Marlin: [FR]: show CPU usage on LCD / how to debug stutter at high speed

it would help to show CPU usage time % on the LCD,

to get a sense how much more speed, etc is still available

All 13 comments

The MEGA 2560 is already under a lot of strain.

This may work for 32 bit processors, however I don't see this as being useful

I'm afraid we cannot show "CPU load" on the screen.. Marlin runs on a micro-controller.

😆

so when printer is stuttering at high speed, how can one tell apart:

a) is it planner queue overflow?

b) is it octoprint serial link underflow?

c) there is no more time left in CPU loop?

Regarding the way to measure the load:

1) MEGA 2560 has 2 timers, right?

2) then I presume it would require minimal extra CPU load to measure loop time?

3) finally there must be a way to differentiate "free vs busy" measured loop time, correct?

Usually the speed is set too high.

Or the belt is looser than it should be.

Or too much weight on the hotend.

Or a worn out drive belt and / or drive pully.

I have tons of things enabled on my system and stuttering is never an issue. (Although, it's not a delta) This 8-bit microcontroller is actually doing quite a bit...seemingly all at once.

@Andrei-Pozolotin I understand the desire to see how much of the CPU is not being used. And there may be ways we can get that number. But there is probably a more useful number (or bar chart) to display. I think it would be valuable to see how many stepper motor buffers are queued up and waiting to be processed. As long as this is 4 or 5 deep, we are in no danger of running out of work to do (and stuttering).

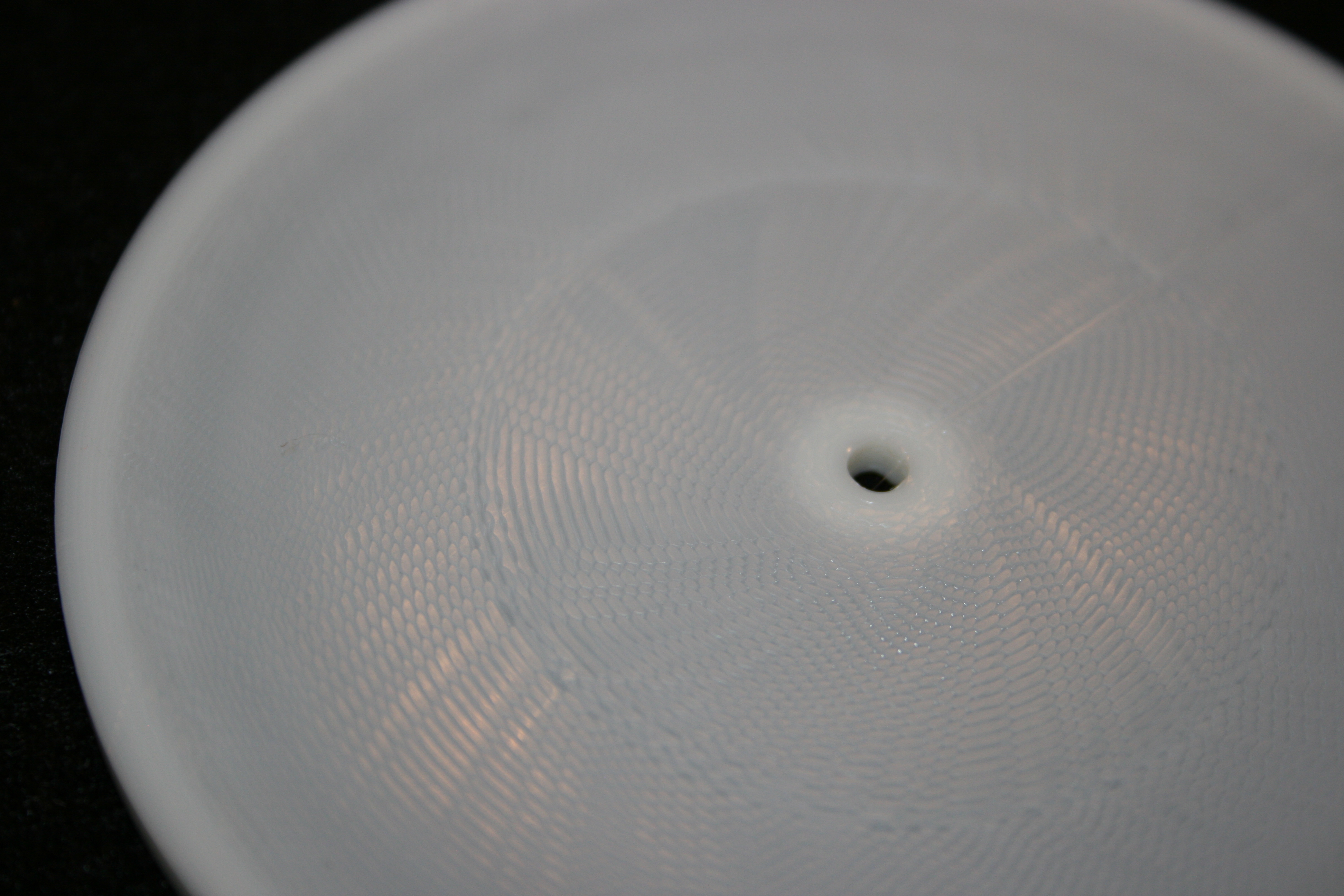

I actually have some code that displays a nice bar chart on MAX7219 8x8 LED Matrix. http://www.ebay.com/itm/MAX7219-8x8-LED-Matrix-Modul-Dot-Matrix-Module-for-Arduino-Raspberry-Pi-MF-/182291658276?var=&hash=item2a716df624:m:mmRWGGyUDu52cCH26Q9wl2g

I've been using it as a debug tool to give me lots of status LED's I can toggle on and off. But It is kind of fun to watch as a print is going to see how full the stepper movement buffers are. I'll probably add the code soon to display that bar chart along with other status indicators for the printer. If you are willing to spend $1.83 and order one... I'll post the .SCAD files to print a nice bracket to hold it (along with debug and reset switches) on your printer.... It probably wouldn't be that hard to add a separate bar chart on it to indicate free CPU time. And temperature stability... And filament usage speed... etc. etc.

@Tannoo Let me twist your arm to order one (or two) of them too... For sure, you will have fun messing with it. But it is a very useful debug tool.

@Roxy-3D thank you for the idea.

I am not sure: why bother with extra display device?

since there is already 22 x 5 LCD in the printer, would it be easy enough

to add a "debug screen" entry to the standard LCD menu,

which would display last X seconds averages for MIN/MAX values of these buffers?

?

@Roxy-3D I've already got a few extra MAX7219's lying around. I'd love to do this!!! :P

I am not sure: why bother with extra display device?

Well.... Remember who you are talking to... I wanted lots of extra debug LED's I could set or reset as the firmware did things to help me debug difficult problems. I wanted the LCD Panel unaffected by debug activity. So that is why it happened.

I am not sure: why bother with extra display device? since there is already 22 x 5 LCD in the printer, would it be easy enough to add a "debug screen" entry to the standard LCD menu,

Yes... In your case you have enough extra space you could do it without gooffing up the normal display. So, maybe the first thing to do is get the Stepper Motor Queue depth plotted on the MAX7219 displays. And... Once that is working for everybody we make a small change to do the same thing on 5x22 displays instead.

@agaskins Here is the .SCAD file for my Max-7219 on a FolgerTech i3-2020. Obviously your machine is different, but you can probably make use of it if you wanted to mount a Max-7219 on the printer.

translate([0,0,25])

rotate([180,0,0])

corner_reset_switch();

module corner_reset_switch()

{

difference() {

union() {

cube([105,71,25]);

translate([97,22,5]) rotate([0,20,0]) cube([15,49,25]);

}

translate([0,0,25]) cube([200,200,200]); // shear off extra from rotated matrix mount

translate([5,5,-.01]) aluminum_frame();

translate([31,30,-2.5]) cube([36.5,39,24]); // Cut off extra material under push switches

translate([71,30,-2.5]) cube([30.0,39,24]); // Cut off extra material under power switch

translate([41,49,-.2]) switch_body();

translate([58,40,-.2]) switch_body();

translate([58,59,-.2]) switch_body();

translate([63,25,-.01]) rotate([0,0,0]) cube([10,10,20]); // for push button switch wires to get in

translate([83,47,-.2]) cylinder(r=3.15, h=50, $fn=45);

translate([90,58,14]) rotate([0,90,0]) cylinder(r=3.5, h=40, $fn=25); // hole for power cord to come in

translate([90,65,5.5]) rotate([0,90,0]) cylinder(r=3.5, h=40, $fn=25); // hole for power cord to come out

translate([106,28,18]) rotate([0,-45,0]) matrix();

translate([95,20,-10]) rotate([0,0,0]) cube([5,15,25]);

}

mouse_ears();

}

module aluminum_frame()

{

difference() {

union() {

cube([21,70,21]);

cube([120,21,21]);

}

translate([7.5,-.1,15.01]) cube([6,55,6]);

translate([22,7.5,15.01]) cube([72,6,6]);

}

}

module switch_body() {

difference() {

cylinder(r=12.7/2, h=30, $fn=50);

translate([6,-10,0]) cube([5,25,30]);

translate([-6-5,-10,0]) cube([5,25,30]);

}

}

module matrix() {

translate([0,0,0]) cube([45,34,12.5]);

translate([-15,8.0, -7]) cube([25,17,14]);

}

module mouse_ears() {

difference() {

union() {

translate([0,0,25 -.55]) cylinder(r=15, h=.55);

translate([107,0,25 -.55]) cylinder(r=15, h=.55);

translate([122,23,25 -.55]) cylinder(r=15, h=.55);

translate([122,70,25 -.55]) cylinder(r=15, h=.55);

translate([0,70,25 -.55]) cylinder(r=15, h=.55);

}

for(i=[0:45:360]) translate([0,0,-.1]) rotate([0,0,i]) translate([6,0,24]) cube([5,1,5]);

for(i=[0:45:360]) translate([107,0,-.1]) rotate([0,0,i]) translate([6,0,24]) cube([5,1,5]);

for(i=[0:45:360]) translate([122,23,-.1]) rotate([0,0,i]) translate([6,0,24]) cube([5,1,5]);

for(i=[0:45:360]) translate([122,70,-.1]) rotate([0,0,i]) translate([6,0,24]) cube([5,1,5]);

for(i=[0:45:360]) translate([0,70,-.1]) rotate([0,0,i]) translate([6,0,24]) cube([5,1,5]);

}

}

funny: disabling of FASTER_GCODE_PARSER removes much stutter (except at small radius)

before

after

That is surprising ! 😱

@Andrei-Pozolotin

it would help to show CPU usage time % on the LCD, to get a sense how much more speed, etc is still available

I'm not sure where to put it but I was thinking of using the lower line of the X,Y,Z box as an optional bar chart to display how full the Stepper Motor command buffer is. It'll be a lot of work to clear more space, but just to see if the idea is useful... If you have a Graphical LCD, I'm thinking you will be able to try it out in a few days.

For insight into internal performance, we recommend using the MAX7219_DEBUG option.

Most helpful comment

@Andrei-Pozolotin I understand the desire to see how much of the CPU is not being used. And there may be ways we can get that number. But there is probably a more useful number (or bar chart) to display. I think it would be valuable to see how many stepper motor buffers are queued up and waiting to be processed. As long as this is 4 or 5 deep, we are in no danger of running out of work to do (and stuttering).

I actually have some code that displays a nice bar chart on MAX7219 8x8 LED Matrix. http://www.ebay.com/itm/MAX7219-8x8-LED-Matrix-Modul-Dot-Matrix-Module-for-Arduino-Raspberry-Pi-MF-/182291658276?var=&hash=item2a716df624:m:mmRWGGyUDu52cCH26Q9wl2g

I've been using it as a debug tool to give me lots of status LED's I can toggle on and off. But It is kind of fun to watch as a print is going to see how full the stepper movement buffers are. I'll probably add the code soon to display that bar chart along with other status indicators for the printer. If you are willing to spend $1.83 and order one... I'll post the .SCAD files to print a nice bracket to hold it (along with debug and reset switches) on your printer.... It probably wouldn't be that hard to add a separate bar chart on it to indicate free CPU time. And temperature stability... And filament usage speed... etc. etc.

@Tannoo Let me twist your arm to order one (or two) of them too... For sure, you will have fun messing with it. But it is a very useful debug tool.