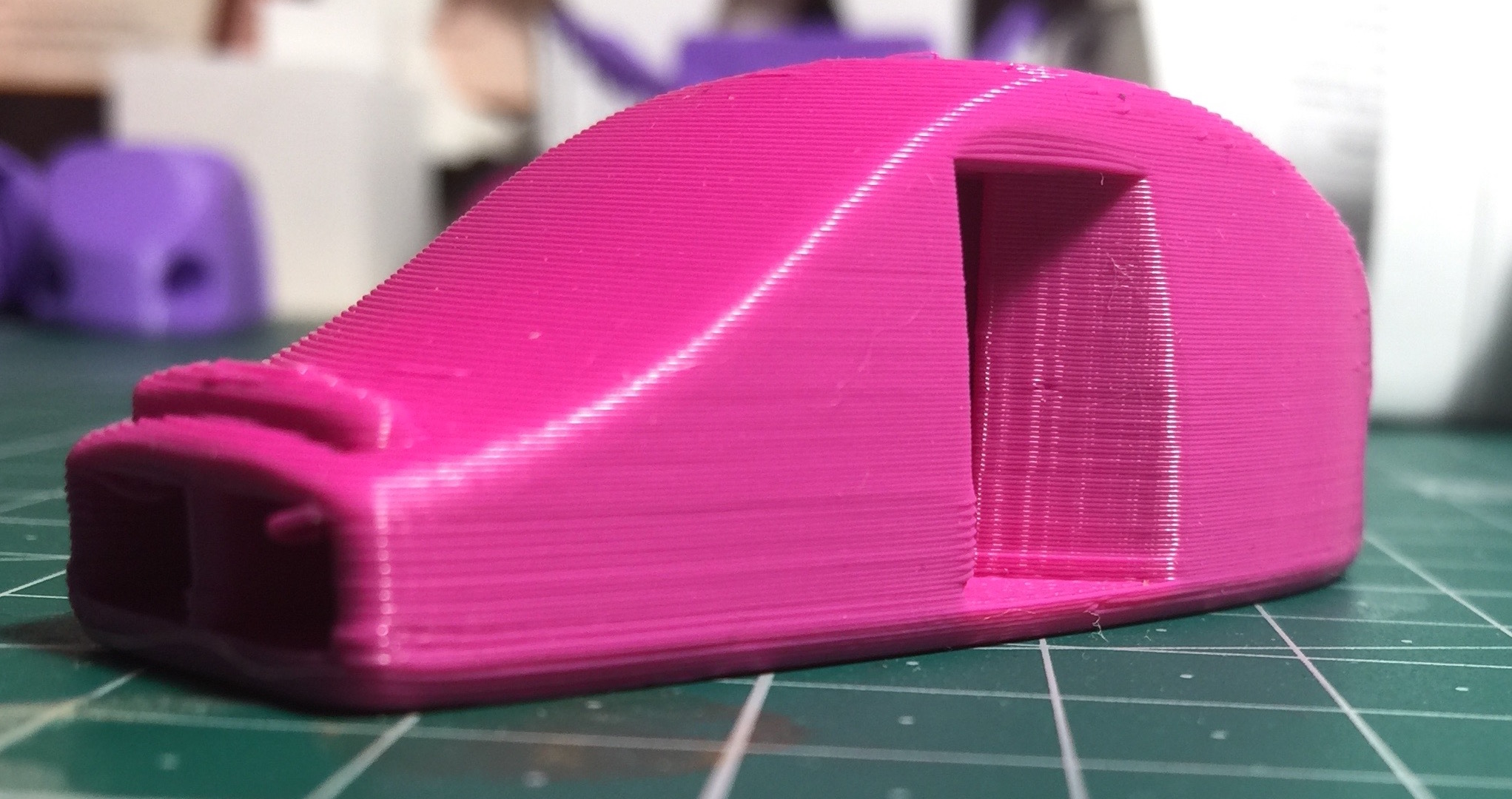

My first print noticing layer shifts.

(These prints were fished from the bin, the support had already been removed

I changed the material, thinking the warping of ABS may have knocked the print head off. Also changed the orientation of the part. Still same result.

This was today. Two distinct layer shifts. all in the Y direction.

I’ve swapped X and Y drivers (A4988) over and restored the same print to see if i get shifts in the X direction or continues with Y, or if it comes out ok.

Will report back once complete. depending on results then, will try different firmware options/versions

Print completed, initially was looking good, but got a very slight layer shift at a higher point than the previous. Still in the Y direction, despite swapping drivers round. Everything else the same. Same code file, (sliced in S3D).

I wasn’t around at the time it occurred, But of the 100’s of prints i've done on this printer over last 2 years, I’ve never ever had layer shift issues..

Next will try with a previous firmware version,

Print completed with no layer shift at all when using a previously compiled 1.1.8

A process of elimination now.....

@autonumous I can see from the pictures you are getting the same over extrision on skips that i am seeing on my prints.

@autonumous Is your gCode using Flips between G0 and G1 commands like mine? Could you post it?

I've reverted certain portions of the planner back to the way they were in 1.1.8 in this branch:

https://github.com/thinkyhead/Marlin/archive/bf1_revert_planner_test.zip

Test with one of the troublesome objects and see if it causes failure. Stop the print as soon as you get any layer shifting to save on material. You can also use M111 S8 to set "dry run" mode, where it won't print, but will just do all the other moves. If you don't see the issue in "dry run" mode but you do in normal printing, that would be another clue.

Dry Run wont work as the skips are sometimes so minute they are not audible. I did a quick print without any real re-calibration. Seems to have fixed the big skips, there were two minor shifts (could be user error, so I will have to retest). I am going to re-calibrate the machine when I get back home from work and try again with this build. Seems to have fixed the glaring skips. The Filament no longer attempts to curl up in the extruder too. I will put the part under the magnifier later and count the layers to see what line of code that relates to. I am still thinking it has to do with those G0 to G1 commands Cura slicer is putting out.

Video of the print

https://youtu.be/LJD0gmED4gQ?t=1729

Link is at the first skip

Dry Run wont work as the skips are sometimes so minute they are not audible.

I see. So you need the object to see that the axis has gotten shifted.

I am still thinking it has to do with those G0 to G1 commands Cura slicer is putting out.

On Cartesians, G0 and G1 are synonymous in Marlin and will produce exactly the same movement. But there might be differences in what the slicer outputs for each one. For example, do the G0 commands in the G-code have a different Fxxx feedrate than the G1 commands?

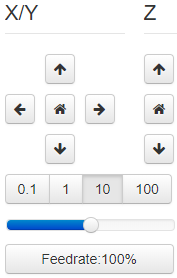

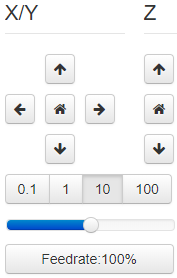

I maybe found out how to provoke this "loud thunk" and, associated therewith, the skipped steps:

In OctoPrint Control Tab, if using following settings and pressing the arrow keys fast in a row, the motors are losing steps:

If I fast press 2 times Y+ then go back to 0 and repeat this process 4-5 times, my hotend will crash into Y0.

This won't ever happen, if I press Y+ slower. It also wont happen, if I alternately press other direction keys, no matter how fast. Only if the same direction key is pressed fast multiple times in a row the problem occurs.

The feedrate is set to 6000 in OctoPrint.

Could be completely unrelated, but maybe it helps.

Did any one tested it with stealthchop off ?? I heared several stories it then stops layershifting. I got also layershifts.I cranked up the current, lowered the speed and stuff like that but it wont help. Also the little 20 by 20 cube after adjusting some things there good now.I got a 80 mm fan cooling the steppers and i got the chineese steppers but the same results as you guys using marlin bugfix 1.1.8 im guessing about 1and a half month old version. And i slice it with S3D. I also got some weird movements between printing

It's not a TMC specific issue.

its the same with normal pululus? well the same marlin i used with normal steppers and it just printed

ok been testing even with treshold of 0 so it goes only in spreadcycle doesnt work also

do you people know any release of bugfix that does work ok???

I suspect the issue is somewhere near the high-speed threshold, such as jerk/acceleration/feedrate being slightly different between firmware versions. The video posted above runs at what I would estimate to be the mechanical limit of the machine, and people above that also seem to be running quite fast.

If it really happens only with complex shapes, maybe the AVR CPU / gcode sender isn't able to keep up and the motion becomes less smooth, causing more vibration and back EMF, overloading the drivers/motors.

Does it also happen when you print really slowly (10mm/s) and with low acceleration (ie. 500mm/s^2)?

I've been running several machines on anything from 1.1.5, 1.1.8 and latest 1.1.x and 2.0.x bugfixes without ever seeing the issue, though I print at 10-20mm/s and with low acceleration.

first layer already thats printing quite slow its the movements between print parts and infills that are tiny

Been experimenting for a while with the same part causing the issues, ran though a set of prints at different speeds. The Left most Is S3D on super fast settings (bordering harmonic resonance) No skips but print quality is basically down the sewer. The next is Cura set to mildly ridiculous speeds; the last is dead slow with all jerk and acceleration down to near minimums. The slower I set the printer the more pronounced it happens.

do you people know any release of bugfix that does work ok???

So far they work great for me, but I haven't used Cura for a while.

I posted a branch in a comment above for testing if anyone else wants to try it out.

I would suggest also testing with an older version of Cura, for example from last year. And start with its default settings.

Just chiming in that I've just finished a TMC2130 build (einsy),everything tuned mechanically. I get the loud "thunk" as well. Running bugfix-1.1.x Seeing these layer skips. I'll recompile with 1.1.8 or 1.1.5 and report back. Slicing with Simplify3D.

Attached is a file I modeled up to test this; seems to cause this issue immediately.

@thinkyhead I cant get S3D to exhibit this behavior. So i have been running with that to get some things done. Prefer Cura, I will do some more testing with Cura at complete bone stock and work up to my settings to see if its any settings issue. I got tons of filament, enough to last me till next year, so I don't mind tossing filament at this. I would like to work with Cura for the quick and easy settings. Also it seems to do a better job with ABS most of the time than S3D. First I am going to switch over to a flying extruder to eliminate Z distance as a possible issue and if it persists I will go to direct drive to see if that is an issue. No skipping in S3D only Cura.

@dammitcoetzee I will run your file in a few to see if I get that with S3D.

I am sorry, for opening this bugreport and then not having the time to test different things. It has been a busy weekend and I have some prints I need to get finished.

The only new Information I can provide is that I don`t think it is related to the S3D Version. Some of my prints with shifts are from files a buddy has reated and he is still using S3D 4.0.0

Are you guys printing via Octoprint or is someone printing via USB or SD card? Around the same time these problems started, there was a new Octoprint version coming out. Maybe the error is there.

We already figured out, it is not a TMC Issue, but we could not narrow it down timewhise. What are the latest bugfix releases you are using that NOT have this problem? Anyone using something newer than my 1.1.8 bugfix from january?

Did someone try the new bugfix that thinkerhead posted here? Any results on that?

Hi!

I got this "new bug" notification because I was subscribed to https://github.com/MarlinFirmware/Marlin/issues/9368 . I temporarily solved my "shifting layer problem" by disabling stealthChop and the 256 steps interpolation. That made my printer (Anet AM8) as loud as is was with the 4988 drivers, but I don't lose steps for now. :|

At the moment I am running bugfix-1.1.x checked out at 05. april ( 98684952e33287008128a551ae6139103740b056 )

I'm wondering if we are seeing a problem with the Stealth-Chop. I'm wondering if when the printer loses position, if it is losing a full step. Can we catch the printer losing 'just a little' bit of position? And then measure how far the layer shifted?

What I'm wondering is if are losing a full step of the motors. And it might be caused because the micro-steps are not powerful enough to hold position?

I don't think so. Someone reported here that he uses A4988 which do not support 256 resolution and not have stealth cop or other fancy stuff.

It's definitely not limited to TMC2130 or StealthChop. My bot uses A4988's, and I get the layer shift issue if I go too much over 1000 mm/s² on acceleration (the printer's fastest "acceptable quality" acceleration is some 3000 mm/s², its mechanical limit is some 6000 mm/s²).

It's definitely not limited to TMC2130 or StealthChop.

OK! But... Are we losing full steps of the stepper motor? If so... That implies the firmware logic is OK, but for some reason we are sending the micro-steps too fast or some how the stepper motors don't have enough power such that they can't keep up. And they lose a step????

Hard to say in my case, but the rattle I hear is very similar to what used to happen before the advent of Linear Advance 1.5, just not as severe. The cause at the time was LA causing the motor to exceed the elsewhere-configured E jerk speed, but LA is turned off on my bot for now while I work on something else. Given that the planner still has a bug or two in how it deals with jerk (see #9917), I guess that's what's happening here and in #10272 and the others with similar probs.

@Grimshadows

I can see from the pictures you are getting the same over extrision on skips that i am seeing on my prints.

I assume you mean the little lumpy bits. These are quite consistent across prints, same places. Not got round to totally removing them, any suggestions?

Is your gCode using Flips between G0 and G1 commands like mine? Could you post it?

Nope, Just took a look at a file, G1’s throughout

Unfortunately, i’ve not got round to performing any further tests, i needed a print doing for a project so stuck with 1.1.8. I hope to be able to test a few things during the week, @thinkyhead will test your branch as soon as i can and report back.

I’m running A4988, as mentioned above, tried swapping drivers round, same issue on same axis (Y)

@viperchannel, Im also printing via Octoprint, will try via the SD also .

So far I have looked at one of the Cura-sliced files, and I noticed that it was changing the acceleration on the fly, first to 2500, then to a very low value — _using the deprecated M204 S parameter_ which sets both travel and default acceleration at the same time.

I'd like to see the same STL file sliced with S3D (that doesn't exhibit the issue) and then sliced with Cura (which does) to see what they are doing differently.

Meanwhile, here's something you can try. Please insert this line and see if it helps:

inline void gcode_M204() {

+ stepper.synchronize();

bool report = true;

…and…

inline void gcode_M205() {

+ stepper.synchronize();

if (parser.seen('S')) planner.min_feedrate_mm_s = parser.value_linear_units();

Here's a branch with these changes already applied:

https://github.com/thinkyhead/Marlin/archive/bf1_synchronize_M204_M205.zip

@Roxy-3D your Theorie is good, but like I said, the 4988 do not support microstepping and the step losses don't happen on previous versions with the same motor current. Since it happens on high and low printing speeds, it could be the data speed or the processing speed, but no idea how to check that

To add a new data point, I've been happily printing with my other printer and seen no skipped steps.

It's a coreXY frame with Archim2 board. So 32bit SAM and TMC2130 drivers in stealthChop and 960mArms.

X/Y max acceleration values are set at 2000mm/s².

X/Y jerk is at 10.

UBL is enabled with fade at 2.0mm.

Linear advance disabled.

Slic3r-dev from a week or two old build.

The branch is (re)based on 5a064d0e94c823de5787105c31c536d5fed7c089 from April 16th.

I'll see if I have time later today to test the cylinder model with my AVR board.

I'd like to see the same STL file sliced with S3D (that doesn't exhibit the issue) and then sliced with Cura (which does) to see what they are doing differently.

@thinkyhead I've been only using Simplify3D and while the gcode it creates does not use M204 or M205, I still experience the "clunks" and problems.

I'm now trying different models to create test print that most often experiences the problem.

like I said, the 4988 do not support microstepping

To the best of my understanding, the 4988 DOES SUPPORT µstepping… see https://www.pololu.com/product/1182 ... I read “Five different step resolutions: full-step, half-step, quarter-step, eighth-step, and sixteenth-step” in the overview…. So @Roxy-3D made a point worth verifying….

@autonumous

I would take a look at Z seam settings, and the speed/distance of retraction. Also Double check your not printing at some wonky half set or some fraction of your actual Z resolution. The calculators at the reprap website will help you with realistic layer heights. ie... for me my real Z resolution is 0.04 or any multiple of that, so a resolution of of 0.1 would not be realistic for me as and I would need to be 0.8 or 0.12.

As far as the issue, I haven't had it creep up on me using S3D, so i have been getting some work done sans Cura. I bit the bullet and tuned S3D for the detail i needed. I am going to revisit Cura after these prints are done.

Someone up a few post back mention EMI as a possibility or Host client lag. I will be changing up a few things to see if maybe Cura is getting behind or overloading the Arduino. I am on a ten foot USB cable so the EMI thing sounds like a good thing to look at. Then again... S3D no issues.

I am running the branch thinky posted.

one thing I did not check in Cura was Z fade.

Sorry, I meant the 4988s don't interpolate the steps up to 256 like the tmcs

Someone up a few post back mention EMI as a possibility or Host client lag. I will be changing up a few things to see if maybe Cura is getting behind or overloading the Arduino. I am on a ten foot USB cable so the EMI thing sounds like a good thing to look at. Then again... S3D no issues.

@Grimshadows I don't even use USB connection currently, my printer is in the other end of the room, I print from SD-card. And I don't use cura, only Simplify3D...

@thinkyhead I've just tried the latest bugfix-1.1.x branch d429d5a but with your suggested updates to M204 & M205 (adding stepper.synchronize();).

The print, was better, but still had layer shifts.

The print, was better, but still had layer shifts.

That's an interesting clue, but still leaves many possibilities open.

The fact that this doesn't occur with 1.1.8, combined with the fact that it tends to occur on curved sections, implicates any one of the changes made to the planner in the last 5 months. So I'll pick a few of those changes and post some test branches with isolated parts reverted. From that process we can narrow down which part of the code needs to be examined more closely.

There are very few differences between 1.1.8 and the current bugfix-1.1.x in the planner/stepper code, but there are one or two that might have some effect. So for our first test, this branch reverts a part of the planner that deals with block chaining:

Please test this branch and report whether the behavior changes for better or worse.

If possible, also check whether the stepper drivers run any hotter when comparing the current code to 1.1.8. Sudden stops and lost steps at random points are a strong indicator that the stepper drivers are going into thermal protection mode.

I'm willing to bet those shifts are are 1 full step on your motors. Can we crank up the power to your stepper motor drivers? Or give the stepper motors more voltage?

So I ran the tests I promised.

1.1.5 and 1.1.8, I actually couldn't get running well. Overall the steppers behaved horribly on them. Not sure why. In fact, at the same current settings I couldn't get them to move well (lots of shuddering and loud noises). I think I may be missing a setting or have my pins.h wrong, but I don't have more time to invest to dig deeper. Today I also tested with the 1.1.x-bugfix and the latest version of the TMC driver, no change.

I installed heatsinks on my trinamics and the steppers and bumped the current up to 1150, a number someone had thrown out in other threads, this seemed to fix it. So for me, I think I have to admit that this problem was mechanical. At least that's what my current round of tests showed. I suppose I need to work on my bearings. However, if I note anything like this cropping up in longer prints I'll report back.

@Roxy-3D The shifts vary. From around 0.4mm to a couple mm. So it is not always just one step. I tried cranking up the steppers untill my motors were at around 60° with the same result. It didn`t help.

@thinkyhead It is not only in curved sections, but maybe it shows more often there. I printed a part which only had straight lines paralell to the X and Y axis and some lines that had an 45° angle and some honeycomb infill and got shifts, but the part had no curves at all.

I don't use them anymore. But if it is a thermal protection problem, shouldn't that been shown as an error message and stop the print when using SPI connected drivers? Some reported they are using the 2130s and have shifts. But the 2130s definitely stop the print when they go in thermal protection.

I have no idea if it has anything to do with that, but I just remembered that I had an additional Problem since I played around with the different versions. I can`t tell on which version it exactly happened, but when cancelling a print via Octoprint, I gut stuck in "cancelling", the printer stopped printing, but kept holding the temp. I had to dosconnect and connect to continue working. Just as an additional clue, maybe it has something to do with all of this.

Does anybody have a file that can reliably reproduce the problem?

Because I need to change my position to Can't reproduce. For me it was a hardware problem.

I just printed a 40x40mm cylinder and it came out better than ever. The printer was cartesian with AVR and TMC steppers on stealthChop.

In my case, the only work around is to not make my belts too tight, to reduce the mechanical load on the motors, but of course that negatively affects print quality if taken too far. The correct tension on belts is such that you should be able to "pluck" the longer side like a bass guitar string, and hear a "note" in that instrument's range. I can't draw mine that tight without causing stalls, even with the motors driven at relatively high current.

Jerk/accel settings that are good for light load probably won't be good for the moderate load that comes with otherwise-properly-functioning printer hardware, and if the firmware's not applying them correctly to begin with, then even light load may still skip.

Increasing drive current helps for some bots, but that makes the machine louder, and isn't good for the driver modules if you don't have a fan on them.

My guess is that @teemuatlut and @dammitcoetzee are experiencing something along these lines.

Oh also, @teemuatlut I was able to reproduce the layer shift with https://www.thingiverse.com/thing:1363023 by the way (it's one of the models I use when recalibrating or dialing in a new filament). My response was to loosen the belt on the affected axis (X), as described above.

I was able to reproduce layer shift with the "Y motor mount" (https://www.thingiverse.com/download:3662264) of this project https://www.thingiverse.com/download:3662264 .

If you print it in a way that the large hole stand verticaly the layer shift always occures at the high, where the large hole closes and the two small holes begin.

Minor correction: even loosening the belt isn't enough. I've got mine pretty much on the edge of acceptable, but still getting occasional layer shifts.

Having the same issue with simplify 3d and a prusa i3 clone. Skipping started with the new bug fix. I currently have active cooling as well so its not overheating.

Sorry to come back with bad news. Did manage to create this issue the other night. Unfortunately I can't share the parts since they are for work. I could print a plate of parts separately no problem. Every time I put them together I'd get this layer skipping. Simplify 3d. One thing I'll note in these models is that the skipping really seemed to reliably happen after 10-20 layers.

There are very few differences between 1.1.8 and the current bugfix-1.1.x in the planner/stepper code, but there are one or two that might have some effect. So for our first test, this branch reverts a part of the planner that deals with block chaining:

Please test this branch and report whether the behavior changes for better or worse.

If possible, also check whether the stepper drivers run any hotter when comparing the current code to 1.1.8. Sudden stops and lost steps at random points are a strong indicator that the stepper drivers are going into thermal protection mode.

(and I'm going to keep posting that until someone tests it and gives a report.)

thanks @thinkyhead for your branch, I’m going to try this today, just diff’ing the configs now. Will report back with progress.

I look forward to your report, whether the reversions to 1.1.8 code help or not. The planner / stepper methods are just the first thing to rule out. It could certainly be due to code changes elsewhere, such as in the Temperature or LCD code, so if the lost steps still occur we will want to look at those changes next.

Tried @thinkyhead “bf1_revert_planner_test" firmware, disabled LIN_ADVANCE, used same gcode as previously, still have a very slight layer shift in the same direction. Nothing like i had previously seen in the earlier prints. I can’t really say if this is better or worse than the previous test (adding stepper.synchronize();))

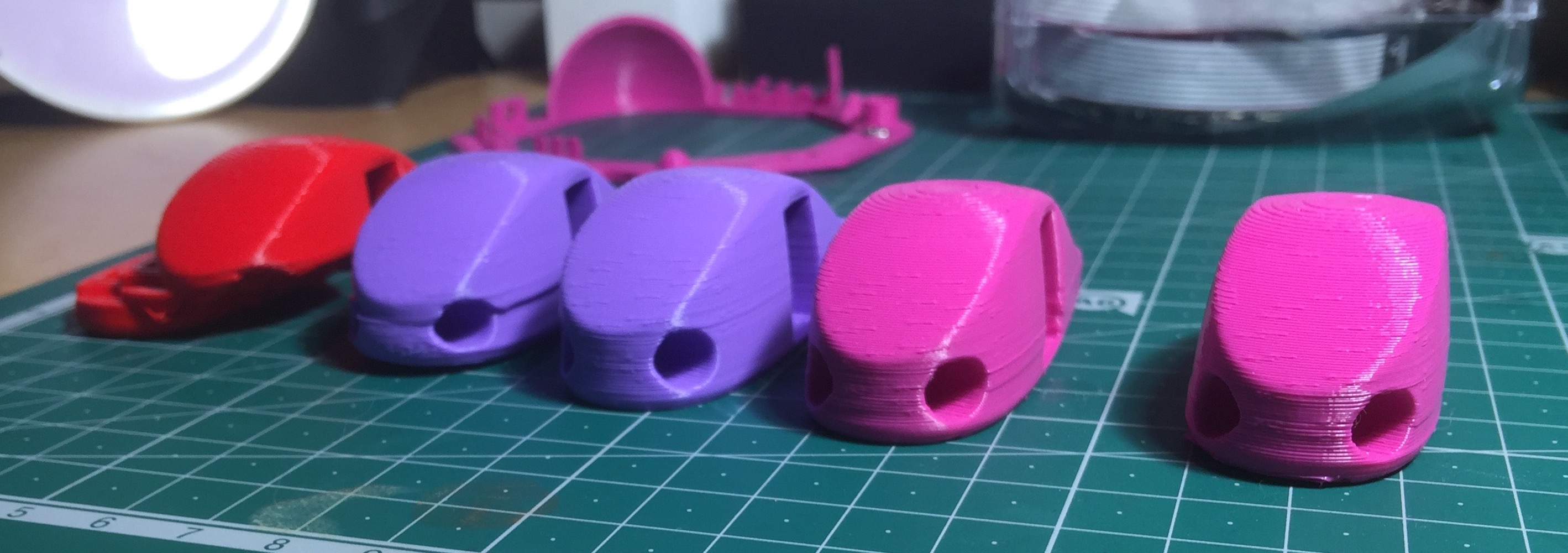

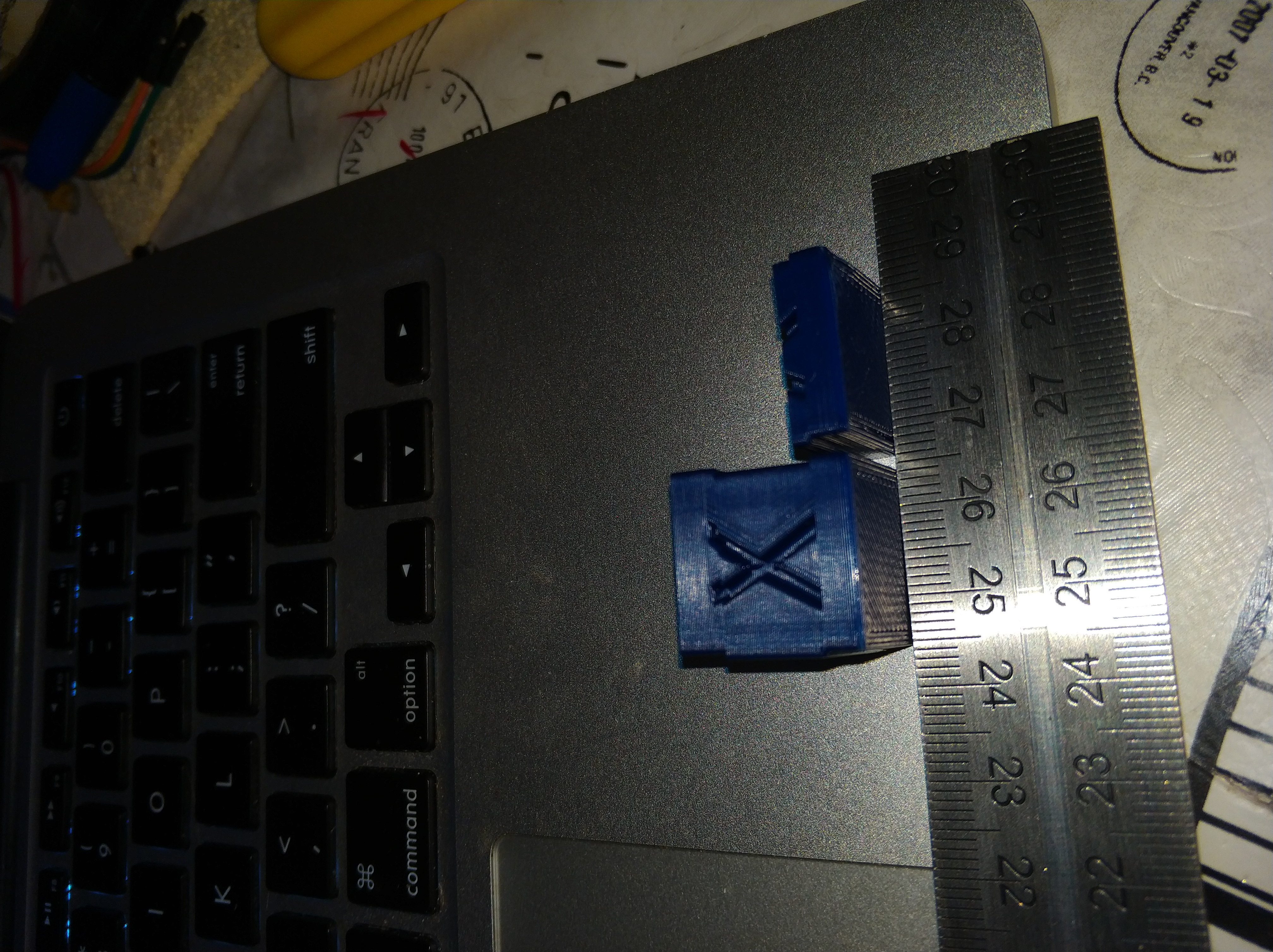

Complete line up of prints, oldest (left) todays right)

The trouble is, it just seems too intermittent, i’ve been printing other things with the most recent bug fix, and i’ve not seen anything like i was seeing originally last week. I’m seeing very minor layer shifts now in the Y direction. Previously (<1.1.8) i swear, never had any layer shift issues, but maybe i just never printed anything that would have ‘triggered’ the issue.

I originally assumed it was something on my machine, or something i had caused (my own tweaks etc), but was strange coincident that somebody else had experienced the same issue and logged a bug report around the same time.

I just wish i could find a small quick print that had the issue.

Looking back over the thread, one thing i’ve realised, my shifts have not been so dramatic since swapping the driver over, maybe i’ll swap back again..

I’m assuming that all these layer shifts are due to lost steps, so they will always be in the direction away from the moves that trigger them. In other words, if the bed is moving backwards when the glitch occurs the layers will be shifted towards the back of the bed.

The thing about spurious lost steps is that we would expect them to occur at random, so there would be equal amounts of shifting in both directions, at least with symmetrical objects like cylinders. But even with cylinders the layer shifting is mostly in one direction, and more concentrated on a single axis. With a perfect cylinder (vase mode being ideal) we should expect to see all the glitches averaging out if the issue is purely software-caused. But even with a perfect cylinder, shifts still seem to be concentrated on a single axis and in a single direction. I’m not sure what that adds up to, but I’m sure it is relevant.

For the most problematic objects, try rotating them 90 degrees on the bed as part of the testing, to see if the error moves to the other axis. Then try rotating them 180 degrees to see if the layer shifting switches its direction. Finally, see if there’s some way to get the slicer to do perimeters counter-clockwise instead of clockwise, to see if that has an effect.

Hey troubleshooters…. Can I assume everyone has tested both _with_ and _without_ bed leveling, to determine whether that is involved? And, you know, have you also tried turning off _other_ features to see if the problem goes away (or doesn't). It would be very helpful to know what minimum set of options is required to trigger step loss.

Hey troubleshooters…. Can I assume everyone has tested both with and without bed leveling, to determine whether that was involved?

@thinkyhead ahh, fair point, I only tested with bed leveling (bilinear) enabled. I have some time tomorrow to run test prints, I'll test without leveling tomorrow. For now, I'm back to 1.1.5 because that's least problematic for me (and zero layer shifts, even if I go with higher acc/jerk values, only ghosting increases).

That last time I got a layer shift, bed leveling was disabled (not even compiled-in).

And… SD printing or host?

And… SD printing or host?

I'm always printing from SD, printer is too far to use USB 😄

Host. My bot lacks LCD/SD.

Using octopi, SD support was not enabled but LCD.

Not been able to do any further testing, but to answer the above questions,

All my prints have been via octoPi, but with SD support compiled in. Also using UBL bed levelling. I’ve only used S3D. I have not tried printing objects in different orientations, i will as soon as i can.

Cool. I downloaded and sliced the valve with S3D and Cura, and if I can reproduce the issue, I should be able to zero in on the day that the issue first started with no more than 7 tests, since 1.1.8 was published just over 120 days ago.

Host. My bot lacks LCD/SD.

Thank You!

You know what we need to do??? We need the configuration.h files from everybody that is seeing layer shifts. We should be able to see where the configured options overlap.

Here's mine: marlin-configs-20180430.zip

Here's mine: marlin-configs-20180430.zip

@autonumous @Jartza @dammitcoetzee @Grimshadows (we have @viperchannel's config!)

@ikarisan I printed the AM8 Y motor mount on the very latest bugfix-2.0.x commit and saw no skipped steps.

@VanessaE I've also printed the CtrlV V3 test piece without an issue.

I printed only round object the last few days and had shifted layers in every print. please find attached my configs from bugfix-1.1.x

I do not have bedleveling at all, print is always through USB from S3D.

I am using 1.1.6 now where everything works fine.

Here my configs from 1.1.x:

Archiv.zip

Apologies for delay, attached are my configs

Also, I’m currently printing in a different orientation, will report results

I just got a shift in the x-axis while printing. I did notice two warnings when I compiled bugfix 2.0.x. One was comparing an unsigned integer to signed integer in stepper.cpp. The other was a pointer initialization type error in one of the libraries. An improperly initialize pointer could cause strange things...

So following on from above, print finished, was all looking good went out of the room and came back to find a layer shift. Again in the Y direction, despite the model being rotated by 90 degrees.

Interestingly I did swap the drivers (A4988) back, (X<->Y). I would say the layer shift is certainly more pronounced in the current configuration.

autonumous - rough idea of which layer the shift occurred? Mine is in the x-axis and is suspiciously close to layer 256.

I've printed the very same whistle as @autonumous and try to push a bit the speed to check if this was a driver temperature issue(Sliced with simplify3d). "Unfortunately" no shift on my print. I do use the bugfix 1.1.x with most of options enabled (SD, Proprietary screen code, Power resume, Emergency parser, Advanced pause ....) and my printer is an anycubic i3 mega with TMC2208. One HW mod I've made is about driver cooling with better fans. Not sure this help.

What I do know is that my modified firmware version has been used by another i3 mega owner and he did see shifts after hours of print (like 8 hours of a 10 hours print). The randomness of the issue looks really related to SW/HW mix.

Is there an easy way for us to compare temperatures of steppers/motors between two firmware versions when printing the same gcode?

An IR Thermometer does the job pretty well for the stepper motors. But it is not reliable for the hotend.

@rgw78 - To be honest the it really does seem to vary. I’d say the lowest i’ve seen is around ~5mm /layer 25. The most recent was about 14mm/layer 70.

I’ll try to measure the heat of the motors next

On my prints it varies. Same object printed several times. Once it happened between the first and second layer, on another it was perfect untill around layer 250. So it is totally random

To everyone who are experiencing this issue, please test the following versions. Neither I nor thinkyhead can currently reproduce the issue which makes it very hard to debug.

It doesn't help us much if all we know is things work in 1.1.5 or 1.1.6 as it has been a very long time ago and there have been many changes since. We need you to help us narrow down the commit(s) that introduced the issue.

April 1st Commit 885ad70c8b7c6e53948624f0c41bd9ad842f4c96

March 1st Commit b86125c6d6e2c7b1a9c5120a625647c0e3a4a99d

February 2nd Commit 68cff5f2451ef10314face0c73bfcb3d4285425e

Jan 1st Commit 949191215ba9fbbd6b2fd0d45a3e01c348235483

I tried the revert planner firmware and can report the issue is still present. Before I used 1.1.8 with A4988 drivers. With this combination I had no issues. The issues started when I installed the TMC2130 drivers. At the moment I am running them at 875mA, CoreXY setup.

I’ve read through this thread again and again, really seems odd, the symptoms are similar for all (layer shift) but no consistent way to reproduce it. As I’ve said before, I’ve not eperienced one layer shift issue on this printer and printed much larger (30cm high) prints in the past with no issue. Im sure thats the same for others. For me the issues just seem to be random, not at any particular layer/time in to the print. I can’t even say when the issues occurred, i only noticed it within a day or so of the start of this thread, and had printed anything for a while before hand.

The other day when swapping my drivers back to their original position, the results were more pronounced, shifts of multiple mm, more like the prints originally reported. I’d not see anything quite that bad, since swapping the first time around, maybe a mm or even just a couple steps.

Today i just checked the voltage of the drivers (A4988), all 5 drivers were set to ~0.36V. I recall setting these when i built the printer in 2016. I compared these to the online build docs, they state 0.55-0.6V !! Not sure if these were later revised, i’ll look through the forums. Else not sure why i set them lower than the recomended values

Anyway I’ve tried setting them to a higher value for now just trying ~0.500v and replicating the above print. I’ll also keep an eye on the motor temps (starting temp 25 degrees)

How hot is too hot with the steppers, "I normally go for too hot to hold"?

I’ve read through this thread again and again, really seems odd, the symptoms are similar for all (layer shift) but no consistent way to reproduce it.

Today i just checked the voltage of the drivers (A4988), all 5 drivers were set to ~0.36V.

I think you can tell we are not claiming the firmware does not have a bug in it that is causing the layer shift problem. And further complicating the diagnosis is the fact Marlin supports so many different hardware configurations that are user controlled.

I haven't seen the problem. But with that said, my configuration is different than any body else in this thread. And I do something most people do not do: I power my stepper motors as hot as I can. I crank the adjustment voltage on the stepper drivers as high as I can and still hold the stepper motors with my hand. (I am saying _IT IS_ uncomfortable to hold my hands on the stepper motors)

The reason I run my stepper motors so hot is I've never had one fail (yet) and for me... it helps when an edge curls and the nozzle runs into it. I've lost position too many times because a curled edge catch on the nozzle. That still happens... but not very often.

I think it would be helpful for a few people in this thread (that can do it) to crank their stepper motor power way up. Let's see if that helps....

Cranking up did not help. I tried it until my motors were at 65C. With my January firmware they run with 45C and lower voltage without shifts.

OK! Thank You for confirming that!

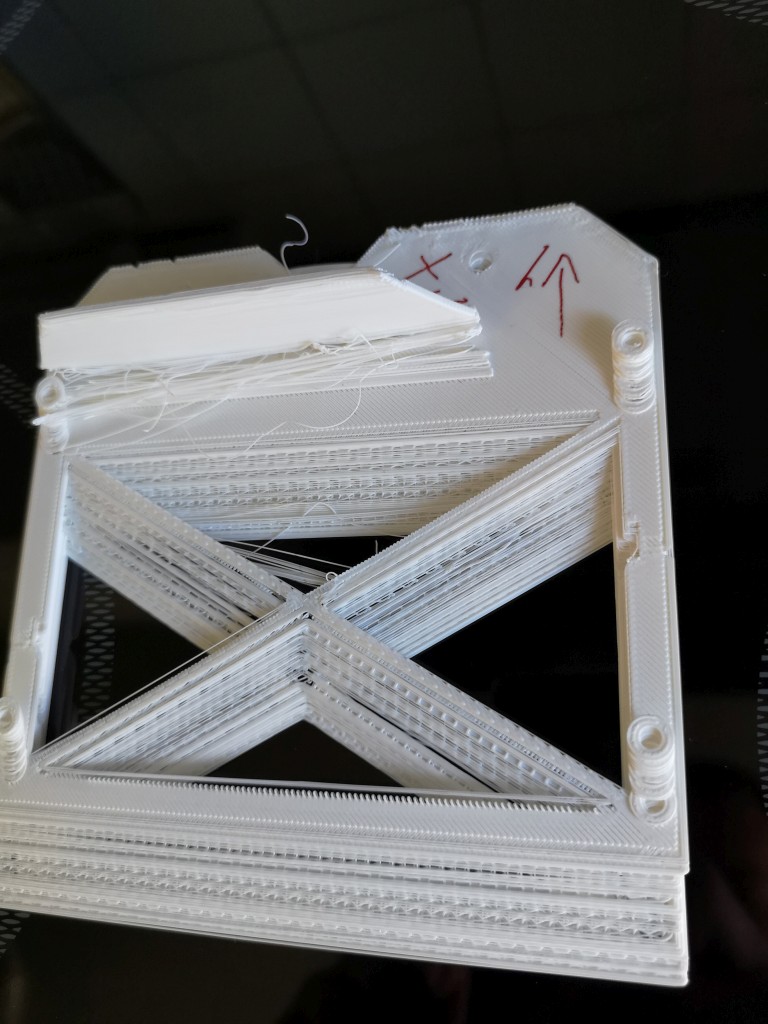

Yesterday I flashed version 156bd28160384c351830c6a3c1ae096cedb13ca3 , resetted my EEPROM and reconfigured it to the values I used before the flash. Using the same values for acceleration, jerk and stepper current I got this result. :( :(

And the motors are rattling like they lose dozens of steps.: https://youtu.be/f19ILbUh5SQ

@ikarisan can you try the commits teemuatlut linked? February 2nd seems like a good starting point. I don't think there is a way out of bisecting the issue.

oops thought i had posted this yesterday..

so after upping the driver voltage to 0.5v...

Initially, print looked better, but on closer inspection, very slight layer shifting. i’ve checked previous prints just to confirm i’m not being too critical, I’m not.

.

.

I’ll try the above commits as soon as I can.

what kind of nemas you using because i have my steppers at 875 chineese ones nema 1.7 amps not stock anet ones

those are 1.2

i do admit ive modified my chineese steppers

by grinding of the top pcb paint to get to the heatpipes for a cooling block

I made an observation today on this topic with my Duplicator 6 running on bugfix-V2.0.x from May 11th (commit 7d78f34) which could be of relevance. The printer was printing fine for about 86 layers, but then I could hear the "thonk" sound, so I checked the print and saw a layer shift on the X axis (about +1.5mm). I immediately paused the print in octoprint and re-homed XY, as I was having success with this method before to save the print when I once accidentially blocked the printhead and it missed steps.

But then when I resumed the print today after re-homing XY, it did not continue in the correct position, but continued at the wrong, layer-shifted position instead. I guess that is not how it should behave?

I started getting this too (occasional random Y axis shift) after upgrading to latest 1.1.x-bugfix and it happens regardless of stepper current. There are no mechanical issues either.

I'm now testing with a replacement driver on that axis just to exclude that as a possible source.

_Everyone please test these._ Once we know roughly when the issue starts, we'll post 4 more. Then 4 more after that, until we know the precise day, hour, and millisecond when the issue began.

April 1st Commit 885ad70c8b7c6e53948624f0c41bd9ad842f4c96

March 1st Commit b86125c6d6e2c7b1a9c5120a625647c0e3a4a99d

February 2nd Commit 68cff5f2451ef10314face0c73bfcb3d4285425e

Jan 1st Commit 949191215ba9fbbd6b2fd0d45a3e01c348235483

I am currently not at home, so I cannot tell you the exact date. But I am running a January Bugfix without any shifts for several days and several kilos of filament. The problem does not exist in my Jan build. I will tell you the exact download date when I am back home. It must be from around January 23rd.

Currently experiencing similar issues on my CoreXY printer running 2.0.x on an AZSMZ board. Latest 2.0.x shows the issue, so do versions going back to Feb. Seems like the printer makes clunking noises on sharp curves with many short segments, and sometimes this is enough to cause layer skipping. Enabling bezier jerk control from the newer versions makes the clunking worse. Very noticeable at high speeds (150mm/s), but the clunking persists even at slower speeds (70-80). Changing accel seems to help, but jerk has no effect. I've attached a zip with a section of a print that shows the issue, as well as my configuration.

I'm printing from SD, but have noticed that in the sections making the clunking noise, the printer sometimes moves slower than normal - is the buffer not being filled fast enough?

config and gcode

Hummm... Just a question ... Does anyone here have skips using a printer based on a 32bit controller ? ... Or the skips are exclusively related to AVR based motion controllers ? ... The cl cl cl cl cl noises could be caused by the planner buffer being empty. I have myself seen this issue when debugging on debug builds, but never on production builds of Marlin, but i run a 32bit controller...

Maybe something is eating too much cycles...

Wild guess... Maybe it is UBL or ABL related ?

Please, to help @thinkyhead , test the builds he posted, post the results, and also mention _the controller being used, and if you were using ABL/UBL , linear advance and its settings_.

This issue is one of those Heisenbugs for me, so I have to bow out of any tests. :confused:

(you know, the kind of glitch that only happens when you're not watching for it and/or not ready to log/backtrace/etc.)

@ejtagle The AZSMZ board I'm using is a 32-bit board, originally designed for Smoothieware. I'm not using any form of software bed leveling, which is why I'm confused why the much faster 32 bit board would be struggling.

@alexyu132 It could be a bug. Marlin uses a "cooperative" approach between the multiple tasks that it has to run to fill the Planner queue, so if anything is taking too long to compute, or if anything is waiting too much time before yielding to the next task, the planner queue could become empty. And that is bad, because the motors could suddenly stop, leading to lost steps.

I have never seen this problem happen to me (yet). There is a very strong ongoing effort to optimize the code to make it run faster, but it is not ready for primetime yet (https://github.com/MarlinFirmware/Marlin/pull/10688) ... Of course, anyone here that wants to try it, of course it can. Maybe it solves the problem, maybe not, maybe has other problems. But it would be great to find out the cause of the layer shifts, to be absolutely sure we have addressed and fixed them

Here's a video of the rattling vibration issues I'm having.

Given that enabling bezier jerk makes the issue worse in my case, it does make sense that something could be taking too much CPU time. @ejtagle I'll test your optimized branch to see if that fixes the issue.

@ejtagle The optimized branch seems to run very erratically on my board, as if something is causing the planner to freeze for extended periods of time. Some sections run normally, but others are extremely slowed down. At times it looks like the print head is snapping to a position rather than smoothly accelerating. Do you know what could be causing this behavior?

I also noticed that it hangs before printing when configured to home Y before X, but switching to normal homing order solved this.

As promised:

Built from jan 24th works,

using ABL, on a ramps 1.4 with and without Lin Adv without any shifts.

Going to test the later ones now

alexyu132: I have also seen this behaviour. I´m not sure if it is related to the junction deviation algorithm (it can be disabled by making sure JUNCTION_DEVIATION is commented out in configuration_adv.h= , or a bug in the planner itself, or maybe it is a "feature" of the planner changes.

There were changes in the planner that restrict the acceleration when the moves are composed by a lot of consecutive small movements, trying to keep centripetal forces small.

I found out that many slicers use some kind of "vibration" mechanism to fill small walls, and the new code would probably think they are 180 degrees zig-zag movements, so they are slown down quite a bit (the older algorithm does allow such movements without slowing down... As you see, there are some things still pending to be tuned or fixed (but you gave me valuable information on the homing order... ;)

What i fear with the current branch (not the PR) is that using UBL + all the other goodies is overloading the processor and there is simply not enough processing power to keep the planner queue full sometimes.... That new PR you tried has several speed optimizations, so there is hope to fix this problem

I'll try disabling junction deviation and see if that fixes the issues.

My printer doesn't use any bed leveling features so those aren't compiled in on my build. With them disabled in the config, would they still cause a speed penalty?

@alexyu132 No, a disabled feature in the config should not cause penalty. Features disabled at runtime (using Gcode) may cause penaties though

Behavior seems unchanged after reverting to normal jerk.

Having the same issues described in this thread on a CoreXY with TMC2130 drivers on bugfix-2.0.x, no "fancy" features enabled (lin advance, bed leveling, junction deviation, etc.). Trying older builds at the moment, starting from https://github.com/MarlinFirmware/Marlin/commit/f8227abf1cbb87231eef2412ddf35d94a4379dd1, though struggling to get the configuration working at the moment (X and Y don't work properly for some reason). Will update if I get the configuration working.

A few days ago, someone posted a new 1.1.8 Bug Fix version specifically for the CR-10 3D printers. I managed to get this version to work, but experienced the same exact layer shift issues as everyone else here. I am currently using the high-torque motors from E3D, with the vref pots on my MKS Base V1.5 board set to 1.12v (I still don't know if this is correct) on my multimeter. Motors run fine, and they seem warm but not hot to the touch when printing.

I have a version of Marlin 1.1.8 (no idea which dev version this is) that runs perfectly fine with no layer shifts. Once I switched back to this version, my layers shifts were gone. With the brand new 1.1.8 Bug Fix for the CR-10, the layer shifts only seemed to happen on the Y-axis, for whatever that's worth.

Could not get my configuration to work for https://github.com/MarlinFirmware/Marlin/commit/f8227abf1cbb87231eef2412ddf35d94a4379dd1, so decided to try https://github.com/MarlinFirmware/Marlin/commit/0945674ba237747756b85b96ffc05ffc7eb63dce (2015-04-15) instead.

Configuration changes to make it work:

- had to disable SD support (SD init error)

- decreased current to X and Y to 800mA (from 1000mA as I had it on latest), otherwise sensorless homing would kick in right away in one direction, drivers (with cooling) would immediately overheat in the other, movements would be erratic

The stepper motors also ended up being significantly cooler (from ~75C to ~40C) and the estimated printed time (sliced in Cura 3.3.1 and printed through repetier host) was considerably more accurate.

Unfortunately still ended up with a random layer shift. Trying at https://github.com/MarlinFirmware/Marlin/commit/8922b56b588bc9c54c3526986b8a056564828abd now.

Tried https://github.com/MarlinFirmware/Marlin/commit/8922b56b588bc9c54c3526986b8a056564828abd (2018-03-15), had to switch X_MIN_ENDSTOP_INVERTING/Y_MIN_ENDSTOP_INVERTING to false on top of above changes. Also failed with a random layer shift, moving to https://github.com/MarlinFirmware/Marlin/commit/c49844df66213dfab5dbcc12d772f0a4279f2141 (2018-02-15).

I can also report that layer shifts only occur on the y axis. Never on x

Also had a layer shift towards the end with https://github.com/MarlinFirmware/Marlin/commit/c49844df66213dfab5dbcc12d772f0a4279f2141, moving to https://github.com/MarlinFirmware/Marlin/commit/571ca728246447d99663e0f23f71cdb2765b69b6 since that seemed to work for other people.

edit: for some reason with https://github.com/MarlinFirmware/Marlin/commit/571ca728246447d99663e0f23f71cdb2765b69b6 (or commits around it), homing works but nothing else... going to give this a little break as I'm starting to lose my patience.

I have a 2.x version from 15th February. There are no issues. I was using it for several months without any problems. After updating a few weeks ago i got this issue.

@thinkyhead maybe this helps

@smoki3 do you know if your version was before or after https://github.com/MarlinFirmware/Marlin/commit/c49844df66213dfab5dbcc12d772f0a4279f2141 ?

It looks like my build is before this commit. This commit is from 16th my working build is downloaded on the 15th

Can confirm that February builds seem to work more smoothly than the latest. Currently running a build from Feb 9 (not sure of the exact commit) and the roughness is much less, though still present occasionally when there are lots of tiny segments.

Just remembered that I have a board running an old bug fix that has the shifting issues: downloaded feb 17 @ 6:05PM, if the folder info is correct. I had swapped that board out because I thought it might be a bad MEGA at the time.

Tried https://github.com/MarlinFirmware/Marlin/commit/d6e29e95974dd3368abc638a87b79ab9e8a41e78 which ended up in another layer shift towards the beginning.

I then tried https://github.com/MarlinFirmware/Marlin/commit/34160806c0e7c199d11c06b56722ee500d97011d and happy to announce it doesn't seem to have the issue!

Both of these commits are within a day of each other (2018-02-01): https://github.com/MarlinFirmware/Marlin/compare/34160806c0e7c199d11c06b56722ee500d97011d...d6e29e95974dd3368abc638a87b79ab9e8a41e78

This is obviously not entirely conclusive as I've only been doing one test per build, but hopefully someone else can confirm.

I'm going to take a little break from this now, feed my trash can and enjoy my printer for a little bit ^^

@grownseed Thank you very much for your debugging! If someone on 2.0 experiencing the problem can confirm that 3416080 is working this would be really helpful. I haven't really noticed anything that could cause shifts in the commits, but I am not really familiar with the code base.

Has anyone tried if the layer shifts are present when compiling without LCD support?

Looks like the latest commits of ejtagle's Marlin fork (with the planner optimizations) no longer have any layer shifting for me. Movement is much smoother even in areas with very small segments.

@alexyu132

Which version are you referring to? Daily Bug-Fix? Where can I download this version to give it a try?

Sounds like…

- The issue arose some time in February, probably between Feb 1 and Feb 15.

- The planner refactoring work from @ejtagle (#10688) is fixing the issue.

We hope to have most of #10688 merged in the next day or two. Meanwhile, feel free to test that branch, which is posted here: https://github.com/ejtagle/Marlin/archive/bugfix-2.0.x.zip

I tested 16f92dc, which includes #10688, with three prints today. Two came out well, but with the other one I was getting massive layer shifts (3 shifts in just 5 or 6 layers).

I won't be around for about a week so I can't do more testprints right now to verify the effectiveness of 16f92dc.

One thing I noticed was that when printing, the printer sometimes seems to stall for a brief moment in the middle of the line, which also resulted in small blobs on the print surface. I especially noted this when printing surface areas with layers in a 45° angle/diagonally to XY, but I also see those blobs on the outside walls of my prints in X or Y direction, so I suppose it stalled in random areas during the print.

I have Linear Pressure Control and Bilinear Auto Bed Leveling with 4x4 gridpoints activated in my config. I could do some more testing in about a week with those features disabled if that helps with narrowing down the source of the layer shifts.

I also am experiencing that brief stalling, that originates vibration and blobs.

I had reported it at #10688 and it still happens now that that PR was merged to bugfix-2.0.

It happens (at least with AVR boards) if LIN_ADVANCE is enabled, even if with no ABL, bezier jerk control disabled, ENDSTOP_INTERRUPTS_FEATURE enabled... I have been playing with the configurations and for as long as LIN_ADVANCE is enabled (even if set to 0), there is brief staling.

@FiCacador : LinAdvance will be fixed ... ! ... But probably there will be a reimplementation to make it compatible with Bézier curves. Just allow us a bit of time, so things settle a bit ... That thread nearly ended in a disaster: Luckily, everything was explained, the merge took place. We know there will probably be some things to be fixed. But trust me: The planner and stepper are at least 10x improved in performance.. ;)

i am very new to printing and i am facing this layer shift issue too.

i am on 1.1.x-bugfix . how can i solve this issue?

Checked out fresh 1.1.x-bugfix, which - from what i can tell - includes the planner refactor/optimizations. The blobs are still present, without LIN_ADVANCE. But more importantly, there are sudden super-jerky Y moves on short segments, that sound as if they'll tear my belts to shreds.

Bezier jerk disabled, 8-bit AVR.

Edit: tried with 2.0.x-bugfix too, with that one, i was occasionally getting odd stutters and jerks even when homing. Not quite sure if that was due to my config, though, as i've never used 2.0.x before.

@orcinus — Yeah, I merged the equivalent changes from #10688 into the bugfix-1.1.x branch about 11 hours ago (1pm US central time) and I did my best to get the exact equivalent to that PR, but it's always possible I let a typo fall in.

Since that PR didn't get extensive testing, it's also possible there are unforeseen side-effects of those changes, which are quite sweeping. But right now it's vital for us to keep bugfix-1.1.x and bugfix-2.0.x as close as possible until we get 1.1.9 released, and we very much want to know if it helps with the layer shifting, so I couldn't let the changes wait once I allowed them into bugfix-2.0.x.

Since we're making you and other users the "canary in the coal mine" on these changes, please proceed with caution and stick close to the power-switch to avert potential damage!

What we really need now is to get in-depth analysis of the behavior following these changes and find out where the edge-cases are. If you're seeing better behavior in bugfix-2.0.x versus bugfix-1.1.x with the same configuration then I'll look closely again and make sure they have perfect parity. I basically did a full paste of stepper.* and planner.* so they should match almost exactly.

And then also compare with yesterday's bugfix-1.1.x to see where it behaves better and where it behaves worse. Though I have a client breathing down my neck, I will do my utmost to examine the acceleration and jerk behavior and make sure anything that got broken by the refactor is fixed as soon as possible.

As an aside, do make sure that ENDSTOPS_ALWAYS_ON_DEFAULT is turned off and that M120 is not being used anywhere, just in case endstop noise could cause an axis to stop. I suspect no one has this problem, since it would cause _massive_ layer shifts — often several centimeters at once. But best to eliminate it as a potential contributor.

I don't know if it could help, but i use this version of Marlin 1.1.8 bugfix : commit e596931aac0c8204f3e42847081a4fece644b8e4 Date: Fri Apr 6 00:30:50 2018 -0500

On a AM8, with TMC2130 (SPI, 24V, spreadcycle only) on X/Y/E, RAMPS 1.4, babystepping, filament change, FULL LCD, SD SUPPORT. I print between 80-120 (infill 150), accel 1500/travel 2200, jerk 15. bltouch with AUTO_BED_LEVELING_LINEAR (before AUTO_BED_LEVELING_BILINEAR without shift also)

And I have any layer shifting with this version (so i will wait before updating).

I can provide my configuration*.h if it could help

I still got a layer shift on latest 2.x! I have bezier jerk enabled, LIN_ADVANCE disabled.

Anyone else?

Everyone please ZIP up and post your configurations. We would like to compare them to see what you all have in common. You can also try disabling optional features to see if the layer shifting goes away. Maybe someone will discover that a certain feature is the cause in that process. We also posted links above for branches that you should test for us so we can figure out when the issue started. If you know anyone else with this issue, pass on those test branches. We think the issue started in the first half of February, and are reviewing commits from that period, but if we can narrow it down to a specific day with your help then we can solve this thing a lot faster. Thanks!

The other cause could be an specific driver... So please, also post the driver model your are using for axis (TMC23xx, TMC21xx, TMC22xx, DRV88xx, A4988 ... )

configs.zip

I using TMC 2130 on X an Y axis

No more layer shifts for me on the latest 2.0.x with the planner refactor merged. Bed levelling, linear advance and bezier jerk are disabled:

marlin-conf.zip.

I have tried this build multiple times, pushing the speed up and no layer shifts (I do have some blobs but I'm ruling other issues out first).

I have TMC2130 drivers on all axes, all stealthchop (hybrid mode disabled), sensorless homing. Do let me know if you need any other information.

Since layer shifting is mostly on the Y axis with moving beds (the heaviest load) we are beginning to suspect underpowered or poorly calibrated TMC2130 drivers. However since this isn’t affecting 1.1.8 we think it could be due to changes in the TMC2130 code or configuration defaults too.

Marlin.zip

x and y tmc2130 standard marlin

@thinkyhead There have been no changes to TMC2130 startup parameters between 1.1.8 and bugfix-1.1.x. We've also had people with Allegro drivers reporting the issue. So while certainly not impossible, I just don't know what we would have changed with TMCs that might have introduced this.

Maybe I can add a little to what @thinkyhead is saying. Now I remember I also started to have layer shift in the Y axis, in probably January or February. They were very suspicious. But at that time i was playing increasing printing speed, so my first suspect was the driver. At that time I was using A4988 drivers for all axes except the extruder (that was a DRV88xx)

After a lot of investigation, and following several online guides with no apparent success, I began suspecting the driver was not reaching the calibrated maximum current, took one of the drivers, reverse engineered the circuit and compared with the datasheet.

I found out that (and this applies to all drivers) that all drivers use a resistence to measure motor current. In the ones I had, that resistance was not of the value that the popolu original design was used.

That changed value resulted in a complete change of current scale.

Chinese manufacturers, in an attempt to make easier to adjust driver current with the preset potentiometer, changed the scale so full clockwise rotation of the calibration potentiometer resulted, instead of a 2A peak motor current (as the original popolu design) just 1A of peak current.

And that makes an incredible difference.

knowing that, i just set the potentiometer to the maximum value, and layer shifts disappeared.

My rule of thumb: If the motor does not heat, raise current!!

If you have A4988 or DRV8825 stepper drivers that you can test, we would be interested to see if it fixes the issue for anyone.

After reviewing commits in February, the most likely change I can find so far seems to be from February 3. Please test Marlin from Feb 1 and then Feb 4 to see if one has the issue and the other doesn’t.

I’m offering a US$100 bounty to whoever can determine the exact change that raised this issue.

@thinkyhead I'm on a coreXY and I was getting layer shifts on my TMC2130 set to 1000mA on both X and Y. In more recent builds (April and May, before the planner refactor), I also noticed that the drivers were heating up considerably more than with previous builds (getting a lot of temperature warnings, almost only on Y), and so did the motors. Builds from before April (sorry haven't had time to narrow that one down) and the current build don't have that problem. I'm wondering if the layer shifts people are reporting are sometimes caused by issues with the drivers themselves, and sometimes by this bug (which in my case I'd narrowed down to a few commits on Feb 1st), compounded with recent changes which are making the drivers and motors work a lot more.

As i told previously, this could be a hardware issue. As you stated, the Y axis is the heaviest one, so it requires quite a bit of driver current. In my case, layer shifts happened not at the beginning... At the middle of the print. The reason was that at that height the tip crashes with a big lever formed by the piece that was printed, and a lot more of torque is required to overcome that extra resistence. Just raising the current solved all the problems (I know, it´s very hard to measure...)

My motors were not even warm before; I raised their current (from ~750 mA to ~1.2A), making them quite warm (around 54°C as measured with a thermocouple stuck into the divot in the center of the exposed back end of the rotor spindle). I have not seen any more layer shifts, at least not below 120 mm/s. A4988 drivers all around.

@ejtagle I use it on a core XY. The X and Y axis have the same load. I also tried to increase the motor current but this doesn't help. I also printed ultra slow for a test.

Just my thoughts: It it possible that MINIMUM_STEPPER_PULSE have an influence? I know for example that DRV8825 doesn't work with MINIMUM_STEPPER_PULSE 0 on 32bit boards.

What i also recognized, that i had to update the TMC binaries with the update.

I think a hardware issue was the first thing suggested but what makes it suspicious is users can go back and forth in commits replicating the issue.

We just need to reliably narrow down on the specific commit(s).

just thinking along any one got the layer shifts also on 24 volts ???

I’m going to postulate that it’s a combination of underpowered steppers with something we did that increased torque at the jerk threshold speeds during direction changes. That would explain why we see this effect multiplied in curves. The reports of extra hot motors is interesting, and maybe that could also be related to some change in our acceleration and jerk code that causes increased torque and thus increased back-current.

So far I haven’t seen any changes that would directly affect acceleration and jerk, but the Feb 3 changes that I’m asking you to rule out did introduce a new variable passed to the planner: the millimeter length of the move. And this value is then used in place of a calculated length. It’s really very minor, so if it can be ruled out that would be helpful.

Again, $100 to whomever discovers the exact point in time where the issue began, as a small token of gratitude from the RepRap community. So far our best guess is “some time in February.”

wel as far i know most for example anet users get really hot motors because there lighter than the standard nemas 1.7 A i hear that alot they try to cool it etc

wile i got a home build and uses the nema's 1.7 a the only get hand warm

Where can I find the February builds? I will try to narrow it down to an exact date. I have all my prints done that have to be done and have some spare filament to test and finally I have some days off from work.