Marlin: The Marlin 2.0 32-bit thread

Board|MCU|State|To-Do

-|-|-|-

8-Bit AVR boards, RAMPS, etc.|Arduino AVR|💚good|

Due, RAMPS FD (v2.A!), etc.|SAM3X8E|💚good|

Duet Wifi + X5|SAM3X8E|❓unknown|E3D Toolchanger on hand

Duet 2 Maestro|SAM3X8E|⚠️beta|

Archim 1.0|SAM3X8E|❓unknown|Only US$170!

Archim 2.0|SAM3X8E|💚beta|needs confirmation

Grand Central|ATSAMD51|🛑tbd|(RAMPS_FD shield should work)

Re-ARM|LPC1768|💚beta|

MKS-SBASE|LPC1768|💚beta|

Smoothieboard|LPC1769|💚beta|

Azteeg X5 GT|LPC1769|💚beta|

Cohesion3D Remix|LPC1769|💚beta|

Selena Compact|LPC1768|💚beta|

Malyan M200|STM32F103C8|💚beta|EMERGENCY_PARSER,NEOPIXEL_LED, etc.

Borg|STM32F765ZGT6|⚠️beta|EMERGENCY_PARSER,NEOPIXEL_LED, etc.

Chitu3D V3.9|STM32F103ZET6|🛑alpha|EMERGENCY_PARSER,NEOPIXEL_LED, LCD, SDCard, MAX6675, etc.

Teensy 3.5|MK64FX|⚠️beta|(need shields)

Teensy 3.6|MK66FX|⚠️beta|(need shields)

Espressif 32 Wifi|ESP32|⚠️beta|(mostly working?)

STEVAL-3DP001V1|STM32F401VE|🛑alpha|(need boards)

- Good: All features working.

- Beta: All features implemented, mostly working.

- Alpha: Some features unimplemented/broken.

This thread is for discussion of 32-bit issues needing work and coordination of the 2.0 release.

All 1715 comments

It's not easy to stop the flow of issues, and we want to keep fixing any bugs that exist in 1.1, of course. So I propose that we take care of the current crop of obvious bugs —and only bugs— do a 1.1.4 release very soon, and one more release —1.1.5— just before we release 1.2.x, the new hierarchical + HAL version of Marlin.

@Tannoo and I have some clean up work going for the LCD header files. As it turns out... The .h files can only be included by one .cpp file because the .h files generate code. While this is not a 'bug fix' it is an important item from a 'code cleanliness' perspective.

We have the Graphical LCD Display code clean up done. The 20x4 LCD Display clean up should progress quickly. https://github.com/Tannoo/Marlin/tree/ultralcd_impl_DOGM.cpp

Release 1.2 (or Marlin 2.0?) with the hierarchical layout, support for some 32-bit boards.

Go with v2.0.

Support for 32bit platforms will indicate a new era for Marlin and for sure will warrant a tick in the major version count.

We have the Graphical LCD Display code clean up done. The 20x4 LCD Display clean up should progress quickly. https://github.com/Tannoo/Marlin/tree/ultralcd_impl_DOGM.cpp

Both the Graphical LCD Panel and the 20x4 LCD Panel .h files are cleaned up in this branch...

Tannoo is going to get the indentation and white space cleaned up....

The .h files can only be included by one .cpp file because the .h files generate code.

That is correct. The LCD-oriented header files may only be included once, and only in ultralcd.cpp. They are essentially just .cpp files, but given .h extensions so that they don't compile outside of ultralcd.cpp.

We could make them into proper .cpp files and fix the unorthodox usage, without any negative affect on performance, but let's wait till @Tannoo's changes are ready.

Is the new file structure going to allow Marlin to use a single file for Configuration? Much like Smoothieware? Is that one of the immediate benefits of doing this, apart from 32 bit and HAL

?

@ImplementOfWar That has not been discussed yet. Smoothieware is able to do certain things by limiting itself to 32-bit boards which have far greater resources. When and if someone implements a configuration system in emulation of Smoothieware, it will have to be for 32-bit boards only.

@thinkyhead What are you thinking for a time table to lock down the code?

I thought I could get the ultralcd_impl_HD44780.h separated into declarations and code generation... But it is turning out to be worse than I expected. We have the DOGM stuff separated, so that is a start. But the 20x4 LCD code is especially bad. It is very very ugly...

So, we could just go with what we have... Or... You can take a look at where we are at: https://github.com/Tannoo/Marlin/tree/ultralcd_impl_DOGM.cpp and see if you can figure out the issues?

You can take a look at where we are at: https://github.com/Tannoo/Marlin/tree/ultralcd_impl_DOGM.cpp

https://github.com/Tannoo/Marlin/tree/LCD_Interactive_Mesh_Edit_Refinements

I should delete the ultralcd_impl_DOGM.cpp branch. It was created as a test bed for the splitting of the DOGM.h file.

We should probably ping the whole @MarlinFirmware/language-team to complete translations.

Do I understand correctly that the new features will not be added before the release of version 2.0 (1.2)?

If so, when can we expect 2.0?

What about PRs that were created before the decision was made?

What about the PRs that were created before the decision was made?

In general... The Pull Requests generate for the current organization that do not make it into the new file layout should not be that difficult to regenerate. The bulk of the files are not going to change. What may change are things like paths to header files or stuff like that. If your Pull Request doesn't make it to the new layout automatically... It will be very straight forward to regenerate it.

thought I could get the ultralcd_impl_HD44780.h separated into declarations and code generation... But it is turning out to be worse than I expected.

The ultralcd_impl_* files were never designed to be standalone, but are really just split out parts of ultralcd.cpp. It would be best to wait till the ultralcd code is converted to a singleton class, and rearrange anything needing rearranging at that time. It will make more sense once it's examined in terms of a class — and ultralcd_impl_* may end up as two instances of a helper class. Or there may be other separation of functionality into more classes. It's something I want to work on more comprehensively, immediately after rearranging the code and getting the HAL working. And I'm pretty sure the LCD menu code can be simplified somewhat also.

Do I understand correctly that the new features will not be added before the release of version 2.0 (1.2)?

Halt means halt. If a larger number of contributors would like to help get the existing PRs merged, that would be an excellent change of pace. There's a lot of backlog to take care of.

If so, when can we expect 2.0?

As soon as I can get it together.

What about PRs that were created before the decision was made?

There's nothing to be done about it. There will never be some point in time where every PR will be merged, so it's best to stop the flow of new PRs and work on the PRs that we already have in front of us. I have been trying to get as many merged as possible, but more keep coming in. And so, we just have to go for it and it's just unfortunate timing for any PRs that will need to be reworked.

As it is, it will be me who has to re-work all the existing PRs into the new layout, because I have the mojo to make that happen as quickly as possible, and I will have all contingencies freshly in mind.

What are you thinking for a time table to lock down the code?

Let's keep fixing bugs all the live long day. Simply don't merge new stuff, and put off new features. If any new features come in while we're working on the transition, we'll simply put them off. Most contributions will be straightforward enough that it will be easy to re-make them for the new layout. Some we may have to work on within the old layout first, then when ready also bring them to the new layout.

We should continue to fix bugs in the 1.1.x branch and I will make sure they are brought into the new layout as well.

As for a timetable, I think we need to go in two stages. First, since we have so much work being done to make the 32-bit code ready, perhaps we should get that into minimal working shape first. Then I can include a genuine HAL as part of the initial 2.0.x branch.

The layout conversion itself isn't hard. The first conversion will take me less than a day to complete, and then we can go over it and see where it needs tweaking.

I'd like to focus on going over the open issues for the next day or two, patch up as many obvious bugs as possible, and merge as many of the lingering PRs as possible. One of PRs contains the 32-bit HAL rebased on the latest bugfix-1.1.x and that will also need to be brought up to date — though not merged with any Marlin 1.1.x.

Once the HAL is working and we're happy with it, then I'll rebase it onto the latest code and use that as the starting-point for Marlin 2.0 with the new file layout.

I think it's a good idea to take the next few days and close as many issues as we can so we have a fresh start.

Yes, it's possible that we could have a 2.0 layout and initial release by the end of the week… but let's loosen up the schedule so we can clear as many issues as possible and just aim to have it ready by July 1. How does that sound?

Yes, it's possible that we could have a 2.0 layout and initial release by the end of the week… but let's loosen up the schedule so we can clear as many issues as possible and just aim to have it ready by July 1. How does that sound?

_July 1st sounds fine... Especially if there is a sample 32-Bit HAL limping along and able to move the nozzle around!!!_

@Roxy-3D I'm pretty sure all the platforms currently in the HAL can do that, if the board supports the Arduino framework it's fairly trivial to implement basic features, the main stumbling block for non Arduino framework devices is the extra features needing Arduino libraries or Classes. I should be able to print tonight on my Re-ARM but the HAL needs further extended to strip all Arduino based features out of the main code and behind an API this will need to be done incrementally once we get the HAL merged.

I should be able to print tonight on my Re-ARM but the HAL needs further extended to strip all Arduino based features out of the main code and behind an API this will need to be done incrementally once we get the HAL merged.

What classes and functions are you missing? Would it be possible to just pull in the Arduino libraries so we don't have duplicated code complicating things?

Things like Print and Wire (as two random examples), just generally anything that is from the Arduino framework will need to be abstracted, this won't lead to code duplication and should lead to much cleaner and more understandable code, anything that can use the Arduino framework still can, although sometimes it may turn out it wasn't even necessary just convenient when it was implemented.

In some cases it may be difficult without introducing some indirection overhead, but anything performance critical already avoids the Arduino framework. It may be a good idea to have folders in the HAL (arduino_framework, mbed_framework) devoted to anything that can be reused among platforms that use that framework, but that's probably discussion for another day.

It may be a good idea to have folders in the HAL (arduino_framework, mbed_framework) devoted to anything that can be reused among platforms that use that framework, but that's probably discussion for another day.

@thinkyhead @p3p Well... Right now is a good time to express opinions and recommendations. It may not be too hard to get the HAL folders setup logically from the very start. But any subsequent, improved layout and organization for the HAL's will be welcomed also.

Would it be possible to just pull in the Arduino libraries so we don't have duplicated code complicating things

In the case of Wire all Arduino based platforms could still use it, but the calls would be through a standard API such as i2c_begin(channel, address), i2c_send_byte(channel, data), that other platforms would implement themselves or through another framework.

What can I do to help with this effort? I've got a bit of free time in the evenings this week, so I'm happy to help out if I can.

I think it is a little too early to do anything. We need the new organization to happen and be in place. But as soon as that happens... Several important items are on the list:

- Simple, step by step directions for getting the firmware onto a Re-ARM board. (Using Cygwin in a Windows environment would be preferable, but if we have to bring up a Linux machine, that would be tolerable.)

-- Any extra configuration required.

-- Steps to compile and build image outside of Arduino

-- Steps to flash including notes on using the 2nd USB port

-- Etc. - Simple, step by step directions for getting the firmware onto other 32-Bit boards.

- It maybe good to have a thread showing how far the boot process is working for each 32-bit board type. And what sub-systems of Marlin still need attention for the board.

- It will also be good to have the 32-Bit developers look at the new layout and suggest changes (and submit Pull Requests) to organize things better for themselves.

I believe there is a lot of pent up demand for an official 32-Bit version of Marlin. If we can just get one board up and working with the new release, and clear instructions so anybody can duplicate the success... We should see a lot of activity. And my guess is a number of different 32-Bit boards will start to have people using them.

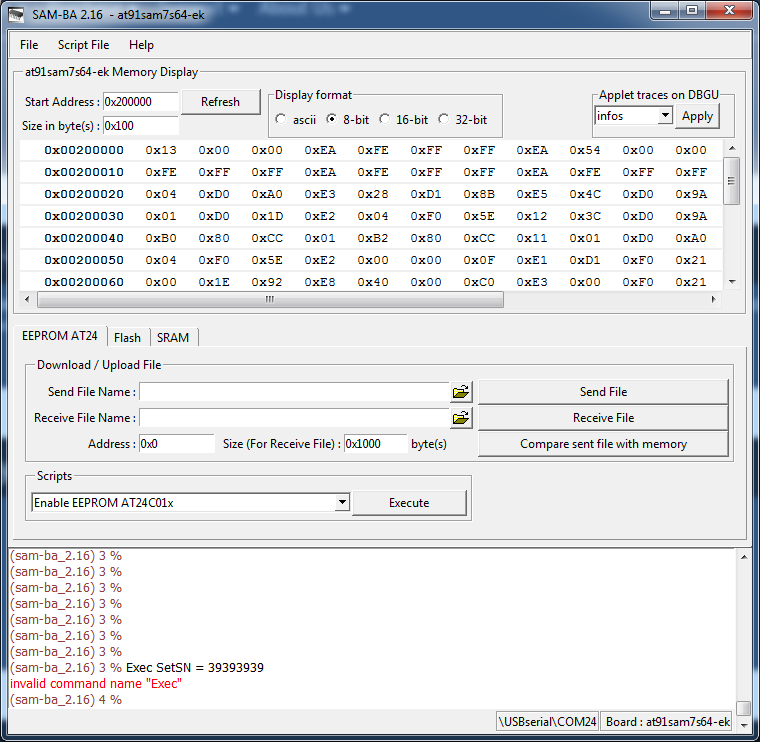

This information is very old, please use the official bugfix-2.0.x branch and using platformio build for LPC1768 if you have a Re-ARM board

Simple, step by step directions for getting the firmware onto a Re-ARM board.

1: Clone https://github.com/p3p/Marlin.git and checkout branch 32bit-bugfix-1.1.x-LPC1768

2: Install PlatformIO IDE

3: Open project in PlatformIO and build for Re-ARM (click bottom left of screen and scroll to bottom of options)

4: Copy firmware (

I've maintained compatibility with the Arduino pin layout so the same pins files should work (tested with RAMPS14).

This is a work in progress so once Marlin is flashed to the Re-ARM you lose access over usb to serial and the micro sd card, you will need another means of accessing the sdcard and an ftdi cable to access the 6 pin hardware serial port on the Re-ARM.

As of today I'm printing* with Re-ARM, steppers, heaters, ADC, SD card and graphical controller all work (character displays probably will not, they are more closely integrating with Arduino) using my RAMPS14, so basic functionality is at least out of the way.

@p3p THANK YOU SO MUCH! I'm going to start messing with getting some simple firmware compiled and loaded into a Re-ARM board using your steps... I'll at least be in a position to start messing with different things when the time comes!

@p3p Up above you say to 'build for Re-ARM'. I can't find that in the list. But I did find Platform NXPLPC NXP mbed LPC1768. Is that the correct selction for the Re-ARM board?

I'm also having trouble getting the project to open up in PlatformIO. But I did get something to happen when I dragged and dropped the platformio.ini file onto my Atom icon on the desk top. A little more info on what I do to open the project would be helpful too!

I too am having trouble.

Though we might need to generate a platform specifically for the Re-ARM

http://docs.platformio.org/en/latest/platforms/creating_board.html

When you open Atom it should open onto a Home screen, one of the Quick Access options is to "Open Project" if you browse to the folder containing platformio.ini and click open, in the left panel you should get the Marlin project file listing (.github, buildroot, &c.) from here you should be able to click the PIO build in the bottom corner and scroll down to Re-ARM

Though we might need to generate a platform specifically for the Re-ARM

Using the LPC1768 board with a modified linker script for compatibility with the smoothieware bootloader works well for now but we could do that in the future. The Re-ARM build is defined in the platformio.ini file so as long as you have correctly checked out the branch it should be there.

Thanks Chris,

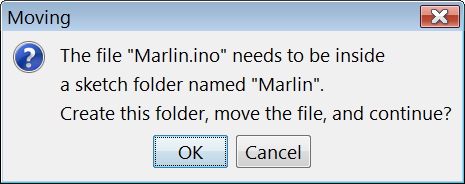

Posting a couple of screenies to help others

https://user-images.githubusercontent.com/6621978/27358346-49d44a66-566a-11e7-9e48-77e386830f93.png

https://user-images.githubusercontent.com/6621978/27358349-517a2268-566a-11e7-88be-2c1e29771f31.png

Ooooops! I managed to do a Re-ARM Upload. But I had my Atmega2560 with a RAMPS board plugged in.... My LCD screen went crazy.

THANKS p3p!!!

Just don't expect too much when (if) you get it on the hardware I only got the heaters working this afternoon ^^ and if you change the config it will probably explode .. I also just noticed an issue with corruption in the serial data during a test so that's my task tonight (he says at 23:30)

Yeah... Don't worry about that! I'm just trying to get up the learning curve because my guess is when we get the new file layout, progress is going to be made fast. I don't want to be left behind.

So... I'm going to be playing with a lot of stuff. Mostly simple stuff. But I want to understand all the steps and how the development environment works. And then... Who knows, maybe I can help with some of the simpler stuff like getting the 20x4 LCD Displays working.

The point is, when 32-Bit progress can be made against the current code base, eventually.... everything will be working even though the code base kept evolving as that was happening. And if people can run the current code base on 32-Bit platforms... More and more people will jump on-board.

Hey @Roxy-3D is that Ray Cortes kickstarter board?

https://www.kickstarter.com/projects/1245051645/re-arm-for-ramps-simple-32-bit-upgrade

I did order it for $48 for my 3D printer and it's gathering dust at the

moment. I would be really interested to see this getting of the ground. I'm

doing a kickstarter for my Gerbil K40 laser controller at the end of the

month so I cannot contribute much but I'm eager to learn how to port code

to this environment. Where can I follow it in detail?

On 21 June 2017 at 08:47, Roxy-3D notifications@github.com wrote:

Yeah... Don't worry about that! I'm just trying to get up the learning

curve because my guess is when we get the new file layout, progress is

going to be made fast. I don't want to be left behind.So... I'm going to be playing with a lot of stuff. Mostly simple stuff.

But I want to understand all the steps and how the development environment

works. And then... Who knows, maybe I can help with some of the simpler

stuff like getting the 20x4 LCD Displays working.The point is, when 32-Bit progress can be made against the current code

base, eventually.... everything will be working even though the code base

kept evolving as that was happening. And if people can run the current code

base on 32-Bit platforms... More and more people will jump on-board.—

You are receiving this because you are on a team that was mentioned.

Reply to this email directly, view it on GitHub

https://github.com/MarlinFirmware/Marlin/issues/7076#issuecomment-309913380,

or mute the thread

https://github.com/notifications/unsubscribe-auth/AIOTKVmipb4ymHxTHrBPpX65nKSnQTPDks5sGEwBgaJpZM4N82_j

.

It is not Ray's board. I have that on my desk too. But I'm trying to learn how to generate code with the PlatformIO IDE.

@p3p I obviously don't understand something... I thought I built the firmware OK, and put it on the SD Memory card. But nothing happened on the Graphical LCD Panel when I started up the board. So I'm not sure what I'm fighting and decided to just try to make an LED blink. I added this code to Marlin_main.cpp

void pinMode(int pin, int mode);

void digitalWrite(int pin, int pin_status);

bool digitalRead(int pin);

void analogWrite(int pin, int pin_status);

uint16_t analogRead(int adc_pin);

void setup_LEDs() {

int p, r, t, s;

for(p=1; p<54; p++) {

pinMode(p, OUTPUT);

for(r=0; r<10; r++) {

digitalWrite(p, LOW); // drive it down

s = 0;

for(t=0; t<5000; t++) {

s=s+digitalRead(20)&0x01;

}

digitalWrite(p, HIGH); // drive it up

for(t=0; t<5000; t++) {

s=s+digitalRead(20)&0x01;

}

digitalWrite(p, LOW); // drive it down

}

pinMode(p, INPUT);

}

}

and then in the setup() function I called it:

void setup() {

#ifdef DISABLE_JTAG

// Disable JTAG on AT90USB chips to free up pins for IO

MCUCR = 0x80;

MCUCR = 0x80;

#endif

#if ENABLED(FILAMENT_RUNOUT_SENSOR)

setup_filrunoutpin();

#endif

setup_LEDs();

I have LED's plugged into different places on the Re-ARM board. (Right now, what would be pins 1,2 and 3 on an ATMega-2560 board) and I do see some changes in them when I reset the board. But I don't get on and off blinks like I expect. Obviously, I'm missing something. Can you change the setup_LEDs() so it blinks an LED for me? With that I'll be able to make a lot more progress.

Without the serial connection it will be hard to know what went wrong, can you confirm the firmware was written correctly, the Re-ARM renames "firmware.bin" to "firmware.cur" after flashing. Assuming that's correct you should at least get serial output (and the logo if the config is compatible with your setup).

Without the serial connection it will be hard to know what went wrong, can you confirm the firmware was written correctly, the Re-ARM renames "firmware.bin" to "firmware.cur" after flashing.

Yes... It is renaming the file.

Assuming that's correct you should at least get serial output (and the logo if the config is compatible with your setup).

I do not have the board connected up to any endstops or stepper motors yet. And I maybe fighting the problem where some graphical displays have reversed cables. I don't know what I'm fighting. That is why I thought I would start small and try to blink an LED. But I can't even make that happen right now. So I have a pretty big learning curve in front of me.

It appears you re-mapped the ReARM connector locations to match the Atmega2560/RAMPS board locations... I'm getting a lot of warnings when trying to use that code. I found the documentation showing the Re-ARM Port and Pin numbers.... I can go after those LED's in the Re-ARM's address space now. And then migrate back to the RAMPS locations...

Don't worry about me... I'll figure it out.

The functions (digitalWrite, pinMode ect) that I wrote make the pin mapping transparent, you just use them as you would on Arduino Mega, not all pins have been mapped yet (or can be) pinmap_re_arm.h controls that.

With nothing plugged into the Re-ARM it should still boot up into Marlin and you can control it via the serial port, without more information about what is being output I can't really help, Displays and controllers I wasn't expecting just to work unless they are identical to reprap full graphic smart controller.

If you don't have a ftdi cable you can forward the serial through an Arduino but I recommend getting one they come in handy.

I just realised you didn't say if the LCD display was powering up or that you used the adaptor cable from http://www.panucatt.com/product_p/glcd-idc.htm to connect it, all that cable does is split pin 1 off so you can connect it to a 5v pin on the Re-ARM.

If you do want to run code on the Re-ARM without any of Marlin getting in the way, there is a main function in HAL.cpp that calls setup and loop just comment them out. From there you should at least be able to toggle Digital outputs for testing.

I do get the Graphics LCD Screen to light up. (RepRap Discount Full Graphic Smart Controller)

I have the split cable and apparently did get the +5 volt wire to work. I just don't have anything being displayed on it (yet). I'll keep plugging away.

And I just brought the LCD Panel up on an ATMega2560 board... So I have the cable correct.... Next I'll move things over to the LPC1768

I'll try to apply the new file layout incorporating the HAL this weekend and post a 2.0.x branch that we can patch up for release. This will just be a first attempt, and can be reworked as needed.

We might still have too many open issues needing fixing before we jump ahead, but at least this will provide a starting point. I haven't counted open issues lately, but I will do an audit and try to produce a list of lingering bugs and issues that we should fix ahead of the new layout.

We might still have too many open issues needing fixing before we jump ahead, but at least this will provide a starting point. I haven't counted open issues lately, but I will do an audit and try to produce a list of lingering bugs and issues that we should fix ahead of the new layout.

@thinkyhead From reading all the new issues and posts to them... There doesn't seem to be anything critical. We have a few questions about BL-Touch probes not working. We have a couple of bed leveling issues across the spectrum of different bed leveling schemes. But nothing dire.

My suggestion would be, we cut and run. Until the new folder and file layout is complete, people can just continue with today's bugfix-v1.1.x .

@thinkyhead @p3p I moved the LPC1768 changes for the Re-ARM board over to 32-Bit-RCBugFix-new just to make sure they don't get forgotten! We need p3p's LPC1768 stuff in the new file & folder layout.

It isn't passing the Travis tests... But it is here as a Pull Request: https://github.com/MarlinFirmware/Marlin/pull/7121 I wonder if we should merge it anyway just to make sure it is part of the mix?

Now that the bugfix-2.0.x branch has been created, we can try to bring over the elements from oh-so-older 32-Bit-RCBugFix-new branch, including your new changes in #7121, if they're ready for inclusion and/or consistent with the HAL stuff from @teemuatlut and @p3p.

I'd like to get the HAL elements pretty well organized ahead of the rest of the code reorganization, since all other components will depend on it.

@thinkyhead The new branch was based on 32-Bit-RCBugFix-new so I'm relatively sure there is nothing missing that was in there (although I seem to remember there was some issue rebasing @teemuatlut's PIN DEBUG code), I was back-porting anything that was general HAL from the LPC1768 branch into the PR but I do have to finish the new SPI integration (I have to implement it for the other platforms), then I would like to continue moving the HAL features into the HAL::Feature naming convention (HAL::ADC , HAL::I2C, ect) with general headers.

You can leave the pins debug for Teensies in whatever state. I'll go over it once everything has settled down.

@thinkyhead You said in the first post that the aim for 1.1.5 was to fix all obvious bugs.. well dual X carriage has been broken since 1.1.1. See #6956 #7050 #7291.

I may be interested in finding a fix for this as I'm building a dual X machine myself, but I can only get to it next week so if it's not solved by then I'll take a crack at it. Further discussion should be made on #7291

@teemuatlut I've tracked down the problem and I have submitted a PR that fixes it. It's great to have more people with DUAL_X_CARRIAGE though as I'm pretty sure there are still bugs related to it.

Good to hear.

Hi, I have dual X carriage printers with RADDS / Due + RADDS LCD Display with SD card.

What LCD option do I select in Marlin2

Thanks - bruce

Is Marlin 2.0 compatible or intended to be compatible with the Azteeg x5 mini? (LPC1769)

https://www.matterhackers.com/store/printer-accessories/azteeg-x5-mini-32bit-all-in-one-controller-v1.1

Is Marlin 2.0 compatible or intended to be compatible with the Azteeq x5 mini? (LPC1769)

Right now, the bulk of the 32-bit activity is on the Panucatt Re-ARM board. That uses a LPC-1768 which is very similar to the LPC-1769. The way the code is being done, the current work should move over to that board with a minimum of effort. If pins are assigned differently, they would just get moved around in a mapping table. And the LPC-1769 is faster so some timer speeds would shift.

Incidentally, Panucatt supplied us with enough Re-ARM boards to get critical mass on the development side. It kind of feels like they want the X5 (and the X5 mini) to support Marlin so that will probably happen as soon as the Re-ARM board is solid. And it might even be possible to make the required changes without connecting an X5 up to a printer. But that remains to be seen...

I'm very happy to hear this. The X5 is the board I want to use. I may have to drop Roy an email to get things rolling on purchasing a couple of them.

If you want to order a single X5 board and get it connected up to a printer... People in this thread should be able to tell you what to edit on the Re-ARM code to make it work with the X5: https://github.com/MarlinFirmware/Marlin/pull/7390

Sounds like a good plan. I'll see about getting one on order shortly. I might have to grab some spare parts and put together a functional 3D printer setup for testing.

And probably... At least from my perspective... I think it is likely the Re-ARM HAL goes away and we have a single LPC-1768(9) HAL. Probably, the changes to the Re-ARM code is very minor to make it work on the X5 board. BUT... That remains to be seen.

In theory the firmware will run as is on an LPC1769 they are binary compatible, but the pins will more than likely be completely wrong.

I did take into account that there would be multiple boards running on the LPC17xx HAL (mostly), there are a few things that will need written for the X5 but are already split out in a way that should make it pretty simple. An internal pin-mapping file will be needed (pinmap_re_arm.h), and the Marlin pin-mapping (pins_RAMPS_RE_ARM.h), the linker script should be fine as should the startup assembly but the System init function will need to detect it's running on an LPC1769 and set the clock appropriately for full support.

You said in the first post that the aim for 1.1.5 was to fix all obvious bugs.. well dual X carriage has been broken since 1.1.1

You can find more recent threads where it was debugged and eventually fixed. If it has become broken again (a regression) then please post a new issue detailing the exact problem(s) seen.

You can find more recent threads where it was debugged and eventually fixed.

He's the one who fixed it =)

I accidentally overwrote the bugfix-2.0.x branch a little while ago.

If the last commit was https://github.com/MarlinFirmware/Marlin/commit/c587d27 then no worries… everything is already restored.

If there's some other commit I missed, let me know.

I should have the X5 GT next week. This will be interesting.

I hadn't thought about this before now but will the Arduino IDE be enough to work with the X5 or do I need to get a different setup going?

I hadn't thought about this before now but will the Arduino IDE be enough to work with the X5 or do I need to get a different setup going?

You need to bring up the PlatformIO-IDE which runs inside of Atom. That will take you a few days. It is very slow to install. And it isn't intuitive to use. You will want to pull down the bugfix-2.0.0 branch and compile that for Re-Arm when you have PlatformIO-IDE installed.

Then you can start making the tweaks to shift from Re-ARM to the X5-GT.

@thinkyhead Does Marlin2 support the RADDS LCD Display with SD card controller, if so which option do I select as I do not see it listed, under "// CONTROLLER TYPE: Standard".

I know I am not a developer here, but would like to test the new marlin with RADDS and X2 on my machine. I am assuming the X2 problem has been rectified.

https://github.com/MarlinFirmware/Marlin/issues/7291

@mperdue - You'll need to create a new pins_YOUR_BOARD.h file. I expect that 99% of the pin mapping can be done there. The remainder will require changes to the file pinmap_re_arm.h in the directory Marlin\src\HAL\HAL_LPC1768\pinmap_re_arm.h. You'll also need to modify boards.h and pins.h to add your board to the list of acceptable boards.

The timers won't need to be touched.

Installing PlatformIO is tedious but not hard. In Atom go to the FILE -> SETTINGS -> Install and search for PlatformIO.. You'll want to install platformio-ide, build-platformio and platformio-ide-terminal. platformio-ide takes a while to install and many (4?) restarts of Atom. Wouldn't hurt to do a couple extra restarts of Atom after it stops requesting restarts.

Once the PlatformIO home/welcome page is displayed

Click on the +New Project button. Select Other under Chose the directory and then enter the directory ABOVE Marlin.

Click -- choose a board -- and scroll down to the Platform NXPLPC area and click on NXP mbed LPC1768.

Click the Process button. Hopefully no errors will pop up.

In the extreme lower left corner of the Atom window there should be something with PIO Build in it. Click on that.

In the window that pops up enter Re-ARM in the search window.

Click on PIO Build (Re-ARM). That'll open up a window where it will show the compiler output.

If you have some compiler errors the window will stay open. Make your corrections and then, to re-run the compiler, click the lightning bolt button on the upper right of the window.

Once it says SUCCESS the executable will be the file firmware.bin in the directory .pioenvs\Re-ARM. Copy that to an SD card and insert in into the SD card reader on the motherboard. After cycling power (reset won't do it) the new code will be loaded and run.

Reset does work for me.

Unfortunately, when I hit Process I get _Uncaught ReferenceError: assignHooks is not defined_

It's the story of my life...

Oh, and the steps are a bit different on a Mac but you certainly got me pointed in the right direction.

Once the PlatformIO home/welcome page is displayed

Click on the +New Project button. Select Other under Chose the directory and then enter the directory ABOVE Marlin.

Click -- choose a board -- and scroll down to the Platform NXPLPC area and click on NXP mbed LPC1768.

Click the Process button. Hopefully no errors will pop up.

That seems an odd way of opening the project, it should just require clicking Open Project then selecting the directory with platformio.ini in.

Sometimes uninstalling then reinstalling platformIO fixes that, sometimes it doesn't.

Did the project folder/directory open? If not got to File -> Add Project Folder and open it.

Try clicking on the PIO Build and see if you can search for the Re-ARM board. If you find it then you probably do a build.

On the left side of the PlatformIO home/welcome screen is a Boards button. Click on that and then search for 1768. Click on the NXP mbed LPC1768 entry. That may also get things linked up.

@Roxy - I can't find the thread that details all our trials & tribulations with platformIO. Can you point us to it?

Roxy edit >>>---> I think this is the start of where I started using PlatformIO and of course.... I had a ton of questions: https://github.com/MarlinFirmware/Marlin/pull/7028#issuecomment-315617978

I found that just opening the project as suggested by @p3p worked OK and I was able to build it. Now I just need to figure out where the .bin file gets put on the Mac...

Roxy edit >>>---> On Windows, it ends up off the main directory of the code:

../whatever/.pioenvs/Re-ARM If you can find anything similar that probably will be it... Alternatively... search from the main directory downward for any .bin or .elf file. That is probably where it will be hiding.

One thought is Apple stuff is really Unix. So if .pioenvs is where it is stored, the . makes it a hidden directory. It might be hiding on you.

@bruce356 - while Marlin 2.0 doesn't have the RADDS display in it you might be able to find one that works. Any controller that uses LCD_PINS_D7 is a candidate.

I'm pretty sure that eventually it'll be supported but that could be a long way down the road.

The MK4duo fork does support it. They have an online configuration tool that lists it as one of the LCD display options.

I'm thinking that PlatformIO hasn't received a lot of awards for being intuitive...

Anyway, I think I have managed to get it to build with Re-Arm so I guess that's a step in the right direction. Maybe I'll have it figured out by the time the board gets here.

I'm thinking that PlatformIO hasn't received a lot of awards for being intuitive...

Once you learn how to open a branch and build it.... The rest of PlatformIO can be ignored. And supposedly, if you ignore the PlatformIO-IDE and just use the PlatformIO makefile stuff... It is perfectly normal.

@Bob-the-Kuhn, thanks for the reply, I tried MK4duo some 6 moths ago and with dual-X carriage it just did not work for me, at that time no one was particularly interested in trying to make X2 work and italian translate was not all that good either.

The configuration tool (similar to Repetier) was at the time helpful but not as clear to me as Repetier config tool to configure for X2. Perhaps its time to revisit MK4duo.

Regards - bruce

FWIW, my X5 GT has a shipping tracking number now so I should be seeing something soon. I guess I need to put together a testbed. :-)

I've been since yesterday thru the pain of setting up platformio, and I'm getting an error afterI solve another. Now it's complaining on this:

Marlin\src/HAL/HAL_LPC1768/pinmapping.h:29:12: error: missing binary operator

before token "("

Has anyone seen this error before?

I get a few more after that, but I think all of them are caused by that failure.

This is the line that fails btw:

#if ENABLED(IS_REARM)

I'm definitely not enjoying platformio and about to try compiling it with Eclipse. Btw this is what I did successfully so far:

I installed VSCode, then installed Platformio as an Extension to it.

Downloaded the latest 2.0 branch.

Save it all to a folder I called Re-arm.

Opened it with VSCode, then set the Re-Arm version as default in platformio.ini (env_default = Re-ARM)

Changed the board in configuration.h to (line 121):

#define MOTHERBOARD BOARD_RAMPS_14_RE_ARM_EFB

And hit ctrl+alt+b to try to build.

During the process I had to download multiple frameworks and what not, some more than once because platformio failed to install them and then started downloading them again, and eventually was happy to start compiling, but spews the error above.

I'm definitely not enjoying platformio and about to try compiling it with Eclipse.

Supposedly PlatformIO is good unless you try to use the IDE version of it. Should we give just the vanilla PlatformIO with the makefile's a try?

@victorpv Sorry you're having issues, I haven't used the VSCode IDE with PlatformIO I only test Re-ARM

PlatformIO builds with Atom, make sure your testing with the latest bugfix-2.0.x though as there is no "stable" version of 2.0.x atm and the first thing I did after thinkyhead merged 2.0.x was fix compilation errors.

I'm going to be buying the LPC1769 based Azteeg x5 mini soon.

I use a mac, so what all would I need as far as a programmer to help contribute to the 32 bit development? I have alot of experience writing iOS software; not much with low level ARM stuff. Willing to help and learn though! :)

Do I even need a programmer if it simply writes the firmware to the microSD card to insert into the Azteeg?

I believe an SD-Card is sufficient. But that is just a guess based on how the other LPC-1768 based boards work.

I'm hoping I won't need to use a virtualbox to run the development software. I am switching from belts to leadscrews so I'm going to need 32 bits and there's no better time than the present.

@klcjr89 I'm waiting on the delivery of an Azteeg X5 GT and I also use a Mac. I suspect we'll be chatting from time to time.

Try this for the toolchain: http://docs.platformio.org/en/latest/installation.html

@mperdue did you not get the X5 mini? Any reason why not if so if I may ask? :)

I went with the GT because he has an experimental board that adds additional motor drivers.

I have read this thread and quite excited as I have had my Re-Arm for ages but not used it and I now am building a P3Steel V4 and want to use the Re-Arm on this. I have installed platformio IDE in Atom and have built the project fine with the help of the great documentation you have put on here. Thanks for all of your hard efforts on this and I hope that I may be able to contribute soon.

@p3p I'll give it a shot in Atom, but I though platformio IDE uses the platformio core to build no matter if you use one editor or the other, but who knows.

I will also definitely try to create an Eclipse project and compile with Eclipse first. If that works, then I can just ignore platformio.

but I though platformio IDE uses the platformio core to build no matter if you use one editor or the other, but who knows.

I've been compiling using PlatformIO-IDE. But I have not edited anything inside of PlatformIO (or Atom). I've just been running my text editor on the side and when I say to build, it figures out which files changed and how to handle it....

The only thing I actually edited was the board selected in configuration.h, and the default env in platformio.ini (otherwise it would try to start building for a mega2560) :(

I downloaded the latest version of the 2.0 32bit branch right before trying to compile it.

I may just remove it all and start from scratch again. I got a few errors when platformio was trying to download gcc, perhaps something else failed...

I may just remove it all and start from scratch again. I got a few errors when platformio was trying to download gcc, perhaps something else failed...

I have had to re-install PlatformIO-IDE twice. I maybe mistaken, but it seems like sometimes it gets sick when an auto-magic update doesn't proceed smoothly. One time Jason quit working after the update. I don't remember what the other part was that got sick a different time.

If there is a way to turn off updates in PlatformIO-IDE, I haven't found it. But once I have a working installation of it, I would prefer not to get any of those updates forced on me. They seem to do more harm than good.

@victorpv are you sure it was the bugfix-2.0.x branch? The compile issue you posted was fixed soon after 2.0.x was created.

In setting window, click the Core tab, then remove the check for Automatically Update.

This applies to Atom updates.

I haven't had any issues with updates. It is annoying, though, to have to restart Atom after each one.

I'm pretty sure it was this one (only a version from Saturday):

https://github.com/MarlinFirmware/Marlin/tree/bugfix-2.0.x

That's the one right?

But I'll download it again later just in case when I can retry.

I remember I checked to make sure that was the branch with the latest commits (compared to the 32bit bugfix and bugfix-new branches)

I'm pretty sure it was this one (only a version from Saturday):

https://github.com/MarlinFirmware/Marlin/tree/bugfix-2.0.x

That's the branch I'm using.

@Roxy-3D, have the UBL storage slots reduced to 8 instead of 10 across the board, or just for the re-arm?

In setting window, click the Core tab, then remove the check for Automatically Update.

This applies to Atom updates.

Thanks! I've got the automatic updates turned off now. Hopefully it quits screwing itself up now.

Re-ARM is artificially limited for no real reason other than I matched (I thought) the EEPROM size for the Persistent Store implementation, in theory you could set it to the filesize limit of the SDCard Filesystem, .. may take a while to save with 4GB of (emulated)EEPROM (how many slots is that ;) ), I didn't look into where else the value was used so I used a safe default.

/src/HAL/HAL_LPC1768/arduino.h

#define E2END 4096 //EEPROM end address

have the UBL storage slots reduced to 8 instead of 10 across the board, or just for the re-arm?

I haven't started checking out UBL on it. I'm trying to find the lock up issue that I'm seeing. But the number of slots for UBL mesh storage is just controlled by how much extra EEPROM space there is (E2END) subtracted from the end of the 'normal' EEPROM usage. But remember... Some of the data types are bigger on the 32-bit machines. So that leaves less room for mesh storage.

I'll keep your observation in mind when I do turn on UBL on the Re-ARM and make sure everything makes sense.

Some of the data types are bigger on the 32-bit machines

Hopefully everything should be portable constant bit width types (int16_t, ect), or moved to them if they are not.. assuming the extra size doesn't improve something on 32-bit,

I'm seeing that about the number of mesh slots.

Some of the data types are bigger on the 32-bit machines

Hopefully everything should be static bit width types (int16_t, ect), or moved to them if they are not.. assuming the extra size doesn't improve something on 32-bit,

Good Point!!!! I'll verify the 'right' thing is happening when I turn on UBL. Otherwise, we should be getting the same number of mesh slots between AVR and Re-ARM !

Ln 235 in pins_RAMPS_RE_ARM.h needs to be uncommented for the encoder to work.

I thought my display took a dump.

@Tannoo I can confirm your findings... Also, I commented out some duplicate definations for the 20x4 LCD because it was flooding the build screen with errors. https://github.com/MarlinFirmware/Marlin/pull/7500#issuecomment-322571840

I did the same, but have not submitted a PR. I put conditionals for the ULTIPANEL so the Ethernet can still be used if not using it for the LCD.

I ended up with this:

#define DOGLCD_A0 59 // J3-8 & AUX-2

#define DOGLCD_CS 63 // J5-3 & AUX-2

#ifdef ULTIPANEL

#define LCD_PINS_D5 71 // ENET_MDIO

#define LCD_PINS_D6 73 // ENET_RX_ER

#define LCD_PINS_D7 75 // ENET_RXD1

#endif

#ifndef ULTIPANEL

#define ENET_MDIO 71 // J12-4

#define ENET_RX_ER 73 // J12-6

#define ENET_RXD1 75 // J12-8

#endif

#define ENET_MOC 70 // J12-3

#define REF_CLK 72 // J12-5

#define ENET_RXD0 74 // J12-7

#define ENET_CRS 76 // J12-9

#define ENET_TX_EN 77 // J12-10

#define ENET_TXD0 78 // J12-11

#define ENET_TXD1 79 // J12-12

flooding the build screen with errors

They are warnings, but will only show up if there have been edits to that file, or the build directory has been deleted, or some other reason for a full re-compile.

Hey - I put that misteak there on purpose just to see if you were paying attention.

Per Trump's rules - if you fix one bug you need to introduce two others.

Bob... Does your Dragon debugger connect to and work with the Re-ARM board?

I thought I had messed up somewhere doing a few cleanups... I reverted all my changes and even swapped displays to find that I didn't do it. Thanks, Bob... lol

My Dragon debugger only works with Atmel chips.

I have another annoying issue that I haven't tracked down yet.

Everytime I reset the board, I have to unplug the USB cable first and wait for the info screen to show up, then plug it back in.

If I don't do that, it will hang. If it does hang, I unplug the USB and reset the board again.

It has done this from the beginning.

I was surprised about the exact opposite... I can press the Reset button on my printer and the SD-Card drive automatically shows back up. And then all I have to do is Disconnect and Reconnect inside of PronterFace and I can talk to the board again...

My Dragon debugger only works with Atmel chips.

You also have an MK-II, Right??? Does that work with the 32-bit boards?

@Tannoo - what display are you using?

I was thinking of trying to find out why, in general, the LCD displays are not working. I know that we've got support for REPRAP_DISCOUNT_SMART_CONTROLLER, the RRD full graphics and the Viki type displays. All those required modifications in order to work.

I have been using the REPRAP_DISCOUNT_SMART_CONTROLLER (20x4) on this re-arm build.

It is currently working just fine.

I also have a REPRAP_DISCOUNT_FULL_GRAPHIC_SMART_CONTROLLER, and it works just fine also.

Everytime I reset the board, I have to unplug the USB cable first and wait for the info screen to show up, then plug it back in.

@Tannoo that's a new one on me, I thought I had that working reasonably well, alas everyones hardware and OS appear to behave differently than mine.. curses

@Tannoo I have your updates to the pins_RAMPS_RE_ARM.h already merged... You don't need to do anything on that...

I just tried it again... nope. The display only gets to the dual solid lines, the re-arm status led stops flashing, and the RGB led (plugged into 4, 6, 11) turns white. The computer sees the connection and then looses the connection a few secs later.

No amount of time so far gets it working.

This is all inicating a processor freeze.

Once I disconnect the usb cable, reset the board, and wait for the screen screens, then plug in the usb, all is fine.

If I plug in the usb while the display is initializing, it halts the boot process and the pc sees the connection. If I pull the usb with a few secs, it continues to boot. If I wait to see what it does... it just remains frozen and the computer looses connection. Then pull the usb and the board has to be reset again.

LN 130 uint32_t data = LPC_ADC->ADGDR; can be removed from hal.cpp, can't it?

Setting #define E2END 5120 //EEPROM end address Now gives me 10 slots -- same as the AVR.

I was using a 32GB card, now using a 16GB card. Still 10 slots.

8 slots isn't enough? But I think that indicates we have some data being used that isn't the same size on the two platforms. We probably should find that and get stuff declared with static bit width types.

8 slots isn't enough?

lol... well, I'm not the one that gave 10 slots to begin with.

Seems like I found my problem, I checked the zip and had downloaded the 2.0.x branch rather than the bugfix2.0.x branch.

Now it's compiling :)

Anyone has an schematic of the Re-ARM in pdf of jpg? I'd like to connect a debugger to it if possible.

My Re-Arm just reset just fine with the USB connection to the PC. BUT... I had removed the SDCard for EEPROM testing.

Oh... and now, it makes a liar out of me by working when I put the SDCard back in hit reset. It restarted without a hitch. Hmmm.

Maybe it was all the git swapping from that last PR.

Does anyone have a schematic of the Re-ARM in pdf of jpg? I'd like to connect a debugger to it if possible.

I thought 2.0.x was already released.... so, sorry for all the fuss.

I just received my Azteeg X5 GT. Can I play too?

Come on in, there's plenty of room. ;)

Thanks Roxy, that helps.

Nevermind about SPI, I see it was already in the works and reverted to keep things running.

And SWD and SWIO are not connected to any pin :(

@victorpv I had hardware SPI integrated (and it is used internally for the onboard sd card), but I couldn't integrate it in a way that would stay constrained behind the HAL so it was reverted until I have time for the full overhaul of how Marlin accesses SPI, the main issue is there is no single point of access to SPI hardware in Marlin atm, and there was some worry that my changes would adversely affect the AVR platforms performance.

I saw that, and the software implementation in a display driver. I bet there is a multitude of files doing something like that, their own software implementation, and all need to be overhauled.

That will be a big effort.

Found a couple of problems with the types in the 2.0 bugfix branch.

First, this function takes const char * as inputs:

void dump_free_memory(const char *ptr, const char *sp)

But 2 lines down it does a cast to uint16 and then a cast to char *

I guess all that's fine in the AVR, but on 32 bits we go from a 32bit pointer, to 16 bits, and then back up to 32bit, and platformio complains. On CPUs with only 64KB of ram most likely not a problem, but with more than 64KB it could result in the wrong value being calculated for the free memory it we chop it all at 16bits.

Can we change (char *)((uint16_t) to (char *)((uint32_t)?

Then there is an issue with this function, which takes 16bit max, which is used in the function above, and I think the type should be changed too:

void print_hex_word(const uint16_t w) { SERIAL_ECHO(hex_word(w));

Then we have the declaration for hex_word...

The second issue with in gcode.h:

https://github.com/MarlinFirmware/Marlin/blob/e68b7afc52792ef7e97dbefc19c82d5b4902744e/Marlin/gcode.h#L259

I get error: invalid conversion from 'const char' to 'char'

Got rid of it casting it to (char *), so in front of each PSTR in that function I added the cast, but I haven't even checked where that variable is used, just trying to get it to compile with the freemem option.

When I wrote that code (https://github.com/MarlinFirmware/Marlin/commit/03aa9a390e8b9fe1326d766dfd34f6436a308f90#diff-a83103266c34b3a2f333ac4eb2375046R117) I didn't believe the 'const' constructor added any value.

#if ENABLED(M100_FREE_MEMORY_DUMPER)

/**

* M100 D

* Dump the free memory block from __brkval to the stack pointer.

* malloc() eats memory from the start of the block and the stack grows

* up from the bottom of the block. Solid test bytes indicate nothing has

* used that memory yet. There should not be anything but test bytes within

+ * the block. If so, it may indicate memory corruption due to a bad pointer.

* Unexpected bytes are flagged in the right column.

*/

void dump_free_memory(char *ptr, char *sp) {

//

// Start and end the dump on a nice 16 byte boundary

// (even though the values are not 16-byte aligned).

//

ptr = (char*)((uint16_t)ptr & 0xFFF0); // Align to 16-byte boundary

sp = (char*)((uint16_t)sp | 0x000F); // Align sp to the 15th byte (at or above sp)

In that part of the code is not the const, but the uint16_t types, since pointers are 32bit in ARM, so char* and uint16_t have a different lenght and would end up truncating the memory addresses, which should be ok in MCU with less than 64KB of RAM, hopefully those 64KB are aligned and only the bottom 16bit of the address are relevant, but since it may end up running on MCUs with more than 64KB, I think that should all be turned to manage 32bit addresses. I'm changing the functions to manage 32bits, but I am wondering if part of this should be moved to the HAL, so it can use 16bits or 32bit depending on the CPU.

In that part of the code is not the const, but the uint16_t types, since pointers are 32bit in ARM, so char* and uint16_t have a different lengths...

Yes... And in the original K&R C book... There was a very causal use of int's to hold pointer values. Pretty much, that code up above works and is portable across machine types. On a 32-bit machine, it could be changed to ((unit32_t) ptr) and you are not going to lose precision. If Kernighan and Ritchie thought it is OK, I'm not going to argue with them.

But here is the thing. Step back a few steps... If that was just

ptr = (char*)((uint) ptr & 0xFFF0); // Align to 16-byte boundary

sp = (char*)((uint) sp | 0x000F); // Align sp to the 15th byte (at or above sp)

It would work just fine. Over specifying types and stuff just makes the code harder to maintain and more difficult to re-use. (int) is just fine when trying to do math on pointer so it can be displayed in a meaningful way.

and would end up truncating the memory addresses, which should be ok in MCU with less than 64KB of RAM, hopefully those 64KB are aligned and only the bottom 16bit of the address are relevant, but since it may end up running on MCUs with more than 64KB,

Ah... What was the name of the function?

void dump_free_memory(char *ptr, char *sp)

How much RAM memory does an AVR (or even an ARM processor) have? I'm thinking an (int) is going to be just fine to do the math and display a meaningful address.

but I am wondering if part of this should be moved to the HAL, so it can use 16bits or 32bit depending on the CPU.

hopefully those 64KB are aligned and only the bottom 16bit of the address are relevant, but since it may end up running on MCUs with more than 64KB,

Agreed... Let's lose the static bit field width and just call it an (unsigned int). The code will be future safe and work just fine in the mean time.

Wow... and I can't remember where I put my keys somedays. Lol

There was a very causal use of int's to hold pointer values

Wouldn't intptr_t be a better option for full portability?

How much RAM memory does an AVR (or even an ARM processor) have? I'm thinking an (int) is going to be just fine to do the math and display a meaningful address.

Many ARMs have way more than 64KB. Some stm32f103, pretty basic and old ones, have 96KB, some F4 have several hundred KBs, still cheap and several years old MCUs.

So I think it we are going to rewrite parts to make them compatible with 32bits, I think we would be better off covering more than 64KB of RAM

I'm agree with (unsigned int), or like Thomas suggested declaring a intptr_t in the HAL to whatever bitwidth is needed similar to what's done for the timers (in ReARM: #define HAL_TIMER_TYPE uint32_t)

I'm definitely not going to correct anything K&R ever wrote ;)

This two lines wouldn't possibly work either:

ptr = (char)((uint) ptr & 0xFFF0); // Align to 16-byte boundary

sp = (char)((uint) sp | 0x000F); // Align sp to the 15th byte

Since 0xFFF0 is equivalent for 0x0000FFF0 for a 32bit number, if the ptr and sp are in 2 different 64KB boundaries, it would mess up the ptr value and all the following calculations.

Wouldn't intptr_t be a better option for full portability?

Maybe... All of this can be debated... But the point I'm trying to make is C is a VERY low level language. It has block structured scope and objects and inheritance. But it lets you get at the very lowest level bit of your machine and its data types.

Pretty much.... You are going to have to really search for a machine where (int) can't hold a (void *).

I'm just saying, that function was there to dump a small block of bytes pointed to by a *ptr. I'm not losing any sleep because I used (int's) to do the math and display addresses.

This two lines wouldn't possibly work either:

Go look at the very original code. What I checked in worked...

The reason I suggested moving it to the HAL is not because I thought it would not work on the AVR using uint, but because I see a concern on code size and ram usage in AVR, and these changes could impact that when compiling for AVR, but if that's not a concern, then we I don't think these needs to go to the HAL, and just changing to (uint) and correcting the mask is more than enough.

Sorry if I wasn't clear above on the reason to suggest bringing it to the HAL.

Probably it should be moved to the HAL. It is very machine dependent code. But who ever decides it should be in the HAL needs to move it for all platforms. Not just theirs. It is kind of like the Configuration.h file. If you really feel there should be a new variable there.... Fine... But you get to change 37 different example files to make it happen.

You are going to have to really search for a machine where (int) can't hold a (void *).

Not really. Pretty much every PC these days is 64-bit, where (void *) is a

(long). Not that I would think we're going to port Marlin to 64-bit any

time soon, but why not use the current facilities for architecture

Independence if they are available?

Ok I'll try to move the architecture dependent parts of that to the HAL.

I have an E3D V6 hotend with a PT100 temperature sensor with amplifier and I followed the E3D instructions when using my RAMPS 1.4. As I'm going to be converting to the Re-ARM my question is, to which pin should I connect the output of the amplifier? I can't use the usual T0 input due to the pull-up resistor. It has to be an analog input with no pull-up.

R63 on the Re-ARM is an analog in with no pull up and not used for anything else.

There a LOT of noise on the analog inputs on the non-T0, T1 & T2 inputs. I've seen readings jump by 20%.

Maybe your best option is to remove the pullup resistor & use the T0 on the Re-ARM board.

Another option is to put a 10uF cap across R63. That should reduce the noise considerably.

Don't forget to supply 3.3V to the PT100 amplifier. Analog inputs on the Re-ARM are NOT 5V tolerant. The PT100 amplifier works just fine at 3.3V and you don't need to change thermistor tables.

@p3p - what's the next thing you'd like me to work on?

R63 ?? Do you mean D63?

@p3p - what's the next thing you'd like me to work on?

Bob... Are you seeing any lock ups?

I've had some issues starting up. I don't think I've had a lock up while writing to the SD card for quite some time.

I haven't tried running UBL.

If you give me the particulars I'll see what I can do.

@TGMods - yes, D63 is correct.

I'm sure everybody else already knows this... But I needed to generate a table for myself and thought I would post it here just in case anybody else needs this information:

* For AVR processors these are the primitive data type sizes:

* -------------------------------------------------

* sizeof(char) : 1 sizeof(unsigned char): 1

* sizeof(short) : 2 sizeof(unsigned short): 2

* sizeof(int) : 2 sizeof(unsigned int) : 2

* sizeof(long) : 4 sizeof(unsigned long): 4

* sizeof(float) : 4 sizeof(double): 4

* sizeof(void *): 2

*

* For ARM processors these are the primitive data type sizes:

* -------------------------------------------------

* sizeof(char) : 1 sizeof(unsigned char): 1

* sizeof(short) : 2 sizeof(unsigned short): 2

* sizeof(int) : 4 sizeof(unsigned int) : 4

* sizeof(long) : 4 sizeof(unsigned long): 4

* sizeof(float) : 4 sizeof(double): 8

* sizeof(void *): 4

@Roxy-3D do you have a gcode file or a reproducible sequence we can use? I've hammered my printer with 0.01mm moves to no effect, and its never come up during normal use. You mentioned you had high steps per unit, so configs too I guess, though I have no hardware that can run high steps, my Z is only 400 (direct drive), same as my other axes.

@Bob-the-Kuhn I'm not sure, I've just been enjoying watch you do all the work while I've been slacking ;), end-stop interrupts should be a quick job, what are we still missing for standard ramps support? (excluding the stack of random accessories people seem to have)

@Roxy-3D and that table is why we don't use those types anymore ^^ (in fact even in "normal" software I always use fixed width types) and as mentioned above other types like intptr_t. (http://en.cppreference.com/w/cpp/types/integer)

do you have a gcode file or a reproducible sequence we can use? I've hammered my printer with 0.01mm moves to no effect, and its never come up during normal use. You mentioned you had high steps per unit, so configs too I guess, though I have no hardware that can run high steps, my Z is only 400 (direct drive), same as my other axes.

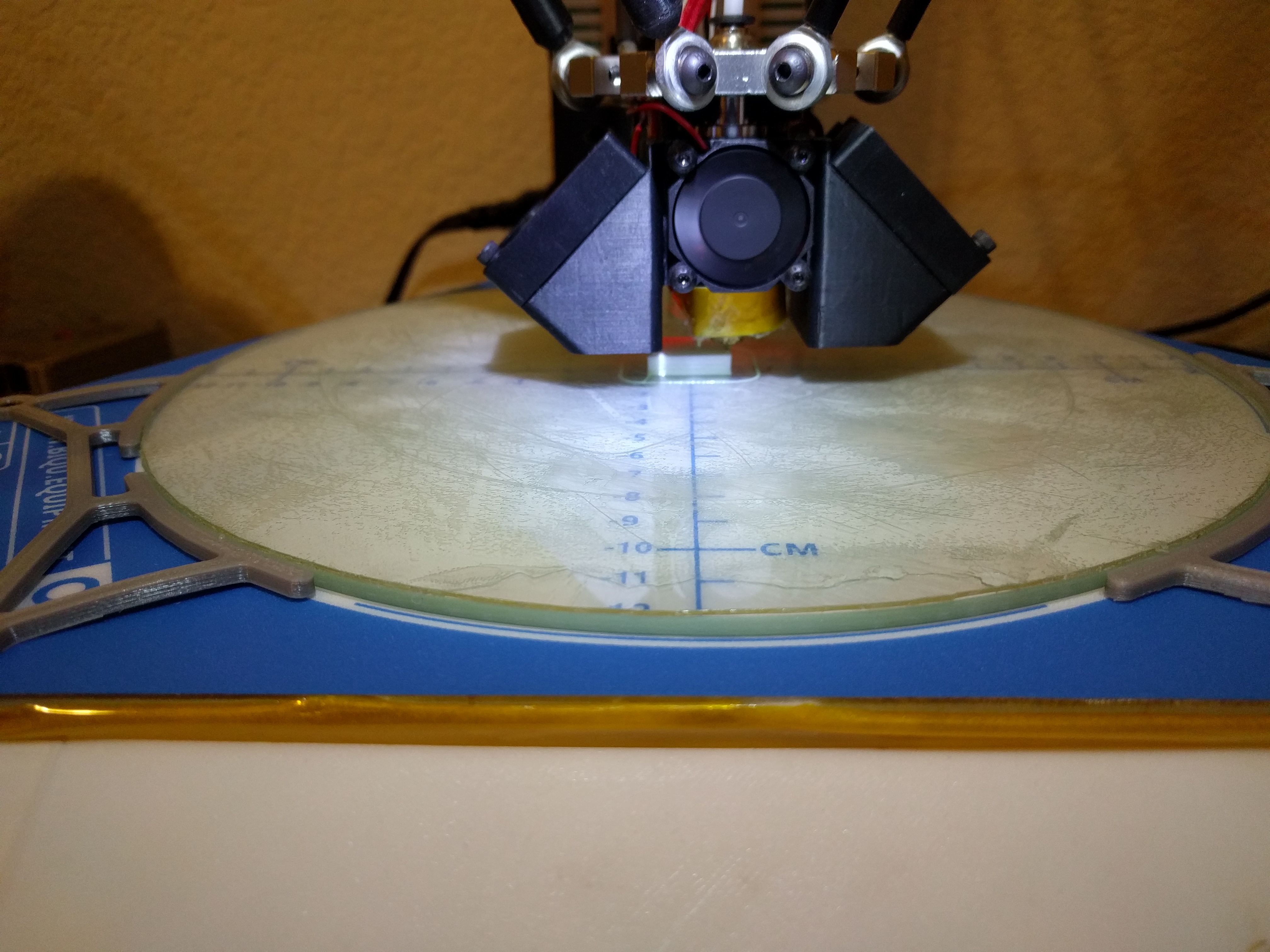

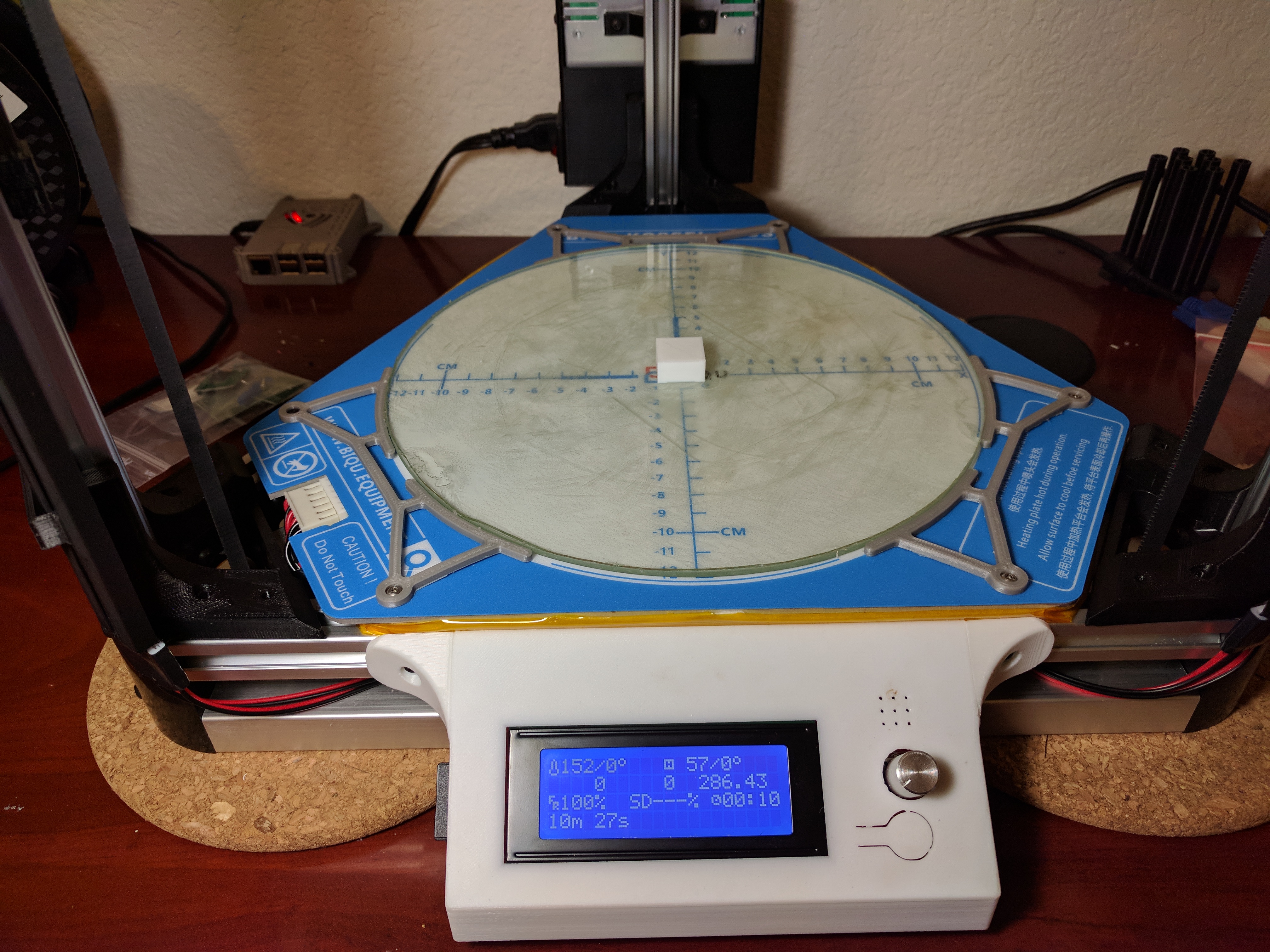

Yes... It is trivial to produce the lockup on my printer. I just have to connect to it in PronterFace and give it one or two .1mm Z moves. About the only thing weird that I have going on is I have a 20x4 LCD Panel on the machine. And the Z-Axis is very slow. Larger Z moves work just fine.

It might be worth while for me to hang a Full Graphic controller off of it and see if the problem is related to the 20x4 LCD Panel. <---<<< I just did this. The problem still happens and is easily duplicated on the Full Graphics LCD Panel.

It would be good if somebody copied my Z-Feed Rate and Step numbers into their configuration and see if they can regenerate the problem. It doesn't even matter if the Z numbers don't make sense on your printer. What is important is the fact the Z-Axis is being told to move just a small tiny amount. So you won't damage anything by doing that. Everybody's Re-ARM board should be running at the same speed. So, my guess is putting my Z numbers into the Configuration.h file probably will make it happen on your machine too!

So, my guess is putting my Z numbers into the Configuration.h file probably will make it happen on your machine too!

@Roxy-3D well, .. unfortunately my printer doesn't have a problem with that config, at least not one that is easy to reproduce with spammed 0.1 to 0.01 moves .. can you try lowering the steps per unit on your machine to see what happens and at what threshold?

I have experienced the same issue Tannoo described above, sometimes the board doesn't start up fine when connected to a computer, sometimes it works, some times it doesn't. The times it doesn't work the serial port shows the yellwo of bang of having a problem in the device manager, and the sdcard can't be read.

I also noticed the board depend on having an sdcard to read the configuration, otherwise it doesn't respond to any command. Wouldn't it be better to just use the firmware settings if the sdcard is not present?

I still need to get it connected to the printer, but I'll try to wire a stepper to check Roxy's problem. I am supposed to send very small Z moves, and then what happens, it locks up?

can you try lowering the steps per unit on your machine to see what happens and at what threshold?

Yes... I will do that. Also... I have a couple of other 'To Do' items related to this problem. I have some debug switches and LED's on the RAMPS board. As far as I know... Nothing should be loading or driving any signals. But I'm going to disconnect all that so I have a vanilla RAMPS setup.

but I'll try to wire a stepper to check Roxy's problem. I am supposed to send very small Z moves, and then what happens, it locks up?

Yes... I'm doing it via PronterFace's Upper Left hand target user interface. If I give it either a +/- .1mm Z-movement, the movement happens. And more often than not, the board locks up. All other movements on the target user interface are fine. (including +/- 1mm and +/- 10mm Z-Movements)

Have you tried Repetier Host?

Have you tried Repetier Host?

No... Not yet anyway. But I'm not trying to work around the problem. I'm trying to figure out why it is happening.

Are you sure something is not wrong with your printrun?

I have experienced the same issue Tannoo described above

@victorpv sorry meant to reply to this but got distracted by Roxy, If there is no sd-card present at boot it reads 0's from the Persistent Storage so gets an EEPROM version mismatch error and continues with defaults, the USB storage will not show up at all because Marlin will tell the host no disk is present in the removable storage.. so .. again its something I can't reproduce, as for it showing a hardware error in device manager for the serial port I think that will be because the USB device stops responding.

@Bob-the-Kuhn @Tannoo no host software should be able to freeze Marlin no matter what it sends

Are you sure something is not wrong with your printrun?

Well... I know the printer's controller board is locking up because when the printer resets, it has X, Y & Z blinking on the LCD Panel. And I can move around and they all keep blinking. But as soon as I send a .1 mm movement on the Z, the LCD Panel quits blinking and everything is locked up.

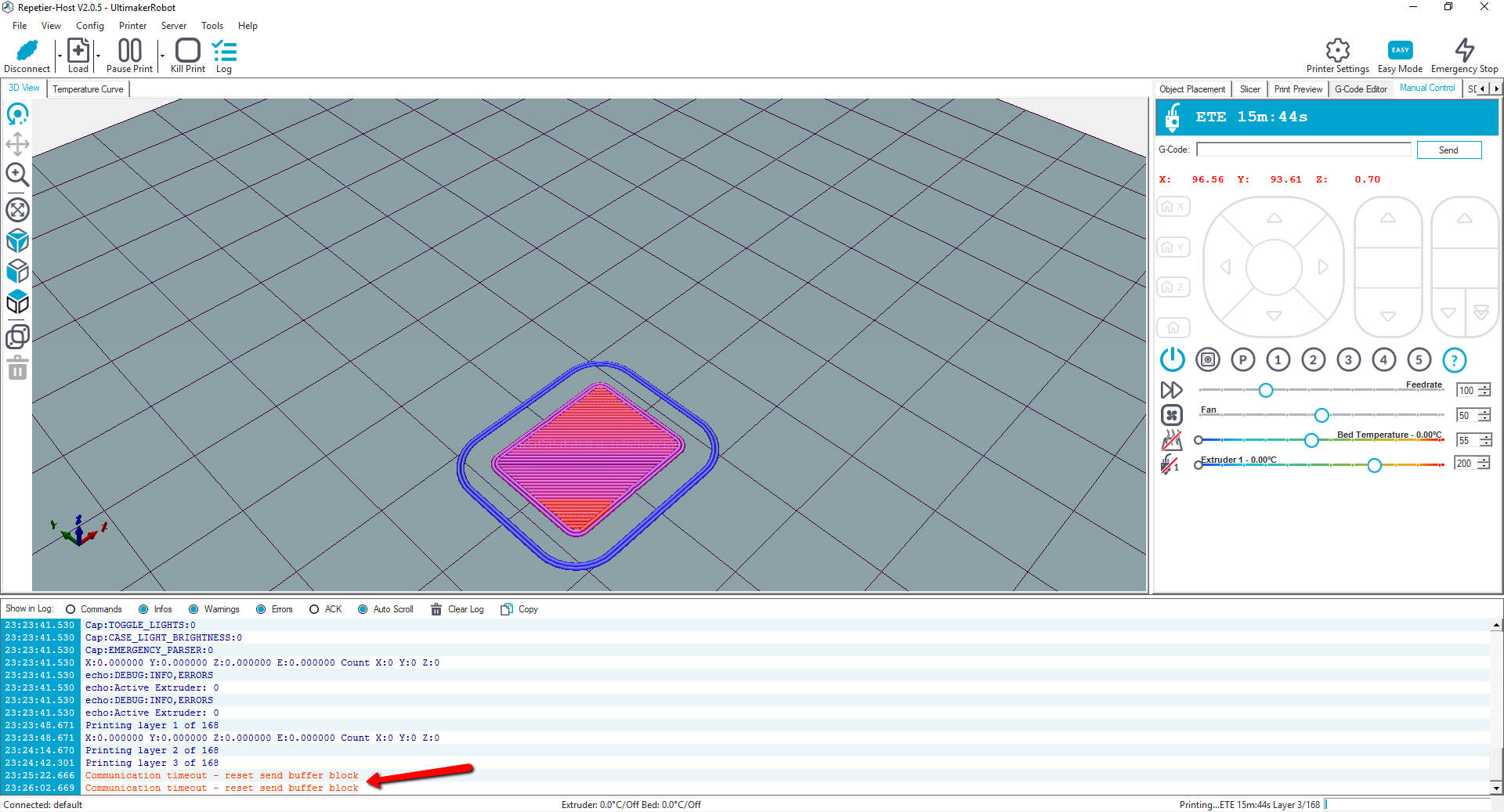

I'm seeing strange behavior with Repetier Host and Pronterface:

- The first 0.1mm command results in the expected Z movement.

- The LCD display update rate changes from 1.0 seconds to 2.6 seconds.

- It still responds to M114 commands.

- Sending a second 0.1mm command results in no Z movement.

- It doesn't respond to M114.

I switched the display to Viki2, switched the thermistor settings to 998 and loaded your config onto a Re-ARM. The Re-ARM has RAMPS, the Viki2 and a logic analyzer attached. Nothing else.

I did change the max acceleration from 4 to 10 and then the 0.1mm movements worked as expected.

I'll do some more poking around this evening.

You also mentioned that the Z was very slow. With a max feedrate of 2mm/s it'll be moving only 120mm per minute.

@Bob-the-Kuhn did you use Roxy's configuation file, or using a different one happens too? I'll tyr first with my current config, that's valid for my printer, and if it works fine, then try the one attached above.

I really wish the Re-Arm had the debug pins connected to some header :( if they produce a revision, they should add that.

In my case it's not locking up so far (with my own config), but after a few of those commands it responds slow for a while, like 5 seconds to send a reply, then after a while seems to respond normal, until I do a few more moves.

I used Roxy's config files and made the following changes

- switched the display to Viki2

- switched the thermistor settings to 998

- enabled pins_debugging

Sorry I think it was a different problem, seems to not be locking up at all.

But when booting it up, it's still having issues. I just tried a different sdcard in case the other had something wrong and still doesn't boot up correctly all the time. It seems to be more likely to boot up fine if I completely unplug the cable. If I use the rest button, almost never will get online.

@victorpv does it start reliably with usb plugged in without an sd-card?

I think the lockup is related to the BLTouch section in the Stepper ISR. Disabling it makes things run normally.

To disable it I changed line 340 in stepper.cpp to:

if (0 && L > ENDSTOP_NOMINAL_OCR_VAL) { \

Some other items:

- The temperature ISR doesn't have a return at the end. Putting one there didn't seem to affect anything.

- The endstop ISR and the Stepper ISR both run every millisecond even when there's nothing to do. Is this by design?

@P3P, it does for me. Currently, it's back to the same shinanigans as discribed before.

Here's the thing... most of the time that I need to reset it, I am making changes to the firmware and doing so through the SD card.

@Tannoo yea I know its not a solution just narrowing things down, could be something todo with the sd-cards you guys are using failing to initialise on the first try and confusing things, I've never had a failed init on the internal card, nevermind a failed start up, and I can't seem to force it to happen.

@Bob-the-Kuhn will need to go over the main interrupts, even at a glance there are uint16_t's used for timer data though as long as its a small enough delta it should be ok .. its currently 4am .. and I've had a drink or 2 but I think those OCR values are for a 2MHz timer not 25MHz they should probably be derived from the timer rate in the HAL

I think the lockup is related to the BLTouch section in the Stepper ISR. Disabling it makes things run normally.

I get to walk back anything I say right now... I've been out playing darts. But I don't have a BL-Touch on that FT-2020. I have an RC servo with a probe leg. For sure this problem happens without a BL-Touch.

That's two of you out on a Saturday night. I sort of remember those days.

I'm running your config so yes, the BLTouch is not enabled but the stepper BLTouch code is still running.

Try this file & see if it fixes the problem. It made my system well behaved. Don't really understand why.

stepper.zip

Since the stepper ISR is running at least every millisecond then there's not a need to run the BLTouch code. That code's purpose was to make sure the ISR ran at least every 1.5 milliseconds while stepping.

Same goes for the ENDSTOP_INTERRUPTS_FEATURE. Right now that ISR runs every millisecond whether the feature is enabled or not. The ISR and the feature aren't needed as long as the stepper ISR is running all the time at 1millisecond or faster.

If Chris has plans to change the stepper ISR then we'll need to re-visit the above.

I have 2 SD cards atm, that I have tried. One is 16GB, the other is 32GB. They both work the first time and almost instantly recognized. The booting issue is the same with both. I've re-formatted both (using them for other things also) and still the same issue.

When I had to re-clone marlin, was the first time it booted normally with the SD inserted. It was only a few boots later that it started doing the same thing again... all without removing the SD card. Now, it does it all the time again.

Do I need to get a smaller card?

Do I need to get a smaller card?

No, shouldn't be an issue, mines a 16GB, do you have the EEPROM enabled? if so is it the same with it disabled?

Ok. Disableing EEPROM does the trick... now it resets just fine without pulling the usb connection.

Fyi, eeprom seemed to work just fine when it was enabled.

So, with eeprom disabled, I cannot have UBL enabled.

I have tried a 2GB and a 4GB ones, so size is not the problem. I'll try disabling eeprom to confirm too.

On my system the boot process is hanging in the USB_Init() routine.

I put some writes to I/O pins into the code. The logic analyzer shows MSC_SD_Init completing but doesn't show USB_Init() completing.

I wasn't able to find the USB_Init() routine so I couldn't do anything more.

EDIT - my logic analyzer might be lying to me.

Thanks Bob now I have no idea whats going on ^^, everything was pointing to a mount issue on the FAT file system rather than a com issue, but USB storage is direct block access and USB_Init should be finished well before Marlin code starts executing.

I see in the comm window (if I get it connected fast enough) that SD_init failed. SD_SUPPORT is enabled.

This only causes the lcd to be completely blank for a few seconds before showing the boot screens.

After boot, the SD card is good to go and can read and write from/to it via the PC.

It may be the LCD SD that is failing. I don't have a card in that one.

@Tannoo that is the LCD SD you would get no error for the system sd card Marlin doesn't know about it, its all in the background (SD_SUPPORT also has no effect on it), you getting that far means you are most definitely getting past USB_Init that is before Marlin boots.

@Bob-the-Kuhn USB_Init is here (Marlin/frameworks/CMSIS/LPC1768/lib/usb/usbhw.cpp) but its low level power and interrupt stuff and doesn't branch very far.

Yes. I disabled SDSUPPORT and it boots sooooo much faster. Lol

If I hook the logic analyzer up to the right pins & label them it goes so much better.

On my unit it's hanging in the while (!USB_Configuration && millis() < usb_timeout) loop. It loops 7 times and then hangs.

well, that is just a flag check wait loop with timeout .. USB_Configuration is set by the usb stack once its negotiated with the host, if the LPC usb stack is crashing randomly we have an issue.

It must have something to do with the configuration. I haven't been able to crash mine using my config, and I used the same config except disabling the eeprom with the HAL I'm writing for an stm32f1 and that didn't fail either. Moving the Z up and down by 0.1. I have 2560 step/mm in Z. I still need to repeat the tests with Roxy's config. But I don't have any LCD connected to the board at the moment (but a 20x4 is included in my config)

I have not gotten mine to lock up either by any Z movements at setting of the MAX_ACCELERATION values of .1 to 20.

I am trying with Roxy's config files. Disabled the sdcard (still the board fails to boot up 75% of the time), when it boots, it will not lockup. I have moved all 3 axes up and down in 0.1, 1, 10 and 100 increments, and so far doesn't lock up. The board is not connected to anything other than the computer and a RAMPS 1.4 shield (no lcd, thermistors, etc)

Have have the same setup, but with 20x4 lcd and one stepper plugged into Z.

Roxy's issue is more than likely some oversights (or additions since it was converted to HAL) in the stepper isr when it tries to subdivide and make sure the endstops are checked often enough.

disabled the sdcard (still the board fails to boot up 75% of the time), when it boots

@victorpv is that with EEPROM disabled

I didn't change anything from his files attached above except that tried with sdcard enabled and sdcard disabled. I have to go check if EEPROM is enabled or not, but would be what's in those files.

I wonder if we have the wrong integer type somewhere and overflows given certain conditions. Yesterday I happened to see a lpexpresso 1768 board for cheap on ebay and ordered it, so I'll be able to plug a debugger. I really miss the debug pins, should have been included in the Re-arm.

I have a work around for the boot problem. Try changing delay(50); to delay(10); on line 81 in the file Marlin\src\HAL\HAL_LPC1768\main.cpp. That allowed my system to boot 25 times in a row.

There's something strange going on where that loop stops but doesn't exit. I used the following code to see what was going on with that loop:

WRITE(75,1);

volatile uint32_t usb_timeout = millis() + 2000;

while ( millis() < usb_timeout) {

delay(1);

WRITE(76, USB_Configuration ? 1: 0);

TOGGLE(72);

}

WRITE(75,0);

The results were:

- 75 went high

- 72 started toggling

- 76 went high 25 mS after 72 started to toggle

- 72 continued to toggle for another 22mS and then stopped - it should have continued to toggle until the 2 second timeout happened

- 75 never went low

I'm scratching my head on why 72 stopped toggling and why 75 never went low.

Is there some kind of a watchdog timer that may be triggering during that

delay?

It's looking like the delay(x) function is hanging. I'll bet it depends on something that hasn't been initialized yet.

I did move the HAL_timer_init(); before the loop but that didn't help.