Cura: Discussion and suggestions about changes for the default Creawesome Creality printer profiles.

The new Creawesome profiles have some odd choices, some missed Cura features and in my opinion, could be better. After a very small Reddit discussion, I compiled my proposed changes and would like to get some feedback and as a possible result, have updated and better default printer profiles included into Cura.

For reference, these are all changes for the "creality/base/base_global_standard.inst.cfg" using the printer "creality_ender3.def" that itself is based on the "creality_base.def.json" definition.

The comments are mostly mine, and might (will) have factual errors and misunderstood functionality as I'm not a Cura expert.

Cura Profile: creawesome_ender3_change_suggestions_v1.zip

Suggested in the discussion but I don't know about them

- Print Thin Walls should be enabled.

- Minimum Extrusion Distance Window: 10 is to large of a value according to /u/Liger_Phoenix

- Line Width should be equal to Nozzle size, according to /u/Liger_Phoenix

creality_base.def.json

Shell

- Outer Wall Wipe Distance: 0 -> 0.2mm // this is supposed to reduce the Z-seam, so why not use it?

- Filter Out Tiny Gaps: False -> True // the tooltip just says "Filter out tiny gaps to reduce blobs on the ouside of the model". Sound fine to me

- Seam Corner Preference: None -> Smart Hiding // Hiding works rather well and looks good.

- Z Seam X: 117.5 -> 0 // Using the Relative Z seam instead

- Z Seam Relative: False -> True // see above

- Optimize wall printing order = true # helps reducing unnecessary travel (Pimentoso)

Material

- Retraction Extra Prime Amount: 0 -> 0.064 // see Enable Coasting at the bottom - should be a nozzle-based function and not a hard value.

Infill

- Infill: Cubic -> Gyroid // /u/Liger_Phoenix: "I find it works everywhere and everytime... ...the gyroid is the optimal starting point for any stock machine."

- Infill Overlap Percentage: 30% -> 15% // 30% can cause issues in narrow spots without much benefit

- Infill Before Walls: False -> True // Much better overhangs and the infill showing up is never going to be an issue with the default 3 walls.

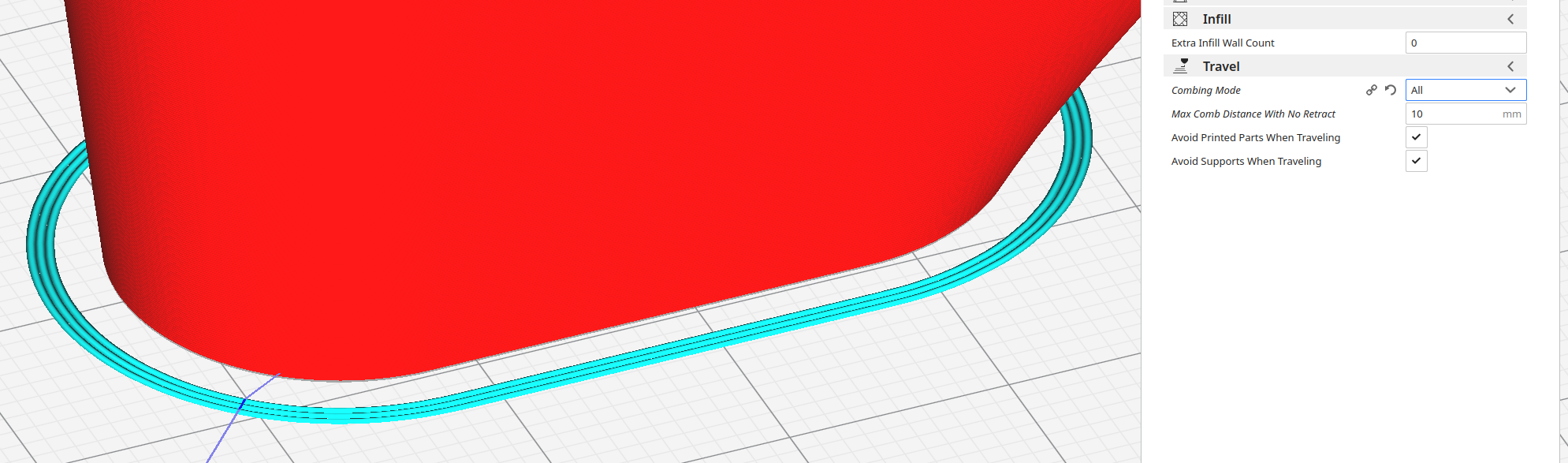

Travel

- Combing: Infill Only -> Not in Skin // Faster priting, but seems to be practically the same quality

- Z-Hop When Retracted: True -> False // Easily causes uneven layers as the leadscrew can bind and the nut has backlash. It's also not really needed for anything if you aren't overextruding and avoid printed parts is enabled.

Support

- Support Type: Buildplate Only -> Everywhere // Supports should always default to everywhere for newbies. Supports = I want the print to succeed.

- Minimum Support Area: 10 -> 5 // Helps support smaller details

Use Towers: False -> True // Helps reduce the generation of tiny thin supports with no chance of staying upLiger0: "I'd disable the towers tho, because towers are bugged and are created randomly even if they don't have to support anything."- Support XY Distance: wall_line_width_0 * 2 -> machine_nozzle_size // Liger0: "if you enable supports everywhere, you have to use a littler x-y support to model distance

- Minimum Support X/Y Distance: wall_line_width_0 -> machine_nozzle_size / 2 // now same as old fdmprinter default

- Support Interface Resolution: 0.2 -> layer_height // Should this be kept at a hardcoded 0.2?

Build Plate Adhesion

- Build Plate Adhesion Type: None -> Skirt // Skirt is always good for priming the nozzle and checking first layer squish

- Skirt Line Count: 4 -> 2 // ...but you don't need 4 lines for it.

Special Modes

* Relative Extrusion: False -> True // /u/Liger_Phoenix: "Relative extrusion can be enabled and is always recommended on Marlin." Breaks scripts. Should not be used.

Experimental

- Slicing Tolerance: Middle -> Inclusive // /u/Tarasque_1024: "anything else might drop details on some models"

- Enable Coasting: False -> True // /u/Liger_Phoenix: "it will work always fine and make seams and underextrusion disappear.

- Overhang wall angle = 50 (Pimentoso)

- Overhang wall speed = 66% # helps having good overhangs at higher speeds (Pimentoso)

- Enable Conical Support: True // These work kinda like support towers but they don't bug out.

- Conical Support Angle: -2

- Conical Support Minimum Width: 10

Printer definitions:

machine_head_polygonshould be removed to let One-At-A-Time print with the head clipping over the build plate edges as Cura uses the "machine_head_with_fans_polygon" to set how close models can be to each other.

[EDIT] Removed support towers, added support XY distance and interface skip heigth

[EDIT2] Support XY distances.

[EDIT3] Remove "machine_head_polygon" from printer profiles.

[EDIT4] Overhang wall angle, Overhang wall speed, Optimize wall printing order, Enable conical supports.

[EDIT5]RElative extrusion breaks scripts and other things as they almost always assume absolute extrusion and will default to them at the end.

All 108 comments

Coasting on a direct drive printer? Are you sure about that? I've only heard complaints about coasting being enabled by default (the main reason for it is that it does work for Ultimaker printers).

Creality machines are all bowden.

I'd also disable "perimeter overlap", it always gave me bad results.

Coasting on a direct drive printer? Are you sure about that? I've only heard complaints about coasting being enabled by default (the main reason for it is that it does work for Ultimaker printers).

Creality machines are all bowden.

I'd also disable "perimeter overlap", it always gave me bad results.

Between this thread and the other where "nallath" is defending the forced adoption and overwriting of saved profiles, it seems obvious that they don't know anything about the machines that are being affected. Opt out (not that there's a way to opt in now) is never the proper procedure and I wonder how badly the code has been written if the only way to update it was to force it to overwrite where it wasn't welcomed.

Between this thread and the other where "nallath" is defending the forced adoption and overwriting of saved profiles, it seems obvious that they don't know anything about the machines that are being affected.

You're right. I have absolutely no idea how ender printers work. I also never pretended to do so.

So we simply rely on what others tell us in that regard. As I've stated before, although this feedback is welcome, it's a bit on the late side to change it.

They probably don't, Cura is from Ultimaker designed for the Ultimaker printers, everything else is a bonus supported by the community. That means us.

In any case, let's concentrate on fixing and making them better than bicker about who did what wrong, it doesn't help anything.

Only who used the creawsome mod knew that was going to be incorporated to Cura because they followed the creator, its group, posts, etc, there is no way other people would have known it.

So of course we had really no way to complain about it before it was done, since none of us was asked and no plublic announcment was ever made, and none of us ever focused on what was happening to that useless mod. That just seemed a different alternative for lazy users (read: not new entry, because new entries can just learn like everyone else), so that shouldn't have affected so much people which had everything ready and optimized profiles that may even use it for work and made a reliable profile, which become unreliable with this new mod without them being aware of it in any way.

By the way, I think who made this mod wanted to help but doesn't really have a clue on what is better for creality printers, so I hope someone will make the changes suggested here.

You could have found out by means of beta's, forums and github. The sad truth here is that we simply have to give priority to people that do involve themselves in the entire process of a Cura release.

The argument regarding that those profiles are bad is re-iterated over and over again, but I've talked to numerous people that claim that the profiles are a vast improvement over what was already there. So who are we to believe then? People who take the time to try and improve Cura or those that we only hear if their workflow is affected? I try to facilitate both, but the earlier we get feedback, the easier (or at all possible) it is.

Even if I were to agree that the change was bad now, I would still not change it back, because it would simply be doubling down on the issues in the next release. I think it's a much better idea to do what @JohnEdwa suggests; Use the profiles as they are and improve on them further.

Issue #6134 is the first proper one to come from the current stock Creawesome settings. Supports are limited to "Touching Buildplate" so they aren't being generated as people expect using recommended settings.

This should be changed immediately to "Everywhere" even if no other changes are made.

If that gets to everywhere, I'd disable the towers tho, because towers are bugged and are created randomly even if they don't have to support anything. This would ruin the surfaces if they are printed on the model.

Also, if you enable supports everywhere, you have to use a littler x-y support to model distance, which could make normal supports harder to remove but helps with supports generated in the mid air oinly partially touching a piece.

The main reason I like using Support Towers is that without them Cura likes to generate supports like these and they have absolutely zero chance of staying attached to the build plate. Well, now that the prime tower got it after over two years of being in the "top 50 important features" list maybe they can add them for the supports as well.

The old XY distance from the fdmprinter default was 0.7mm, Creawesome has it as wall_line_width_0 * 2, meaning with the 0.4mm nozzle * 1.1 * 2 -> 0.88mm.

Should it be one line width from the wall instead or would that be too close and risk fusing... Maybe 1.5?

If we want the supports to be created from the model overhangs, 0.8 is way too high. 0.3 to 0.5 should be for a 0.4 nozzle.

Would seem logical to then set them to be based on the nozzle size.

- Support X/Y Distance: wall_line_width_0 * 2 -> machine_nozzle_size

- Minimum Support X/Y Distance: wall_line_width_0 -> machine_nozzle_size / 2 (which would be the same value it used to be with the old fdmprinter setup)

It should be a good idea to let the user choose either to use Creawsome or a standard profile, my cr-10s prints great with a slightly modified standard profile, and not any better prints with Creawsome

Every printer is not the same

The only setting that makes sense on the creawsome mod is the 0.04 layer height interval on adaptive layer.

I think it's too conservative, 0.02mm or even the old stock 0.01mm should be perfectly doable if your leadscrew and stepper are aligned. The Creality printers have 1/16th microstepping on the Z-axis with the 0.04mm lead so it can move in 0.0025mm increments (in theory, it only has 6.25% of the max torque so asking it to do just that has a very high chance of not working), and those would be 1/2 and 1/4th steps.

It's not like a printer that homes, uses babystepping or even mesh bed calibration will ever actually be doing perfectly aligned full steps when changing layers.

I think the Creawesome dev jumped on the "Magic Numbers" bandwagon slightly too hard.

The 0.04 increments actually help in accuracy.

If it was actually moving with full steps I would absolutely agree, going from a full step 0.04mm to a full step 0.08mm has 100% the torque and it will hit that step position exactly. But it's not. You home your printer and the stepper stops at a 6/16th microstepped position because that's where your end switch is. Now when you start printing with those 0.04mm incremental layers, you are asking it to move from 0.00mm + 6/16th microstep to 0.04mm + 6/16th. Then to 0.08mm + 6/16th. Then 0.12mm + 6/16th and so on.

It makes very little difference for it to move to that 0.04mm + 6/16th or to 0.04mm + 12/16th, it has to move to a microstepped position anyway. Only diffrence is that if you ask it to move from 6/16ths to 7/16ths, the static friction will most likely prevent it, until enough small steps have accumulated and it can "unstick" itself and move to wherever it should now be. This is why you shouldn't do too small movements.

[EDIT]

@huginen What they should have done is to leave the old printers as legacy for us with custom profiles, but made it so that all new ones are created with (fixed) Creawesome profiles, because the old defaults really weren't that good. For theEnder 3, yeah it had some tweaks, but a CR-10 S4 and S5 for example had nothing. The only difference for the Cura defaults that aren't tuned for any printer was setting the build volume, and that's it.

I noticed the printhead size is configured wrong as it prevents you from printing one at a time to the edge of the build plate - I think it is the same as Issue #5590. I've fixed it before but I can't remember how I did it...

It's not the skirt/brim thing either, as those clearly fit.

[EDIT2] Ah, it was removing "machine_head_polygon" and leaving only "machine_head_with_fans_polygon".

[/EDIT]

I might suggest some too.

- Overhang wall angle = 50

- Overhang wall speed = 66% # helps having good overhangs at higher speeds

- Optimize wall printing order = true # helps reducing unnecessary travel

Oh neat, hadn't even noticed those overhang ones exist.

Another one in the experimentals is "Conical Supports". When you set it to a small negative angle they work how I want Support Towers to work like without the buggy behaviour of generating supports that don't do anything randomly. That is, it makes sure the support is a certain minimum size at the bottom.

I still gotta test how it works in more situations though.

Also default first layer height to layer height instead of them being kept separated values.

Another one in the experimentals is "Conical Supports". When you set it to a small negative angle they work how I want Support Towers to work like without the buggy behaviour of generating supports that don't do anything randomly. That is, it makes sure the support is a certain minimum size at the bottom.

I still gotta test how it works in more situations though.

I really like conical support myself and use it quite often. We have to re-evaluate to put it outside of experimental. As far as I know the last bug that was in there recently was fixed in 4.2: That it could expand to outside of the build volume.

Conical support is very effective when combined with supporting to build plate only, because the support can crawl around your object then similar to tree support.

does anyone feel like this "upgrade" ruined your prints? it appears as though simply upgrading cura has caused my brim lines to be separate. It doesn't appear as though I am able to achieve the proper "squish" any more no mater how I adjust the build plate or adjust the z probe offset. This issue became prevalent after the upgrade, as I use my printer daily, I noticed the change immediately, but chalked it up to me needing to fine tune based on the new functionality. I do not see a way for me to "fine tune" this to the level I had it tuned prior to the upgrade. To put it simply, I do not see a benefit in this change, and believe this should have been optional, or should be further exposed in the configuration allowing me to adjust the "improved" values. basically, I feel like I am dead in the water right now. Nothing I do brings my quality back. I will be compiling a ver 4.1 release and not upgrading going forward.

Because the line width is now set to 1.1*nozzle size, so it risks to cause underextrusion, while before you risked overextrusion. Either set manually the line width each time or calibrate the flow.

Let's show you what the creugly mod implementation has caused to users:

https://www.reddit.com/r/CR10/comments/ctlspe/left_print_is_older_cura_right_print_is_newest/

In a few words, only issues.

The only way I can succeed printing now is enabling firmware retraction, but that causes a lot of stringing.

Also, 30% of infill overlap causes issues with material on the corners, I lowered it to 20.

Then another stupid thing is skirt gets disabled when enabling support.

I can fully confirm my issues are resolved fully by reverting to a fresh copy of cura 4.1. I lost my customizations because I wanted to ensure there was no leftovers, and did a full uninstall reinstall. Even without customized profile, my prints are of better quality than 4.2 prints. I feel confident that there are issues with this functionality that should not have made it to production, without further testing. I do not believe the issues are limited to configurable changes within cura 4.2.

Edit: now the skirt disabled when support enabled has been fixed by ghostkeeper. Still I have issues with retraction causing clogs with 4.2.1 unless I use firmware retraction.

There are a lot of people reporting how shit the creugly implementation was, yet just another one:

https://www.reddit.com/r/3Dprinting/comments/ckq73i/thanks_cuts_for_forcing_the_creawesomemod_upon_us/

I feel so strongly about this issue, and the way that Ultimaker is handling the issue, that I am compelled to copy/paste my message left on a seperate thread. I challenge all readers of this post to make your voice heard as well. Although I personally will no longer have a vested interest in the ultimaker cura development process, For your own sake, Please challenge the pride and ego of the development resources responding to our posts, and request this functionality be corrected.

" Ok, I will not be purchasing an ultimaker printer, and I will no longer be using the ultimaker software. The consistent response of "we made this change, your not happy about it, you should have done something about it, we're open source" is bogus. Not everyone in the world has time to help ultimaker make money and build as a company. Even if you offer an open source product, it is possible that your small group of people made a bad decision. The Creawsome functionality should not have been introduced, and your pride will simply not allow you to admit that this was a rush job. You guys saw a few happy campers within the same cohort, and though this functionality was great. This is a direct failure by the "open source community" working on Cura, and you are being absolutely rude, condescending, and off putting. You are not special because you are offering an open source product, and the users of the product should not be made to feel like we owe you something, we should be happy with what you give us, and we should shut up if were not contributing to your growth.

As I said before, I will not purchase an ultimaker printer, And I will not be using the Ultimaker Cura platform. I can deal with issues, bugs, and things that need my attention, But I will not support a company so off putting, and whom responds with the remarks such as yours. It is obvious that this is an issue, it reaches many of your users, and you refuse to take any other position than for us to contribute or shut up.

The functionality is NOT correct, It does not improve the software, and IS AN ISSUE. Try to sweep it away any way you want, but this is a MAJOR FAILURE! "

Since with the creugly implementation, using the creality machine definitions has become impossible, I will have to use and set from 0 a generic fdm machine from now on. Thanks for making life so hard to the community making your software unusable...

(Maybe the general complaints about how unfair, wrong or plain evil people seem to feel the well intentioned decisions of the people making free software (and mods of that software) for us can be kept to reddit / facebook etc. Or at the very least another thread as this was intended to actually try to remedy the situation. Everyone knows that you are dissatisfied, the point has been made. Several times. Maybe we in the creality community can start trying to fix things?)

For me I’ve found that the retraction set as default for this profile has been insufficient to prevent stringing, I’ve seen the suggestion of enabling coasting and have yet to try it, maybe retraction distance should be upped to 6.0 anyway?

I feel that we have a bit more caution now for changing settings suggested by individual users, partially due to the feedback we've gotten about the recent Creality setting changes. And there are a few suggestions even in this thread that contradict each other. But to make any improvements here we need some more force of action. I understand that making pull requests is complex if you're not used to the workflow, so how about this: If two people tested an actual print with the same setting change and found it improved, we'll make the change. Does that sound okay?

Things that multiple people have confirmed and should already be applied if people agree with this workflow:

- Support Type: Everywhere (by JohnEdwa, Liger0 and Kazooless)

- Build Plate Adhesion Type: Skirt (by JohnEdwa, Liger0, Kazooless and Silvatech)

- Skirt Line Count: 2 (by JohnEdwa) or 3 (by Liger0 and Kazooless)

- Optimise Wall Printing Order: enable (by Pimentoso and Kazooless)

- Combing: Not in Skin (by JohnEdwa and Kazooless) vs. None (by Liger0), may depend on material

- Z Seam Corner Preference: Smart Hiding (by JohnEdwa and Kazooless)

- Line width: =machine_nozzle_size (by Liger0 and Silvatech)

- Minimum Support Area: 5 (by JohnEdwa and Silvatech)

- Compensate Outer Wall Overlaps: disable (by Liger0 and Silvatech)

- Z Hop: disable (by Kazooless and Silvatech)

Currently open proposed changes in this topic tested by only one person afaik:

- Retraction Extra Prime Amount: =machine_nozzle_size * 16 / 100 (by Liger0)

- Support X/Y Distance: =machine_nozzle_size (by Liger0, to accompany the new Support Type value)

- Minimum Support X/Y Distance: =machine_nozzle_size / 2 (by Liger0)

- Support Interface: disable (by Liger0)

- Overhang Wall Angle: 50 (by Pimentoso)

- Overhang Wall Speed: 66% (by Pimentoso) or more than that (by Silvatech)

- Infill Pattern: Gyroid (by Liger0) or Grid (by Kazooless)

- Infill Overlap Percentage: 20% (by Liger0)

- ~Infill Before Walls: enable (by JohnEdwa)~ According to Liger0 and Silvatech, this is ineffective

- Infill Wipe Distance: =machine_nozzle_size / 2 (by Liger0)

- Skirt Minimum Length: 250mm (by Liger0)

- Relative Extrusion: enable (by Liger0) vs. disable (by Kazooless and JohnEdwa)

- Conical Support: enable (by JohnEdwa)

- Conical Support Angle: -2 (by JohnEdwa)

- Conical Support Minimum Width: 10 (by JohnEdwa)

- Fan off for PETG (by Tilllt) or 50% (by Silvatech) or 20% (by Liger0)

- Z Seam Placement: Sharpest Corner (by Kazooless) vs User Specified (by JohnEdwa)

- Coasting: disable (by Kazooless) or enable (by Liger0)

- Outer Wall Wipe Distance: =nozzle_size / 2 (by Liger0)

- Max Comb Distance With No Retract: 15mm (by Liger0)

- Initial Layer Height: =layer_height (by Liger0)

- Z Hop Height: =layer_height (by Liger0)

- Retraction Speed: 20 (by Silvatech)

Currently open proposed changes that were just intuition, or at least worded like it, and seem to not be tested at all yet:

- Print Thin Walls: enable

- Filter Out Tiny Gaps: enable

- ~Z Seam Relative: enable~ contradicted by Kazooless

- Support Interface Resolution: =layer_height

- Slicing Tolerance: Middle (personally I doubt that this will have the desired effect though)

One proposed change here is to set the Z Seam X to 0 because of using relative mode. We're probably going to do that across default (to make it auto-adjust based on relative). We've had some feedback from other people about this as well.

There is also a proposed change to machine_head_polygon to remove it entirely, but that can cause the print head to collide with previously printed models so I wouldn't advise it. If the print head needs to be corrected though that can be done.

Could you guys test each other's proposals? And correct me where I'm wrong in this list?

In my use case with creawsome and/or cura 4.2.1 the practical problems I came across was IMHO

- part fan in material settings for PETG should be off.

I don't advice creating a profile driven fan speed, that has to be completely used from the material. For instance, to work with petg I NEED to use fan at 30%.

For the combing, yeah, not in skin can still work, depending on material.

For the infill, as I read people using octoprint may have issues with gyroid but it is not for a stock machine. Maybe the box dialogue could put the advice that it could oversaturate and cause stutter if not using an sd card?

I did fairly intensive testing with PETG and the default fan settings will lead to bad prints. I would bet that the results with fan off are - for the majority of people - better than with fan on. Fan @ 30% depends on your fan, your duct etc so yes, defaulting to a certain intermediate setting doesn't really make sense. But fan OFF makes more sense than the default like it is now. Just try it.

I can't actually try it because with cura 4.2.1 all my prints fail with filament being grind unfortunately.

But I agree with petg having the stock fan OFF could be better, just don't force a profile rpm.

For instance I use a 5015 fan which blows pretty hard.

I also agree with this, it worked good on older cura versions:

Outer Wall Wipe Distance: 0.2mm

which should not be a driven value but a machine_nozzle_size/2

I also suggest keeping a skirt line count to 3, it bonds better for me than 2.

If two people tested an actual print with the same setting change and found it improved, we'll make the change. Does that sound okay?

How soon is the next beta/release? My idea is to compile the changes we agree to here and then post them to Reddit for people to test and give more feedback without officiall pushing them into Cura. It would also give more accurate results as Creality printers are often heavily modified, so what works for the stock printer or my printer might not be what most people would use, nor a good default setting.

And the more we change, the more people will complain things changed again. The list I made is not an "all of these should be changed" one, but just suggestions of ones that could be. And I definitely don't try to push myself as an expert in any way - I don't want my head to be the next one on the chopping block.

There is also a proposed change to machine_head_polygon to remove it entirely, but that can cause the print head to collide with previously printed models so I wouldn't advise it. If the print head needs to be corrected though that can be done.

Because there are two polygons, machine_head_with_fans_polygon and machine_head_polygon. The one without will also collide with the outside of the build plate stopping you printing in the corners, and therefore you can hardly use the "one at a time" mode at all as you will run out of space even with tiny things. Either that is bugged in in Cura, or it isn't supposed to be used like this.

If you remove it leaving just the other polygon it will work as long as the grey area doesn't hit another part, but they can overlap as there isn't any reason it can't move in the same empty spot while printing.

I would categorize the change roughly in order of importance as follows (and I repeat, these are my opinions):

Bugfixes/rollbacks:

Most are also values from the old definition.

- Support Type: Everywhere (by JohnEdwa and Liger0)

- Build Plate Adhesion Type: Skirt (by JohnEdwa and Liger0)

- Skirt Line Count: 2 (by JohnEdwa)

- Skirt Minimum Length: 250mm (by Liger0)

- These are Issue #6147 related, so actual values might change?:

- Support X/Y Distance: =machine_nozzle_size (by Liger0, to accompany the new Support Type value)

- Minimum Support X/Y Distance: =machine_nozzle_size / 2 (by Liger0)

- Minimum Support Area: 5 (by JohnEdwa)

General Improvements:

- Infill Before Walls: True (by JohnEdwa)

- Optimise Wall Printing Order: enable (by Pimentoso)

- Z Seam Relative: enable

- Z Seam X: 0

This is what the definitions were trying to do with the seam before the relative was added as a setting - put the seam at the back of the model. - Filter Out Tiny Gaps: enable

I've always used this but I don't know how/if it works.

"Controversial" (for a lack of a better term, everyone has their own preferences and opinions, so testing and gathering more feedback on these would be required before implementation):

- Support Interface: disable (by Liger0)

And JohnEdwa - this creates issues with the supports fusing into the model for many people but I'm not sure if disabling it would require tweaking other support settings as well. As a default for not properly calibrated printers I think they should be disabled. - Support Interface Resolution: =layer_height

- Line width: =machine_nozzle_size (by Liger0)

I use nozzle_size * 1.05 following Slic3r suggestions., but without "Print Thin Walls" this won't print a wall that is exactly 0.4mm. However, that will also print super tiny things, usually resulting in strange artefacts. - Print Thin Walls: enabled

See above. - Outer Wall Wipe Distance: 0.2mm

- Z Hop: disable

I don't think Z-hop works with a Creality printer because the Z-axis is far from perfect and will bind, resulting in uneven layer height - Infill Pattern: Gyroid (by Liger0)

Gyroid is slightly overkill imho, but it's pretty and works well, so I don't see why not. - Infill Overlap Percentage: 20% (by Liger0)

- Combing: Only in Skin (by JohnEdwa) vs. None (by Liger0), may depend on material

None causes surface scarring, but it is slightly faster. IMHO quality > quantity.

Experimental (and therefore maybe not suitable as defaults? Also mostly untested)

- Relative Extrusion: enable (by Liger0)

- Overhang Wall Angle: 50 (by Pimentoso)

- Overhang Wall Speed: 66% (by Pimentoso)

- Conical Support: enable (by JohnEdwa)

- Conical Support Angle: -2 (by JohnEdwa)

- Conical Support Minimum Width: 10 (by JohnEdwa)

Things I don't know enough about:

- Fan off for PETG (by Tilllt)

- Slicing Tolerance: Middle

- Retraction Extra Prime Amount: =machine_nozzle_size * 16 / 100 (by Liger0)

- Outer Wall Wipe Distance: 0.2mm

But even before we do these changes (as I repeat, Outer Wall Wipe Distance should be 0.2mm only for 0.4mm nozzle size and use half the nozzle as default, just like coasting as they use the same principle pretty much), I really believe there is a serious extrusion flaw, as me and a tons of other people keep having failed prints because of grinded filaments.

I am actually trying a custom FFF to see if this issue is just profile related.

About supports, Z should hide X/Y, because having a good support with the correct number of layers is more important than X/Y. Altought there are bugs related to the number of separation layers yet.

Another useful thing is to put as a Zhop default the layer height value, tho it should still be disabled by default. But this way, if someone enables it, he should be able to revert to suggested default which is layer height. This helps since nozzle won't drag and only one layer height will reduce most of the stringing.

How soon is the next beta/release?

In about 2 weeks is the next beta, I believe.

I also don't suggest using the option to "enable infill before walls", because that caused underextrusion to me on the points where the infill touched the walls, so the infill was showing and even worse it was not because of material excess but material missing.

I also suggest to disable the externall wall overlap compensation, because that ruins all the sharp corners making them round.

The internal one is fine, because it is not reall visible.

Cannot really understand why Gyroid is listed as maybe default. It shakes a shit out of the ender..

Then you probably still use the stock crap fire hazard firmware. My cr10s doesn't move.

Well, if that happens with the stock firmware then gyroid shouldn't be the default for the profiles. It's not really needed most of the time anyway, grid or even lines works perfectly well enough as tested by Stefan from CNC kitchen. (in Simplify3D, Rectilinear is the same as Curas' Lines).

And the problem with Cubic is that it has a chance of leaving very large gaps that result in bad top layers.

Stock firmware will randomly freeze and make the printer catch fire anyway. It also will give bad result even without gyroid because of the absurd jerk and acceleration.

Creality printers should not be even powered on before upgrading firmware.

Btw, grid is still a good pattern, so having it as default is still fine to me.

@Ghostkeeper would it be possible to add in the floating box of the infill that the gyroid could oversaturate the serial connection, from what I hear? I use sd card so I can't confirm

@Ghostkeeper would it be possible to add in the floating box of the infill that the gyroid could oversaturate the serial connection, from what I hear?

It's possible but I don't think it's a good idea to add too much details about each individual pattern in that text. I've written about the problem in my article about Cura's infill patterns in the Settings Guide though.

@Ghostkeeper would it be possible to add in the floating box of the infill that the gyroid could oversaturate the serial connection, from what I hear?

It's possible but I don't think it's a good idea to add too much details about each individual pattern in that text. I've written about the problem in my article about Cura's infill patterns in the Settings Guide though.

Is that guide actually directly accessible from within Cura?

Yeah it's in the Marketplace. You need to install the plug-in first. That article there is not on the Marketplace yet though. My updated plug-in is still under review for the past 2 weeks because the guy that reviews these is on vacation right now. The version on the Marketplace has an older article.

Hi guys. @JohnEdwa, thanks for starting this thread and the Reddit thread as well. @Ghostkeeper, thanks for your efforts and active input.

I thought I'd add my 2 cents here as well, especially since feedback has been requested by Ultimaker. I don't have an opinion on a lot of the settings mentioned since they really are just preferences. But I do have a suggestion for legacy settings. I also have a question and the answer to it may bring about other ideas.

The question first. When CreawesomMod first came out the information about it said it was more than just a custom profile; we were told there were "under the hood" changes made. Looking at one of the original documents it says part of the changes made were "* Deeply defined machine & * Fixed default feedrate, accel and jerk _hidden settings_." So the question is, if all the visible settings were made to be identical to the earlier versions settings, would the resulting gcode be the same as the earlier version?

I ask this because I have not found doing just that produces the same quality print; v4.2.0 produces a lower quality print. I have yet to try a plain out-of-the-box profile from 4.2.0 but I will soon.

My suggestion regarding profiles is to add the profiles from the earlier versions back in so that imported profiles from earlier versions do not change. The definitions could be added back but they wouldn't have to be made available in the GUI. That way, there is no appearance of backtracking or changing your mind, but any imported profile will give the user all of the expected settings. And if it turns out the current defaults do produce nice prints and the old profiles don't, then people would be able to figure that out on their own or through others sharing in forums.

For a few of the settings, here are my votes:

Support Type: Everywhere (by JohnEdwa and Liger0) YES

Build Plate Adhesion Type: Skirt (by JohnEdwa and Liger0) YES

Skirt Line Count: 2 (by JohnEdwa) 3 or 4, not 2.

Optimise Wall Printing Order: enable (by Pimentoso) YES

Z Seam Relative: enable NO

I would prefer Z Seam: Sharpest Corner

Seam Corner Preference: Smart Hiding YES (This has already proven to be awesome)

Z Hop: disable YES

Infill Pattern: Gyroid (by Liger0) NO, grid is fine for default

Combing: Only in Skin (by JohnEdwa) vs. None (by Liger0)

Only in Skin - YES, in my experience stringing WILL occur if you don't use combing

Relative Extrusion: enable (by Liger0) NO

I'm still testing this and suspect it will be better based on reading, but I think more of us should actually test it out first and then report back

Enable Coasting NO!!! A lot of us update our firmware and turn on Linear Advance. Coasting is recommended to be turned off for that.

A big still not considered by the most people reason the new profile gives way worse print quality than the old one is, other than the stupid retraction and all other settings that the

Outer Wall Wipe Distance

is off instead of half the nozzle size.

Also the stupid line width causing under extrusion, which should be equal instead to nozzle size and then calibrate flow to fix overextrusion.

Relative extrusion works fine, it just doesn't work in Cura reader (but works in other slicers readers).

Disabling the wall overlap compensation for the external wall is also a very important thing as I said.

For the combing "not in skin" I found 15mm to work better than 30mm too. 30mm causes underextrusion.

Also the stupid line width causing under extrusion, which should be equal instead to nozzle size and then calibrate flow to fix overextrusion.

@Liger0, regarding the default line width, I'm fine either way. I have some profiles using the nozzle size and some using 120%. I tend to use the 120% for parts & 100% for artistic stuff. I have my e-steps and flow dialed in really well and find I can get great walls (close to perfect measurements) with either setting.

For your combing comment, I don't follow what you mean by the mm's.

@kazooless

Z Seam Relative: enable NO

I would prefer Z Seam: Sharpest Corner

Z Seam Relative just makes the Z seam coordinates be related to each individual model and not the build plate. The current setting is trying to push the seam at the very back of the model, which will simply work better with multiple objects if you use the realative option.

Pictures tell thousand words, so 9001 hours in MSpaint.

And the issue with Sharpest Corner is that doesn't work on objects that don't have clear corners and it will just randomly start wherever and cause the seam to be very visible, very likely at the front surface and ruin the visual quality of the print.

User Specified combined with Smart Hiding tries to put it in a corner at the back of the object, and if there are no corners, it puts it at the back in a straight line.

[EDIT] I noticed that enabling Relative Extrusion will inevitably result in bad behaviour because so many scripts assume all Gcode is using absolute values. So as an example, "Pause at height" will always stick "M82" at the end, no matter what mode Cura is currently using, which means the print breaks.

Therefore Relative Extrusion should not be used.

Then you probably still use the stock crap fire hazard firmware. My cr10s doesn't move.

I have to agree, if firmware and that is setup right gyroid actually works really good.

I feel that we have a bit more caution now for changing settings suggested by individual users, partially due to the feedback we've gotten about the recent Creality setting changes. And there are a few suggestions even in this thread that contradict each other. But to make any improvements here we need some more force of action. I understand that making pull requests is complex if you're not used to the workflow, so how about this: _If two people tested an actual print with the same setting change and found it improved, we'll make the change._ Does that sound okay?

Things that multiple people have confirmed and should already be applied if people agree with this workflow:

Happy to hear you guys are looking into changing it.

I suggest first don't override people current profile setups. It really causes alot of problems.

* Support Type: Everywhere (by JohnEdwa and Liger0)

Don't really matter, but honestly I feel plate only makes more sense, but really it dont matter its easy to adjust.

* Build Plate Adhesion Type: Skirt (by JohnEdwa and Liger0)

Agree

* Line width: =machine_nozzle_size (by Liger0)

BIG YES and its the big huge problem thats screwing up alot of doing anything in the current 4.2.1 even I change the nozzle size it now wants to use the new crazy forumlas on this instead of what should be a logical base to start.

* Seam Corner Preference: Smart Hiding (by JohnEdwa)

Should be ok

* Retraction Extra Prime Amount: =machine_nozzle_size * 16 / 100 (by Liger0)

Sounds about right

* Support X/Y Distance: =machine_nozzle_size (by Liger0, to accompany the new Support Type value)Makes sense

* Minimum Support X/Y Distance: =machine_nozzle_size / 2 (by Liger0)

Not sure on this id have to do saome testing so wont comment.

* Support Interface: disable (by Liger0)

agree

* Optimise Wall Printing Order: enable (by Pimentoso)

seems fine

* Overhang Wall Angle: 50 (by Pimentoso)

seems good

* Overhang Wall Speed: 66% (by Pimentoso)

Hoenstly overhang to me works better at even faster then that, but I guess depends how fast your printing I suppose.

* Infill Pattern: Gyroid (by Liger0)

Yep I like gyroid, but grid is fine to

* Infill Overlap Percentage: 20% (by Liger0)

agree

* ~Infill Before Walls: enable (by JohnEdwa)~ According to Liger0, this is ineffective

I agree with LIger0 on this its not effective in prints I have tried it on in the past.

* Combing: Only in Skin (by JohnEdwa) vs. None (by Liger0), may depend on material

Not sure on this

* Minimum Support Area: 5 (by JohnEdwa)

sounds like a good number on this. I recently had to play alot with support.

* Skirt Line Count: 2 (by JohnEdwa) or 3 (by Liger0)

Boy hmm lets go with 2 even though I alot of times go 3 or 4, but this depends on filament im using etc etc

* Skirt Minimum Length: 250mm (by Liger0)

Sounds good

* Relative Extrusion: enable (by Liger0)

sounds fine

* Conical Support: enable (by JohnEdwa)

I prefer zigzag but thats a personal preference and John probably knows more then me on that.

* Conical Support Angle: -2 (by JohnEdwa)

not sure

* Conical Support Minimum Width: 10 (by JohnEdwa)

minimum width makes sense.

* Fan off for PETG (by Tilllt)

I generally on petg have my fan at 50% actually like way prusa does this where its factor on travel and all for when fan is turned off and on. 0 better then 100% On fan :P

* Compensate Outer Wall Overlaps: disable (by Liger0)

AGREE

Currently open proposed changes that were just intuition, or at least worded like it, and seem to not be tested at all yet:

* Outer Wall Wipe Distance: 0.2mm

makes sense

* Print Thin Walls: enableNot sure on this one

* Filter Out Tiny Gaps: enable

makes sense

* Z Seam Relative: enable

make sense

* Z Hop: disable

Big yes

* Support Interface Resolution: =layer_height

Make sense

* Slicing Tolerance: Middle (personally I doubt that this will have the desired effect though)

When ive played with this setting recently middle seem to be best, but not sure if it was because of the other changes or not. I would have to investigate.

Let's not forget the first layer height = layer height that I proposed earlier. Sometimes when changing the layer height I forget to change first layer height and it's so bad.

Also, this is what I have with "infill before walls", even with 4 perimeters. I don't suggest to enable this.

https://i.imgur.com/upt9nvI.jpg

For the "Overhang wall angle it really depends on the material.

For PLA I do 70° overhang at 100% speed with no problem.

At 5 walls there is absolutely zero possibility that the infill would actually show through as that is 2mm of wall, and that artifact has to be the result of something different.

And reason you should do infill before walls is that it gives overhangs and bridges something to attach themselves into.

I have that always with that option On, that is the reason I have it off. The number of walls doen't really matter.

I understand that this discussion is about proposal for new cura default settings for the ender3... Wouldnt it make sense to have a seperate repo for the refining of the settings and when people agree that the settings are good, just issue a PR and merge them with the then actual cura?

this is generic for creality printers. Also let's not forget to add if you people also agree to default zhop height to layer height even having it off by default.

Enable Coasting NO!!! A lot of us update our firmware and turn on Linear Advance. Coasting is recommended to be turned off for that.

I agree but Linear Advance is for expert users that are dialing in the printing a lot and know what they do. If you enable linear advance in the firmware and dial it correctly, you will know to disable coasting in the profile.

But coasting gives (well, will give since the blob issue will be fixed for 4.3) a huge benefit for all machines with stock and not very advanced functions.

Also the stupid line width causing under extrusion, which should be equal instead to nozzle size and then calibrate flow to fix overextrusion.

@Liger0, regarding the default line width, I'm fine either way. I have some profiles using the nozzle size and some using 120%. I tend to use the 120% for parts & 100% for artistic stuff. I have my e-steps and flow dialed in really well and find I can get great walls (close to perfect measurements) with either setting.

For your combing comment, I don't follow what you mean by the mm's.

After proper calibration they both can work well.

The point is that using a line width > nozzle you are in a case that will cause udnerextrusion to people and this isn't good for a starting point profile since people, especially the new entries, will first do their first prints to test their hardware with stock profile and learn from it.

But I see people are going crazy about it because of underextrusion issues caused by the larger line width, and it's not a good thing.

Using line width=nozzle size will always work on the other side, it may just cause a bit of overextrusion that won't affect the success of the print and the quality and can be calibrated later with flow or a user fixed line width easily.

For the combing, I mean that I had better results using a "max combing distance without retraction" of 15mm instead of 30mm.

The question first. When CreawesomMod first came out the information about it said it was more than just a custom profile; we were told there were "under the hood" changes made. Looking at one of the original documents it says part of the changes made were "* Deeply defined machine & * Fixed default feedrate, accel and jerk hidden settings." So the question is, if all the visible settings were made to be identical to the earlier versions settings, would the resulting gcode be the same as the earlier version?

The original CreawsomeMod had some interface elements also overwritten with its own. This broke in Cura 4.1 though because we'd made new interface elements that referred to the overwritten ones. We didn't take these changes into Cura 4.2. CrawsomeMod also changed the printer definitions for default feedrate, acceleration and jerk settings. Those settings were taken along to Cura 4.2. You can still see them if you load fieldOfView's Machine Settings plug-in, but they are normally hidden. They can influence the g-code, but most of them will only do so in a very minor way. For instance, the maximum feedrate influences time estimates which causes a different time estimate to be put in the g-code and may cause pre-heat commands for extruder switches to be placed earlier or later because it estimates the printing to take longer or shorter compared to the pre-heat time.

I understand that this discussion is about proposal for new cura default settings for the ender3... Wouldnt it make sense to have a seperate repo for the refining of the settings and when people agree that the settings are good, just issue a PR and merge them with the then actual cura?

We've asked people to submit PRs to change these settings but that seems to be difficult for some people (forking, committing, etc. and people don't monitor the PRs). So I thought that this thread would be simpler for them.

I've updated my list here: https://github.com/Ultimaker/Cura/issues/6106#issuecomment-524241165

Tomorrow I'll apply the top entries. I've tried to filter out only comments that were actually tested by people.

Nice. Also take note of the zhop to default to layer height if it gets manually enabled.

Also

Outer Wall Wipe Distance: nozzle/2

not 0.2mm.

I applied the changes that were verified by 2 people or more. That doesn't mean that this is now a stop on changes though. Please keep 'em coming and remember to verify each other's findings :+1:

Also, apart from the decision on it being enabled or not by default, could there be a button to easily revert the coasting volume to nozzle_diameter^3?

Same for other settings, since often there is a value preset but once modded there is no button to turn it back to default.

We have a ticket open to change the fx button into a sort of revert button that removes a value from a custom profile.

To all contributing to/following this issue: A beta of Cura 4.3 is available. Now would be a good time for feedback on the changes to the Creality profiles.

where is the best place to report issues on the profiles? Your process on all this is a bit confusing. I was originally (long time ago) trying to post on your forum then when found no re ponce I just gave up.

Also profiles for different materials are different. I guess that we are speaking here about PLA profile, which won't work for example with PETG.

aside from speed and fan off, profiles for petg and pla should be the same

So thats why it is necessary to have different settings for different materials.

this is for various materials. Fans off for petg also is under vote, and I approve. If needed, people can enable it and set material fan speed to 20% or so.

To all contributing to/following this issue: A beta of Cura 4.3 is available. Now would be a good time for feedback on the changes to the Creality profiles.

Applied changes are being fine to me.

Another change I would suggest is infill wipe distance to half nozzle size.

So the speed setting for retraction is to high should be around like 25 or 30 for an ender 3 ender 5. 45 with 5 meters will cause it to jam often with PETG.

where is the best place to report issues on the profiles? Your process on all this is a bit confusing. I was originally (long time ago) trying to post on your forum then when found no re ponce I just gave up.

Github (so here). The forums are just not suited for keeping track of issues.

where is the best place to report issues on the profiles? Your process on all this is a bit confusing. I was originally (long time ago) trying to post on your forum then when found no re ponce I just gave up.

Github (so here). The forums are just not suited for keeping track of issues.

their process makes no sense to me either. I agree forums make a logical place for feedback.

I think it's fairly simple.

Community forums are, like the name suggests, for discussing with and between the community members. The Github issue tracker is for reporting issues and suggesting feature requests to the developers.

By all means, if it works better for you, discuss what needs to be changed in community forums and then create a single PR here (showing the backing of the community).

Our normal process for changing profiles is for people to make a pull request on Github. We won't normally make any changes at all to profiles for printers other than Ultimaker's. You have to do that yourselves basically. We'll test if the profiles load in Cura but that's it.

However for this particular issue we've seen that lots of people had ideas to change the profiles but weren't making pull requests. And if pull requests are made they aren't usually discussed or contested. So I'm offering to tally up the results of this discussion thread and apply the changes for you. The current tally is still kept up to date in this issue: https://github.com/Ultimaker/Cura/issues/6106#issuecomment-524241165

Fan off for PETG (by Tilllt) or 50% (by Silvatech) or 20% (by Liger0)

Nah don't write fan speed, let the material do and just disable by default.

Retraction Retract Speed for PETG: 20 (by Silvatech)

Same here, let the material do what the user wants instead of writing the value in the profile

The material profile can specify a fan speed that's different for each printer or nozzle. So yes, if a change needs to happen only for PETG, I'd not put it in the printer definition but in the material profile. And also not in the quality profile either. Ideally the quality profile only contains settings that need to change when you change the quality profile drop-down/slider.

retraction speed to clarify should be 20 even with PLA it does a much better job. It just completely jams a stock Ender at 45 with PETG was all I was trying to add. speed of 45 is only fine direct extrusion in my experience. Fan speed on the other hand is for more materiel related.

Why is the "adaptive layer" setting enabled by default in all profiles?

It's not, as far as I can tell. Here I added a new CR-10 printer and show the Use Adaptive Layers setting:

Maybe it's in a profile you're using?

No, the stock profiles all have adaptive layer on by default to me. :\

Could you share a project file that reproduces the problem?

Can we consider these changes complete for now? We haven't had big complaints recently.

I guess so. Personally, after using the new profile names, I still would prefer to see them renamed back to the old names. When I switch to a printer which doesn’t have a Creality base definition, I can’t share my printer profiles. I find that very annoying.

Jeff Kazules

Sent from my iPhone

On Jul 23, 2020, at 5:36 AM, Ghostkeeper notifications@github.com wrote:

Can we consider these changes complete for now? We haven't had big complaints recently.—

You are receiving this because you were mentioned.

Reply to this email directly, view it on GitHub, or unsubscribe.

If the profiles are not specific to Creality printers you could share custom profiles with other printer types that don't have printer-specific quality profiles. However that would also mean that the Creality profiles would be part of the global profiles. They are specialised to Creality printers though, so I don't think that would be a good idea.

Basically, the requirement for using a custom profile is that the profiles that the custom profile was based on need to also be available for the printer that you're using. This requirement is preventing access to custom profiles based on Creality profiles when you're using non-Creality printers.

This thread was about individual setting default values though, not about custom profiles.

Ahh, you’re right wrong thread. Sorry about that.

For printer profiles, I am not seeing many complaints in the communities I hang out in any longer, so I’d say this can be closed.

On the custom profiles topic, I understand everything you said there and I’m just putting in my 2 cents that after using it this way for all these months, I am definitely of the opinion this is not a good thing. Especially now that I have added other branded printers. If there is still an old thread on that topic open, I can add these comments there.

Thanks Ghostkeeper!

Jeff

On Jul 28, 2020, at 4:07 AM, Ghostkeeper notifications@github.com wrote:

If the profiles are not specific to Creality printers https://github.com/Ultimaker/Cura/blob/56fc5f9706c9d7e7d3f70a7fc166ad91aedbbc0e/resources/quality/creality/base/base_0.4_PLA_standard.inst.cfg#L4 you could share custom profiles with other printer types that don't have printer-specific quality profiles. However that would also mean that the Creality profiles would be part of the global profiles. They are specialised to Creality printers though, so I don't think that would be a good idea.

Basically, the requirement for using a custom profile is that the profiles that the custom profile was based on need to also be available for the printer that you're using. This requirement is preventing access to custom profiles based on Creality profiles when you're using non-Creality printers.This thread was about individual setting default values though, not about custom profiles.

—

You are receiving this because you were mentioned.

Reply to this email directly, view it on GitHub https://github.com/Ultimaker/Cura/issues/6106#issuecomment-664977387, or unsubscribe https://github.com/notifications/unsubscribe-auth/ACJIUPM3CJ5ZUM3GFFKOPKLR52WONANCNFSM4IIK3LSA.

https://github.com/Ultimaker/Cura/issues/6124 is the closest bug report that I could find. If you want to open a new discussion about how/which profiles are matched to each printer, that's fine too. It's a complex topic and there will not be an answer that works for everyone, but if there are ideas out there on how to improve I'd certainly like to hear them.

I think that removing "adaptive layers" from 0.16mm layer height on the cr10s would be good.

@Ghostkeeper I'm not sure it's present in other settings depending on the nozzle size, but removing adaptive layers in all the profiles where it's enabled would be useful.

I thought Adaptive Layers was kind of the point of the "Dynamic Quality" profile. What would make it "dynamic".

Well, I only consider the basic layer height when using a profile, and I think that having a basic 0.16mm one would be useful. Since none of the other layer heights has adaptive layers, only using it on a profile would be confusing as you may not notice it and just select it because of its layer height.

@Ghostkeeper So, to pick up or start or restart the topic about "how/which profiles are matched to each printer," you would prefer we go to #6124 and discuss? Or would you just like a new discussion dedicated to the idea started?

Regarding "Adaptive Layers," here are my two cents: If "Dynamic" has that name because of adaptive layers, then to make that clear, move the option to the Quality section so it stands out. I realize it is in experimental now and I don't know how you decide it is ready to be moved to a permanent section, but that is my first suggestion. If that isn't possible, code a flag that turns on in that section which calls attention to the fact it is turned on.

I'd prefer keeping that discussion in its dedicated issue at #6124 indeed, Kazooless.

We can't move Adaptive Layers to the "Quality" setting category since its implementation is experimental. The problem is not that the settings haven't been properly tuned or anything, but that the setting breaks the following settings:

- Top Thickness

- Bottom Thickness

- Maximum Skin Angle for Expansion

- Gradual Infill Step Height

- Gradual Support Infill Step Height

- Infill Layer Thickness

- Support Infill Layer Thickness

- Support Z Distance (#6188)

- Support Roof Thickness

- Support Floor Thickness

- Support Overhang Angle (#4396)

- Support Stair Step Height

- Tower Roof Angle

- Ooze Shield Angle

- Maximum Model Angle

- Infill patterns that have a variation over the layers (like Gyroid or Cubic Subdivision).

Basically everything that needs a certain measurement of height across different layers is not calculated correctly any more.

Just because one profile wants to use the setting is not a reason to consider this bug any less serious.

I know that the standard response from some developers to being unsure of something is to put warning messages in the user's face, but 99.9% of the time that's not what the user wants to see and just annoys them. We try to prevent having warning messages that always trigger upon doing something normal (like switching to a certain profile). The better solution is to make sure that the user needs to explicitly enable experimental things (which is why this setting is in a category called "experimental") or to accept that they might get a less-than-optimal print result sometimes. Since these profiles have been optimized by users of this third-party printer, we trust on them that they've accepted the results as they are. Maybe the printer deals with wrong overhang angles or thin skins particularly well, or maybe the settings have been tuned to accommodate for such discrepancies when they occur.

@Ghostkeeper wouldn't it be better to make the line width parametric by default, so to set it as "nozzle_size" rather than a fixed value? You can easily use the same profile for multiple usages when swapping nozzle in this case.

Indeed the default in fdmprinter sets the line width to be equal to the nozzle size.

The creality_base definition overrides it with the same formula, I see. Unnecessary, but harmless.

@Ghostkeeper @Liger0 , thanks for merging the thread, having read the above I understand why 'adaptive layers' still experimental but perhaps this is just a title issue. The default profiles in Cura are Super 0.12, Dynamic 0.16, Standard 0.2 and Low 0.28. Can the '0.16mm' text be removed from the 'Dynamic' description as by the settings it will often not be anywhere like 0.16mm?

Cura actually adds that itself. The profile is just titled "Dynamic Quality".

Maybe it would be good to make the layer height a bit smaller in the header bar than the rest, to make it clear that it's not part of the profile title. But that could also look a bit weird with different font sizes on one line.

Perhaps change 'Dynamic Quality' to 'Dynamic Layer Height (Experimental)' so it is clearly different from the tried and tested layer heights. Then, add a new 'Fine Quality' default 0.16 with no dynamic setting.

This would fix any risk of user misunderstanding on this feature since its experimental.

I have tried to print but am having consistantly bad results under some circustances.

When there is a traveling move that goes outside, for example if there is a support inside of a part, the perimeters end up Deformed and "go inside", like if a compensation happens.

The correlation with the gcode is very clear, as that is exactly around where the travel move happens.

The image doesn't show that much as white is hard to photograph, so the deformation on the front won't be visible, but it is at least as much as the one on the left side, which is a bit visible. The face is straight in all directions, so there shouldn't be such a deformation/concavity toward inside, the left side should be straight as a \ symbol. Instead, it seems the first mm of the left side are vertical...

This is ruining much of the things I print and I can't end up with a solution.

This is happening on cura 4.8 at least, but I didn't do extensive tests with previous versions.

@Ghostkeeper any hint about what the possible causes would be is welcome, just in case no one ends up noticing this thread.

Unfortunately the Ultimaker forum isn't of any use, I never get any replies in any section and any kind of topic.

@Liger0 It's doing that because the Combing Mode is set to "Not in Skin". So it won't travel through the skin then, which is only an issue down at the first few layers in your case. Try setting that to "All".

When I tried, it had that travel without and with all combing modes..

This is what I'm seeing with "Not in Skin":

And this with "All":

This is by loading your project file in the current 4.8.

I don't think this is a slicing issue, I think the OP is saying the first few mm of print height is vertical when it should be tapered or sloping (used / symbol). I think this is just elephant foot issue. Edit.. the photo shows this not the sliced image.

Ah yeah the deformation is probably because there is an internal hole at that height which makes the inside of the model less stiff and then more prone to shrinkage.

Most helpful comment

(Maybe the general complaints about how unfair, wrong or plain evil people seem to feel the well intentioned decisions of the people making free software (and mods of that software) for us can be kept to reddit / facebook etc. Or at the very least another thread as this was intended to actually try to remedy the situation. Everyone knows that you are dissatisfied, the point has been made. Several times. Maybe we in the creality community can start trying to fix things?)

For me I’ve found that the retraction set as default for this profile has been insufficient to prevent stringing, I’ve seen the suggestion of enabling coasting and have yet to try it, maybe retraction distance should be upped to 6.0 anyway?